Hydraulic Compression Fitting Pressure Ratings Explained

Table of Contents

Introduction

Hydraulic compression fittings are at the heart of hydraulic systems in construction, automotive, aerospace, and manufacturing to create secure connections and ensure efficient operation. Pressure ratings indicate the maximum pressure a fitting can withstand under normal operating conditions. Knowing these ratings accurately helps prevent system failure and ensures the reliable, safe operation of hydraulic systems, as proven by industry standards and rigorous testing protocols.

What Are Hydraulic Compression Fittings?

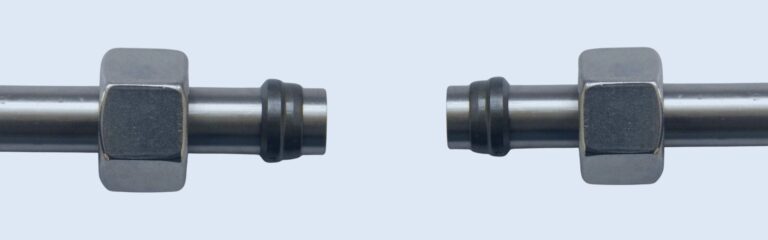

Hydraulic compression fittings are essential components in hydraulic systems, used to connect tubes and hoses securely to ensure efficient and leak-free fluid transfer. They work by compressing a ferrule—a small ring that fits over the tubing—against the tubing wall to create a tight seal. This section explores the various types, materials, and applications of hydraulic compression fittings.

Types of Hydraulic Compression Fittings

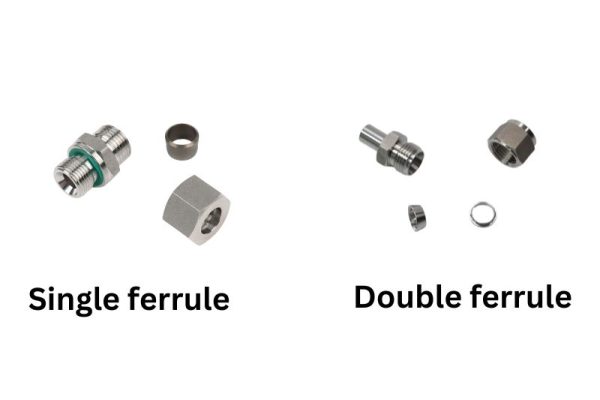

Single Ferrule Fittings

These fittings use a single ferrule to compress the tubing. The ferrule deforms slightly to create a tight seal around the tube when the nut is tightened.

Double Ferrule Fittings

These fittings use two ferrules—a front ferrule and a back ferrule. The front ferrule creates a seal against the fitting body, while the back ferrule grips the tubing securely.

Common Materials

Brass

Properties: Brass is a versatile metal with good corrosion resistance and moderate strength. It is also easy to machine and install.

Usage: Suitable for low to medium-pressure applications. Commonly used in plumbing, heating, and general hydraulic systems where corrosion resistance is necessary but high pressure is not a factor.

Stainless Steel

Properties: Stainless steel is highly resistant to corrosion and can withstand high pressures and temperatures. It also offers excellent strength and durability.

Usage: Ideal for high-pressure and corrosive environments. Frequently used in industries where hygiene and cleanliness are critical, such as food processing, pharmaceuticals, and chemical processing.

How They Work

The basic principle behind hydraulic compression fittings involves the compression of a ferrule to form a tight seal around the tubing. When the fitting nut is tightened, the ferrule deforms slightly, creating a seal that is both secure and resistant to leakage. This design allows for easy installation and maintenance, as well as reliable performance under varying pressures and environmental conditions.

Applications

Hydraulic compression fittings are found in numerous applications across different industries:

Automotive: Used in brake lines, fuel systems, and power steering systems.

Aerospace: Essential for hydraulic systems that control flight surfaces and landing gear.

Manufacturing: Used in hydraulic presses, injection molding machines, and assembly lines.

Construction: Critical in heavy equipment such as excavators, cranes, and bulldozers.

By selecting the appropriate type and material of hydraulic compression fittings, engineers can ensure the reliability and efficiency of hydraulic systems, maintaining performance under various operational conditions.

Understanding Pressure Ratings

Pressure ratings are a crucial aspect of hydraulic compression fittings, determining their suitability for specific applications. A pressure rating indicates the maximum pressure a fitting can safely withstand, considering its design and material strength. These ratings help ensure system integrity and safety, preventing failures and leaks under operational conditions.

Types of Pressure Ratings

Working Pressure

Definition: Working pressure, also known as operating pressure, is the maximum continuous pressure that a fitting can handle during normal operations without compromising its integrity.

Importance: Ensuring that the system operates within the working pressure limits helps maintain safety and reliability. This rating is critical for selecting fittings for daily use where consistent pressure is applied.

Example: A fitting with a working pressure rating of 3000 psi can handle continuous pressure up to 3000 psi during normal operations without failure.

Burst Pressure

Definition: Burst pressure is the pressure at which a fitting will fail or burst. It is typically much higher than the working pressure and represents the maximum pressure a fitting can endure before catastrophic failure.

Importance: Understanding the burst pressure helps in designing systems with safety margins. It indicates the absolute limit beyond which the fitting cannot function safely.

Example: A fitting with a burst pressure rating of 12000 psi will fail if the pressure exceeds this limit, providing a safety margin of four times the working pressure (if the working pressure is 3000 psi).

Determining Pressure Ratings

The pressure rating of a fitting is influenced by several factors, including:

Material Strength: Different materials have varying levels of strength and durability. For instance, stainless steel can typically handle higher pressures than brass due to its superior tensile strength and corrosion resistance.

Design Factors: The design of the fitting, including wall thickness and geometry, also plays a significant role. Fittings with thicker walls and robust designs can withstand higher pressures.

Temperature Effects: Elevated temperatures can reduce the material’s strength, lowering the fitting’s pressure rating. Manufacturers often provide derating factors to adjust pressure ratings based on operating temperatures.

Industry Standards and Testing

Pressure ratings are established based on industry standards and rigorous testing protocols. Common standards include:

SAE J514: Provides guidelines for hydraulic tube fittings, ensuring consistent performance and safety.

ISO 11926: Covers ports and stud ends for general use and fluid power applications, setting international benchmarks for pressure ratings.

Testing methods to verify pressure ratings include:

Proof Testing: Apply twice the maximum working pressure to check for leaks or deformations.

Burst Testing: Applying pressure until the fitting fails to determine the burst pressure.

Impulse Testing: Subjecting the fitting to cyclic pressure pulses to simulate real-world operating conditions.

Factors Affecting Pressure Ratings

Several factors influence the pressure ratings of hydraulic fittings, determining their suitability for various applications and environments. Understanding these factors helps in selecting the right fittings to ensure system safety and efficiency.

Material Strength

Stainless Steel: Known for its high tensile strength and excellent corrosion resistance, stainless steel fittings typically have higher pressure ratings compared to other materials. They are ideal for high-pressure and harsh environments such as offshore drilling and aerospace applications.

Brass: While brass fittings are more affordable and offer good corrosion resistance, their pressure ratings are generally lower than those of stainless steel. Brass is suitable for low to medium-pressure applications, including plumbing and automotive systems.

Temperature Variations

Effect on Material Properties: High temperatures can weaken the material, reducing its ability to withstand pressure. For example, the strength of stainless steel decreases at elevated temperatures, necessitating a lower pressure rating.

Derating Factors: Manufacturers provide derating factors to adjust the pressure ratings based on operating temperatures. These factors ensure that the fittings can handle the pressure safely at different temperatures.

Connection Types

Threaded Connections: Threaded fittings are commonly used for their ease of installation and versatility. However, they may have lower pressure ratings compared to welded or flared fittings due to potential leak paths in the threads.

Flared Connections: Flared fittings offer a more secure and leak-resistant connection, suitable for high-pressure applications. The flaring process strengthens the connection point, enhancing its pressure rating.

Welded Connections: Welded fittings provide the highest pressure ratings due to the seamless connection they create. They are used in applications where leaks are unacceptable, such as in critical hydraulic systems in aerospace and industrial machinery.

Testing Methods for Pressure Ratings

To ensure that hydraulic fittings meet specified pressure ratings and perform reliably under various conditions, several testing methods are employed:

Proof Test

Description: This non-destructive test involves applying twice the maximum working pressure to the fitting. The purpose is to check for any leaks, deformations, or other signs of failure.

Significance: A successful proof test indicates that the fitting can safely handle its rated working pressure in regular use without any issues.

Burst Test

Description: A destructive test where the fitting is subjected to four times the working pressure until it bursts. This test determines the maximum pressure the fitting can endure before failing.

Significance: Burst tests provide crucial data on the safety margins of fittings, ensuring that they can withstand unexpected pressure surges.

Best Practices for Maintaining Clean Hydraulic Fluid

Description: This cyclic endurance test subjects the fitting to repeated pressure pulses to simulate real-world conditions. The fitting is pressurized to 133% of its working pressure at a high frequency for a specified number of cycles.

Significance: Impulse tests predict the lifespan of fittings under dynamic conditions, ensuring their durability and reliability in operational environments.

Salt Spray Test

Description: This corrosion resistance test involves exposing the fitting to a saline environment to evaluate the durability of its material and coatings.

Significance: Salt spray tests help determine the suitability of fittings for corrosive environments, ensuring long-term performance and resistance to rust and corrosion.

Calculating Pressure Ratings

Calculating the pressure ratings of hydraulic compression fittings is a crucial process that ensures the fittings will perform safely and efficiently under operational conditions. One common method used for this calculation is the Lame formula, which is applied to determine the design pressure based on the material properties and dimensions of the fitting.

The Lame Formula

The Lame formula is expressed as:

P=S(D²-d²/D²+d²)

where:

P is the design pressure,

S is the allowable stress of the material,

D is the outside diameter of the fitting,

d is the inside diameter of the fitting.

This formula helps engineers calculate the maximum pressure that a fitting can withstand by considering the inherent material properties and the geometric dimensions.

Steps in Calculating Pressure Ratings

Determine Material Allowable Stress (S)

The allowable stress is a material-specific value that indicates the maximum stress the material can handle without failure. This value is derived from material standards and is often provided by material manufacturers.

Measure the Outside Diameter (D)

The outside diameter of the fitting is measured to ensure accurate calculations. This dimension is critical as it impacts the overall strength and pressure rating of the fitting.

Measure the Inside Diameter (d)

Similarly, the inside diameter must be measured. The difference between the outside and inside diameters determines the wall thickness, which directly affects the pressure rating.

Apply the Lame Formula

Plug the values of S, D, and d into the Lame formula to calculate the design pressure (P). This gives the maximum pressure that the fitting can safely withstand.

Importance of Accurate Calculations

Accurate pressure rating calculations are vital for the following reasons:

Safety: Ensures that the fittings can handle the operational pressures without risk of failure, thereby preventing accidents and injuries.

System Performance: Guarantees that the hydraulic system operates efficiently without unexpected downtimes or maintenance issues.

Regulatory Compliance: Helps in adhering to industry standards and regulations, ensuring that the fittings meet the necessary safety and performance criteria.

By understanding and applying the correct pressure rating calculations, engineers can design more reliable and safe hydraulic systems that meet the demands of their specific applications.

Common Challenges and Solutions

Hydraulic systems, while highly efficient, can encounter several issues related to the fittings used. Addressing these challenges is essential for maintaining system integrity, safety, and performance. Here are some common problems and their solutions:

Leaks

Leaks are a prevalent issue in hydraulic systems, often resulting from improper installation or fittings that do not meet the required pressure ratings. Leaks can lead to reduced system efficiency, increased maintenance costs, and potential safety hazards.

Corrosion

Corrosion is a significant concern, especially in harsh environments such as marine, industrial, and outdoor applications. Corroded fittings can weaken and eventually fail, leading to system breakdowns and potential safety risks.

Pressure Surges

Pressure surges, or transient spikes in pressure, can exceed the rated pressure of the fittings, leading to failures. These surges can occur due to sudden changes in flow rates, system startup, and shutdown, or operational anomalies.

Conclusion

Understanding hydraulic compression fitting pressure ratings is essential for designing safe and efficient hydraulic systems. By selecting the right fittings and adhering to industry standards, professionals can ensure system reliability and performance. This knowledge helps prevent system failures, maintain safety, and optimize the overall functionality of hydraulic applications across various industries.

If you still have any questions about hydraulic compression fittings, please feel free to contact Topa!

FAQ

What is a hydraulic compression fitting?

A hydraulic compression fitting is a mechanical device used to connect tubes and hoses in hydraulic systems, ensuring secure and leak-proof connections. It works by compressing a ferrule against the tubing to create a tight seal.

What are the types of hydraulic compression fittings?

There are two main types: single ferrule fittings, which use one ferrule to compress the tubing, and double ferrule fittings, which use two ferrules (a front and back ferrule) for a more robust connection.

Why are pressure ratings important for hydraulic fittings?

Pressure ratings indicate the maximum pressure that a fitting can safely withstand. Understanding these ratings ensures system integrity, safety, and performance by preventing leaks and failures under operational conditions.

What materials are commonly used for hydraulic compression fittings?

Common materials include brass, suitable for low to medium-pressure applications, and stainless steel, ideal for high-pressure and corrosive environments.

How are pressure ratings determined?

Pressure ratings are determined by the design and material strength of the fitting, often calculated using formulas like the Lame formula. They also involve rigorous testing methods such as proof tests, burst tests, and impulse tests.

What are the common challenges with hydraulic fittings and their solutions?

Common challenges include leaks (solved by correct fitting selection and proper installation), corrosion (solved by using corrosion-resistant materials), and pressure surges (solved by designing systems with pressure relief mechanisms and selecting fittings with appropriate pressure margins).