What is a Ferrule Fitting: The Detailed Guide

Table of Contents

Introduction

Ferrule fittings are essential components in various piping and tubing systems, designed to provide secure, leak-proof connections. A ferrule fitting consists of a nut, a ferrule, and a fitting body that work together to clamp the tubing, ensuring a tight seal. They are commonly used in applications where leak prevention is paramount, including fluid and gas transfer systems, instrumentation, and process control environments. The key benefits of ferrule fittings include their resistance to vibration, ability to withstand extreme temperatures, and compatibility with a variety of materials.

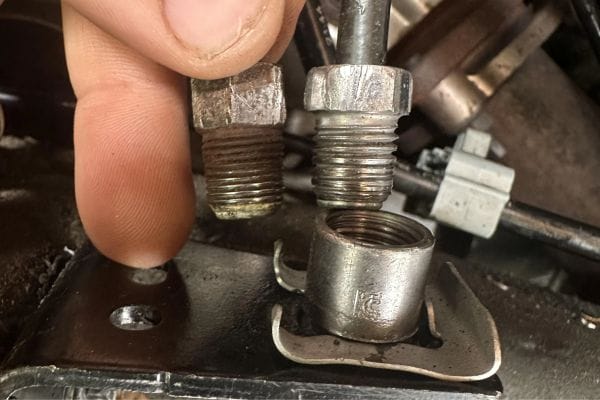

What is a Ferrule Fitting?

Ferrule fittings are essential mechanical components used to join tubing or piping systems, ensuring a secure and leak-proof connection. They are widely utilized in various industries due to their reliability and effectiveness. Ferrule fittings consist of three main parts: a nut, a ferrule (or ferrules in the case of double ferrule fittings), and a body. Each of these components plays a crucial role in forming a tight, leak-proof seal.

Components of Ferrule Fittings

Nut:

The nut is the outer part of the ferrule fitting, designed to be screwed onto the body. It plays a critical role in the fitting’s function. When the nut is tightened, it compresses the ferrule(s) against the tube and the fitting body. This compression is what creates the seal. The design of the nut allows for easy tightening and loosening, facilitating quick installation and maintenance.

Ferrule:

The ferrule is a ring-like component that is positioned around the tube inside the fitting. Ferrules can be single or double, depending on the type of ferrule fitting. When the nut is tightened, the ferrule(s) deform slightly, gripping the tube firmly. This deformation is crucial as it forms a tight seal between the tube and the fitting, preventing any leaks. The ferrule’s material and design are engineered to withstand high pressures and temperatures, ensuring durability and reliability in demanding applications.

Body:

The body is the main part of the ferrule fitting. It provides the structural foundation where the tube is inserted, and the nut is screwed onto it. The body typically has a precision-machined interior to ensure a proper fit with the tube and ferrule. It is designed to handle the mechanical stresses and environmental conditions it will be exposed to, making it a critical component in the fitting’s overall performance.

How Ferrule Fittings Work

When assembling a ferrule fitting, the tube is first inserted into the body of the fitting. The nut is then screwed onto the body, compressing the ferrule(s) around the tube. As the nut is tightened, the ferrule(s) deform slightly and grip the tube, creating a seal. This highly effective sealing mechanism allows ferrule fittings to withstand high-pressure and high-temperature environments. The deformation of the ferrule(s) is precisely controlled to ensure that the seal is both tight and durable, preventing leaks even under extreme conditions.

Types of Ferrule Fittings

Ferrule fittings are designed to meet the diverse needs of various applications, and they come in different types and materials to ensure compatibility and reliability. Understanding the distinctions among these types and materials is crucial for selecting the right fitting for your specific requirements.

Single Ferrule vs Double Ferrule Fittings

Single Ferrule Fittings:

Description: Single ferrule fittings have one ferrule that deforms to create a seal. The ferrule compresses around the tube when the nut is tightened, forming a secure connection.

Applications: These fittings are simpler in design and are often used in less demanding applications where moderate pressure and vibration are expected. They are ideal for general-purpose use, such as in water supply systems, gas pipelines, and low-pressure hydraulic systems.

Advantages: The simplicity of single ferrule fittings makes them cost-effective and easy to install. They require fewer components, which can simplify the inventory and reduce costs.

Double Ferrule Fittings:

Description: Double ferrule fittings consist of two ferrules – a front ferrule and a back ferrule. The front ferrule creates a seal with the tube and the fitting body, while the back ferrule holds the tube securely in place.

Applications: These fittings are preferred for high-pressure and high-vibration environments, such as in aerospace, petrochemical, and high-performance hydraulic systems. They provide a more reliable seal and better resistance to mechanical stresses.

Advantages: The double ferrule design offers superior performance in demanding conditions. The back ferrule’s grip on the tube enhances stability, preventing movement and potential leaks. This design also distributes stress more evenly, reducing the likelihood of tube deformation.

Material Options

Stainless Steel:

Properties: Stainless steel is known for its excellent corrosion resistance, strength, and durability. It can withstand harsh environments and high temperatures, making it suitable for a wide range of applications.

Applications: Commonly used in industries such as chemical processing, food and beverage, marine, and pharmaceutical due to its resistance to corrosion and ability to maintain integrity in aggressive environments.

Brass:

Properties: Brass is valued for its machinability, cost-effectiveness, and resistance to corrosion in non-aggressive environments. It is also easier to work with compared to stainless steel.

Applications: Often used in lower-pressure applications, such as in plumbing, instrumentation, and residential gas lines. Brass fittings are ideal for use where moderate mechanical strength and corrosion resistance are required.

Other Materials:

Carbon Steel: Known for its high strength and toughness, carbon steel is used in applications where high pressure and temperature resistance are necessary. It is less resistant to corrosion compared to stainless steel, so it is often coated or treated.

Plastic: Plastic ferrule fittings are lightweight and resistant to corrosion and chemical attack. They are used in applications where metal fittings would be unsuitable, such as in certain chemical handling systems and potable water lines.

Exotic Alloys: Materials such as Hastelloy, Monel, and Inconel offer superior resistance to corrosion, high temperatures, and mechanical stress. These are used in highly specialized applications like aerospace, nuclear, and chemical processing.

Industry Standards and Specifications

Ferrule fittings must conform to various industry standards to ensure compatibility, safety, and reliability in critical applications. These standards provide guidelines on dimensions, materials, performance, and testing to ensure that fittings meet the requirements for their intended use.

ASTM (American Society for Testing and Materials): Provides international standards for materials, products, systems, and services. ASTM standards ensure that ferrule fittings meet specific quality and safety criteria.

ASME (American Society of Mechanical Engineers): ASME standards govern the design, manufacture, and testing of mechanical components. Ferrule fittings conforming to ASME standards are ensured to perform reliably in mechanical systems.

ISO (International Organization for Standardization): ISO standards are globally recognized and ensure that products meet international safety, reliability, and performance requirements. Ferrule fittings that adhere to ISO standards can be used confidently in global markets.

Benefits of Using Ferrule Fittings

Ferrule fittings offer a multitude of benefits that make them the preferred choice for many applications. Their design and functionality provide significant advantages in terms of performance, maintenance, and versatility.

Leak-Proof Connections

One of the primary benefits of ferrule fittings is their ability to create leak-proof connections. This is crucial in high-pressure systems where even minor leaks can lead to significant losses or safety hazards. The ferrule’s design ensures that it deforms to create a tight seal around the tube, preventing any fluid or gas from escaping.

Ease of Installation and Maintenance

Ferrule fittings are designed for easy installation without the need for special tools. This simplicity not only speeds up the installation process but also reduces the likelihood of installation errors. Additionally, they can be easily disassembled and reassembled, facilitating maintenance and repairs. This ease of use translates to reduced downtime and lower maintenance costs.

Durability and Reliability

Ferrule fittings are built to withstand harsh environments and high pressures. Their robust construction ensures long-term durability, even in the most demanding conditions. This reliability is especially important in industries such as aerospace and chemical processing, where failure is not an option. Ferrule fittings provide peace of mind by maintaining their integrity over time.

Versatility

The versatility of ferrule fittings makes them suitable for a wide range of industries and applications. From industrial machinery and automotive systems to aerospace and medical equipment, ferrule fittings provide reliable connections in diverse environments. Their ability to handle different types of fluids and gases further enhances their applicability across various sectors.

Installation Process for Ferrule Fittings

Installing ferrule fittings correctly is crucial to ensuring their performance, reliability, and longevity. Proper installation helps maintain the integrity of the connection, preventing leaks and ensuring the system operates effectively. Here is a detailed, step-by-step guide to installing ferrule fittings, along with common mistakes to avoid and tips for ensuring a secure connection.

Step-by-Step Guide to Installing Ferrule Fittings

Preparation:

Gather Necessary Tools: Before beginning the installation, collect all the necessary tools. This typically includes wrenches, a tube cutter, deburring tools, and cleaning supplies.

Clean Tubing and Fittings: Ensure that both the tubing and the fittings are clean and free of any debris, dust, or grease. Contaminants can compromise the seal and lead to leaks.

Cutting the Tube:

Measure and Mark: Measure the required length of the tube and mark it.

Cut the Tube: Use a tube cutter to cut the tube to the desired length. Ensure that the cut is square and precise. An uneven cut can lead to improper sealing and potential leaks.

Deburr the Edges: After cutting, deburr the edges of the tube using a deburring tool. This removes any sharp edges or burrs that could damage the ferrule or compromise the seal.

Inserting the Tube:

Insert the Tube into the Fitting Body: Carefully insert the tube into the fitting body until it stops. Ensure that the tube is fully seated and straight within the fitting to prevent misalignment.

Tightening the Nut:

Hand-Tighten the Nut: Begin by hand-tightening the nut onto the fitting body. This helps align the components and prepares them for final tightening.

Use a Wrench to Tighten Further: Using a wrench, tighten the nut according to the manufacturer’s instructions. Typically, this involves tightening the nut one and a quarter turns beyond hand-tight. Follow the specific guidelines provided by the fitting manufacturer to avoid over-tightening or under-tightening.

Checking the Connection:

Inspect for Proper Alignment: After tightening, inspect the connection to ensure that the tube is properly aligned and that the fitting is securely in place.

Check for Leaks: Perform a pressure test or use a leak detection solution to check for any leaks around the fitting. Ensuring a leak-free connection is critical for the system’s performance.

Common Mistakes to Avoid

Over-Tightening or Under-Tightening the Nut: Both can compromise the integrity of the connection. Over-tightening can deform the ferrule or tube, while under-tightening can result in a weak seal.

Not Cutting the Tube Squarely: An uneven cut can prevent the ferrule from sealing properly, leading to leaks.

Using Incompatible Materials: Ensure that the tubing and fittings are made from compatible materials to avoid corrosion or other issues.

Tips for a Secure Connection

Follow Manufacturer Guidelines: Always adhere to the installation instructions provided by the fitting manufacturer. These guidelines are designed to ensure optimal performance and reliability.

Regularly Inspect Fittings During Use: Periodically check the fittings for signs of wear, corrosion, or leaks. Regular maintenance helps detect issues early and prolongs the life of the fittings.

Use Proper Tools: Using the correct tools for cutting, deburring, and tightening ensures that the fittings are installed correctly and reduces the risk of damage.

Cleanliness is Key: Keeping the tubing and fittings clean throughout the installation process is essential for creating a secure, leak-proof connection.

Comparison with Other Fittings

Ferrule fittings offer several distinct advantages over other types of fittings, making them a preferred choice for various applications. Here is a detailed comparison with other common fitting types, highlighting the unique benefits of ferrule fittings.

Ferrule Fittings vs. Compression Fittings

Seal Quality:

Ferrule Fittings: Ferrule fittings provide a highly secure seal due to the deformation of the ferrule around the tube, creating a tight, leak-proof connection. This makes them particularly well-suited for high-pressure applications where maintaining a reliable seal is critical.

Compression Fittings: While compression fittings also create a seal by compressing a ring or ferrule around the tube, they generally do not achieve the same level of sealing performance as ferrule fittings. They are more prone to leaks under high-pressure conditions and may not perform as well in dynamic environments with significant vibration or temperature fluctuations.

Improper Thread Sealant Application

Ease of Installation and Disassembly:

Ferrule Fittings: Ferrule fittings are easier to install and disassemble compared to threaded fittings. They do not require pipe threading, which can be time-consuming and require specialized tools.

Threaded Fittings: Threaded fittings involve screwing components together, which can be more labor-intensive. Proper sealing often requires additional materials such as thread sealant or tape to prevent leaks.

Resistance to Vibration and Thermal Cycling:

Ferrule Fittings: Designed to withstand vibration and thermal cycling better than threaded fittings. The ferrule’s deformation creates a stable and secure connection that maintains its integrity even under dynamic conditions.

Threaded Fittings: More susceptible to loosening under vibration and can experience leaks due to thermal expansion and contraction. Regular maintenance may be required to ensure the integrity of the connection.

Conclusion

Ferrule fittings are a versatile and reliable solution for connecting tubing and piping systems across various industries. They offer leak-proof connections, ease of installation, and durability, making them suitable for high-pressure and high-temperature applications. Understanding the types, benefits, and installation processes of ferrule fittings helps ensure their effective use in critical applications. By choosing the right ferrule fitting for your specific needs, you can enhance the performance and reliability of your systems. If you need a ferrule fitting, please contact us, we are always at your service!

FAQ

Ferrule fittings are used to create secure, leak-proof connections between tubes or pipes in various systems. They are commonly used in high-pressure applications such as hydraulic systems, chemical processing, and aerospace industry.

To install a ferrule fitting, cut the tube to the desired length, insert the tube into the fitting body until it stops, hand-tighten the nut, and then use a wrench to tighten further as per manufacturer’s instructions. Ensure the connection is aligned properly and check for leaks.

Ferrule fittings are made from various materials including stainless steel, brass, carbon steel, plastic, and exotic alloys like Hastelloy, Monel, and Inconel. The choice of material depends on the application requirements such as pressure, temperature, and corrosion resistance.

Single ferrule fittings use one ferrule to create a seal, suitable for less demanding applications. Double ferrule fittings have two ferrules: a front ferrule for sealing and a back ferrule for gripping the tube, providing better performance in high-pressure and high-vibration environments.

Yes, ferrule fittings can be reused if they are in good condition. However, it’s important to inspect the ferrules and the fitting for any signs of wear or damage before reinstallation to ensure a secure and leak-proof connection.

To choose the right ferrule fitting, consider the application’s pressure, temperature, and chemical compatibility requirements. Select the appropriate material and type (single or double ferrule) based on these factors.