FAQ

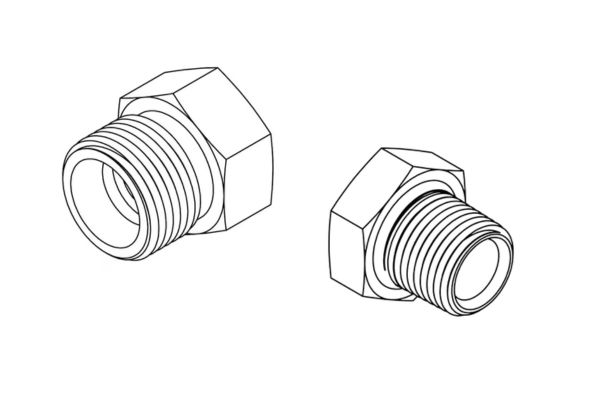

What are hydraulic plugs?

Hydraulic plugs are fittings used to seal or protect the open end of hydraulic hoses. They are used to prevent damage to the threads caused by the entry of dirt or liquids.

What are hydraulic plugs used for?

Hydraulic plugs prevent moisture, dirt, liquids, dust, and other contaminants from entering the hydraulic system during processes like production and transportation. Some can be used many times and many of them are versatile enough for various processes.

what are the materials of hydraulic plugs?

Hydraulic plugs are available in steel, stainless steel, aluminum and galvanized materials, etc.

Which plugs can adapt to high pressure?

Plugs made of steel, stainless steel and galvanized steel can be adapted to high pressure environments, and they are also highly resistant to corrosion.

Which plugs can adapt to low pressure?

Aluminum hydraulic plugs can be used in low voltage environments, which are lighter in weight and also resistant to corrosion.

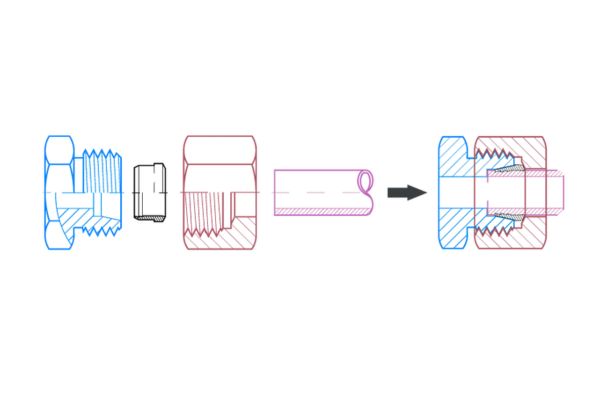

What is the difference between caps and plugs?

Caps have a female thread with a hex-shaped head. With a male thread, the plugs’ head could be square, countersunk, hex-shaped, or designed with a socket.

How to choose hydraulic plugs?

You should consider four factors. First, the application environment. Second, usefulness. Third, materials. Fourth, the installation requirements.

How many types of hydraulic plugs?

There are a variety of hydraulic plugs, including countersunk and hexagonal socket plugs, hexagonal head plugs, square head plugs, and pipe plugs,etc.

Can hydraulic plugs be customized?

Yes, we have a fully equipped workshop to produce plugs with specific requirements. We can make customized plugs according to your draft or technical details.

How to make an order?

You can contact us through the email address and phone number on the website, directly tell us the product model you need or tell us your requirements, we will help you choose the right products.