Choosing the wrong hose leads to leaks and dangerous failures. You might blame the application or the operator, but the hose’s hidden quality is often the real problem.

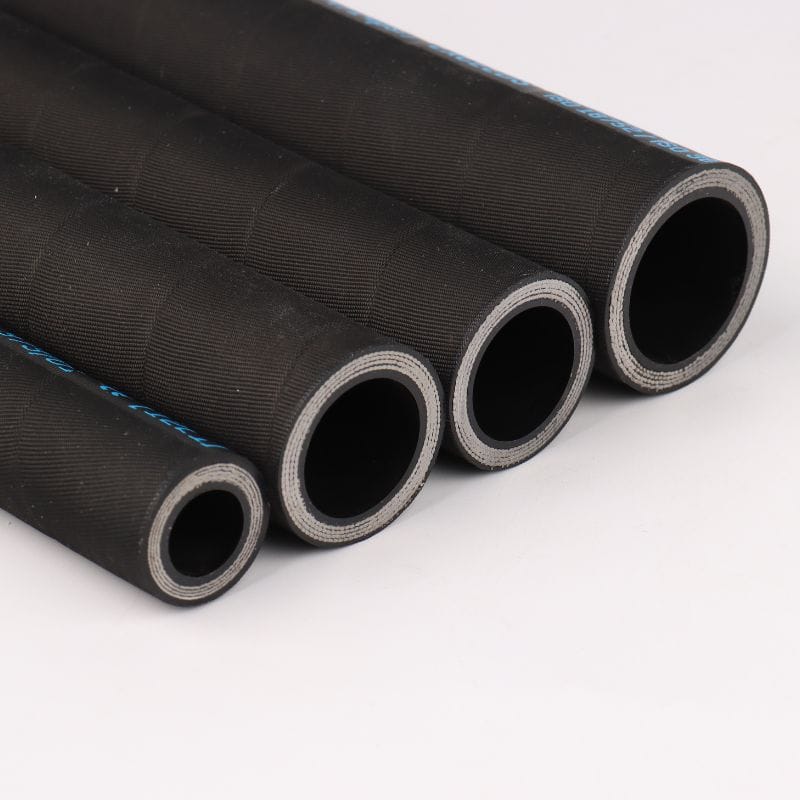

A standout hydraulic hose is defined by its material quality, reinforcement strength, cover durability, and precision manufacturing. Key features include a premium synthetic rubber tube, high-tensile steel reinforcement, a low bend radius, and rigorous impulse testing that exceeds industry standards, ensuring safety and a longer service life.

Does the Inner Tube Compound Really Affect Hose Lifespan?

Your hose failed from the inside out. You see cracks and stiffness, but the cause—poor rubber chemistry—has been there since day one, a hidden flaw.

Absolutely. The inner tube’s synthetic rubber compound directly dictates its resistance to hydraulic fluid, heat, and aging. A superior compound like NBR (Nitrile) prevents degradation, cracking, and swelling, ensuring a long, reliable service life.

The inner tube is the heart of the hydraulic hose. It’s the only part that is in constant contact with the hydraulic fluid. If it fails, the entire hose fails. We use a high-grade NBR (Nitrile Butadiene Rubber) for our standard hoses for one primary reason: it provides excellent resistance to the petroleum-based oils that are common in most hydraulic systems. A cheaper rubber compound will react with the oil over time, causing it to become hard and brittle. This leads to cracking, and small pieces of rubber can flake off, a process called delamination. These small black particles then travel through your hydraulic system, contaminating the fluid and acting like sandpaper inside your expensive pumps, valves, and cylinders. So, a cheap hose can end up destroying a machine worth thousands of dollars. Our choice of a premium inner tube compound is a direct investment in protecting your entire system.

Isn’t All Steel Wire Reinforcement the Same?

Your hose bursts under a pressure spike. You thought it met the pressure rating, but the weak reinforcement wire gave way unexpectedly, causing dangerous downtime and a safety hazard.

Not at all. We use high-tensile steel wire with a superior coating. This provides higher pressure resistance and, critically, ensures exceptional adhesion to the rubber layers, preventing delamination under impulse pressure and flexing.

The steel wire reinforcement is the muscle of the hose; it’s what contains the pressure. There are two critical factors here that separate a high-quality hose from a standard one. The first is the strength of the wire itself. We use high-tensile steel, which means it can withstand higher forces. This allows us to build hoses that can handle extreme pressures without being excessively heavy or stiff. The second factor is even more important: the bond between the wire and the rubber. This coating acts like a primer, allowing the rubber to form a strong chemical bond with the steel during the vulcanization (curing) process. Without this bond, repeated pressure impulses and flexing can cause the layers of the hose to separate. Using high-tensile, brass-coated wire is a manufacturing detail that directly translates to a safer, more durable hose that can resist bursting.

Why Does the Way the Wires Are Applied Matter?

Your hose seems stiff and hard to install. It fights you at every turn, kinking easily and putting stress on your fittings even before it is pressurized.

The braiding or spiraling technique significantly impacts flexibility and impulse life. Our computer-controlled machines ensure a consistent braid angle and tension, creating a hose that is both stronger and more flexible, making installation easier and reducing stress on fittings.

How the reinforcement wire is applied is just as important as the wire itself. Most hydraulic hoses use a braided construction where the wires crisscross over each other. The angle of this braid is critical. If the angle is correct and consistent, the hose will expand and contract predictably under pressure, and it will have good flexibility. Our production process uses computer-controlled braiding machines that maintain the perfect braid angle and tension along every inch of the hose. This precision engineering prevents gaps in the braid, which would create weak spots, and it results in a hose that feels balanced and is easy to work with. For our highest pressure hoses, we use spiral construction, where layers of wire are laid parallel to each other. This also requires extreme precision to ensure all wires carry the load equally. This focus on manufacturing technology is why our hoses have excellent flexibility and can survive high-impulse applications.

How Can the Outer Cover Prevent a Catastrophic Failure?

You find a hose with its outer cover worn away. It looks like a cosmetic issue, but moisture is now seeping into the wires, silently rusting them from the inside out.

The outer cover is the hose’s first line of defense. We use a durable synthetic rubber compound resistant to abrasion, ozone, and weathering. Many of our hoses also meet MSHA flame-resistance standards for added safety.

The outer cover does much more than just hold the hose together. Its main job is to protect the steel reinforcement wires from the outside world. We formulate our covers to resist three main enemies. The first is abrasion. Hoses on mobile equipment are constantly rubbing against machine frames and other components. Our tough covers resist being worn away. The second enemy is ozone, a gas in the atmosphere that attacks rubber and causes it to crack. Our covers have special chemical additives to resist this ozone degradation. The third is weather, including UV light from the sun. For customers in demanding industries like mining, we offer hoses with MSHA-accepted covers. This is a critical safety standard from the US Mine Safety and Health Administration, which means the cover is flame-resistant and will not propagate a fire. A durable outer cover is not a luxury; it is essential for ensuring the hose reaches its full service life.

Why Should You Care About a Hose’s Exact Diameter?

You struggle to get a fitting onto your hose. It is either too tight or too loose, leading to a difficult assembly or a weak, unreliable crimp.

Strict control of the hose’s inner and outer diameters is critical for a perfect crimp. Our hoses are manufactured to tight tolerances, ensuring they are perfectly compatible with standard fittings, guaranteeing a secure, leak-proof seal every time.

A hose assembly is a system where the hose and the fitting must match perfectly. This perfection depends on precise dimensions. When you crimp a fitting onto a hose, you are compressing the ferrule to a specific final diameter. This crimp diameter is calculated based on the hose having a specific wall thickness. If the hose’s Outside Diameter (O.D.) is inconsistent—if it’s too big in some places and too small in others—you cannot get a reliable crimp. An oversized hose can lead to an under-crimped assembly, which can blow off under pressure. An undersized hose can lead to an over-crimped assembly, where the ferrule cuts into the reinforcement wires, creating a hidden weak point. During our production process, we use continuous laser micrometers to monitor the hose’s diameter in real-time. This guarantees that every meter of hose meets the strict international standards, so our customers can have confidence that their crimps will be secure and leak-free.

Can a Hose Really Perform in Both Freezing Cold and Extreme Heat?

Your equipment has to work in harsh climates. A standard hose gets brittle in the cold or soft in the heat, leading to premature failure and costly downtime.

Yes. Our hoses are designed with advanced rubber compounds that maintain their flexibility and performance across a wide operating temperature range, typically from -40°C to +100°C (-40°F to +212°F), for reliability in any environment.

Rubber is very sensitive to temperature, and this is where the quality of the chemical compound really shows. A hose made with a low-quality rubber formulation will become very stiff in cold weather. When flexed, this stiff rubber can crack, causing an immediate failure. In very hot conditions, the same low-quality rubber can become too soft, losing its strength and ability to support the reinforcement layers. We design our rubber compounds to perform consistently across a very wide temperature spectrum. We achieve this by using specific polymers and plasticizers that keep the hose flexible and pliable in freezing temperatures, yet stable and strong when exposed to high heat from the engine or the environment. This means our customers in the cold climates of Europe can trust our hoses just as much as our customers in the heat of the Middle East or Africa.

Isn’t the Stated Working Pressure Enough of a Guarantee?

Your hose is rated for 3000 PSI, but it failed in a 2500 PSI system. You trusted the static rating, but failed to account for dynamic pressure shocks.

No. Working pressure is a static rating. We rigorously impulse test our hose assemblies, subjecting them to repeated pressure spikes (often to 133% of working pressure) for hundreds of thousands of cycles to prove their real-world durability.

The working pressure listed on a hose is its rating for a smooth, constant pressure. But that’s not how a real hydraulic system works. In the real world, systems experience constant pressure spikes, or “impulses,” every time a valve is opened or closed or a cylinder hits the end of its stroke. These impulses can be much higher than the average working pressure. The only way to know if a hose can survive this is to test it. We conduct rigorous impulse testing in our quality lab, following international standards like SAE J343. This test involves taking a hose assembly, putting it on a test bench, and hitting it with rapid pressure spikes for hundreds of thousands of cycles. For a standard 2-wire hose, the requirement is often 200,000 cycles without failure. We test our products to meet and often exceed these standards. This is a promise that our hose is not just strong, but tough enough for the real world.

Does a Tighter Bend Radius Truly Make a Difference?

You are routing a hose in a tight space. You have to force it into a sharp bend, creating a kink that restricts flow and will cause a premature failure.

Yes, a lower (tighter) bend radius makes installation significantly easier and safer. Our hoses are engineered to be more flexible without kinking, allowing for cleaner routing in compact machinery and reducing stress on the hose and fittings.

The minimum bend radius is the tightest curve you can route a hose into without damaging it or restricting the flow of fluid. A smaller number is better because it means the hose is more flexible. This is a huge advantage for technicians and engineers. Modern equipment is becoming more and more compact, leaving very little room for plumbing. A hose with a low bend radius can be routed neatly around corners without kinking. This saves installation time and frustration. More importantly, it improves the safety and longevity of the assembly. Forcing a hose into a bend that is too tight is one of the leading causes of premature failure. It puts immense stress on the reinforcement wires on the outside of the bend. Our hoses are designed for high flexibility, which is a direct result of using high-quality materials and precision manufacturing techniques.

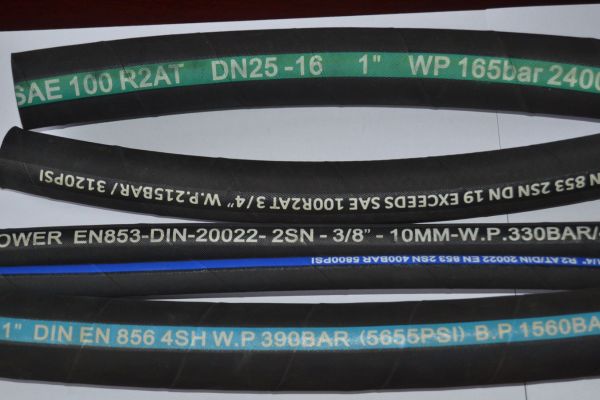

Is the Printing on a Hose More Than Just a Logo?

You need to replace a failed hose in the field. But the markings are smeared or gone, and you cannot identify its type or pressure rating for a safe replacement.

Absolutely. The layline is a critical data source. We use a durable ink-jet printing process to provide a clear, permanent layline that includes the hose type, size, pressure rating, and date of manufacture for easy identification and traceability.

The continuous line of text printed on a hose is called the layline, and it is the hose’s ID card. A professional hose will have a layline that is both easy to read and durable. It needs to survive oil, grease, and abrasion without rubbing off. We use a high-quality ink-jet process to ensure this. The information on the layline is critical for safety and proper maintenance. It clearly states the hose specification (e.g., SAE 100R2AT), the size (e.g., -08 or 1/2″), and the maximum working pressure. This prevents a technician from accidentally replacing a high-pressure hose with a lower-rated one. We also include the date of manufacture. This helps with proper inventory management, ensuring that older stock is used first (First-In, First-Out), and it provides full traceability for our quality control process.

Do I Need a Different Hose for Every Type of Hydraulic Fluid?

You switch to a biodegradable hydraulic fluid for environmental reasons. Your standard hoses suddenly start to swell, crack, and fail, contaminating your new, expensive fluid.

Not always. Our standard hoses are compatible with a wide range of common petroleum-based fluids. We also offer specialty hoses designed specifically for biodegradable fluids, water-glycol mixtures, and other special applications, ensuring reliable performance.

This final point brings us back to the importance of the inner tube compound. While our standard Nitrile (NBR) tube is perfect for the vast majority of systems that use mineral or synthetic oil, some applications require different fluids. For example, some industries use water-based fluids for fire resistance, or biodegradable ester-based fluids for environmental reasons. These fluids can be chemically aggressive to standard rubber. Using the wrong hose will cause the inner tube to swell, break down, and fail very quickly. As a comprehensive supplier, we provide solutions for these challenges. We work with our customers to understand their application and offer specialty hoses with different tube materials (like EPDM or Chloroprene) that are specifically designed to be compatible with these fluids. This is a key part of our one-stop sourcing advantage—we have the right product for your specific need.

These ten features combine to create a hose that is more than a component. It is an investment in your equipment’s reliability, safety, and long-term performance. Contact Topa today and we can customize the best quality products to meet your needs!