In all kinds of industrial applications, hydraulic hoses play a vital role as a key component in the transmission of high-pressure hydraulic fluid. For enterprises, choosing the right hydraulic hose is not only related to the operational efficiency of the equipment, but also directly affects the overall production safety and cost control. At a time when global sourcing is becoming more and more common, more and more companies are looking to overseas markets, especially China. As an important force in the global manufacturing industry, China has shown strong competitiveness in the field of hydraulic hoses, not only a wide range of products, stable quality, and more attractive price. So, is it worthwhile to purchase hydraulic hoses from China? What are the advantages and considerations?

Introduction to Sourcing Hydraulic Hoses from China

China has emerged as one of the largest manufacturers of hydraulic hoses in the world. Ready for the good part? With its well-established infrastructure, advanced manufacturing technologies, and cost-effective production, China offers significant advantages for businesses looking to source hydraulic hoses at competitive prices. However, sourcing from China can come with challenges, such as quality control issues, shipping delays, and communication barriers. Understanding these challenges and knowing how to overcome them can help you make informed decisions that benefit your business.

China’s hydraulic hose manufacturers cater to a variety of industries, from automotive to construction, offering customized solutions to meet specific requirements. This is where it gets interesting… The country’s ability to scale production quickly and efficiently makes it a top choice for both small and large businesses seeking reliable suppliers.

Benefits of Sourcing from China

- Cost-effective pricing: Competitive labor and production costs in China make hydraulic hoses more affordable than those from other countries.

- Wide range of options: Suppliers in China offer a variety of hose types, sizes, and materials to meet diverse industry needs.

- Reliable production capacity: Chinese manufacturers have the capacity to produce large volumes of hoses in a short amount of time, ensuring timely deliveries.

Why Choose China for Hydraulic Hose Procurement

When choosing a supplier for hydraulic hoses, China presents an appealing option for many businesses. The country’s combination of affordability, scalability, and manufacturing expertise makes it a dominant force in the global hydraulic hose market. Let’s take a deeper look at why sourcing hydraulic hoses from China could be a smart move for your business.

Cost Advantages of Sourcing from China

One of the biggest advantages of sourcing from China is the lower cost of production. The overall cost savings go beyond just the product price. Labor costs are significantly lower in China compared to Western countries, allowing suppliers to offer competitive pricing without compromising on product quality. Additionally, bulk purchasing from Chinese suppliers often leads to volume discounts, further reducing the cost per unit.

Manufacturing Expertise in China

China has developed an extensive network of manufacturers specializing in hydraulic hoses. These manufacturers are equipped with state-of-the-art technologies that allow them to produce high-quality hoses at scale. Many Chinese manufacturers have adopted international quality standards, such as ISO 9001, ensuring their products meet global expectations for performance and safety.

Efficient Supply Chain and Logistics

China boasts an advanced supply chain and logistics infrastructure, making it easier to source hydraulic hoses. With ports like Shanghai and Shenzhen, manufacturers can quickly ship products worldwide, ensuring timely delivery. Additionally, many suppliers offer comprehensive shipping solutions, including air and sea freight options, to help you get your products at the best rates.

Key Factors to Consider When Sourcing Hydraulic Hoses from China

When sourcing hydraulic hoses from China, it’s important to keep certain factors in mind to ensure you’re getting the best product and value. Choosing the right supplier and understanding the quality control processes can make all the difference.

Quality Control Standards

One of the first things to look for when sourcing from China is the supplier’s commitment to quality. Suppliers should adhere to international standards like ISO 9001, which ensures that the hydraulic hoses meet global quality requirements. Before placing an order, ask the supplier about their quality assurance processes, including testing and certification.

Supplier Reputation and Experience

It’s crucial to choose a supplier with a proven track record in manufacturing hydraulic hoses. Look for suppliers who have been in business for several years and have a reputation for delivering high-quality products on time. You can also check customer reviews and case studies to gauge the supplier’s reliability.

Customization Options

While many businesses need standard hydraulic hoses, others may require custom solutions. It’s important to work with a supplier who can customize hoses to meet specific requirements. Whether it’s a custom length, unique fittings, or specialized materials, make sure your supplier can accommodate your needs.

Cost-effective Sourcing: How to Get the Best Deals

While sourcing hydraulic hoses from China offers competitive pricing, there are still strategies to ensure you’re getting the best deal. By negotiating effectively and considering the total cost of ownership (TCO), you can maximize the value you get from your purchase.

Negotiating Prices with Suppliers

One of the most effective ways to lower costs when sourcing from China is through negotiation. Chinese suppliers often expect some level of negotiation, so don’t be afraid to ask for discounts, especially when ordering in bulk. If possible, try to secure long-term contracts that will further reduce costs.

Volume Discounts and Bulk Orders

Volume discounts are another way to save when sourcing hydraulic hoses. Suppliers may offer lower prices per unit for larger orders. If you anticipate ongoing demand, ordering in bulk can lead to substantial savings over time.

Total Cost of Ownership (TCO)

When sourcing from China, it’s important to consider the total cost of ownership (TCO), which includes factors such as shipping, customs duties, and any additional costs related to quality control. While the upfront cost may be lower, additional fees can add up. Make sure to factor in all costs to ensure that the final price aligns with your budget.

Ensuring Quality Control When Buying Hydraulic Hoses from China

When sourcing hydraulic hoses from China, quality control is a critical factor to ensure you receive reliable and durable products.China’s manufacturing industry is known for its scale, but with that comes variability in product quality. To make sure you’re receiving the best, it’s essential to focus on quality assurance throughout the production and shipping process.

The Role of Quality Assurance Programs in China’s Manufacturing Process

Quality assurance (QA) programs are a vital part of the production process in China. Reputable manufacturers implement robust QA systems to ensure that every product meets industry standards. These programs typically involve several stages, including raw material inspection, in-process checks, and final testing before shipment. High-quality manufacturers follow international standards such as ISO 9001, ensuring consistency and reliability in the products they produce. By selecting a manufacturer that adheres to these standards, you can be confident that the hydraulic hoses you receive will perform as expected.

China’s large manufacturing sector is often equipped with advanced technologies, which help streamline quality assurance processes. For instance, automated systems may be used to test hose strength, pressure tolerance, and flexibility during production. This can significantly reduce human error and improve overall product quality. Working with a manufacturer that has a strong QA program means fewer defects, longer-lasting hoses, and greater customer satisfaction.

How to Perform Quality Checks Before Shipment

Before your hydraulic hoses leave the factory, it’s crucial to perform quality checks to ensure they meet your specific requirements. A pre-shipment inspection helps verify that the hoses meet your specifications and are free from defects that could cause issues during use. There are several key checks to perform:

- Visual Inspection: Check for visible defects such as cuts, abrasions, or signs of weak spots.

- Pressure Testing: Test the hoses to ensure they can withstand the required pressure without bursting or leaking.

- Material Verification: Confirm that the materials used in the hose construction match the agreed-upon specifications, particularly the inner liner, reinforcement layers, and outer covering.

- Size and Compatibility Checks: Ensure the hoses meet the required diameter and length specifications for your system.

These checks can be done either by your team or by the manufacturer’s quality control department. Some suppliers even offer photos and video inspections to give you a clear view of the product before it ships.

Working with Third-Party Inspection Services to Ensure Product Quality

To further safeguard the quality of your hydraulic hoses, you can work with third-party inspection services. These inspection companies can visit the factory on your behalf to perform independent checks and verify that the hoses meet the required standards before they’re shipped. Third-party inspectors will conduct comprehensive tests, including:

- Visual Inspection: They’ll ensure the hoses meet the agreed-upon specifications.

- Functional Testing: The hoses will undergo stress tests to confirm that they perform under pressure and in various environmental conditions.

- Documentation Review: They’ll check for compliance with relevant regulations and certifications.

Working with a trusted third-party inspector can give you peace of mind, especially if you’re sourcing from a new or unfamiliar supplier. It’s an additional investment, but it can save you from receiving defective products and protect your business from costly returns or repairs.

How to Choose the Right Hydraulic Hose for Your Needs: Contact Topa

Choosing the right hydraulic hose is essential to ensuring optimal performance in your hydraulic systems. Selecting the appropriate hydraulic hose depends on various factors such as system requirements, pressure ratings, temperature conditions, and compatibility. Let’s explore how to make the right choice for your business.

Select the Type of Hydraulic Hose Based on System Requirements

The first step in choosing the right hydraulic hose is understanding your system’s needs. Different hydraulic systems require different hose types, so it’s essential to select a hose that matches the specific conditions under which the system operates. For example, high-pressure systems will require hoses with reinforced layers to withstand the stress, while low-pressure systems might only need a simple, non-reinforced hose.

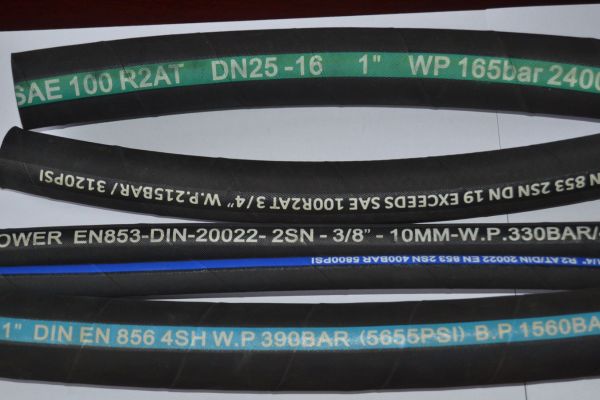

Hydraulic hoses come in various types, including SAE, DIN, and BSP, each designed to handle specific pressures and applications. If your hydraulic system requires precise specifications, it’s essential to choose a hose that not only fits in terms of size but also one that can withstand the intended use.

Understanding Pressure Ratings, Temperature Ranges, and Compatibility

Hydraulic hoses are rated for specific pressure and temperature ranges. If a hose is used outside of its pressure rating, it can fail, leading to potential system downtime and costly repairs. Understanding the pressure rating helps you choose a hose that can handle the fluid pressure without bursting.

Temperature ranges are another crucial factor. Hydraulic hoses can operate in a variety of environments, from freezing cold to extremely hot temperatures. Here’s the kicker… Choosing a hose that can tolerate your system’s temperature extremes will prevent hose degradation and extend its lifespan.

Compatibility is equally important when selecting hydraulic hoses. Make sure the material of the hose is compatible with the hydraulic fluid it will carry. For instance, some materials are more resistant to certain chemicals than others, so understanding the chemical composition of the fluid will help you avoid material failure.

Key Specifications to Consider: Inside Diameter, Reinforcement, Outer Cover

When selecting a hydraulic hose, the inside diameter (ID) is an essential specification to consider. The ID determines how much fluid can pass through the hose, and it must align with the requirements of your hydraulic system to maintain flow rates. A hose with an ID that is too small will restrict fluid flow, while one that is too large could lead to inefficiency.

Reinforcement is another key specification. Reinforced hoses are designed to handle higher pressures and are typically made of steel or synthetic fibers. If your hydraulic system operates under high pressure, reinforced hoses are essential to ensure durability and prevent rupture.

The outer cover of the hose serves as a protective layer against environmental factors like abrasion, UV exposure, and chemicals. A strong outer cover will extend the life of the hose by shielding it from external damage.

Customizing Hydraulic Hose Options: When and Why to Consider Customization

When to Choose a Custom Hydraulic Hose for a Specific Application

Custom hydraulic hoses are ideal when standard hoses do not meet your system’s unique requirements. Certain applications may require hoses with special reinforcements, specific lengths, or unique materials that are not readily available in standard product offerings. For example, if your system operates under extreme pressure or temperature conditions, a custom hose may be the only viable option to ensure long-term performance.

Additionally, industries like aerospace, oil and gas, and heavy machinery may require specialized hoses to fit in confined spaces or to handle aggressive fluids. Custom hoses ensure that your hydraulic system operates optimally, avoiding issues like reduced performance or hose failure.

Customization Options: Sizes, Materials, Colors, and Logos

One of the biggest advantages of customizing hydraulic hoses is the flexibility it offers. You can customize various aspects of the hose, including:

- Sizes: Custom hoses can be made to the exact length and diameter needed for your system.

- Materials: Choose from a variety of materials, such as rubber, thermoplastic, or stainless steel, to meet the requirements of your specific application.

- Colors: Custom colors can be chosen for easy identification and system management.

- Logos: Adding a company logo to the hose can improve branding and enhance system organization.

Benefits of Working with Topa to Customize Hydraulic Hose

Benefits of working with Topa for custom hydraulic hoses

When it comes to customizing hydraulic hoses, there are several advantages to working with a Chinese manufacturer.Topa is known for its ability to scale production quickly and efficiently, making it easier to customize hydraulic hoses at a competitive price. In addition, Topa offers in-house design and engineering services, which helps streamline the customization process and ensures the hose meets your exact needs.

Topa’s strong manufacturing capabilities also mean that you have access to a wide range of materials and customization options, allowing you to customize hydraulic hoses for the most demanding applications. But most importantly …… With the right supplier, you’ll receive high-quality customized hose quickly and at an affordable price.

| Customization Option | Description | Benefits |

| Sizes | Tailor the length and diameter of the hose | Ensures compatibility with your system’s requirements |

| Materials | Choose from various materials like rubber, steel, or thermoplastic | Meets specific pressure, temperature, and chemical requirements |

| Colors | Custom colors for easy identification | Improves system organization and management |

| Logos | Add branding or identification logos | Enhances visibility and brand recognition |

Conclusion

Take the next step in sourcing high-quality hydraulic hoses from China by partnering with trusted suppliers who can meet your specific requirements. At Topa, we are committed to providing you with the best hydraulic hoses, tailored to your needs. Contact us today to place your order and experience the Topa difference—your trusted partner in hydraulic hose sourcing!

FAQ

What is a hydraulic hose?

A hydraulic hose is a flexible tube used to transport hydraulic fluid in systems, allowing fluid to transfer energy to power machinery and systems.

How do I select the right hydraulic hose for my system?

Choosing the right hydraulic hose involves considering pressure ratings, temperature ranges, compatibility with the fluid being used, and the hose’s dimensions and reinforcement.

Why should I source hydraulic hoses from China?

China offers cost-effective pricing, high manufacturing capabilities, and a wide selection of hydraulic hoses to suit various industries and applications.

When should I consider customizing a hydraulic hose?

Customization is ideal when your system requires specific dimensions, materials, or additional features that standard hoses cannot provide.

How do I ensure the quality of hydraulic hoses sourced from China?

To ensure quality, work with suppliers who adhere to international quality standards, perform regular quality checks, and offer certifications like ISO 9001.

What are the advantages of customizing hydraulic hoses from China?

Customizing hydraulic hoses from China allows for tailored solutions that fit specific system needs, offering flexibility in materials, sizes, and design at competitive prices.