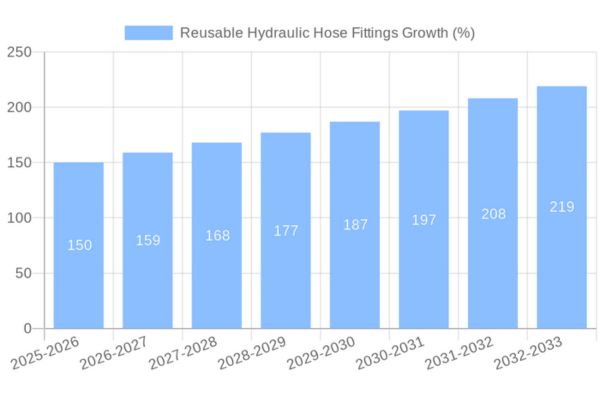

The global reusable hydraulic hose fittings market is poised for significant growth, projected to reach an estimated $2.5 billion in 2025 and exhibit a Compound Annual Growth Rate (CAGR) of 6% from 2025 to 2033. This robust expansion is primarily fueled by the increasing adoption of hydraulic systems across diverse sectors such as construction, agriculture, and industrial manufacturing.

Market Overview and Growth Drivers

Market Size and CAGR

The global reusable hydraulic hose fittings market is experiencing a period of robust expansion. In 2025, the market size is estimated to be $2.5 billion. This growth trajectory is expected to continue, with a projected Compound Annual Growth Rate (CAGR) of 6% from 2025 to 2033. This indicates a steady and significant increase in market value over the forecast period, driven by various underlying factors.

Key Growth Factors

Several critical factors are propelling the growth of the reusable hydraulic hose fittings market:

- Rising Adoption of Hydraulic Systems: The increasing integration of hydraulic systems in heavy machinery and equipment across diverse sectors, particularly in construction and mining, is a primary driver. Reusable fittings are preferred in these applications due to their durability and reliability compared to single-use alternatives.

- Advancements in Material Science: Continuous innovation in material science is leading to the development of more resilient and longer-lasting fittings. These advancements extend the lifespan of the fittings and contribute to reduced replacement costs, making reusable options more economically viable.

- Emphasis on Safety and Efficiency: Industrial operations are increasingly prioritizing safety and efficiency. Reusable fittings offer superior leak prevention and facilitate quicker maintenance turnaround, which are crucial for minimizing operational disruptions and enhancing overall safety standards.

- Stringent Environmental Regulations: A growing global focus on sustainable practices and environmental protection is significantly bolstering the market. Regulations promoting the minimization of waste and the responsible use of resources encourage the adoption of reusable components, aligning with broader environmental objectives.

These factors collectively create a strong foundation for the sustained growth of the reusable hydraulic hose fittings market, highlighting its importance in modern industrial and construction landscapes.

Market Concentration and Characteristics

The global reusable hydraulic hose fittings market exhibits a moderate level of concentration, with a significant portion of production and consumption centered in developed economies. While major players control a substantial share, numerous smaller regional entities cater to specific niche demands.

Geographic Concentration

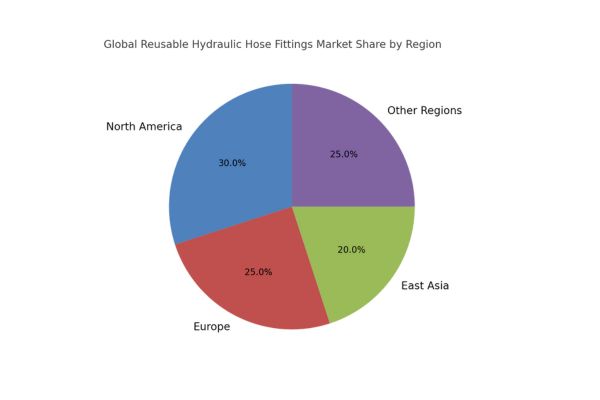

The market’s geographic concentration is heavily skewed towards regions with robust industrial and construction sectors. The estimated annual unit consumption is approximately 1.2 billion units globally. Key concentration areas include:

- North America: Accounts for an estimated 30% market share, driven by its strong construction and industrial sectors.

- Europe: Holds approximately 25% market share, characterized by the significant presence of established manufacturers and a mature market.

- East Asia: Represents about 20% market share, experiencing rapid growth fueled by industrialization and expanding manufacturing capabilities.

Innovation Characteristics

Innovation in the reusable hydraulic hose fittings sector is characterized by several key trends aimed at improving performance, efficiency, and longevity:

- Focus on Lightweight Materials: Development and adoption of advanced polymers and alloys to reduce weight, thereby improving overall system efficiency and handling.

- Development of Quick-Connect Systems: Innovations in quick-connect mechanisms are designed to minimize downtime and simplify maintenance procedures, enhancing operational efficiency.

- Integration of Sensors and Smart Technologies: The incorporation of sensors and smart features for real-time monitoring and predictive maintenance capabilities, allowing for proactive issue resolution and reduced unexpected failures.

Product Insights and Segmentation

Reusable hydraulic hose fittings are indispensable components within hydraulic systems across a multitude of industries. Their inherent value proposition stems from their exceptional durability, which facilitates repeated use and significantly reduces operational expenditures when compared to their disposable counterparts. These fittings are available in diverse configurations, including various elbow types and straight designs, alongside specialized versions engineered for particular applications. Ongoing technological advancements are primarily concentrated on refining sealing mechanisms, bolstering corrosion resistance, and integrating intelligent features for predictive maintenance, all of which collectively enhance system reliability and minimize downtime. The selection of appropriate materials is paramount, necessitating a careful balance between strength, flexibility, and compatibility with the wide array of hydraulic fluids in use.

Segmentation by Type

The market for reusable hydraulic hose fittings is segmented by type, each serving specific routing and connection needs:

| Type | Function | Application | Key Feature |

| Elbow 45° | Provides a 45-degree turn in the hydraulic line. | Facilitates efficient routing in confined or complex spaces. | Strong and leak-resistant under pressure, ensuring system integrity. |

| Elbow 90° | Offers a 90-degree turn for right-angle connections. | Used in hydraulic setups requiring sharp turns. | Robust construction to handle forces at acute angles for long-term performance. |

| Straight | Connects hydraulic lines in a straight configuration. | Serves as direct connectors between fittings or components for linear flow. | Simple, secure design for reliable fluid transfer. |

Segmentation by Thread

| Thread Type | Full Name / Standard | Characteristics | Applications |

| BSP (British Standard Pipe) | BSPP (Parallel) / BSPT (Tapered) | Common in Europe and Commonwealth countries; BSPP uses O-ring seal, BSPT uses tapered thread seal. | Construction machinery, agricultural equipment, industrial piping (Europe, Asia). |

| NPT (National Pipe Taper) | NPT (Tapered) / NPSM (Straight) | North American standard; tapered threads create metal-to-metal seal. | Building equipment, oil & gas, mobile hydraulics. |

| JIC (Joint Industry Council) | SAE J514 37° Flare | 37° flare seat provides high-pressure sealing; for tube and hose connections. | Aerospace, defense, industrial hydraulics. |

| Metric Threads | ISO 9974 / DIN 24° | Metric-based; available in flat face or 60° cone seal designs. | Automation, construction, agriculture equipment. |

| ORFS (O-Ring Face Seal) | SAE J1453 | Flat face with O-ring seal for leak-free, high-pressure applications. | Agriculture, mining, heavy construction. |

Segmentation by Application

Reusable hydraulic hose fittings find extensive use across a broad spectrum of industries, each with unique demands and operating conditions:

| Sector | Demand | Requirement |

| Construction | Heavy-duty fittings are critical for construction machinery due to harsh operating environments and high-pressure demands. | Must withstand extreme conditions, vibrations, and heavy loads. |

| Agriculture | Requires fittings that can endure constant vibration and exposure to diverse weather conditions, including dust, moisture, and temperature fluctuations. | Durability and resistance to environmental factors are key. |

| Industrial | A broad range of applications, necessitating fittings with varying specifications based on pressure, fluid type, and operating conditions. | Versatility and adaptability to specific industrial processes. |

| Mining | Rigorous conditions in mining operations necessitate robust, long-lasting fittings capable of handling significant pressure, abrasive materials, and shocks. | Extreme durability and resistance to wear and tear. |

| Material Handling | Equipment such as forklifts and cranes rely on dependable hydraulic systems, making fitting durability critical for continuous operation. | Consistent performance under repetitive stress and heavy loads. |

Regional Insights and Trends

Regional trends in the reusable hydraulic hose fittings market are closely tied to varying levels of industrialization, infrastructure development, and economic growth across different parts of the world. Each region presents unique dynamics and growth trajectories.

North America and Europe

North America and Europe represent mature markets for reusable hydraulic hose fittings. These regions are characterized by:

- Established Players: A strong presence of well-established manufacturers and a sophisticated industrial base.

- Technological Advancements: A continuous focus on research and development, leading to the adoption of cutting-edge technologies and innovative product designs.

- High Demand: Consistent demand driven by robust construction, manufacturing, and agricultural sectors.

- Regulatory Compliance: Strict adherence to environmental and safety regulations, which further encourages the use of high-quality, reusable fittings.

These regions continue to be significant contributors to the global market, setting trends in product innovation and application.

East Asia

East Asia is a region experiencing rapid growth in the reusable hydraulic hose fittings market, primarily fueled by:

- Increased Manufacturing: A booming manufacturing sector, particularly in countries like China, which drives significant demand for hydraulic systems and components.

- Industrial Expansion: Ongoing industrialization and the development of new industrial zones, leading to increased adoption of heavy machinery and equipment.

- Infrastructure Projects: Large-scale infrastructure development projects, such as new transportation networks and urban development, require extensive use of hydraulic equipment.

- Growing Awareness: Increasing awareness among end-users about the long term benefits and cost-effectiveness of reusable fittings.

This region is expected to play an increasingly dominant role in the global market in the coming years.

South America and Africa

South America and Africa represent emerging markets with considerable growth potential, though they are subject to certain macroeconomic and infrastructural limitations. Key characteristics include:

- Developing Industrial Sectors: Nascent but growing industrial and construction sectors that are gradually increasing their demand for hydraulic systems.

- Resource Extraction: Significant potential driven by mining and other resource extraction industries, which heavily rely on hydraulic machinery.

- Infrastructure Limitations: Challenges related to underdeveloped infrastructure and economic volatility can impact market growth.

- Increasing Investment: Growing foreign direct investment in infrastructure and industrial projects is expected to stimulate demand for hydraulic components.

Despite current limitations, these regions offer long-term growth opportunities as their economies and industrial capabilities continue to develop.

Emerging Trends and Future Outlook

Several key trends are actively shaping the reusable hydraulic hose fittings market, pointing towards a future characterized by enhanced efficiency, sustainability, and technological integration. These trends are not only influencing product development but also driving changes in manufacturing processes and market dynamics.

Efficiency and Downtime Reduction

The increasing demand for improved operational efficiency and reduced downtime is a significant driver of innovation. This trend manifests in:

- Quick-Connect Systems: The widespread adoption and further development of quick-connect systems are crucial for minimizing the time required for installation, maintenance, and replacement of fittings, thereby reducing equipment downtime.

- Predictive Maintenance: Fittings featuring integrated sensors are becoming more prevalent. These smart components enable real-time monitoring of hydraulic system performance, allowing for predictive maintenance and proactive issue resolution before failures occur.

Environmental Regulations and Sustainability

Stringent environmental regulations are profoundly impacting the market, fostering a greater emphasis on sustainability:

- Leak Prevention Technologies: A strong focus on developing and implementing advanced leak-prevention technologies is driven by regulations concerning fluid leaks and the disposal of hazardous hydraulic fluids. This minimizes environmental contamination and promotes safer operations.

- Sustainable Materials: There is a growing push towards using materials that have a minimal environmental impact throughout their lifecycle, including recyclable and eco-friendly options.

Material Advancements

Continuous advancements in material science are leading to the development of superior fittings:

- Lightweight and High-Strength Materials: The adoption of advanced alloys and polymers is improving the performance and efficiency of fittings by reducing weight while maintaining or enhancing strength and durability.

- Corrosion Resistance: Innovations in materials and coatings are leading to enhanced corrosion resistance, extending the lifespan of fittings in harsh operating environments.

Driving Forces, Challenges

The reusable hydraulic hose fittings industry is influenced by a complex interplay of driving forces, inherent challenges, and significant growth catalysts. Understanding these dynamics is crucial for comprehending the market’s current trajectory and future potential.

Driving Forces

Several powerful forces are propelling the growth and adoption of reusable hydraulic hose fittings:

- Rising Demand for Efficient Hydraulic Systems: As industries increasingly embrace automation and seek to optimize operational performance, the demand for high-performing, low-maintenance hydraulic systems is escalating. Reusable fittings contribute significantly to achieving these efficiencies.

- Stringent Environmental Regulations: A global push towards environmental sustainability has led to stricter regulations concerning fluid leaks and the disposal of hazardous hydraulic fluids. This regulatory pressure directly incentivizes the use of reusable fittings, which minimize leakage and reduce waste.

- Technological Advancements: Continuous innovation in materials science, design methodologies, and quick-connect technologies is enhancing the functionality, durability, and overall longevity of reusable fittings, making them more attractive to end-users.

- Focus on Reducing Downtime: In critical industrial operations, minimizing downtime is paramount. Reusable fittings, with their ease of maintenance and robust design, play a vital role in ensuring continuous operation and reducing costly interruptions.

Challenges and Restraints

Despite the strong growth drivers, the market for reusable hydraulic hose fittings faces certain challenges:

- High Initial Costs: The upfront investment for reusable fittings can be higher compared to their disposable counterparts. This initial cost barrier can deter some potential adopters, particularly in cost-sensitive applications.

- Technical Complexity: The advanced features and sophisticated quick-connect mechanisms in some reusable fittings might introduce a degree of technical complexity in their design, installation, and maintenance, requiring specialized knowledge or training.

- Material Compatibility: Ensuring compatibility between the fitting materials and the specific hydraulic fluids used is crucial for longevity and performance.Incorrect material selection can lead to premature failure and system issues.

- Limited Market Awareness: In certain regions or among specific end-users, there may still be limited awareness regarding the long-term cost benefits and operational advantages of reusable fittings, hindering broader adoption.

Conclusion

While challenges such as initial investment costs and technical complexity persist, the long-term value proposition of reusable fittings continues to strengthen. The industry’s commitment to sustainability, efficiency, and technological advancement ensures its vital role in supporting global industrial growth and environmental stewardship for years to come.

At Topa, we transform these market advantages into real-world solutions for your business. Our reusable hydraulic hose fittings are engineered to withstand the most demanding conditions, while delivering consistent performance and reduced downtime. Contact us today to discuss your specific requirements and see how our solutions can reduce your maintenance costs, extend equipment life, and support your sustainability goals.

FAQ

What is driving the growth of reusable hydraulic hose fittings?

The market is growing due to rising use of hydraulic systems in construction, agriculture, and manufacturing. Demand for durability, safety, and sustainability also fuels adoption.

Why choose reusable fittings instead of crimp or one-time fittings?

Reusable fittings can be assembled and disassembled multiple times, reducing replacement costs and downtime. They offer a more sustainable and cost-effective solution over time.

Which industries use reusable hydraulic hose fittings the most?

They are widely used in construction, mining, agriculture, manufacturing, and heavy equipment industries where reliability and easy maintenance are critical.

What materials are commonly used for reusable fittings?

Common materials include carbon steel, stainless steel, and brass. New alloys and polymers are being developed to reduce weight and improve corrosion resistance.

Which regions are leading the market for reusable fittings?

North America and Europe are mature markets with strong demand, while East Asia is rapidly expanding due to industrial growth and large-scale infrastructure projects.

What are the main challenges in adopting reusable fittings?

Higher initial costs, limited awareness in developing regions, and the need for proper installation skills can slow adoption—but long-term savings offset these hurdles.