What is a Hose Barb: The Comprehensive Guide

Introduction

Hose barbs are critical components in numerous industries, playing a vital role in fluid transfer systems. Their simplicity and effectiveness make them indispensable in systems that require secure and leak-proof connections. A hose barb is a fitting used to connect flexible hoses to rigid systems such as pipes or other fittings. It features a series of ridges or barbs that grip the inside diameter of the hose, creating a tight seal. The main components of a hose barb include the barb itself, the shank, and the end connection. These fittings can be made from various materials, including brass, stainless steel, and plastic, each chosen for its specific properties to suit different applications.

Understanding Hose Barbs

A hose barb is a type of fitting used to connect flexible hoses to rigid pipes, tubing, or other fittings. It is designed with a series of ridges or barbs along its shank that grip the inside diameter of the hose, ensuring a secure and leak-proof connection. The basic working principle of a hose barb is to provide a mechanical hold on the hose through the barbs, which prevent the hose from slipping off under pressure. This secure connection is often reinforced with clamps or bands to enhance the grip and ensure reliability in high-pressure or high-vibration environments.

Types of Hose Barbs

Hose barbs come in various shapes and configurations to suit different applications and installation requirements. Some of the common types include:

Straight Hose Barbs: These are the most basic type, featuring a straight design that is ideal for connecting hoses in a linear configuration. They are often used in simple applications where the hose needs to run in a straight line from one point to another.

Elbow Hose Barbs: Designed with a 90-degree bend, elbow hose barbs are used when the hose needs to change direction. This type is particularly useful in tight spaces where a straight hose connection is impractical.

T-shaped Hose Barbs: These fittings have three connection points, forming a T-shape. They are used to split a single hose line into two or combine two lines into one. T-shaped hose barbs are commonly used in irrigation systems and fuel distribution.

Y-shaped Hose Barbs: Similar to T-shaped barbs, Y-shaped hose barbs also have three connection points but are designed to split or combine hoses at a more acute angle. They are often used in applications where space constraints or specific flow requirements necessitate such a configuration.

Reducer Hose Barbs: These barbs have different diameters on each end, allowing for the connection of hoses with different internal diameters. They are used when there is a need to transition from one hose size to another within a system.

Material

Hose barbs are manufactured from various materials, each chosen for its properties to match specific application needs. Common materials include:

Brass: Known for its corrosion resistance and durability, brass is a popular choice for applications involving water, air, and certain chemicals.

Stainless Steel: Offers excellent corrosion resistance, strength, and temperature tolerance, making it suitable for harsh environments and critical applications.

Plastic: Lightweight and resistant to many chemicals, plastic hose barbs are used in applications where metal fittings might be susceptible to corrosion or where weight reduction is crucial.

Applications

Hose barbs are versatile fittings used across a wide range of industries and applications. Some of the common industries and specific use cases include:

Automotive: In the automotive industry, hose barbs are used in fuel lines, coolant systems, and air conditioning systems. Their ability to provide secure connections ensures the safe and efficient operation of vehicles.

Agriculture: Hose barbs are widely used in irrigation systems, connecting hoses that deliver water and nutrients to crops. Their reliability and ease of use make them ideal for agricultural applications.

Manufacturing: In manufacturing plants, hose barbs are used in pneumatic and hydraulic systems to connect hoses that transport air, fluids, and lubricants. Their durability ensures they can withstand the demanding conditions of industrial environments.

Home and Garden: Hose barbs are commonly found in home and garden applications, such as connecting garden hoses, drip irrigation systems, and water supply lines.

Components

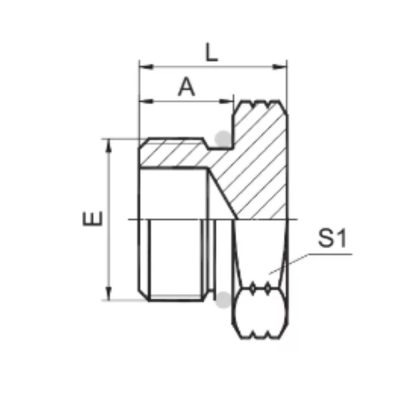

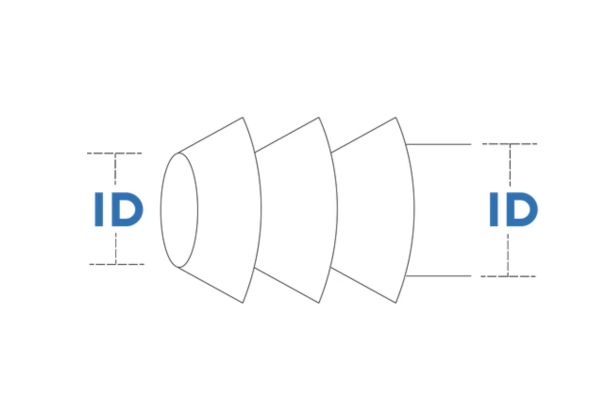

Barb

Structure: The barb is the ridged section of the fitting that is inserted into the hose. The ridges, or barbs, grip the inside of the hose, creating a tight seal.

Importance: The barb’s primary function is to prevent the hose from slipping off, especially under pressure. The design of the barb ensures that the hose remains firmly in place, reducing the risk of leaks and disconnections.

Shank

Structure: The shank is the smooth part of the fitting that connects the barb to the end connection. It provides a stable base for the barb and can vary in length depending on the specific hose barb design.

Importance: The shank ensures that the barb is securely attached to the end connection, maintaining the integrity of the entire fitting. It also contributes to the overall strength and durability of the hose barb.

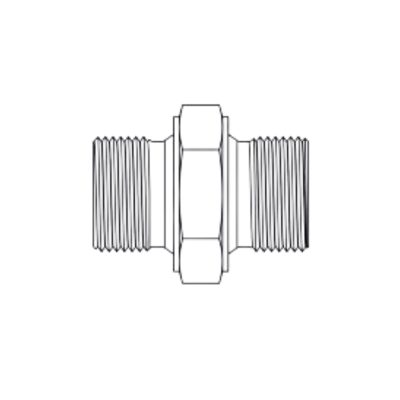

End Connection

Structure: The end connection is the part of the hose barb that connects to the system, which could be another hose, a pipe, or a piece of equipment. Common types include threaded, push-fit, and flange connections.

Importance: The end connection is crucial for integrating the hose barb into the larger system. It must be compatible with the components it connects to, ensuring a secure and reliable link.

How Hose Barbs Work

Mechanics of Sealing

Hose barbs create a seal through the ridged design of the barb section. When the hose is pushed onto the barb, the ridges grip the inside of the hose, creating friction that prevents the hose from sliding off. This friction-based grip is enhanced by the elasticity of the hose material, which contracts around the ridges, further securing the connection.

Importance of Proper Installation and Hose Compatibility

Proper installation ensures that the barb fully engages with the hose, maximizing the grip and seal. Using the correct hose size and material is crucial to ensure compatibility. A hose that is too loose or too tight can compromise the seal and lead to leaks or hose failure.

Selecting the Right Hose Barb

Material Compatibility with the Fluid Being Transferred

Chemical Resistance: Ensure that the material of the hose barb is compatible with the fluid it will be in contact with. For example, stainless steel is highly resistant to corrosive chemicals, while plastic might be suitable for less aggressive fluids.

Durability: Choose a material that can withstand the fluid’s characteristics, including its pH level, viscosity, and potential for causing wear or degradation.

Pressure and Temperature Requirements

Pressure Rating: Verify that the hose barb can handle the system’s operating pressure. Using a barb with a lower pressure rating than required can lead to leaks or failure.

Temperature Tolerance: Select a hose barb material that can withstand the system’s temperature extremes. For instance, stainless steel can handle higher temperatures than plastic or brass.

Size and Type of Hose Being Used

Hose Diameter: Ensure the barb size matches the hose’s inner diameter. An improper fit can lead to leaks or the hose detaching from the barb.

Hose Type: Consider the hose material and flexibility. Some hoses may require specific barb designs to ensure a secure fit, such as those used in high-vibration environments.

Common Mistakes to Avoid

Using Incompatible Materials

Typical Error: Choosing a hose barb material that is not compatible with the fluid or environmental conditions can lead to rapid degradation, corrosion, or chemical reactions.

Troubleshooting Tip: Always verify the chemical compatibility charts and manufacturer recommendations for both the hose barb and the fluid being transferred.

Incorrect Pressure and Temperature Ratings

Typical Error: Selecting a hose barb that does not meet the system’s pressure and temperature requirements can cause premature failure, leaks, and safety hazards.

Troubleshooting Tip: Check the specifications of both the hose barb and the system’s requirements. Consult with the manufacturer if unsure about the suitability of a specific barb for your application.

Mismatched Hose and Barb Sizes

Typical Error: Using a hose barb that is too large or too small for the hose can compromise the seal, leading to leaks or hose detachment.

Troubleshooting Tip: Measure the inner diameter of the hose accurately and select a barb that matches this size. If the fit is too tight or too loose, consider alternative barb sizes or consult with the manufacturer for advice.

Neglecting Clamps or Securing Mechanisms

Typical Error: Failing to use clamps or other securing mechanisms can result in the hose slipping off the barb under pressure.

Troubleshooting Tip: Always use appropriate clamps or bands to secure the hose over the barb. Tighten them to the recommended torque to ensure a secure connection.

Improper Installation Techniques

Typical Error: Incorrectly installing the hose barb, such as not pushing the hose far enough onto the barb or failing to twist the hose during installation, can lead to an insecure connection.

Troubleshooting Tip: Follow the installation guidelines carefully. Ensure the hose is fully seated on the barb and use proper techniques to achieve a secure fit.

Installation Process

Select the Right Hose and Barb

Compatibility Check: Begin by ensuring that the hose barb and hose are compatible in terms of size and material. The inner diameter of the hose should match the outer diameter of the barb for a snug fit. Additionally, the materials should be compatible with the fluid being transferred to prevent corrosion or degradation. For instance, if you’re working with chemical fluids, a stainless steel barb might be necessary, whereas for water applications, brass or plastic could suffice.

Application Suitability: Verify that both the hose and barb are suitable for the application’s pressure and temperature requirements. This step is crucial to ensure the long-term reliability and safety of the connection.

Cut the Hose

Measuring the Hose: Measure the hose length required for your setup. Ensure you have enough hose to reach between connection points without stretching.

Cutting Process: Use a sharp utility knife or a hose cutter to cut the hose to the desired length. Make sure the cut is clean and straight, as an uneven cut can compromise the connection. A clean cut ensures that the hose seats properly on the barb, reducing the risk of leaks.

Prepare the Barb

Inspection: Before inserting the barb, inspect it for any defects such as cracks, burrs, or deformities. Even minor imperfections can affect the seal and lead to leaks.

Cleaning: Ensure the barb is clean and free from any debris, oils, or residues. Any contaminants on the barb can compromise the connection and lead to leakage or hose degradation over time.

Insert the Barb

Insertion Technique: Push the barb into the hose, making sure the ridges fully engage with the hose interior. To facilitate easier insertion, you can slightly twist the hose as you push it onto the barb. This twisting action helps the hose to sit more securely on the ridges, enhancing the grip and ensuring a tight seal.

Depth Check: Ensure that the hose is pushed far enough onto the barb so that all the ridges are covered. This maximizes the contact area and ensures a secure connection.

Secure the Connection

Clamp Selection: Choose an appropriate hose clamp or band to secure the hose over the barb. The type of clamp should be suitable for the pressure and environmental conditions of your application. Common types include worm-drive clamps, spring clamps, and ear clamps.

Positioning the Clamp: Position the clamp over the barbed section of the hose barb, ensuring it is centered over the ridges. This placement is crucial for distributing the clamping force evenly and maintaining a secure connection.

Tightening the Clamp: Tighten the clamp to the manufacturer’s recommended torque specification. Over-tightening can damage the hose or the barb, while under-tightening may result in a loose connection that can lead to leaks. Use a torque wrench if possible to ensure precise tightening.

Final Inspection: After securing the clamp, visually inspect the connection to ensure the hose is fully seated on the barb and that the clamp is properly positioned and tightened. Give the hose a gentle pull to ensure it is firmly attached and will not slip off under pressure.

Tips for Ensuring a Secure and Leak-Proof Connection

Use Clamps

Additional Security: Always use appropriate clamps to secure the hose over the barb. Clamps provide an extra layer of security by applying consistent pressure around the hose, which helps maintain a tight seal. This is especially important in high-pressure or high-vibration environments where the hose might otherwise slip off the barb.

Types of Clamps: Different types of clamps can be used depending on the application, including worm-drive clamps, spring clamps, and ear clamps. Choose the type that best suits your specific needs, taking into account factors such as the operating pressure and environmental conditions.

Correct Positioning: Position the clamp directly over the barbed section of the hose barb, ensuring it is centered and evenly tightened to distribute pressure uniformly. This helps prevent leaks and ensures the hose remains securely attached.

Check for Compatibility

Material Matching: Ensure the hose and barb materials are compatible with each other and with the fluid being transferred. Incompatible materials can lead to chemical reactions, corrosion, or degradation, compromising the connection and potentially causing leaks or failures.

Temperature and Pressure Considerations: Verify that both the hose and barb can withstand the system’s temperature and pressure conditions. Using components that are not rated for the specific conditions of your application can result in premature wear, leaks, or catastrophic failure.

Manufacturer Recommendations: Always refer to the manufacturer’s recommendations for material compatibility and operational limits. This information is critical for selecting the right components for your system.

Conclusion

In conclusion, hose barbs are critical components in any fluid transfer system. Their simplicity, reliability, and versatility make them indispensable in various industries. We encourage readers to consider hose barbs as essential parts of their fluid transfer setups and to ensure they select the right type and material for their specific needs. For more information or expert advice on choosing and installing hose barbs, please contact us who can provide tailored solutions to meet your requirements.

FAQ

A hose barb is a type of fitting used to connect flexible hoses to rigid systems like pipes or other fittings. It features ridges or barbs that grip the inside of the hose, creating a secure and leak-proof connection.

Hose barbs can be made from various materials including brass, stainless steel, and plastic. The choice of material depends on the specific application and the fluids being transferred.

Select a hose barb based on the material compatibility with the fluid, the pressure and temperature requirements of the system, and the size and type of hose being used. Ensure the hose barb matches these factors to maintain a secure connection.

No, it’s important to use appropriate clamps such as worm-drive clamps, spring clamps, or ear clamps that are suited to your specific application. Properly positioned and tightened clamps ensure a secure and leak-proof connection.

Regular maintenance is crucial. Inspect the connections periodically for any signs of wear, leaks, or corrosion. Replace any damaged components promptly to ensure the integrity of the system.

If a leak occurs, first check that the hose is properly seated on the barb and that the clamp is correctly positioned and tightened. If the leak persists, inspect for any damage or defects in the hose, barb, or clamp, and replace any faulty compone