How to Identify Metric vs BSP Hydraulic Fittings

Table of Contents

Introduction

Using the wrong type can lead to leaks, system malfunctions, and even catastrophic failures, jeopardizing not only the machinery’s performance but also workplace safety. This article aims to demystify the process of distinguishing between Metric and BSP hydraulic fittings. By arming you with the necessary knowledge and tips, we endeavor to enhance your system’s efficiency and safety, ensuring that you choose the correct fitting type every time you encounter a hydraulic system. Understanding the subtleties of each fitting type not only optimizes operational performance but also minimizes risks associated with hydraulic systems.

Details on Metric Fittings

Metric hydraulic fittings are essential for the seamless operation of a variety of hydraulic systems, characterized by their specific dimensions, thread types, and sealing methods. Understanding these characteristics is crucial for ensuring compatibility and functionality within hydraulic systems.

Dimensions

When discussing the dimensions of Metric hydraulic fittings, it’s important to recognize that these components are meticulously standardized to ensure consistency across diverse applications. Metric fittings are measured using millimeters, which applies to both the outer diameter of the threads and the pitch, or the distance between each thread. This metric measurement system facilitates precise engineering and manufacturing across global industries.

Diameter of Threads

The diameter of Metric fittings can vary significantly depending on the application’s demand for strength and the space available for the fitting. Smaller diameters, such as M8 (8 millimeters), are typical in applications where space is limited and less fluid volume is required. These smaller fittings are common in light machinery or compact hydraulic systems within automotive contexts, where every millimeter of space must be efficiently utilized.

Pitch of Threads

The pitch in Metric fittings refers to the distance from the crest of one thread to the crest of the next. For example, an M8x1.0 fitting has a pitch of 1.0 millimeters, indicating very fine threading. Fine threads provide a higher degree of thread engagement and a better seal, which is crucial for systems operating under high pressure. On the other end of the spectrum, larger fittings like M48x2.0 have a pitch of 2.0 millimeters, which is suited for handling greater volumes and pressures, typical in industrial machinery such as construction equipment or heavy-duty manufacturing lines.

Common Sizes and Uses

The range from M8x1.0 to M48x2.0 covers a wide variety of applications. The smaller sizes (M8 to M16) are often used in precision applications such as hydraulic braking systems or fuel injection systems where tight seals and small clearances are paramount. Mid-range sizes (M18 to M30) are frequently found in commercial vehicles and agricultural equipment, balancing robustness and space efficiency. The largest sizes (M32 to M48 and beyond) are typically reserved for heavy industrial applications where large volumes of fluid must be moved reliably, such as in hydraulic presses or mining machinery.

Types of Metric Threads

Parallel (Straight) Threads

Description: As the standard thread type for Metric fittings, parallel threads maintain a consistent diameter across the entire length of the thread. This uniformity means that the threads do not taper towards the end, which is typical in some other thread types.

60-Degree Thread Angle: Metric threads are characterized by a 60-degree angle between the thread flanks. This angle is optimal for balancing force distribution across the thread faces, which is crucial when the fittings are subjected to high pressures.

Sealing Mechanism: Parallel threads themselves do not generally provide a seal but are used in conjunction with either O-rings placed in the mating face (face seal) or by compression of a soft sealing material as in a bonded seal. This arrangement is critical for preventing leaks and is especially effective in high-pressure systems.

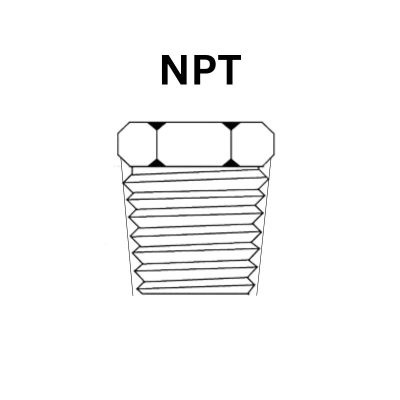

Tapered Threads

Description: While less common in Metric system fittings and more frequently found in the NPT (National Pipe Taper) threads, tapered threads do feature in some Metric applications, particularly where a metal-to-metal seal is required. These threads taper, becoming narrower towards the end of the fitting, which allows them to form a seal as they are screwed into a receiving fitting.

Sealing Mechanism: Tapered threads rely on the mechanical deformation between the thread crests and roots for sealing, which occurs when the threads are tightened. This type of seal is generally used in applications where chemical compatibility or extreme temperatures preclude the use of elastomeric seals.

Buttress Threads

Description: Although not as common in hydraulic fittings, buttress threads are worth mentioning for their unique structure. These threads are designed to handle extremely high axial forces in one direction. They feature a normal 60-degree angle on one flank and a much steeper angle on the other.

Application: Buttress threads are typically used in applications involving large forces, such as in jacks, vises, and presses, where the load is predominantly in one direction.

Geographical Locations and Application Environments

Metric hydraulic fittings are predominantly used in regions where the metric system is the standard for measurement, which includes most of Europe, Asia, and South America. Their adoption is particularly widespread in industries where precision and standardization across international borders are crucial.

Countries and Regions

Countries such as Germany, China, Japan, and Brazil, with large manufacturing sectors, heavily use Metric fittings. These nations often have stringent standards that require the reliable performance of hydraulic systems in various applications.

Industries and Types of Machinery

Metric fittings are commonly found in automotive manufacturing, aerospace, and heavy machinery industries. For example, they are used in the hydraulic systems of cars, aircraft, construction equipment, and factory automation systems. The precision of Metric fittings makes them suitable for applications where exact fluid control is necessary, such as in robotic systems or in the hydraulics of precision machining tools.

Details on BSP Fittings

Classification and Characteristics

BSP (British Standard Pipe) fittings, crucial for their robust design and versatility, are widely utilized across various industries. These fittings adhere to British standards, making them vital in environments that demand tight seals and long-term durability.

Understanding BSP Fittings Dimensions

Thread Diameter

The diameter of BSP threads is crucial as it determines the scale and suitability of the fitting for various pipe sizes. Measured in inches, the diameter gives a clear indication of the fitting’s size, ensuring that it matches the corresponding pipes or hoses in the hydraulic system.

Common diameters include sizes such as 1/8”, 1/4″, 1/2″, 3/4″, and 1″, among others. Each size serves distinct functions, from light residential water systems to heavy industrial hydraulic applications.

Number of Threads Per Inch (TPI)

TPI is another critical dimension in BSP fittings that influences the tightness and seal quality of the connection. The thread count per inch impacts how the fitting will engage and seal with its mating component.

Higher TPIs typically mean finer threads, which can provide a more secure fit and better sealing capabilities. For instance, a higher TPI fitting might be used in applications where higher pressure tolerance is needed.

Thread Types

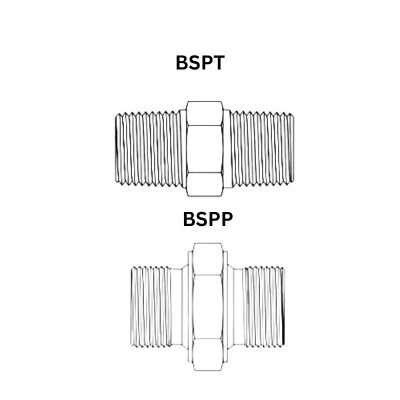

BSPP (G): British Standard Pipe Parallel threads maintain a consistent diameter throughout, which prevents the sort of tapering typical of other thread types. This design is essential for applications requiring stable and uniform sealing pressure. BSPP fittings are generally used where the seal’s integrity is crucial, utilizing bonded seals or washers placed at the base of the thread to secure a leak-free connection.

BSPT (R): In contrast, British Standard Pipe Tapered threads narrow as they advance deeper into the fitting, providing a progressively tighter fit. This inherent taper allows for a metal-to-metal seal, which becomes more effective as the fitting is tightened, enhancing its ability to handle systems operating under variable pressures.

Sealing Features: The choice of sealing method is crucial in preventing fluid leakage and maintaining system integrity.

BSPP Fittings typically incorporate elastomeric seals such as O-rings, which are positioned to compress against the mating surface, thereby creating a high-integrity seal that can withstand fluctuations in pressure and temperature.

BSPT Fittings rely on the metal-to-metal contact between the tapered threads and the female receptacle. This contact forms a dynamic seal that adjusts under pressure and can be particularly effective in environments where chemical compatibility and temperature resistivity are necessary.

BSP fittings are predominantly used in the United Kingdom and many Commonwealth countries, where British standards have been historically implemented. These regions include parts of Africa, India, Australia, and the Middle East, where the legacy of British engineering continues to influence local industries.

How to Distinguish Between BSP and Metric Fittings

Distinguishing between BSP and Metric fittings is essential for ensuring the correct parts are used in hydraulic systems, which can prevent leaks and component mismatches that lead to system failures.

Identification Tools and Techniques

Tools Needed

Thread Gauge: A crucial tool that allows you to measure the threads per inch (TPI) for BSP fittings and the pitch for Metric fittings.

Calipers: Used to measure the outer diameter of the threads accurately.

Thread Pitch Gauge: Specifically helpful for quickly determining the pitch of Metric threads.

Magnifying Glass: Useful for closely examining thread shape and any markings that indicate thread type.

Reference Charts: Having charts that delineate BSP and Metric thread specifications can be a quick reference to confirm your measurements.

Step-by-Step Identification Guide

Step 1: Measure the Diameter

Use the calipers to measure the outer diameter of the threads. Record this measurement. Remember, BSP diameters are typically expressed in inches, while Metric diameters are measured in millimeters. This initial measurement is critical as it provides the first indication of the fitting standard.

Step 2: Determine the Thread Pitch or TPI

For Metric fittings, measure the distance between thread peaks in millimeters (pitch). For BSP fittings, count the number of thread peaks per inch (TPI). Align the gauge appropriately with the threads and ensure it matches perfectly to avoid measurement errors. This step helps further differentiate the standard by focusing on thread spacing.

Step 3: Inspect the Thread Profile

Visual Inspection: Use a magnifying glass or thread profile gauge to examine the thread shape closely. It’s crucial to observe the angle and sharpness of the threads.

Metric Threads: Look for a 60-degree angle between the threads, which are typically sharper and more defined. Metric threads are known for their precise, angular profile, which contributes to their efficient sealing capability.

BSP Threads: Identify a 55-degree thread angle. BSP threads tend to have a more rounded and less sharp profile compared to Metric threads. This slight roundness helps in creating effective seals in high-pressure systems.

Step 4: Check for Standard Markings

Inspect the fitting for any manufacturer’s markings that indicate the standard. Commonly, fittings are marked with ‘M’ for Metric or ‘BSP’ for British Standard Pipe. These markings are usually found on the body or the side of the fitting and can be a quick way to identify the type without detailed measurement.

Step 5: Consult Reference Charts

After gathering all your data, refer to a reference chart that lists specifications for BSP and Metric fittings. Match your measurements and observations to the specifications on the chart. This step is crucial as it helps confirm your findings and ensures you have correctly identified the type of fitting.

Common Mistakes

Identifying hydraulic fittings correctly is critical to maintaining system integrity. Here are some common errors that occur during the identification of Metric and BSP fittings, along with practical tips to avoid them:

Confusing Metric and BSP Threads Due to Similar Sizes:

Metric and BSP threads can sometimes be similar in size but differ significantly in thread pitch and type, leading to incorrect identification and compatibility issues.

Misreading Thread Pitch and TPI:

Incorrectly measuring the thread pitch for Metric or threads per inch (TPI) for BSP can result in the selection of incompatible parts, which may cause leaks or thread damage when forced together.

Overlooking Thread Damage or Wear:

Worn or damaged threads can be misleading during measurements, potentially resulting in erroneous identification.

Assuming All Fittings with the Same Appearance are Identical:

Fittings might look similar but could have different specifications; relying solely on visual cues without precise measurement can lead to mistakes.

Conclusion

Throughout this article, we have explored the critical distinctions between Metric and BSP hydraulic fittings—two predominant types of fittings essential in various hydraulic systems across industries. Proper identification of these fittings is not only crucial for system compatibility but also for ensuring operational efficiency and safety.

FAQ

What are Metric hydraulic fittings?

Metric hydraulic fittings are based on the International System of Units (SI) and use millimeters to measure thread diameter and pitch. They typically feature a 60-degree thread angle and are common in systems outside of North America, particularly in Europe and Asia.

What are BSP hydraulic fittings?

BSP hydraulic fittings conform to British standards with specifications measured in inches. They can have either parallel (BSPP) or tapered (BSPT) threads, with a characteristic 55-degree thread angle, predominantly used in the UK and Commonwealth countries.

How can I identify whether a fitting is Metric or BSP?

Measure the outer diameter and thread count (TPI for BSP, pitch for Metric). Metric threads are sharper with a 60-degree angle, while BSP threads are more rounded with a 55-degree angle. Also, check for any standard markings on the fittings.

Can Metric and BSP fittings be interchanged?

Generally, Metric and BSP fittings are not interchangeable due to differences in thread forms and angles, which can lead to leaks and fitting damage if forced together.

Why is it important to use the correct type of hydraulic fitting?

Using the correct fitting type ensures compatibility and integrity of the hydraulic system, prevents leaks, and maintains operational safety and efficiency.

What tools are needed to measure and identify Metric and BSP fittings?

Digital calipers to measure the outer diameter, a thread pitch gauge to identify the thread pitch or TPI, and possibly a magnifying glass to examine the thread profile closely.