Your hydraulic system is failing, causing leaks or even shattered parts. You’ve checked the pressure and the fluid, but neglected a critical factor: temperature, which silently leads to costly downtime.

Temperature dramatically impacts both the fitting’s metal body and its elastomer seals. Extreme cold makes them brittle and hard, while high heat weakens metal and degrades seals. Matching materials to the operating temperature is essential for a reliable, leak-free connection.

How Does Extreme Cold Affect Fitting Metals?

It’s a bitterly cold morning and a hydraulic fitting on your machine suddenly shatters. The failure seems to have come out of nowhere, causing a massive leak and bringing your work to a halt.

Extreme cold makes certain metals, especially carbon steel, lose their toughness and become brittle. An impact or shock that would normally be harmless can cause a catastrophic fracture without any warning.

The Ductile-to-Brittle Transition

Most carbon steels have a “Ductile-to-Brittle Transition Temperature” (DBTT). Above this temperature, the metal is ductile—it will bend or stretch before it breaks. Below this temperature, it becomes brittle and will fracture suddenly under load. For many standard carbon steels, this transition zone starts around -30°C to -40°C. A sharp impact from a tool or a jolt from machine operation can be enough to initiate a failure.

Material Choices for Freezing Conditions

For applications consistently below freezing, material selection is critical.

- Standard Carbon Steel: Generally acceptable for temperatures down to -40°C (-40°F), but its impact resistance is reduced.

- 304/316 Stainless Steel: These are excellent choices. Austenitic stainless steels do not have a DBTT and retain their ductility and toughness even at cryogenic temperatures. They are the go-to materials for extreme cold.

- Brass: Brass also remains ductile in the cold but has a much lower pressure rating than steel, limiting its use in high-pressure hydraulic systems.

What Happens to Seals in Freezing Temperatures?

You start your machine on a frigid morning and notice a slow, persistent leak from a fitting. As the system warms up, the leak seems to stop on its own, leaving you confused.

In cold temperatures, elastomer seals like standard Buna-N harden and lose their flexibility. They can’t conform to machine surfaces to create a good seal, resulting in leaks until the system’s heat softens them again.

This is one of the most common service calls I hear about in winter. It’s often not a “bad” fitting, but simply a seal operating below its effective temperature range. An engineer in the northern USA was having this exact problem on his fleet of snow-clearing equipment. The machines leak every morning. We supplied him with fittings using low-temperature Viton seals, which stay flexible at colder temperatures. This simple change completely solved his “morning leak” problem across the entire fleet.

Understanding Glass Transition Temperature

Every elastomer has a glass transition temperature (Tg). This is the temperature at which the flexible, rubbery material becomes a hard, glassy, and brittle solid. A standard Buna-N (Nitrile) seal has a Tg around -35°C, but it starts to lose its effective sealing ability well before that, typically around -20°C. The seal becomes too stiff to adapt to imperfections in the metal surfaces or to rebound from pressure changes.

The Risk of Compression Set

If a seal is compressed while it is in its “glassy” state (frozen), it can become permanently deformed. When it warms up, it won’t return to its original shape, a phenomenon called compression set. This will create a permanent leak path that won’t go away, forcing you to replace the seal. This is why it’s critical to allow systems to warm up gradually if possible and to use the correct low-temperature seal material from the start.

How Does High Heat Impact Fitting Strength?

Your hydraulic system runs very hot, close to an engine or in a hot factory. You’re starting to see issues like stripped threads and even hydraulic fittings deforming under normal operating pressure.

High temperatures reduce the tensile strength of metals. A carbon steel fitting rated for 5,000 PSI at room temperature might have its safe working pressure reduced by 20% or more at 200°C. This makes it vulnerable to failure.

Applying Pressure De-Rating Factors

Reputable manufacturers provide data showing how much you must reduce a fitting’s maximum working pressure as the temperature rises. This is called a de-rating factor. For example, a carbon steel fitting might have its pressure rating reduced by 15% at 150°C and by 25% at 250°C. You must always use the pressure rating that corresponds to your system’s highest operating temperature, not its room-temperature rating.

Material Performance at High Temperatures

- Carbon Steel: Begins to lose significant strength above 200°C (approx. 400°F). It’s very effective for most standard systems but has its limits.

- Stainless Steel (304/316): Retains its strength much better at higher temperatures compared to carbon steel. It is often the preferred choice for systems operating consistently above 150°C.

- Brass: Weakens significantly at high temperatures and is generally not recommended for high-pressure hydraulic systems above 100°C.

Why Do Seals Fail in High-Temperature Systems?

You have a machine with a known hot spot, and you are constantly replacing the O-rings in the nearby fittings. The old seals you remove are always hard, brittle, and cracked.

High temperatures cause elastomer seals to age and degrade rapidly. The heat breaks down the polymer structure, causing the seal to permanently lose its elasticity and ability to seal. This is an irreversible chemical change.

Why Do Seals Fail in High-Temperature Systems?

Seals are designed to maintain tight, leak-free connections in hydraulic and fluid power systems. However, when exposed to elevated temperatures for long periods, their performance can degrade rapidly. Understanding the root causes of seal failure helps in choosing the right material and extending system reliability.

Thermal Degradation of Materials

At high temperatures, elastomeric seals like Buna-N or EPDM lose elasticity and begin to harden. This reduces their ability to conform to mating surfaces, leading to micro-gaps where fluid can escape. Over time, the seal may crack or crumble, completely losing its sealing function.

Compression Set

Continuous exposure to heat accelerates the “compression set” effect, where a seal permanently deforms and fails to return to its original shape after being compressed. This means the seal can no longer maintain contact pressure, resulting in leaks.

Chemical Breakdown

High temperatures can accelerate chemical reactions between hydraulic fluids and seal materials. For example, petroleum-based oils may attack non-compatible elastomers, breaking down their molecular structure faster when heat is present.

Oxidation and Hardening

Heat combined with oxygen exposure causes oxidation, which stiffens the seal material. This leads to brittleness and eventual cracking, especially in seals that are not formulated for high-temperature resistance.

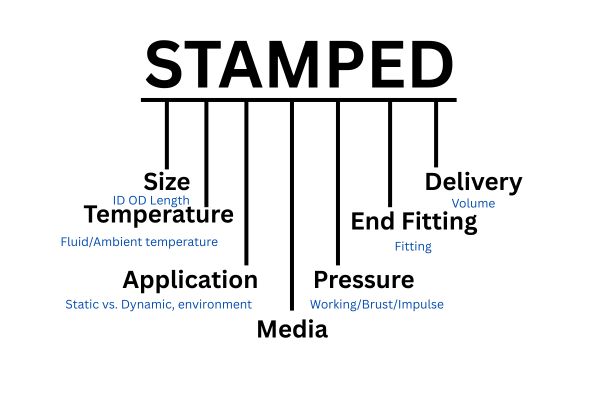

High-Temperature Seal Material Guide

The seal material is just as important as the fitting metal. Choosing the right one is critical for high-heat applications.

| Seal Material | Common Name | Max Temperature | Notes |

| Nitrile | Buna-N, NBR | ~100°C (212°F) | Standard choice. Good for general use, but fails quickly in high heat. |

| Fluorocarbon | Viton®, FKM | ~200°C (400°F) | Best all-rounder. Excellent heat and chemical resistance. Our most common upgrade. |

| EPDM | EPDM | ~150°C (300°F) | Good for heat, but NOT for petroleum-based fluids. Used with fluids like Skydrol. |

| Perfluoroelastomer | Kalrez®, FFKM | ~320°C (600°F) | For extreme heat and chemical exposure. Very high cost. Used in specialty applications. |

For over 90% of high-temperature hydraulic systems, Viton (FKM) is the perfect balance of performance and cost.

Which Fitting and Seal Combination Is Best?

You face a wide range of temperatures, from chilly mornings to hot operating conditions. How do you select one combination that provides reliable performance without overspending on exotic materials?

The best approach is to match the combination to your specific temperature range. For most systems, carbon steel with Buna-N is fine. For high heat or wider ranges, upgrading to a Viton seal is the most cost-effective solution.

The Workhorse: Carbon Steel + Buna-N

This is the most common combination in the world for good reason. It’s cost-effective and provides excellent, reliable service in the most common operating range of -20°C to +100°C. For the vast majority of mobile and industrial hydraulic systems, this is the default and correct choice.

The Smart Upgrade: Carbon Steel + Viton (FKM)

This is a powerful and very cost-effective upgrade. For a small increase in price, you get a massive increase in high-temperature performance (up to 200°C). This is the perfect choice for equipment with hot spots, like near an engine or turbocharger, or for systems that work hard and run hot. It provides a huge safety and reliability margin.

The Premium Solution: Stainless Steel + Viton (FKM)

When you need the ultimate performance, this is the answer. You get the superior strength retention and corrosion resistance of stainless steel combined with the excellent heat resistance of a Viton seal. This combination is ideal for marine environments, chemical plants, food processing, or any application where you need peak performance across a wide temperature range and in corrosive conditions.

| Option | Materials & Seal | Temperature Range | Best For |

| The Workhorse | Carbon Steel + Buna-N | -20°C to +100°C | Standard choice for most mobile and industrial hydraulic systems |

| The Smart Upgrade | Carbon Steel + Viton (FKM) | Up to 200°C | Hot spots near engines/turbos; systems that run hot; higher safety margin |

| The Premium Solution | Stainless Steel + Viton (FKM) | Wide range, up to 200°C+ | Marine, chemical, food processing, corrosive or extreme environments |

How Do You Verify Temperature Ratings From a Supplier?

You ordered hydraulic fittings that were supposed to be high-temp rated, but the seals failed anyway. How can you trust that you are getting what you paid for?

Always demand a technical data sheet (TDS) from your supplier. This document should state the exact materials used for both the fitting body and the seal, along with their certified operating temperature and pressure ranges.

Reading the Data Sheet

When you look at a TDS, don’t just look for a single temperature number. Look for:

- Fitting Body Material: Is it listed as 1045 Carbon Steel, 316 Stainless Steel, etc.?

- Seal Material: Is it clearly identified as NBR (Buna-N), FKM (Viton), etc.?

- Plating Specification: For carbon steel, does it specify the plating type for corrosion resistance?

- Pressure De-rating Chart: A good data sheet will include a chart or table showing how the maximum pressure changes with temperature.

The Danger of Vague Specifications

Be wary of any supplier who cannot provide this information or who uses vague terms like “high-temp rubber” or “rust-resistant steel.” These terms are meaningless without specific material grades and temperature ratings. This lack of detail is often a red flag for a lower-quality product that may not perform as expected under real-world conditions. A professional supplier will always be able to provide precise specifications.

Conclusion

Temperature is not an afterthought; it is a primary design factor. By matching both the fitting metal and seal material to your full operating temperature range, you ensure safety, prevent leaks, and maximize uptime.

Looking for reliable hydraulic fittings, hoses, and seals that match your system’s exact requirements? At Topa, we provide high-quality, pressure-tested products with fast delivery and competitive pricing. Whether you need standard parts or customized solutions, our team is ready to support you. Contact us today to place your order and keep your operations running smoothly—dependable products are just one step away.

FAQ

How does extreme cold affect hydraulic fittings?

Cold temperatures make metals like carbon steel brittle and seals like Buna-N stiff. This can cause fittings to fracture or leak until the system warms up.

What materials are best for fittings in freezing conditions?

304/316 stainless steel and brass remain ductile in cold temperatures. Stainless steel is preferred for high-pressure systems, while brass is suitable for lower-pressure applications.

Why do seals fail in high-temperature systems?

Heat accelerates seal aging through hardening, compression set, oxidation, and chemical breakdown, causing seals to lose elasticity and crack.

Which seal material works best for high heat?

Viton (FKM) is the most cost-effective choice, handling up to ~200°C. For extreme applications, perfluoroelastomers like Kalrez (FFKM) can withstand ~320°C.

How do I know if a fitting and seal are truly temperature-rated?

Always check the supplier’s technical data sheet (TDS). It should list the exact material grades, seal type, and a pressure de-rating chart for different temperatures.

What’s the safest fitting and seal combination for most hydraulic systems?

Carbon steel with Buna-N is the standard choice for -20°C to +100°C. For hotter systems or wider ranges, upgrading to Viton seals is the smarter solution.