How to Install Barbed Hose Fittings?

Table of Contents

Introduction

Barbed hose fittings are specialized connectors designed to create a secure, leak-resistant joint between a hose and another component, typically a pipe or another hose. These fittings feature barbs or ridges along their outer surface that grip the inside of the hose when inserted, providing a tight seal.

Definition and Components of Barbed Hose Fittings

Barbed Hose Fittings Components

Barbs: These are the ridges or serrations along the fitting’s surface that grip the hose when inserted, ensuring a tight seal.

Body: The main body of the fitting, which varies in shape and size depending on its specific application and connection requirements.

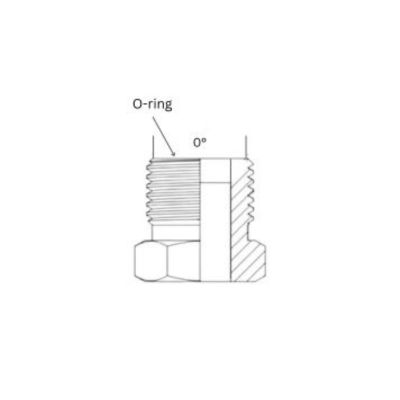

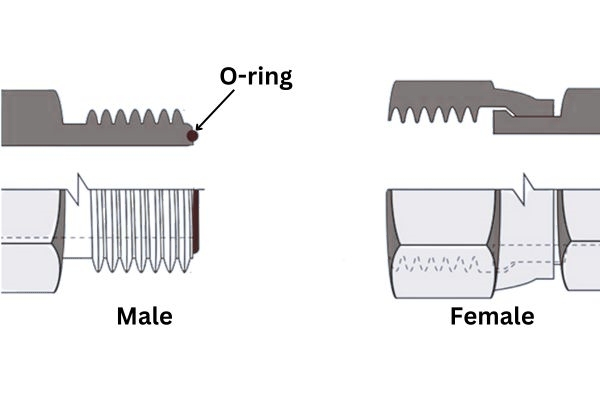

Threads: Some fittings may include threaded ends to facilitate attachment to other components such as pipes or equipment.

Types of Materials Used

Barbed hose fittings are available in a variety of materials to suit different applications and environmental conditions:

Brass: Commonly used for its durability, corrosion resistance, and suitability for hot water and hydraulic applications.

Stainless Steel: Known for its strength, corrosion resistance, and ability to withstand high temperatures and pressure.

Plastic (e.g., Nylon, Polypropylene): Lightweight options suitable for less demanding applications where chemical resistance and cost-effectiveness are key considerations.

Applications in Different Industries

Barbed hose fittings find extensive use across various industries, including:

Automotive: Used for fuel lines, coolant systems, and vacuum hoses.

Plumbing: Ideal for connecting hoses to fixtures, water pumps, and irrigation systems.

Industrial: Essential for fluid transfer in manufacturing processes, pneumatic systems, and hydraulic machinery.

These fittings provide versatile and reliable connections that cater to specific operational requirements, ensuring efficient fluid handling and minimizing the risk of leaks in critical applications. Understanding the different types and materials of barbed hose fittings is crucial for selecting the right components that best fit your industry’s needs.

Choosing the Right Barbed Hose Fitting

The appropriate barbed hose fitting is crucial for establishing a reliable and efficient fluid handling system. Here are comprehensive factors to consider:

Material Compatibility

Chemical Compatibility: Ensure the fitting material is compatible with the fluids or gases it will encounter. This prevents chemical reactions that could lead to corrosion or material degradation over time.

Temperature and Pressure Ratings: Select fittings rated to withstand your specific application’s operating temperatures and pressures. This ensures safety and prevents performance issues under varying conditions.

Application Specificity

Industry Requirements: Adhere to industry standards and regulations that may specify certain materials or configurations for fittings. Compliance ensures compatibility with industry norms and enhances system reliability.

Environmental Conditions: Evaluate environmental factors such as UV exposure, abrasion, and weather conditions. Choose fittings that are resilient to these elements to maintain longevity and performance.

Size and Measurement Guidelines

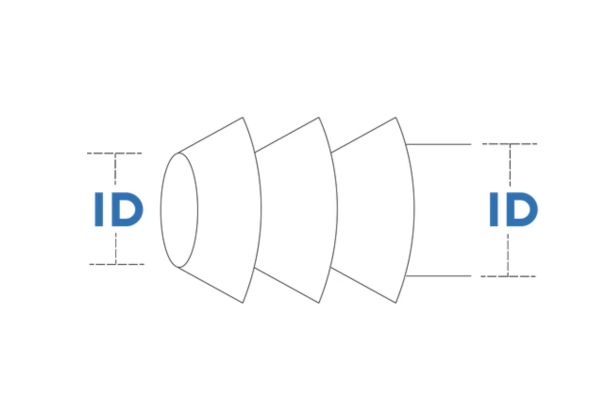

Inner Diameter (ID): Accurately measure the inner diameter of the hose to select a fitting with an appropriate barb size. This step is critical for establishing a secure connection that maintains fluid integrity.

Thread Size: Determine the thread size needed for the fitting to properly attach to other components or equipment in your system. Matching thread types and sizes ensures compatibility and prevents potential leaks or fitting misalignment.

By carefully evaluating these factors and guidelines, you can confidently choose barbed hose fittings that meet your specific application requirements. This proactive approach enhances system reliability, minimizes downtime, and optimizes overall operational efficiency in industrial environments. Regular maintenance and periodic inspections further ensure continued performance and longevity of your fluid handling systems.

Common Mistakes to Avoid in Fitting Selection

Incorrect Material Selection: Choosing fittings that are not compatible with the fluid or environment can lead to premature failure or safety hazards.

Improper Sizing: Using fittings with mismatched sizes can cause leaks or fittings that are difficult to install.

Neglecting Pressure Ratings: Fittings rated below the operating pressure may fail under stress, causing leaks or system damage.

Ignoring Environmental Factors: Failing to consider environmental conditions can lead to fittings deteriorating prematurely due to exposure to chemicals, temperature extremes, or UV radiation.

Step-by-Step Installation Process

Ensure a successful installation of barbed hose fittings by following these detailed steps:

Preparation

Before beginning the installation process, it’s crucial to prepare adequately:

Inspecting the Hose and Fitting: Thoroughly examine both the hose and the barbed fitting for any signs of damage, such as cracks, cuts, or deformities. This step ensures that all components are in optimal condition to prevent leaks or failures during operation.

Cutting the Hose to the Correct Length: Measure and cut the hose to the appropriate length using hose cutters or a sharp utility knife. A clean, straight cut is essential to facilitate a proper seal with the barbed fitting, ensuring a secure connection.

Lubrication

Proper lubrication enhances the installation process and ensures a secure connection:

Importance of Lubricating the Hose: Applying a suitable lubricant to the outside of the hose and the barbs of the fitting reduces friction during insertion. This minimizes the risk of damaging the hose material and makes it easier to achieve a tight fit without excessive force.

Types of Lubricants Suitable for Various Materials: Choose lubricants that are compatible with the hose material to avoid degradation or damage. For example, silicone lubricants are suitable for rubber hoses, while soapy water works well with plastic hoses. Avoid using petroleum-based lubricants, as they can deteriorate certain materials over time.

Insertion

Inserting the barbed fitting into the hose requires careful technique to ensure a secure and leak-free connection:

Techniques for Insertion: Gently twist and push the barbed fitting into the hose, employing a twisting motion to help the barbs grip the hose material securely. This technique ensures that the fitting is properly seated without damaging or distorting the hose.

Ensuring a Secure Fit Without Damaging the Hose: Avoid applying excessive force that could potentially damage the hose or stretch the material around the barbs. The fitting should fit snugly without gaps between the hose and the fitting body to maintain integrity.

Securing the Connection

Once the fitting is inserted, secure the connection effectively to prevent leaks:

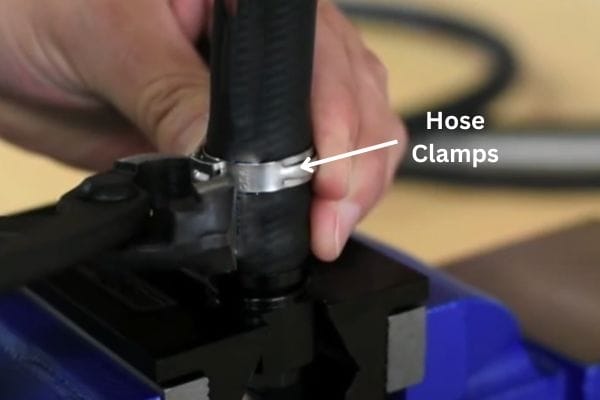

Using Hose Clamps Effectively: Position hose clamps over the barbed portion of the fitting, ensuring they are evenly spaced and securely fastened around the hose. Select clamps that match the hose diameter to achieve optimal sealing and prevent movement.

Tightening the Clamp to Prevent Leaks: Gradually tighten the hose clamp using a screwdriver or wrench until it is snug against the hose and fitting. Be cautious not to over-tighten, as this may cause damage to the hose or fitting threads.

Testing the Installation

After securing the connection, it’s crucial to verify its integrity and functionality:

Methods for Pressure Testing the Connection: Utilize a pressure testing tool or apply compressed air or water to the system to check for leaks under operational conditions. Monitor the connection closely for any signs of leakage, especially around the barbed fitting and hose clamp areas.

Inspecting for Leaks and Addressing Any Issues: Thoroughly inspect all connections for leaks immediately after testing. If leaks are detected, revisit the installation steps to identify potential causes such as improper insertion, inadequate lubrication, or insufficient tightening of hose clamps. Make necessary adjustments to achieve a tight seal and ensure reliable performance.

By following these step-by-step guidelines, you can ensure the successful installation of barbed hose fittings, maintaining efficiency and reliability in your industrial applications. Regular inspections and proactive maintenance will further enhance system performance and longevity.

Troubleshooting Common Issues

Encountering challenges during the installation of barbed hose fittings is common in industrial applications. Here’s how to troubleshoot and resolve common problems effectively:

Identifying and Fixing Leaks

Inspect the Connection:

Check for Visible Signs of Leakage: Thoroughly examine the area around the fitting and hose clamp for any signs of moisture or drips.

Trace the Leak: Identify the source of the leak, which may result from improper insertion, insufficient tightening of the hose clamp, or compatibility issues between materials.

Reevaluate Installation Steps:

Ensure Proper Insertion: Verify that the barbed fitting is correctly inserted into the hose without causing damage to the hose material or fittings.

Secure Hose Clamp: Ensure the hose clamp is securely tightened around the barbed fitting, creating a tight seal without gaps.

Apply Sealant or Tape:

Use Thread Sealant or Teflon Tape: Apply a suitable thread sealant or Teflon tape to threaded fittings to prevent leaks at connection points.

Seal Around Hose Barb: Apply a small amount of sealant around the hose barb before inserting it into the hose to enhance sealing and prevent leaks.

Replace Damaged Components:

Inspect and Replace: If leaks persist despite adjustments, inspect and replace damaged hoses, fittings, or clamps that may be causing the issue to ensure a secure connection.

Addressing Fittings That Are Difficult to Install

Lubricate Adequately:

Use Suitable Lubricant: Apply a lubricant compatible with the hose and fitting materials to reduce friction during installation and ease fitting insertion.

Ensure Compatibility: Verify that the lubricant chosen does not degrade or damage the materials involved.

Use Proper Tools and Techniques:

Utilize Hose Cutters: Use hose cutters to achieve clean, straight cuts on the hose, facilitating easier installation of fittings.

Techniques for Insertion: Employ twisting and pushing motions when inserting the fitting into the hose to help the barbs grip securely without applying excessive force.

Consider Heat Assistance:

Heat Application: For rigid or stubborn hoses, gently heat the hose with hot water or a heat gun to increase flexibility, making it easier to fit onto the barbed fitting without damaging the materials.

Handling Compatibility Issues Between Hose and Fitting Materials

Verify Material Compatibility:

Check Manufacturer Specifications: Refer to manufacturer guidelines or consult with suppliers to confirm compatibility between the hose and fitting materials to avoid chemical reactions, corrosion, or degradation.

Select Appropriate Fittings:

Material Selection: Choose fittings made from materials that are compatible with the fluid or gas being transferred through the system to ensure long-term reliability and performance.

Consider Environmental Factors: Evaluate environmental conditions such as UV exposure, temperature variations, and chemical exposure that may affect material integrity.

Implement Protective Measures:

Use Specialized Materials: Consider using fittings with alternative materials or coatings that enhance compatibility and durability in challenging environments.

Protective Coatings: Apply protective coatings or treatments to fittings exposed to harsh conditions to prolong their lifespan and maintain performance.

By following these troubleshooting steps and proactive measures, you can effectively resolve installation challenges with barbed hose fittings, ensuring reliable operation and minimizing potential issues in industrial settings. Regular inspection and maintenance will further enhance system integrity and performance over time.

Maintenance and Best Practices

Maintaining barbed hose fittings is essential for prolonging their lifespan and ensuring reliable performance in industrial applications. Here are key tips and best practices:

Tips for Maintaining Barbed Hose Fittings

Regular Inspection:

Conduct routine inspections of fittings, hoses, and clamps for signs of wear, corrosion, or leaks.

Inspect fittings after installation and periodically during operation to detect potential issues early.

Replacement Schedules:

Establish a maintenance schedule for replacing fittings and hoses based on manufacturer recommendations or observed wear.

Replace components promptly if they show signs of damage or deterioration to prevent failures and leaks.

Cleaning and Lubrication:

Clean fittings and hoses regularly to remove debris, dirt, or contaminants that can affect sealing and performance.

Apply appropriate lubrication during installation and maintenance to facilitate easier fitting insertion and prevent friction-related damage.

Tightening and Adjustment:

Ensure hose clamps are securely tightened to maintain a tight seal around barbed fittings.

Periodically check and adjust clamp tightness to compensate for any loosening due to vibration or temperature changes.

Best Practices for Ensuring Longevity and Performance

Use Compatible Materials: Select fittings and hoses that are compatible with the fluids, gases, and environmental conditions they will encounter.

Follow Installation Guidelines: Adhere to manufacturer installation instructions and industry best practices to ensure proper fitting assembly and sealing.

Monitor Operating Conditions: Regularly monitor operating temperatures, pressures, and environmental factors to anticipate potential issues and take preventive action.

Conclusion

In summary, selecting and installing barbed hose fittings requires attention to detail and adherence to best practices to ensure optimal performance and longevity. By employing safe installation techniques and proactive maintenance, you can maximize the efficiency and longevity of barbed hose fittings to ensure the continued success of your industrial operations.

FAQ

BSP hydraulic hose fittings are standardized fittings used to connect hydraulic hoses and pipes. They ensure a secure and leak-free connection in hydraulic systems.

Topa provides a wide range of BSP hydraulic hose fittings in various sizes to accommodate different hydraulic system requirements.

Yes, Topa’s BSP hydraulic hose fittings are designed to meet international standards and are compatible with fittings from other reputable brands. This ensures versatility and ease of integration into existing hydraulic setups.

Our BSP hydraulic hose fittings are manufactured using high-quality materials such as [specify materials, e.g., stainless steel, brass] to ensure durability, corrosion resistance, and long-term performance in demanding environments.

Yes, Topa understands the importance of meeting specific customer requirements. We offer customization options for BSP hydraulic hose fittings, including special sizes, configurations, and finishes to suit unique applications.

Ordering from Topa is straightforward. Simply [describe the ordering process, e.g., visit our website, contact our sales team], provide details about the BSP hydraulic hose fittings you need, and our team will assist you with pricing, availability, and delivery options.