Choosing the right hydraulic seal is crucial for the optimal performance of fluid power systems, as seals play a key role in preventing fluid leakage, maintaining pressure, and ensuring smooth operation. Inadequate seal selection can lead to significant issues such as leaks, causing contamination and system instability. This results in costly downtime and reduces the efficiency of the entire hydraulic system, leading to higher energy consumption, increased maintenance costs, and premature component wear.

Understanding Hydraulic Seals: What Are They and How Do They Work?

Definition of Hydraulic Seals

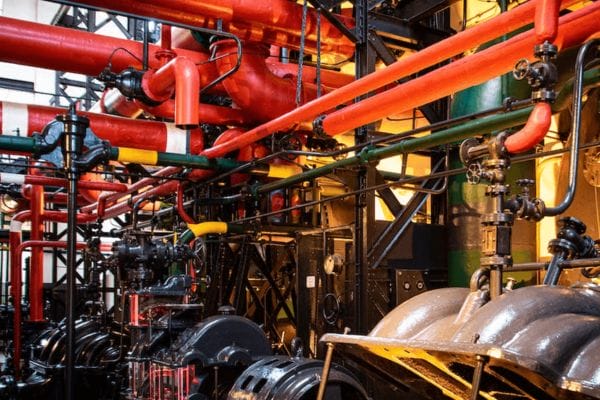

Hydraulic seals are specialized components used in hydraulic systems to prevent fluid leakage, ensure pressure retention, and reduce friction between moving parts. They create a barrier that separates fluids, gases, or other substances within a hydraulic system, ensuring that pressure and fluid flow are maintained properly. Hydraulic seals are designed to perform under high-pressure, high-temperature, and often corrosive conditions, making them essential for the efficient operation of hydraulic machinery.

The Role of Seals in Hydraulic Systems

Seals play a vital role in the functioning of hydraulic systems by ensuring that hydraulic fluid stays confined to the designated pathways, preventing leaks and maintaining pressure integrity. This helps to avoid contamination, reduce wear and tear on system components, and maintain operational efficiency. Seals also protect against external contaminants that could damage sensitive components, like pumps and valves, ensuring that the system operates smoothly and with minimal risk of failure.

Dynamic vs Static Seals: What’s the Difference?

The primary distinction between dynamic and static seals lies in their movement and application within the hydraulic system:

Dynamic Seals: These seals are designed to withstand motion between two components. They are used in areas where there is relative motion, such as piston rods, shafts, or valves. Dynamic seals must be capable of withstanding the movement without losing their sealing effectiveness, even under high pressure and temperature conditions.

Static Seals: Static seals, on the other hand, are used in stationary parts of the system where no movement occurs between the two surfaces. These seals provide a reliable barrier against leakage in places like the interface between the cylinder and its cap or at connections where parts are held in place.

O-Ring Seals: Simple Yet Effective

How O-Rings Work: Design and Functionality

O-rings are circular seals with a round cross-section, typically made from elastomeric materials. When installed in a groove, they form a tight seal by applying pressure against the mating surfaces, preventing leakage. The O-ring’s elastic properties allow it to deform when pressure is applied, filling gaps and maintaining a reliable seal even under varying conditions. The simple design—just a ring—makes O-rings versatile and easy to install, but their effectiveness relies heavily on the correct sizing and material selection to match the pressure, temperature, and fluid types within the hydraulic system.

Common Applications and Limitations

O-rings are used in a variety of hydraulic applications where sealing is needed to prevent fluid leakage. Common uses include:

Cylinder Seals: O-rings are often used in hydraulic cylinders to create a seal between the piston and cylinder wall, preventing leakage of hydraulic fluid.

Valve Seals: They are also employed in valves to maintain proper fluid pressure and prevent contamination in fluid lines.

Flange Connections: O-rings are widely used in sealing flange connections in hydraulic systems and pumps.

However, O-rings also have limitations:

Temperature Sensitivity: O-rings can degrade under extreme temperatures, both high and low, which may limit their use in certain high-temperature applications.

Pressure Limitations: O-rings may not be suitable for very high-pressure environments without additional support or modifications.

Compression Set: If exposed to long periods of pressure without movement, O-rings can experience a compression set, causing them to lose their sealing ability over time.

Materials Used for O-Rings

The performance of an O-ring largely depends on the material it is made from. Different materials offer varying levels of resistance to heat, chemicals, and pressure. Common materials include:

Nitrile (Buna-N): Offers good resistance to oil and fuel but has limited high-temperature tolerance.

Viton (FKM): A highly durable material that performs well at higher temperatures and provides good resistance to chemicals and oils.

EPDM (Ethylene Propylene Diene Monomer): Ideal for use with water, steam, and some acids, but it is not suitable for petroleum-based fluids.

Silicone: Provides excellent low-temperature flexibility and resistance to ozone, but it may not handle high-pressure systems well.

Polyurethane: Known for its high abrasion resistance and ability to withstand high-pressure and high-temperature environments.

Piston Ring Seals

Understanding the Function of Piston Ring Seals

Piston ring seals are specifically designed to provide a tight seal between the piston and cylinder walls in hydraulic cylinders or engines. The seal is created by the flexible, elastic nature of the piston ring, which presses against the inner surface of the cylinder while the piston moves up and down. This prevents hydraulic fluid from leaking past the piston and into other areas of the system, ensuring the integrity of the fluid pressure and maintaining system efficiency. Piston rings are also crucial for maintaining compression in engines or hydraulic systems, ensuring that the fluid is effectively contained within the system during operation.

Ideal Use Cases

Piston ring seals are best suited for applications that involve high-pressure and high-speed movements. Some ideal use cases include:

Heavy-Duty Hydraulic Cylinders: Piston rings are commonly used in industrial machinery, construction equipment, and other hydraulic systems where high pressure is generated. They help maintain the hydraulic pressure and prevent leakage, which is critical for machine performance.

Engines and Compressors: In both internal combustion engines and air compressors, piston rings prevent fluid or gas leakage, maintain pressure, and ensure the system operates efficiently under high-speed conditions.

High-Temperature Systems: Piston rings are also used in environments with elevated temperatures where other sealing methods may not be as effective. They provide a stable seal even in challenging thermal conditions, ensuring optimal performance.

Automotive and Aerospace Applications: Due to their wear resistance and high-pressure capabilities, piston ring seals are used in the automotive and aerospace industries, where reliability and performance are critical.

Common Material Choices for Piston Ring Seals

The material selection for piston ring seals is critical to ensuring their performance in high-pressure and high-speed environments. Common materials include:

Cast Iron: Traditionally used for piston rings, cast iron offers excellent wear resistance and is cost-effective for many applications. However, it may not perform well in extremely high-pressure or high-temperature environments.

Steel: Steel piston rings are known for their strength and durability, making them suitable for high-pressure, high-speed applications. They are often coated with materials like chromium or nitriding to enhance wear resistance.

Bronze: Used in some applications, bronze piston rings offer high wear resistance and excellent heat dissipation properties. They are commonly found in marine and industrial machinery.

Carbon Composite Materials: Carbon-based piston rings are used in extremely high-performance applications, such as aerospace, due to their excellent resistance to wear and ability to withstand extreme temperatures.

Polyurethane and Other Elastomers: These materials are sometimes used in hydraulic systems for lighter-duty applications where elasticity and wear resistance are key factors, offering flexibility and reduced friction.

V-Ring Seals

How V-Ring Seals Work and Their Design Features

V-ring seals are designed with a distinctive V-shaped cross-section, which helps them provide a tight seal in hydraulic systems. The sealing action occurs when the V-ring is compressed between the rotating or reciprocating component and the housing or counter surface. The design ensures that the lip of the V-ring maintains consistent contact with the sealing surface, effectively preventing leakage while reducing friction. The elastic properties of the material used for V-rings allow them to deform and adapt to the varying pressure and temperature conditions in a hydraulic system, ensuring a reliable seal even under extreme stress.

The unique design of the V-ring provides a flexible and durable solution for sealing, especially in dynamic applications. The sealing lip of the V-ring presses against the surface, while the body of the seal supports the structure and resists wear. V-rings can be installed on both rotary and reciprocating components, making them versatile for a wide range of hydraulic applications.

When to Choose V-Ring Seals for Hydraulic Cylinders

V-ring seals are ideal for use in hydraulic cylinders where high pressure, temperature, and dynamic movement are common. Some key considerations for choosing V-ring seals include:

High-Pressure Systems: V-ring seals excel in hydraulic applications with high-pressure demands, such as industrial presses, heavy-duty machinery, and construction equipment. Their ability to withstand significant pressure without leakage makes them indispensable in these systems.

Rotating and Reciprocating Motion: V-rings are versatile and can be used for both rotating and reciprocating motions, making them suitable for dynamic sealing applications where components move back and forth or rotate. They’re commonly used on piston rods and in rotary seals.

Exposure to Harsh Environments: If your hydraulic system operates in extreme conditions—such as high temperatures or environments exposed to chemicals and abrasives—V-ring seals are a great choice. Their ability to resist wear, chemicals, and extreme temperatures ensures that they will last longer in these demanding conditions.

Continuous Operation: For systems that require continuous operation, V-rings can provide a longer-lasting seal. Their durability ensures that the system operates smoothly with minimal maintenance, reducing the need for frequent seal replacements.

V-ring seals are particularly beneficial for applications in hydraulic cylinders that require durable, long-lasting performance under demanding conditions.

Best Practices for Installing V-Ring Seals

To ensure optimal performance and longevity, proper installation of V-ring seals is crucial. Here are some best practices to follow:

Clean the Installation Area: Before installing a V-ring, ensure that the sealing surface is clean and free of debris, dirt, or contaminants. Any particles on the surface can cause the seal to wear prematurely or fail to seal properly.

Check the Fit: Ensure that the V-ring is the correct size for the application. The seal should fit snugly into its groove without being overstretched or compressed. A properly sized seal will create the necessary pressure for an effective seal.

Proper Alignment: Align the V-ring correctly with the sealing surfaces to ensure it makes full contact with both the dynamic and static parts. Misalignment can result in leaks and premature wear.

Lubrication: Lightly lubricate the V-ring and the sealing surface before installation. This helps reduce friction during initial operation and extends the life of the seal.

Avoid Over-tightening: When installing the components around the V-ring, avoid over-tightening the parts. Over-tightening can distort the seal and reduce its sealing efficiency. Ensure that the proper torque specifications are followed for the hydraulic system’s components.

Inspect for Damage: Before installation, visually inspect the V-ring for any signs of damage such as cracks, cuts, or deformation. A damaged seal should not be used, as it will fail to provide a proper seal.

Y-Ring Seals: The Secret to Reliable Hydraulic Sealing

What Makes Y-Ring Seals Unique?

Y-ring seals are distinguished by their unique Y-shaped cross-section, which consists of a flexible sealing lip and a supporting body that provides the necessary pressure to maintain a reliable seal. This design allows the Y-ring to perform exceptionally well in both static and dynamic sealing applications, particularly where there are varying pressures and temperatures. The Y-ring’s sealing lip is designed to press tightly against the mating surfaces, forming a reliable barrier that prevents leakage, while the body of the Y-ring ensures the seal remains intact under pressure.

What makes Y-rings especially effective is their ability to adapt to the varying conditions within hydraulic systems. As pressure fluctuates, the lip of the Y-ring maintains a tight seal, and its flexibility ensures it continues to perform well even under high pressures or when exposed to contaminants. This adaptability makes Y-ring seals highly versatile in many different hydraulic applications.

How Y-Rings Improve Seal Longevity and Reliability

Y-ring seals offer numerous advantages that contribute to their longevity and reliability:

Increased Contact Pressure: As pressure increases in the system, the lip of the Y-ring presses even tighter against the sealing surface, improving the seal’s effectiveness and reducing the likelihood of fluid leakage. This ensures a more reliable seal over time, even in high-pressure environments.

Reduced Wear and Tear: The Y-ring’s flexible design helps it absorb the mechanical stresses that occur during the operation of hydraulic cylinders, reducing wear and tear. The seal maintains its integrity and continues to perform well for a longer period.

Consistent Sealing Performance: Thanks to its ability to adjust to pressure changes, Y-rings offer consistent sealing performance across a range of pressures and operating conditions. This helps avoid the need for frequent replacements and minimizes system downtime.

Improved Resistance to Contaminants: The design of the Y-ring makes it less prone to damage from contaminants that might infiltrate the system. The sealing lip is effective at keeping debris out of the critical sealing area, preventing the ring from wearing prematurely.

This combination of durability, pressure adaptability, and reliability makes Y-ring seals a great choice for applications that demand long-lasting, high-performance sealing.

Best Applications for Y-Ring Seals

Y-ring seals are best suited for applications that involve high-pressure, dynamic, and extreme conditions. They excel in situations where both axial and radial sealing is needed, and where the seal needs to withstand fluctuating pressures or temperatures. Common applications include:

Hydraulic Cylinders: Y-rings are often used in hydraulic cylinders to seal the piston or rod areas. They are ideal for sealing in both reciprocating and rotating motions, where consistent performance and pressure retention are critical.

Pumps and Motors: In hydraulic pumps and motors, Y-rings are used to maintain the pressure within the system, preventing leakage around rotating components and ensuring efficient fluid flow.

Heavy-Duty Machinery: Y-rings are frequently found in construction, mining, and agricultural machinery where high pressures and rugged conditions demand durable, reliable sealing solutions.

Aircraft and Aerospace Applications: In aerospace systems, where high pressure and low tolerance for leaks are critical, Y-ring seals offer a lightweight, reliable sealing option that can withstand extreme temperatures and pressures.

Industrial Equipment: Y-rings are commonly used in industrial equipment such as compressors, valves, and hydraulic presses, where effective sealing is crucial to maintain system efficiency.

Thanks to their adaptability, Y-ring seals are employed in a wide range of industries and applications where high reliability and durability are paramount.

Material Options for Y-Rings and Their Benefits

The performance of Y-ring seals is highly dependent on the material from which they are made. The choice of material affects their resistance to wear, temperature, pressure, and chemical exposure. Common materials for Y-rings include:

Nitrile (Buna-N): Nitrile is the most commonly used material for Y-rings due to its excellent resistance to oils, fuels, and hydraulic fluids. It performs well in a wide range of temperatures but may not be suitable for extreme temperatures or exposure to ozone or sunlight.

Viton (FKM): Viton is a synthetic rubber with superior resistance to high temperatures, chemicals, and weathering. It is often used in more demanding applications, such as high-temperature environments or where aggressive chemicals are present.

EPDM (Ethylene Propylene Diene Monomer): EPDM is used in Y-rings for applications involving water, steam, or mild chemicals. It offers excellent weather, ozone, and aging resistance, making it suitable for applications where the seal will be exposed to the elements.

Polyurethane: Polyurethane Y-rings are known for their high abrasion resistance and are often used in high-pressure environments where wear is a concern. They are particularly effective in situations where high elasticity and toughness are needed.

PTFE (Polytetrafluoroethylene): PTFE is highly resistant to heat, chemicals, and friction, making it suitable for extreme conditions. PTFE Y-rings are often used in applications where other materials would degrade or lose sealing capability.

How to Choose the Right Hydraulic Seal for Your System

Key Factors to Consider

When selecting a hydraulic seal for your system, several key factors must be considered to ensure optimal performance and longevity. These factors help determine which type of seal will meet the demands of your application:

Pressure: The hydraulic system’s operating pressure is one of the most critical factors when choosing a seal. High-pressure systems require seals that can withstand greater force without deforming or leaking. For such systems, seals made from materials with high tensile strength, like steel-reinforced elastomers or PTFE, are often used.

Temperature: Temperature fluctuations can significantly affect the performance of hydraulic seals. Both high and low temperatures can cause materials to degrade or lose their elasticity, leading to leaks. Select seals made from temperature-resistant materials, like Viton or EPDM, for high-temperature environments, and materials like nitrile for lower temperature applications.

Fluid Compatibility: The hydraulic fluid used in your system—whether it’s mineral oil, synthetic oil, water-based fluids, or others—determines the chemical compatibility of the seal. Some materials are more resistant to specific fluids, so it’s important to choose a seal material that won’t degrade or lose its sealing properties when exposed to your particular fluid type.

By taking pressure, temperature, and fluid compatibility into account, you can ensure that your seal will perform as expected throughout its service life.

Common Mistakes to Avoid When Choosing Seals

Choosing the wrong seal can lead to leaks, damage to hydraulic components, and costly system downtime. Here are some common mistakes to avoid when selecting hydraulic seals:

Not Considering Fluid Compatibility: One of the biggest mistakes is ignoring the compatibility of the seal material with the hydraulic fluid. Using a seal material that reacts with the fluid can cause degradation, leading to leakage and performance issues.

Underestimating Temperature Variations: Failing to account for the full temperature range in which the hydraulic system operates can lead to seal failure. Always consider both the maximum and minimum temperature extremes to select a material that will not lose elasticity or become brittle.

Using a Seal with Insufficient Pressure Rating: Choosing a seal with an inadequate pressure rating for the hydraulic system can cause the seal to fail prematurely. Always check the seal’s pressure limit and compare it with the maximum pressure the system will generate.

Ignoring Seal Installation and Maintenance: Even the best seals can fail if they are not installed correctly. Ensure that seals are properly sized and installed, and regularly maintain them to avoid premature wear.

Choosing a Seal Based on Price Alone: While cost is important, selecting seals based only on price may compromise system performance. Consider long-term costs, such as downtime and repair, and invest in high-quality seals that match your application needs.

Conclusion

The right seal not only reduces fluid loss, minimizes wear, and enhances reliability but also helps extend the lifespan of the entire system by lowering maintenance costs and preventing frequent replacements. To optimize seal performance, always match seals to system requirements, invest in quality, ensure proper installation, maintain a regular inspection schedule, and keep seals lubricated and protected from contaminants.

FAQ

What factors should I consider when choosing a hydraulic seal?

When choosing a hydraulic seal, consider the operating pressure, temperature, fluid compatibility, and the appropriate seal type (e.g., O-ring, V-ring, Y-ring).

How do I know which seal type is right for my system?

The seal type depends on your system’s needs: use O-rings for static seals, V-rings for dynamic sealing in high-pressure conditions, and Y-rings for both static and dynamic sealing under fluctuating pressures.

Why is fluid compatibility important for hydraulic seals?

Fluid compatibility ensures the seal material won’t degrade or lose its sealing properties when exposed to the hydraulic fluid, preventing leaks and system failures.

Can I use the same seal for different pressure levels?

No, each seal type has a specific pressure rating. Make sure to select seals rated for the pressure your system will experience to avoid premature failure.

How often should I replace hydraulic seals?

Seal replacement depends on the wear and tear from pressure, temperature, and movement. Regular inspections should be conducted to monitor seal conditions and prevent leaks before they occur.

What can cause hydraulic seals to fail prematurely?

Common causes of premature seal failure include incorrect installation, wrong material choice, exposure to incompatible fluids, or excessive pressure or temperature beyond the seal’s capabilities.