Brass DOT Compression Fittings - For Nylon Tubing

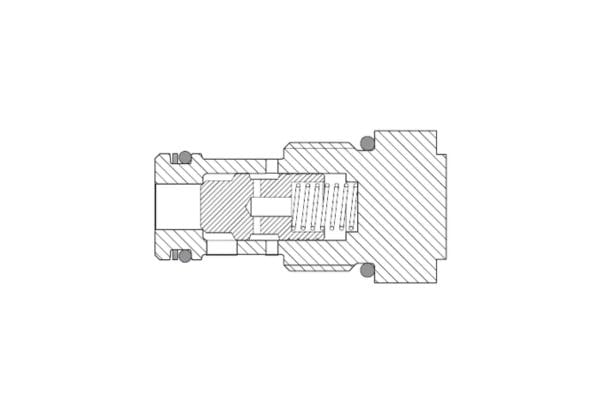

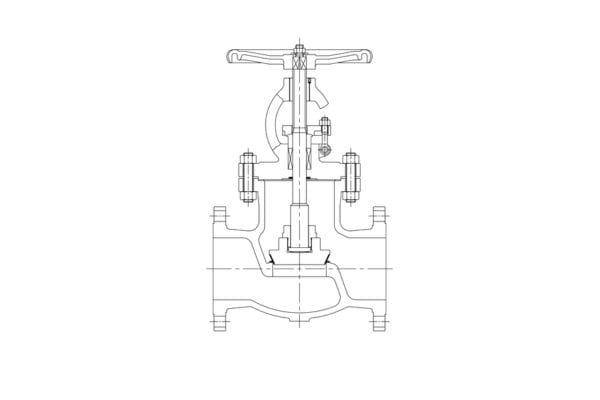

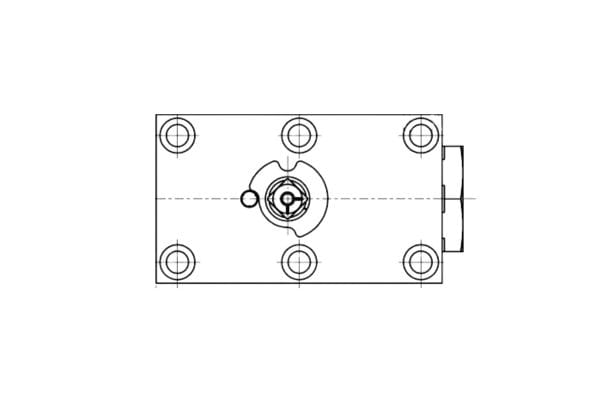

A brass DOT compression air brake fitting is a type of fitting used in air brake systems in vehicles, particularly commercial vehicles like trucks and buses.

Topa can supply various types of brass DOT compression fittings. These brass DOT brake line compression fittings are suitable for a wide range of air brake applications and are of the highest quality and at a fair price.

Therefore, if you have questions about dot compression fittings, please contact us and we will answer your questions as soon as possible.

Brass DOT Compression Fittings Video

This video features various Topa brass DOT compression fitting types.

Brass dot air line fittings can be applied in many applications, they all play an important role in those applications.

If you have any questions about brass dot air brake fittings or other products, please contact us.

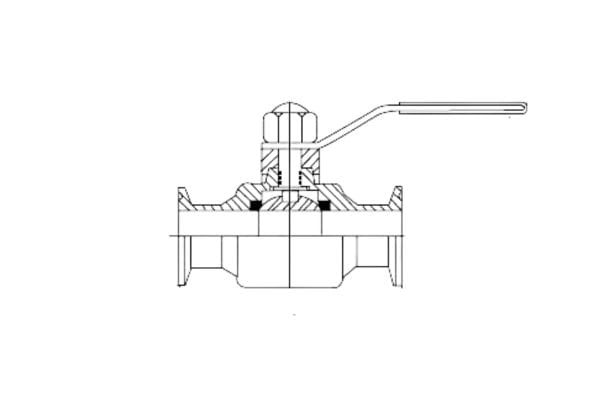

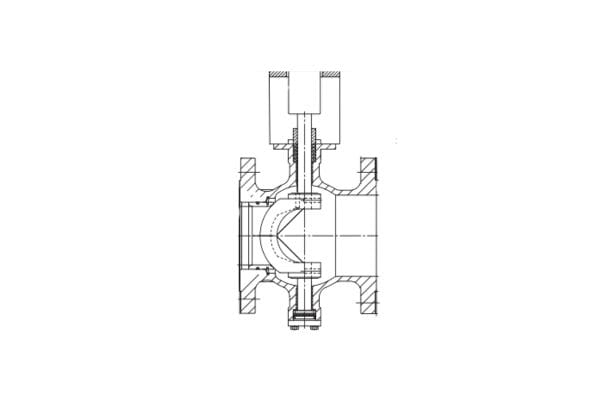

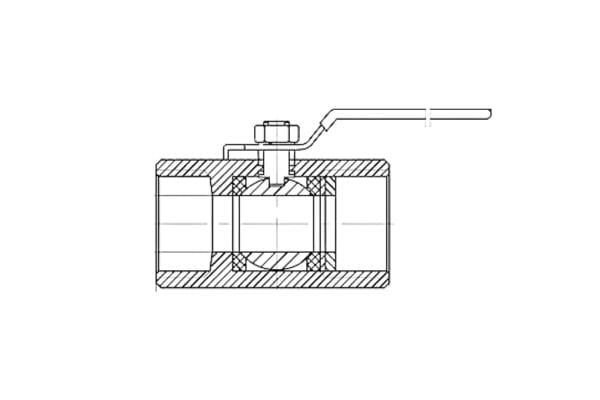

Brass Fitting Catalog

Topa offers various types of brass fittings, and this catalog includes all of them.

Please contact us if you need more information on brass fittings or would like some free samples.