North America’s Hydraulic Buyers Are Under Pressure—Here’s What’s Really Going On

For years, the hydraulic fittings market in the United States, Canada, and Mexico has been considered mature and relatively stable. But that perception is changing rapidly. Mid-sized companies—particularly those with 50 to 200 employees—are now facing growing uncertainty on multiple fronts. Conversations with buyers and procurement teams across the region reveal four key pain points that are reshaping how smart businesses approach hydraulic component sourcing.

Supply Chain Disruptions Are No Longer the Exception—They’re the Norm

Buyers who once relied on a predictable “order-ship-deliver” cycle are now facing serious setbacks:

- Ocean freight delays caused by port congestion or cancelled sailings

- A 30% year-over-year increase in shipping costs for 40-foot containers

- Small and mid-sized orders pushed to the back of the line as large buyers dominate production queues

- Shipment errors, lack of tracking, and last-minute schedule changes

These issues don’t just affect timelines—they impact everything from inventory planning to jobsite continuity. Delayed or inaccurate deliveries can derail critical projects and erode client trust. In many cases, companies managing a fragmented supplier network are bearing the full brunt of these risks.

Environmental Compliance Is Becoming Mandatory—Not Optional

Regulatory pressure in North America is increasing sharply, especially in sectors tied to infrastructure, energy, and government contracts. Buyers are frequently required to comply with strict environmental standards, including:

- Low-leakage or leak-free hydraulic systems

- Use of certified biodegradable fluids and lubricants

- Component compliance with EPA and CSA regulations

- Documentation to prove system integrity and prevent legal liabilities

The challenge? Many suppliers remain unaware of these updated standards—or are unable to provide the technical documentation, certifications, or testing reports needed to support compliance. As a result, the burden shifts entirely to the buyer, who risks project penalties or disqualification.

The Skilled Labor Gap Is Real—and It’s Slowing Down Installations

Across the hydraulic industry, an aging workforce and a shortage of new technical talent have created a skills gap that can no longer be ignored:

- Experienced technicians are retiring faster than they’re being replaced

- Young workers are reluctant to enter mechanical trades

- Internal teams are stretched thin, often unfamiliar with newer, more complex systems

It’s increasingly common for teams to request remote technical assistance simply to complete standard installations—particularly for newer or custom components. Without adequate support from their suppliers, companies are left to troubleshoot under pressure, often with costly consequences.

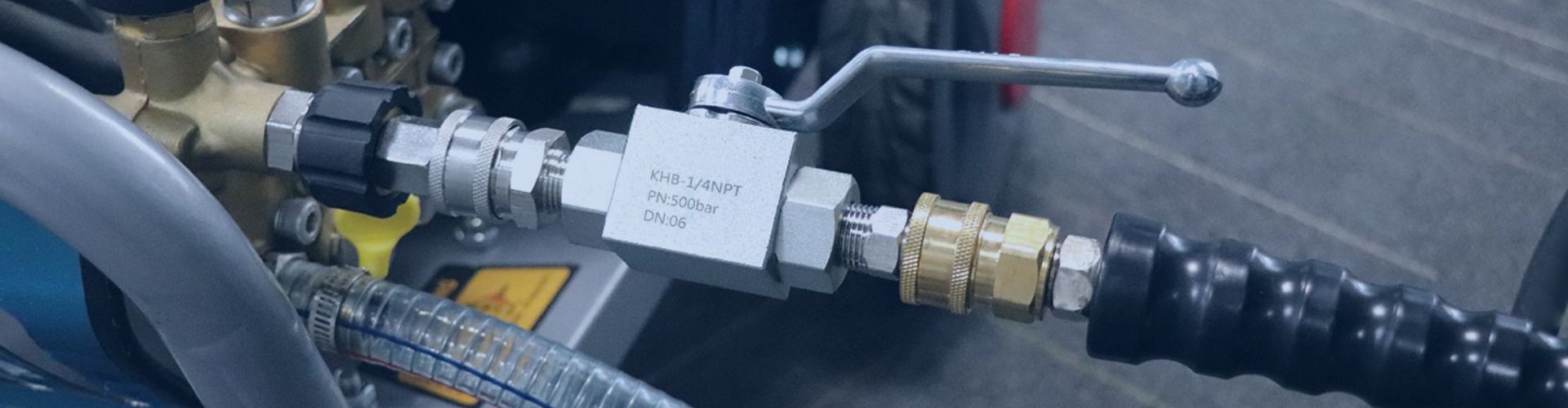

New-Generation Equipment Is Evolving—But the Fittings Market Isn’t Keeping Up

Modern hydraulic machinery is getting smarter, more compact, and digitally connected. But the component supply side hasn’t fully caught up. Today’s buyers are seeking fittings that meet new performance standards:

- Space-saving designs for compact equipment layouts

- Faster, more responsive actuation under high pressure

- Compatibility with sensors, control systems, and IoT platforms

- Resistance to harsh environments, including salt, heat, and chemicals

Unfortunately, many traditional or trading-style suppliers still focus on outdated standard products. Their custom solutions—if available—are often slow, expensive, and hard to modify, forcing procurement teams to scramble for last-minute workarounds.

South American Buyers Are Changing Priorities: Service and Stability Now Matter More Than Price Alone

Historically, businesses across Brazil, Argentina, Chile, and other South American countries focused primarily on securing the lowest-cost hydraulic components. For smaller operations and mid-sized companies, budget constraints left little room for anything but the most economical option.

But the market is changing. Procurement teams and project managers are realizing that a product which fails during operation—or arrives too late to be useful—ends up costing far more in lost productivity, repairs, and delays.

Here’s what’s driving this shift in mindset:

Construction and Agricultural Expansion Is Raising the Bar for Product Reliability

Across South America, infrastructure and farming industries are expanding rapidly. Government-funded housing projects in Brazil and record-setting agricultural output across the region have increased the demand for heavy-duty machinery and systems that can perform reliably under pressure.

This shift in demand brings new expectations:

- Equipment must handle longer hours of operation without breakdowns

- Fittings must meet higher standards for sealing, durability, and pressure resistance

- Buyers are increasingly willing to invest in dependable components if it means avoiding mid-operation failures

Cheap but unreliable components no longer meet the standards of today’s projects.

Tight Project Timelines Make Delays Unacceptable

Many South American projects are under strict timelines, often driven by seasonal cycles, labor contracts, or financing deadlines. A missed delivery window can disrupt an entire project phase or delay a key harvest period.

As a result, buyers now prioritize:

- Faster and more reliable delivery, supported by clear tracking and transparent logistics

- Shorter lead times with realistic commitments, not vague timelines

- Consistent product availability to avoid stockouts that halt work

Timeliness has become just as important as price—if not more.

Value for Money Is Now Defined by Durability and Service

While cost sensitivity remains a reality, the definition of “value” has changed. Buyers are no longer just comparing prices—they’re assessing total cost of ownership and operational lifespan.

Today’s South American buyers are looking for suppliers who can:

- Offer guidance on maintenance, part replacement, and system optimization

- Supply components that can be repaired or reused instead of discarded

- Provide access to preventive care materials such as kits and instructions

Suppliers who support longer equipment life and reduce the frequency of replacements now hold a competitive edge.

Language and Support Remain Critical—but Still Lacking From Many Suppliers

Language barriers and a lack of localized support continue to frustrate many South American buyers. Even when products are of acceptable quality, poor communication and inaccessible technical support can create serious operational setbacks.

These common pain points often surface:

- Installation manuals that are incomplete, outdated, or not translated

- Support inquiries answered in broken English or ignored entirely

- No available guidance when issues like leakage or misfitting occur on site

As a result, many buyers are actively seeking suppliers who can provide:

- Technical support teams fluent in Spanish or Portuguese

- Properly localized documentation and video tutorials

- After-sales service that is responsive, accurate, and familiar with local application conditions

Reliable service in the right language has become a determining factor in long-term supplier relationships.

How Should Buyers Choose the Right Hydraulic Fittings Supplier Today?

In today’s market—where disruptions are frequent, regulations are evolving, and service expectations are rising—selecting the right hydraulic fittings supplier has become far more than a matter of price or catalog variety. Whether you operate in North America or South America, choosing the right partner can make or break your operations.

Here’s what smart buyers are now using as key criteria when evaluating suppliers:

Technical Support You Can Rely On

For North American buyers, having access to a supplier that can provide remote diagnostics, CAD interpretation, and hands-on installation guidance is no longer a bonus—it’s a requirement. The increasing complexity of equipment demands knowledgeable partners who can assist beyond just the sale.

In South America, language is a key barrier. A supplier who can speak Spanish or Portuguese fluently, and provide instructions, installation materials, and technical documents in the local language, immediately stands out. This kind of localized technical support saves time, avoids miscommunication, and builds trust.

Environmental Compliance Isn’t Optional

Buyers in the U.S. and Canada are under mounting pressure to meet strict environmental standards. That means selecting suppliers who offer eco-friendly hydraulic oils, low-leakage designs, and compliance documentation aligned with EPA, CSA, or similar standards.

While in South America, the regulatory pressure may be slightly lower, reliability is still a must. Buyers now prefer products that meet basic sealing and pressure standards without over-engineering, striking a balance between compliance and cost-efficiency.

Reliable Lead Times and Stock Availability

North American customers increasingly demand firm delivery commitments, especially when juggling tight project deadlines. The ability to bundle multiple SKUs into a single shipment for faster and more cost-effective logistics has become a real advantage.

South American customers often struggle with product availability and extended shipping times. Suppliers who have buffer stock, flexible production, or even regional agents are quickly gaining attention as more reliable long-term partners.

Flexible Product Customization

North American clients tend to request customized parts—whether it’s a different thread type, upgraded material, private labeling, or technical adjustments based on specific operating conditions. Suppliers must be equipped to handle engineering-to-order workflows efficiently.

South American buyers often face budget and quantity constraints, so suppliers who accept low minimums for customization or offer flexible specs within existing designs are seen as much more adaptable and buyer-friendly.

After-Sales Support and Communication Matters

It’s not enough to just deliver the product. North American buyers expect 24/7 customer service in English, detailed product documentation, and someone who can walk them through troubleshooting without delay.

In South America, after-sales service is often the biggest gap. A supplier who can provide localized manuals, native-language support staff, and responsive follow-up, especially when issues arise, will retain business far longer than one who simply disappears after delivery.

Controlling Costs Without Compromising Value

North American clients have started looking beyond sticker price. What matters more now is total value—technical reliability, long-term compatibility, reduced maintenance costs, and supplier accountability.

Meanwhile, South American customers continue to watch budgets closely, but with a new perspective: they’re looking for the best value-to-performance ratio, not just the cheapest deal. They understand that paying a little more for better durability, support, or lead times often saves far more in the long run.

In summary, whether you’re in Toronto or São Paulo, Houston or Buenos Aires, the logic is the same:

You don’t just need a supplier.

You need a partner—one who understands your operating environment, speaks your language (literally and technically), and helps you move faster, safer, and smarter.

Why Topa? We’re Not Just Another Vendor—We’re Your Hydraulic Support Team

Buying Hydraulic Fittings Isn’t Just About Price—It’s About the Right Solution

In today’s market, purchasing hydraulic fittings is no longer a simple matter of finding the lowest quote. You’re not just buying a part—you’re securing a solution that ensures stable supply, technical confidence, and long-term performance.

Whether you’re operating in the U.S., Canada, Brazil, Argentina, or Peru, what you really need is a supplier who can offer more than just hardware. You need a partner who understands the realities of your operation and helps you solve problems, not create them.

So if you’re looking for:

- Custom hydraulic fittings tailored to your machine, system, or application

- Bundled shipments that combine multiple product types into one container to cut shipping time and cost

- Detailed technical manuals, installation drawings, and usage guidance

- Reasonable pricing combined with predictable lead times and responsive support

Then look no further—Topa is here to help.

Choose Topa Now

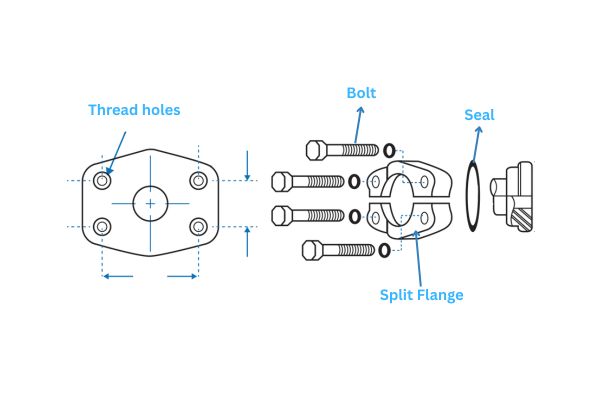

✅ One-Stop Hydraulic Sourcing

We supply a full range of hydraulic products—fittings, hoses, adapters, quick couplers, brass parts—so you can order everything in one place. No more juggling multiple suppliers.

✅ Custom Manufacturing Made Easy

Got a sketch, sample, or spec sheet? Our engineers can turn it into a fully functional product, with support for custom threading, materials, plating, and packaging—even in small to mid-size batches.

✅ Fast, Flexible Delivery

We operate with tight production planning, fixed supplier partnerships, and real-time logistics coordination to give you accurate lead times and faster shipping—even when you need mixed-item orders.

✅ Multilingual Technical Support

Our team offers English, Spanish support. Whether you need installation guidance, product selection help, or troubleshooting, we’re here to help—no language barriers, no delays.

✅ Clear, Honest Communication

You’ll never be left wondering where your shipment is, or who to contact. Our sales and support teams respond quickly, offer clear documentation, and always keep you in the loop.

✅ Built for Global Buyers

We understand the challenges buyers face across North America and South America—tight budgets, project delays, demanding clients. That’s why we engineer our service around your reality, not ours.

If you’re tired of working with suppliers who just send quotes but disappear when issues arise—it’s time to work with someone who truly understands hydraulic fittings from your perspective.

📩 Contact Topa today and let’s build a smarter, smoother supply partnership for your next project.