Grease Fitting Clogged? Here's How to Restore Flow

Table of Contents

Introduction

Imagine you’re in the middle of a crucial maintenance task on your heavy machinery, and just as you start to pump grease into a fitting, you hit an impasse—a clogged grease fitting. This common yet vexing problem can lead to increased wear and tear on your equipment, reducing its efficiency and lifespan. In this post, we will delve into the causes of clogged grease fittings, how to diagnose and fix them, and essential preventative maintenance tips to keep your machinery in top condition.

Understanding Grease Fittings

Definition and Purpose

Grease fittings, also known as grease nipples or Zerks, are small mechanical devices designed to allow lubrication to be applied to moving parts of machinery and equipment. These fittings are strategically placed on machinery to ensure that grease can be injected directly into bearing surfaces and other friction points. The primary purpose of grease fittings is to maintain the optimal performance and longevity of machinery by reducing friction and wear, thereby preventing the breakdown of components due to lack of lubrication.

Types of Grease Fittings

There are several types of grease fittings, each designed for specific applications and environments:

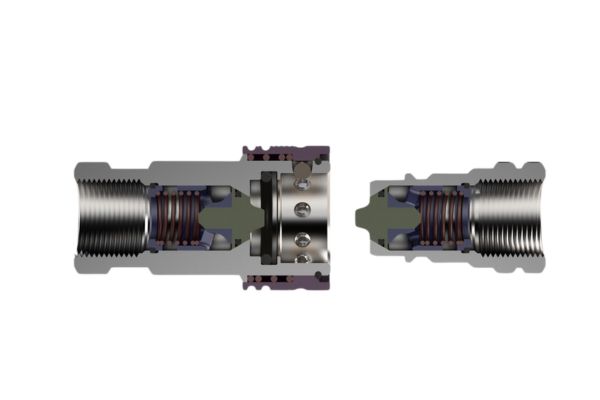

Standard Grease Fittings: The most common type, featuring a ball check valve to prevent dirt from entering and grease from leaking out.

Flush Type Grease Fittings: These sit flush with the surface, making them ideal for applications where protruding fittings might be damaged or obstruct operations.

Button-Head Grease Fittings: Characterized by a larger head, they are used in high-volume applications and are less prone to damage from contaminants.

Angle Grease Fittings: Available in various angles (e.g., 45-degree, 90-degree), these are used in hard-to-reach places where a straight fitting would be impractical.

Common Applications

Grease fittings are ubiquitous across various industries due to their crucial role in maintaining machinery. They are commonly found in:

Automotive Industry: Used in vehicles for lubricating chassis, steering systems, and suspension components.

Agriculture: Essential tractors, harvesters, and other farming equipment to keep moving parts well-lubricated.

Manufacturing: Found in a wide range of machinery, including conveyor belts, assembly lines, and robotic arms.

Construction: Used in heavy machinery such as excavators, bulldozers, and cranes to ensure reliable operation under harsh conditions.

Causes of Clogged Grease Fittings

Contamination

One of the primary causes of clogged grease fittings is contamination from dirt, debris, and other foreign particles. When machinery operates in dirty or dusty environments, these contaminants can easily find their way into the grease fitting. The ball check valve, which is designed to keep out dirt, can sometimes fail if not properly maintained, allowing particles to enter the fitting. Once inside, these contaminants mix with the grease and create blockages that impede the flow of lubrication. This contamination not only clogs the fittings but can also cause abrasive wear to the internal components of the machinery, leading to more significant mechanical issues over time. Regular cleaning of the fitting areas and ensuring the grease gun and nozzles are clean can help prevent contamination-related clogs.

Hardened Grease

Another common cause of clogged grease fittings is the hardening of old grease. Over time, grease can degrade, especially if exposed to high temperatures, excessive moisture, or air. This degradation causes the grease to lose its lubricating properties and harden into a solid, wax-like substance that can block the fitting. Hardened grease can be particularly challenging to remove because it creates a solid plug within the fitting, preventing new grease from entering. This is often exacerbated in machinery that is not used regularly, as the grease sits idle for extended periods. To prevent this, it is crucial to use the appropriate type of grease for the operating conditions and to adhere to a regular lubrication schedule that keeps the grease fresh and functional.

Improper Grease Type

Using the wrong type of grease can also lead to clogged fittings. Different types of machinery and operating conditions require specific types of grease, each formulated with unique properties to suit particular applications. For example, high-temperature environments require a grease that can withstand heat without breaking down, while high-load applications need a grease with excellent pressure resistance. Using a grease that is not compatible with the machinery or its operating environment can cause it to break down prematurely, harden, or become too thick to flow through the fittings. Additionally, mixing different types of grease can cause them to react chemically, leading to the formation of clogs. It is essential to consult the machinery’s maintenance manual or a lubrication specialist to select the right grease for each application.

Lack of Maintenance

Irregular maintenance is a significant factor in the clogging of grease fittings. When machinery is not lubricated on a regular schedule, grease can dry out, harden, and block the fittings. Additionally, irregular maintenance means that small issues, such as minor contamination or the beginning stages of grease hardening, go unnoticed and unaddressed, eventually leading to full blockages. Consistent maintenance schedules are crucial to ensuring that grease fittings remain free-flowing and effective. This includes regular inspections, cleaning of fittings, and timely lubrication. Adhering to a maintenance routine helps identify potential problems before they become severe and ensures that all components receive adequate lubrication, thereby extending the life of the machinery.

Diagnosing a Clogged Grease Fitting

Visual Inspection

The first step in diagnosing a clogged grease fitting is a thorough visual inspection. Begin by cleaning the area around the grease fitting with a rag or brush to remove any dirt or debris. This ensures that you can clearly see the fitting and its immediate surroundings. Look for signs of hardened grease around the fitting, which can indicate a blockage. Also, check for any visible cracks or damage to the fitting itself. If the fitting is damaged, it may need to be replaced. Pay attention to any accumulated dirt or debris that could be obstructing the fitting. Ensuring the fitting is clean and intact is a crucial first step in diagnosing a clog.

Grease Gun Resistance

A practical method to detect a clogged grease fitting is by using a grease gun. Attach the grease gun to the fitting and begin to pump grease. Normally, you should feel a consistent resistance as the grease flows into the fitting and lubricates the component. However, if the fitting is clogged, you will notice an unusual amount of resistance or even complete blockage, preventing the grease from flowing. In some cases, the grease gun might also leak around the connection to the fitting, indicating that the grease is not entering the fitting as it should. This resistance is a clear sign that the fitting is clogged and needs attention.

Checking Grease Flow

After suspecting a clog based on visual inspection and grease gun resistance, the next step is to check the grease flow through the fitting. To do this, you can use a small wire or a fitting cleaning tool to clear any obvious blockages. Insert the wire into the fitting to see if it encounters any resistance or blockage. If the wire does not pass through easily, this confirms the presence of a clog. Alternatively, if you have a grease fitting cleaner, you can attach it to the fitting and attempt to force a small amount of lubricant through it. Observe if the grease exits the fitting from the other side, indicating a clear passage. If the grease does not flow, the fitting is still blocked and may require further cleaning or even replacement.

Step-by-Step Guide to Unclogging a Grease Fitting

Preparation

Before you start unclogging a grease fitting, it’s essential to prepare both the area and the necessary tools. Begin by gathering the tools and materials you’ll need: a grease gun, grease fitting cleaner, wire brush, cleaning solvent, a small wire or pin, safety gloves, and safety glasses. Ensure the machinery is turned off and cooled down to prevent accidents. Clean the area around the grease fitting with a cloth to remove surface dirt and debris. This step is crucial to avoid introducing new contaminants into the fitting. Lay down a protective sheet or container to catch any grease or debris that might be expelled during the cleaning process. Having everything ready and organized will make the process smoother and more efficient.

Cleaning the Fitting

Once the area is prepared, focus on cleaning the exterior of the grease fitting. Use a wire brush to scrub away any hardened grease, dirt, or debris from around the fitting. This step ensures that when you begin the unclogging process, you don’t inadvertently push external contaminants further into the fitting. After brushing, apply a cleaning solvent to dissolve any remaining grease or grime. Wipe the fitting with a clean rag to remove the solvent and any loosened debris. At this point, the exterior of the fitting should be free of dirt and ready for the next steps.

Using a Grease Fitting Cleaner

A grease fitting cleaner is a specialized tool designed to clear blockages from grease fittings. To use it, first, ensure that the cleaner is filled with a compatible solvent or light oil. Attach the cleaner’s nozzle to the grease fitting, ensuring a secure and tight fit. Once attached, press the cleaner’s handle or plunger to inject the solvent into the fitting. This action should force the solvent through the fitting, breaking up and dissolving the clog. Repeat this process several times, if necessary, to ensure the blockage is thoroughly cleared. Be patient and persistent, as stubborn clogs might take a few attempts to break up completely.

Flushing the Fitting

After using the grease fitting cleaner, the next step is to flush out any remaining old grease and contaminants. Attach a grease gun filled with the appropriate type of grease to the fitting. Begin pumping grease into the fitting slowly. Initially, you might see some old, contaminated grease being expelled from the fitting. Continue pumping until you see clean, new grease coming out. This process ensures that all the old grease and any dissolved contaminants are pushed out, leaving only fresh grease inside the fitting. If the grease still does not flow, repeat the cleaning process or consider using a small wire to manually dislodge any remaining blockage.

Testing the Fitting

Once you believe the clog has been cleared and fresh grease is flowing, it’s crucial to test the fitting to ensure it’s fully functional. Start by detaching the grease gun and cleaning any expelled grease from around the fitting. Reattach the grease gun and pump a small amount of grease into the fitting. Observe whether the grease flows smoothly into the fitting and reaches the intended lubrication point. Check the machinery’s components to confirm that the grease is properly lubricating the moving parts. If the grease flows without resistance and reaches the necessary areas, the fitting is successfully unclogged. If there’s still resistance or the grease doesn’t flow correctly, repeat the previous steps or consider replacing the fitting if it appears damaged.

Unclogging a grease fitting requires careful preparation, thorough cleaning, and proper use of tools like grease fitting cleaners and grease guns. By following these steps, you can effectively clear blockages and ensure that your machinery remains well-lubricated and operates smoothly. Regular maintenance and proper lubrication are key to preventing clogs and extending the life of your equipment.

Preventative Maintenance Tips

Regular Inspection

Regular inspections are crucial for maintaining the functionality of grease fittings and preventing clogs. During inspections, check each grease fitting for signs of dirt, debris, or hardened grease around the nozzle. Look for any visible damage to the fittings, such as cracks or wear, which can lead to leaks and contamination. Also, observe the condition of the grease itself; if it appears discolored or contaminated, it might indicate a problem. Regular inspections help identify potential issues early, allowing you to address them before they cause significant damage.

Proper Grease Selection

Choosing the right type of grease for your machinery is essential to prevent clogs and ensure effective lubrication. Different types of machinery and operating conditions require specific greases with unique properties. Consider factors such as temperature, load, speed, and environmental conditions when selecting grease. High-temperature environments, for instance, require grease with high thermal stability, while high-load applications need grease with superior pressure resistance. Consult your machinery’s maintenance manual or a lubrication specialist to determine the appropriate grease type. Using the correct grease not only enhances lubrication efficiency but also reduces the risk of grease hardening and clogging the fittings.

Routine Cleaning

Incorporating routine cleaning into your maintenance schedule is vital to keep grease fittings free from dirt and debris. Clean the fittings regularly using a wire brush and cleaning solvent to remove any accumulated grease and contaminants. Pay special attention to fittings in dirty or dusty environments, as they are more prone to clogging. After cleaning, inspect the fittings for any signs of wear or damage. Routine cleaning helps maintain the integrity of the fittings and ensures that the grease flows smoothly. Additionally, keeping the grease gun and nozzles clean prevents the introduction of new contaminants during lubrication.

Conclusion

In conclusion, maintaining free-flowing grease fittings is crucial for the optimal performance and longevity of your machinery. We’ve covered the importance of regular inspections, choosing the right grease, routine cleaning, and setting up a scheduled lubrication plan. By following these preventative maintenance tips, you can prevent clogs, reduce downtime, and ensure your equipment operates smoothly. Implement these practices in your maintenance routine and share your experiences to help others in the industry. For further assistance and detailed guides, visit our additional resources or contact our support team for professional advice.

FAQ

Grease fittings can clog due to contamination from dirt and debris, hardened grease, using the wrong type of grease, or lack of regular maintenance.

It’s recommended to inspect grease fittings during each routine maintenance session or at least once a month, depending on the operating conditions of your machinery.

The type of grease you should use depends on your machinery’s operating conditions, such as temperature, load, and speed. Consult your machinery’s maintenance manual or a lubrication specialist for the best choice.

Signs of a clogged grease fitting include excessive resistance when using a grease gun, no grease flow, and visible contamination or hardened grease around the fitting.

You’ll need a grease gun, grease fitting cleaner, wire brush, cleaning solvent, a small wire or pin, and safety equipment like gloves and safety glasses.

Prevent clogging by conducting regular inspections, using the correct grease, performing routine cleaning, and maintaining a scheduled lubrication plan.