Relation Between Hydraulic Hoses and Chemical Compatibility

Introduction

Due to the diverse environments in which hydraulic systems operate, hydraulic hoses are exposed to a wide variety of chemicals ranging from hydraulic fluids and coolants to cleaning agents and lubricants. This exposure makes chemical compatibility a critical factor in ensuring the life and efficiency of hoses. By understanding the factors that affect chemical compatibility and learning how to select the right hydraulic hose, you can improve the reliability and safety of your system. This article will provide comprehensive guidance on selecting hoses that will withstand the specific chemical environments encountered to ensure optimum performance and extend the life of hydraulic systems.

Understanding Hydraulic Hose

Understanding Hydraulic Hose

Hoses are flexible conduits designed to transport hydraulic fluid between different components within a hydraulic system. These hoses are essential for the efficient transfer of fluid power, allowing machinery and equipment to perform tasks such as lifting, pressing, and moving heavy loads. The primary function of hoses is to serve as a flexible connection between stationary and moving parts, accommodating movement, vibration, and thermal expansion.

Basic Structure and Components

Hoses are typically constructed with three main layers:

Inner Tube: The innermost layer is designed to be compatible with the hydraulic fluid it will carry. This layer must resist corrosion and swelling caused by the fluid, ensuring a smooth and unobstructed flow. Materials commonly used for the inner tube include synthetic rubber, thermoplastics, and PTFE (Teflon).

Reinforcement: The middle layer provides the hose with its strength and flexibility. It is usually made from braided or spiral-wound wire or textile materials. The reinforcement layer helps the hose withstand high pressures and prevents it from collapsing or bursting under load.

Outer Cover: The outermost layer protects the hose from external damage, such as abrasion, weathering, and chemicals. It is typically made from synthetic rubber or thermoplastic materials, which provide durability and resistance to environmental factors.

Types of Hoses

Hoses come in various types, each suited for specific applications and environmental conditions:

Rubber Hoses: These hoses are highly flexible and suitable for a wide range of applications. They are commonly used in industrial and mobile equipment due to their excellent durability and resistance to abrasion and weathering.

Thermoplastic Hoses: Lighter and more flexible than rubber hoses, thermoplastic hoses are ideal for applications requiring tight bends and ease of handling. They are resistant to chemicals and UV radiation, making them suitable for outdoor and chemical-intensive environments.

PTFE (Teflon) Hoses: Known for their exceptional chemical resistance and high-temperature tolerance, PTFE hoses are used in demanding applications where exposure to aggressive chemicals and extreme temperatures is common. They are also known for their low friction properties, which help reduce pressure drop and improve flow efficiency.

Common Applications

Hydraulic hoses are integral components in a variety of industries and applications:

Industrial Machinery: Hydraulic systems are used in manufacturing plants, where they power machinery such as presses, conveyors, and robotic arms. The flexibility and strength of hoses enable these machines to perform precise and repetitive tasks efficiently.

Construction Equipment: Heavy equipment such as excavators, bulldozers, and cranes rely on hydraulic systems for movement and operation. Hoses facilitate the transfer of fluid power, allowing these machines to lift heavy loads, dig trenches, and perform other construction tasks.

Automotive Systems: Hoses are found in various automotive systems, including power steering, braking, and suspension systems. They ensure smooth operation and control by efficiently transmitting hydraulic fluid to the necessary components.

Materials Used

The choice of materials used in hoses is critical to their performance and longevity:

Rubber Compounds: Common rubber compounds used in hoses include Nitrile Butadiene Rubber (NBR), Ethylene Propylene Diene Monomer (EPDM), and Chloroprene (Neoprene). These materials offer good flexibility, abrasion resistance, and compatibility with a range of hydraulic fluids.

Thermoplastics: Thermoplastic materials, such as Nylon and Polyurethane, are used in hoses that require high flexibility and resistance to chemicals and UV radiation. They are lighter than rubber hoses and can handle tight bending radii.

PTFE (Teflon): PTFE hoses are highly resistant to chemicals, high temperatures, and pressure. They are often used in applications where traditional rubber or thermoplastic hoses would fail due to aggressive chemical exposure or extreme operating conditions.

What is Chemical Compatibility?

Chemical compatibility refers to the ability of a material, in this case, a hydraulic hose, to resist and maintain its integrity when exposed to various chemicals. It involves the evaluation of how different chemicals interact with the hose materials, including the inner tube, reinforcement, and outer cover. A chemically compatible hose will not degrade, swell, crack, or otherwise fail when in contact with specific chemicals it is designed to handle.

Why it Matters in Hydraulic Systems

In hydraulic systems, ensuring chemical compatibility is crucial for several reasons:

Prevention of Hose Degradation: Incompatible chemicals can cause the hose material to deteriorate, leading to leaks, bursts, and ultimately, system failure. This degradation can be due to chemical reactions that weaken the hose structure, making it brittle or causing it to swell.

Maintaining System Efficiency: Chemical incompatibility can lead to blockages or reduced flow rates due to hose swelling or deformation. This can affect the efficiency of the hydraulic system, leading to decreased performance and increased energy consumption.

Ensuring Safety: Leaks or bursts caused by chemical incompatibility can pose serious safety hazards, including fire risks, environmental contamination, and harm to personnel. Ensuring chemical compatibility helps maintain a safe working environment.

Extending Hose Lifespan: Using hoses that are compatible with the chemicals in the system helps extend their lifespan, reducing the frequency of replacements and maintenance costs.

Factors Affecting Chemical Compatibility

Temperature: The temperature of both the hydraulic fluid and the operating environment can affect chemical compatibility. Higher temperatures can accelerate chemical reactions, leading to faster degradation of the hose material. It is important to choose hoses that can withstand the expected temperature ranges.

Concentration of Chemicals: The concentration of chemicals in the hydraulic fluid can impact the rate of hose degradation. Higher concentrations may increase the likelihood of chemical reactions with the hose material. Understanding the specific concentration levels is essential for selecting compatible hoses.

Duration of Exposure: The length of time the hose is exposed to certain chemicals can influence its compatibility. Continuous or prolonged exposure can have more severe effects compared to intermittent contact. Evaluating the expected exposure duration is crucial in hose selection.

Pressure: The operating pressure within the hydraulic system can also affect chemical compatibility. High pressure can exacerbate the effects of chemical interactions, leading to quicker deterioration of the hose material. Ensuring that the hose can handle the system’s pressure while maintaining chemical resistance is vital.

Common Chemicals in Hydraulic Systems

Hydraulic systems encounter a variety of chemicals, each with unique properties that can affect hose compatibility:

Hydraulic Fluids: These are the primary chemicals in hydraulic systems and come in different types:

Petroleum-based Fluids: Commonly used due to their good lubricating properties and thermal stability. However, they can be incompatible with certain hose materials.

Water-based Fluids: These include water-glycol solutions and emulsions, which are less flammable but can cause swelling or degradation in some rubber hoses.

Synthetic Fluids: These are engineered for specific properties, such as fire resistance or biodegradability. Their chemical composition varies, requiring careful compatibility assessment.

Cleaning Agents: Used for maintenance and cleaning of hydraulic systems, these chemicals can be harsh and may degrade hose materials if not compatible. Common cleaning agents include detergents, solvents, and degreasers.

Coolants: Used to manage heat within the hydraulic system, coolants can vary in chemical composition. Compatibility with coolant formulations is essential to prevent hose degradation and system inefficiency.

Lubricants: Additional lubricants may be used in hydraulic systems to reduce friction and wear. These can interact with hose materials, necessitating compatibility checks to ensure they do not compromise hose integrity.

Selecting the Right Hydraulic Hose

Choosing the right hydraulic hose for a specific application involves considering several key criteria to ensure optimal performance and longevity. The primary factors to evaluate include:

Chemical Compatibility

Ensuring the hose material is resistant to the chemicals it will encounter is crucial. This involves checking the compatibility of the hose’s inner tube, reinforcement, and outer cover with the specific fluids and chemicals used in the system. Incompatible materials can lead to hose degradation, leaks, and system failure.

Pressure Rating

The hose must be capable of withstanding the maximum operating pressure of the hydraulic system. Pressure ratings are typically specified in PSI (pounds per square inch) or bar. It is important to choose a hose with a pressure rating that exceeds the system’s maximum pressure to ensure safety and durability.

Temperature Rating

Hydraulic systems can operate in a wide range of temperatures. The hose must be able to maintain its integrity and performance within the expected temperature range of the application. This includes both the temperature of the hydraulic fluid and the ambient temperature. Exceeding the hose’s temperature rating can lead to material breakdown and failure.

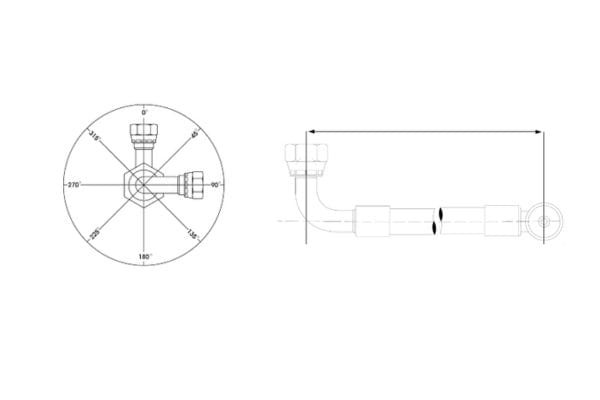

Flexibility and Bend Radius

The flexibility of the hose is essential for installations that require tight bends and maneuverability. The bend radius is the minimum radius a hose can bend without kinking or compromising its structural integrity. Choosing a hose with appropriate flexibility and bend radius ensures ease of installation and reduces the risk of damage during operation.

Steps to Ensure Proper Selection

Selecting the right hydraulic hose involves a systematic approach to match the hose characteristics with the application requirements. The following steps can guide this process:

Identifying the Chemical Environment

Begin by identifying all chemicals and fluids the hose will come into contact with. This includes hydraulic fluids, cleaning agents, coolants, and lubricants. Document the concentration, temperature, and duration of exposure for each chemical.

Matching Hose Materials with Chemical Resistance Requirements

Use chemical resistance charts and manufacturer guidelines to match the identified chemicals with suitable hose materials. Ensure that the inner tube, reinforcement, and outer cover materials are all compatible with the chemicals they will encounter. Consider using hoses specifically designed for high chemical resistance, such as those made from PTFE or certain thermoplastics.

Verifying Manufacturer Specifications

Consult the manufacturer’s datasheets and technical specifications for the chosen hose. Verify that the hose meets or exceeds the required pressure and temperature ratings for the application. Check for any additional certifications or compliance with industry standards that may be necessary for the specific environment or application.

Considering Application-Specific Requirements

Evaluate other application-specific factors, such as the required length, fitting compatibility, and any additional protective features like abrasion resistance or fire retardancy. Ensure the hose selection accommodates these needs to enhance overall system performance and safety.

Conducting Field Testing

Where possible, conduct field testing of the selected hose in the actual operating environment. This can help verify its performance under real-world conditions and identify any unforeseen issues with chemical compatibility or physical durability.

By following these steps and considering all relevant criteria, industry professionals can ensure they select the right hydraulic hose for their specific applications. This careful selection process enhances the reliability, safety, and efficiency of hydraulic systems, ultimately contributing to better performance and reduced maintenance costs.

Maintenance and Safety

Proper maintenance of hoses is essential to ensure their longevity and the overall efficiency of the hydraulic system. Regular inspections and maintenance routines can help identify potential issues before they lead to system failures.

Signs of Chemical Degradation

Cracking or Hardening: Exposure to incompatible chemicals can cause the hose material to become brittle, leading to cracks or hardening.

Swelling or Blistering: Chemicals can cause the hose to swell or blister, which can be an indication of internal degradation.

Discoloration: Changes in the color of the hose material may indicate chemical reactions taking place.

Soft Spots: Areas of the hose that feel unusually soft or mushy may be undergoing chemical breakdown.

Leaks: Any signs of fluid leakage at hose connections or along the hose length can be a result of chemical incompatibility causing material breakdown.

Proper Storage and Handling of Hoses

Storage Conditions: Store hoses in a cool, dry place away from direct sunlight, heat sources, and chemicals that could cause degradation. Avoid storing hoses in a coiled position for extended periods to prevent kinks and stress.

Handling Procedures: When handling hoses, avoid dragging them over sharp edges or rough surfaces. Use appropriate lifting techniques and equipment to prevent damage from excessive bending or stretching.

Protective Measures: Use hose protectors or sleeves to shield hoses from abrasion, chemicals, and environmental factors during operation and storage.

Troubleshooting Chemical Compatibility Issues

Identifying and addressing chemical compatibility issues promptly can prevent significant damage to hydraulic systems. Here are common problems and their solutions:

Common Problems and Solutions

Problem: Hose Swelling or Blistering

Solution: Verify the chemical compatibility of the hose material with the fluids in use. If incompatibility is confirmed, replace the hose with one made from a compatible material, such as PTFE or a specially formulated rubber compound.

Problem: Cracking or Hardening of the Hose

Solution: Inspect the chemical composition of the hydraulic fluid and other chemicals the hose is exposed to. Ensure the hose material is suitable for these chemicals. If necessary, switch to a hose with higher resistance to the specific chemicals.

Problem: Discoloration or Soft Spots

Solution: Check the temperature and concentration of the chemicals in use. High temperatures and concentrations can accelerate chemical reactions. Adjust the operating conditions or select a hose with better chemical and temperature resistance.

Problem: Fluid Leaks

Solution: Inspect the hose for signs of chemical degradation and check the fittings for proper installation. Replace any damaged hoses and ensure all connections are secure and compatible with the hose material.

When to Replace Hoses

Visible Damage: Replace hoses showing signs of cracking, swelling, blistering, discoloration, or soft spots.

Leaks: Immediately replace hoses that exhibit any fluid leakage to prevent further damage and potential safety hazards.

Degraded Performance: If a hose shows reduced flexibility, increased pressure drop, or other performance issues, it may be time for a replacement.

Regular Maintenance Schedule: Follow a proactive maintenance schedule that includes periodic hose replacement based on manufacturer recommendations and the specific operating conditions of the hydraulic system.

Conclusion

Selecting the right hydraulic hose involves evaluating chemical compatibility, pressure and temperature ratings, and flexibility. Proper selection of hoses, tailored to the specific chemicals and operating conditions, significantly impacts system efficiency and longevity. By adhering to guidelines for hose selection and maintenance, professionals can mitigate risks, reduce downtime, and ensure a safe working environment. Investing time and resources into understanding and implementing chemical compatibility measures ultimately leads to more resilient and effective hydraulic systems.

FAQ

Chemical compatibility ensures that the hose material can resist degradation and maintain its integrity when exposed to specific chemicals, preventing leaks, bursts, and system failures.

Refer to the chemical resistance charts provided by the hose manufacturer and consult their guidelines. It’s also helpful to conduct field testing in the actual operating environment.

Signs include cracking, hardening, swelling, blistering, discoloration, soft spots, and leaks. Regular inspections can help identify these issues early.

Common materials include synthetic rubber compounds (like NBR and EPDM), thermoplastics, and PTFE (Teflon), each offering varying degrees of chemical resistance.

Hydraulic hoses should be inspected regularly, with the frequency depending on the operating conditions and manufacturer’s recommendations. Monthly or quarterly inspections are common practices.

If you suspect an issue, immediately inspect the hose for signs of degradation and consult the manufacturer’s guidelines. Replace the hose with one that has proven compatibility with the chemicals in your system.