Proper Assembly of Parallel Thread Adjustable Fittings

Table of Contents

Introduction

Parallel thread fittings are essential components in various industrial applications, providing secure connections between hydraulic systems, pipelines, and machinery. These fittings feature parallel threads, which differ from tapered threads by maintaining a consistent diameter along their length, ensuring a tight seal with the help of a sealing washer or O-ring. This guide aims to provide a comprehensive overview of the correct assembly procedures for parallel thread fittings.

Understanding Parallel Thread Fittings

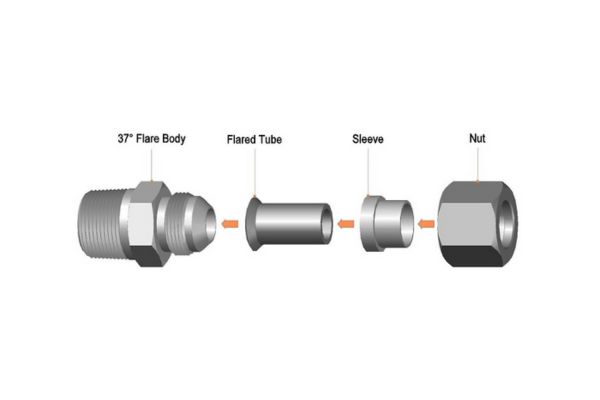

Components and Their Functions

Body:

The body of a parallel thread adjustable fitting is the primary component that connects with other parts of the system. It serves as the structural foundation, housing the threads and adjustment mechanism. The body ensures that the fitting maintains its integrity and provides a stable connection point for the other elements of the system.

Adjustment Mechanism:

The adjustment mechanism within these fittings is crucial for achieving precise alignment and secure connections. This mechanism typically includes a locknut or a similar device, which helps maintain the set position once the fitting is adjusted. The adjustment mechanism allows for fine-tuning, ensuring that the fitting can be positioned accurately within the system.

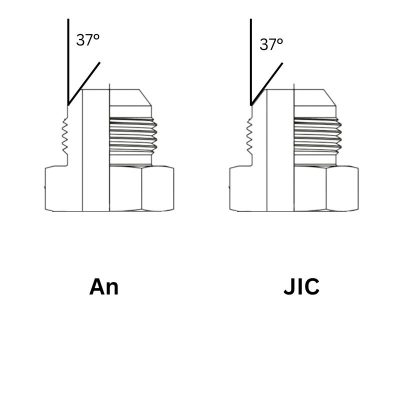

Threads:

The threads on these fittings are parallel, meaning they maintain a consistent diameter along their length. Unlike tapered threads, parallel threads do not taper but instead rely on a sealing washer or O-ring to achieve a leak-free connection. Key specifications of threads include the thread size, pitch, and profile, which must be compatible with corresponding components to ensure a proper fit and seal.

Applications and Benefits

Parallel thread fittings are utilized across a broad spectrum of industries due to their versatility and reliability. Common applications include manufacturing, automotive, aerospace, and various hydraulic and pneumatic systems. These fittings are chosen for their ability to provide secure, leak-free connections, even in high-pressure environments.

Easy Adjustability:

One of the primary benefits of parallel thread fittings is their easy adjustability. The adjustment mechanism allows for precise alignment, making installation and maintenance straightforward. This feature is particularly valuable in complex systems where exact positioning is essential for optimal performance.

Reliable Sealing:

The design of parallel thread fittings ensures a reliable seal, reducing the risk of leaks. This is achieved through the use of sealing washers or O-rings, which compensate for the lack of taper in the threads. The result is a robust, leak-free connection that can withstand varying operational conditions.

Compatibility with High-Pressure Systems:

These fittings are engineered to perform under high-pressure conditions, making them suitable for demanding applications. Their robust construction and reliable sealing capabilities ensure that they can handle the stresses associated with high-pressure environments without compromising performance.

Types of Parallel Threads

BSPP (British Standard Pipe Parallel)

BSPP threads are one of the most common types of parallel threads used globally, especially in Europe. These threads are characterized by a uniform diameter along their length and a 55-degree thread angle. BSPP threads rely on a bonded seal or an O-ring in a groove to create a leak-tight connection, making them suitable for applications where reliable sealing is crucial, such as hydraulic and pneumatic systems.

UNF (Unified National Fine)

UNF threads are widely used in North America and are part of the Unified Thread Standard. They have a finer pitch compared to UNC (Unified National Coarse) threads, allowing for a greater number of threads per inch. This fine threading provides a stronger and more secure connection, ideal for applications requiring high precision and where space constraints demand a tighter thread fit, such as in automotive and aerospace industries.

ISO Parallel Threads (Metric)

ISO parallel threads, also known as ISO 228-1 or G threads, follow the metric standard and are commonly used worldwide. These threads have a 60-degree thread angle and a consistent diameter, which makes them suitable for a wide range of applications. ISO parallel threads are often found in European and Asian machinery and are preferred for their international standardization, ensuring compatibility across different equipment and components.

NPS (National Pipe Straight)

NPS threads are used primarily in the United States and Canada and are similar in design to NPT (National Pipe Tapered) threads but maintain a constant diameter along their length. They are often used in low-pressure applications where the primary sealing method is a gasket or an O-ring rather than the threads themselves. NPS threads are common in plumbing and piping systems where precise alignment is required without the need for thread interference.

SAE Straight Thread

SAE straight threads are designed to provide a reliable, reusable connection in hydraulic and other fluid power systems. These threads are specified by the Society of Automotive Engineers (SAE) and are often used in conjunction with O-rings or other seals to ensure a leak-free connection. The threads themselves provide the mechanical hold, while the seal ensures the system’s integrity under high pressure. This combination is widely used in automotive and industrial applications for its robustness and reliability.

Step-by-Step Assembly Process

Inspection of Components

Checking for Cleanliness:

Before beginning the assembly process, it is crucial to ensure all components are free from dirt, debris, and contaminants. Contaminants can compromise the seal and connection, leading to potential leaks and system failures. Use a clean, lint-free cloth to wipe down each part. For more stubborn debris, consider using a mild solvent that is compatible with the materials of the fittings. Ensuring cleanliness helps maintain the integrity of the assembly and prevents premature wear.

Inspecting Threads for Damage or Wear:

Carefully examine the threads on all components for any signs of wear, deformation, or damage. Even minor imperfections can hinder proper assembly and lead to issues such as cross-threading or inadequate sealing. Use a magnifying glass if necessary to get a detailed view of the thread condition. If you find any damage, replace the affected parts to ensure the assembly process proceeds smoothly and securely.

Aligning the Threads

Importance of Alignment:

Proper thread alignment is essential to prevent cross-threading, which can damage the threads and compromise the seal. Cross-threading occurs when threads are misaligned, causing them to cut across each other rather than mesh smoothly. This not only damages the threads but also affects the fitting’s ability to seal properly.

Techniques for Preventing Cross-threading:

Start threading by hand: Begin the threading process manually to ensure the threads engage smoothly. Hand-threading allows you to feel for any resistance, which could indicate misalignment.

Use light pressure: Apply gentle pressure to guide the threads into place. If you encounter resistance, stop and realign the threads before continuing.

Tightening Components

Recommended Torque Specifications:

Refer to the manufacturer’s guidelines for specific torque values for your fittings. Using the correct torque ensures a secure fit without over-tightening, which can strip the threads or damage the fitting.

Techniques for Even Tightening:

Apply torque evenly: Distribute the torque evenly across the fitting, using a crisscross pattern if applicable. This helps to prevent uneven stress on the fitting and ensures a secure connection.

Avoid sudden or excessive force: Gradual and steady pressure should be used when tightening. Sudden force can lead to over-tightening or damage to the threads.

Ensuring Proper Sealing

Use of Thread Sealants:

Applying a thread sealant, such as PTFE tape or liquid sealant, is essential for ensuring a leak-free connection. Wrap PTFE tape around the male threads, ensuring even coverage without excess. For liquid sealants, apply a thin, uniform layer to the threads. Sealants fill the gaps between threads, enhancing the seal and preventing leaks.

Checking for Leaks and Verifying the Seal:

Pressurize the system: After assembly, gradually pressurize the system to its operating pressure.

Inspect for leaks: Use soapy water or a leak detection fluid on the connections and watch for bubbles, which indicate leaks. Address any leaks by disassembling and reassembling the fitting with additional sealant if necessary.

Verification and Final Checks

Steps to Ensure the Assembly Is Complete and Correct:

Double-check all connections and fittings: Ensure all parts are properly tightened and aligned.

Confirm proper torque and alignment: Verify that all connections meet the recommended torque specifications and that the threads are correctly aligned.

Tips for Testing the Assembled Fitting:

Conduct a pressure test: Perform a pressure test to ensure the integrity of the seal. This involves pressurizing the system and monitoring for any signs of leakage.

Monitor for signs of leakage or pressure drop: Keep an eye on the system over time to detect any gradual leaks or pressure drops, which could indicate an issue with the assembly.

Common Issues and Troubleshooting

Cross-threading

Cross-threading occurs when the threads on the fittings are misaligned during assembly. This misalignment causes the threads to cut across each other rather than engage smoothly, leading to damage to both the male and female threads. Cross-threading not only makes it difficult to achieve a secure connection but can also result in leaks and compromised system integrity. This issue often arises when excessive force is applied during the initial threading, or when the threads are not started correctly by hand.

Inadequate Sealing

Inadequate sealing is another common problem in the assembly of parallel thread fittings. This issue often stems from insufficient application of thread sealant, incorrect torque application, or using the wrong type of sealant for the specific threads and operating conditions. Inadequate sealing can lead to leaks, which compromise the efficiency and safety of the system. It’s crucial to ensure that the sealant is applied correctly and that the fittings are tightened to the manufacturer’s specified torque values to achieve a proper seal.

Troubleshooting Tips

Identifying and Addressing Common Issues

For Cross-threading:

Disassemble and Inspect Threads: If cross-threading is suspected, immediately stop the assembly process and disassemble the connection. Carefully inspect both the male and female threads for any signs of damage or wear.

Realign Carefully: Clean the threads and realign them carefully. Start the threading process by hand to ensure the threads engage smoothly. If the threads are significantly damaged, consider replacing the affected components to avoid future issues.

For Sealing Issues:

Reapply Thread Sealant: If you encounter sealing issues, disassemble the fitting and remove any old sealant. Clean the threads thoroughly and reapply the appropriate thread sealant. Ensure an even and sufficient application, covering all thread surfaces that will engage.

Ensure Proper Torque: Use a torque wrench to tighten the fittings to the manufacturer’s specified torque values. This ensures a secure fit and proper sealing without over-tightening, which could damage the threads or the seal.

Solutions for Common Problems

Use Thread Gauges to Verify Thread Integrity:

Thread Gauges: Thread gauges are essential tools for verifying the integrity and compatibility of threads. Use them to check the pitch, diameter, and profile of the threads before assembly. This helps ensure that the threads are in good condition and compatible, preventing cross-threading and sealing issues.

Routine Inspections: Regularly inspect and verify thread integrity using thread gauges, especially if fittings are reused or have been stored for an extended period.

Replace Damaged Components as Necessary:

Identifying Damage: If you identify any damage to the threads or fittings during inspection, replace the damaged components immediately. Using compromised parts can lead to repeated assembly issues and potential system failures.

Quality Assurance: Ensure that replacement components meet the required specifications and quality standards. Using high-quality parts reduces the risk of future problems and enhances the overall reliability of the system.

By addressing common issues such as cross-threading and inadequate sealing through careful inspection, proper technique, and the use of appropriate tools and sealants, you can ensure reliable, leak-free connections in your parallel thread adjustable fittings. Consistent attention to detail and adherence to best practices will help maintain the integrity and efficiency of your hydraulic or pneumatic systems.

Conclusion

Proper assembly of parallel thread fittings is critical for system performance and longevity. Key steps include thorough inspection, correct alignment, proper tightening, and effective sealing. By following the outlined procedures and maintaining regular inspections, you can ensure the reliability and efficiency of your fittings, preventing costly downtime and repairs. Follow this guide to achieve optimal results with your parallel thread fittings. Share this post with your peers and explore additional resources or contact us for further assistance.

FAQ

Parallel thread fittings are connectors used in hydraulic and pneumatic systems to join different components. They feature parallel threads, which maintain a consistent diameter and typically use a sealing washer or O-ring to ensure a leak-proof connection.

To prevent cross-threading, always start threading the components by hand to ensure smooth engagement. Use light pressure to guide the threads into place and avoid using excessive force, which can cause misalignment and damage.

The choice of thread sealant depends on the specific application and the type of fluid being used in the system. PTFE tape and liquid thread sealants are common options. Ensure you use a sealant that is compatible with your system’s materials and operating conditions.

After assembly, pressurize the system to its operating pressure and inspect the connections using soapy water or a leak detection fluid. Look for bubbles forming around the fittings, which indicate leaks. Address any leaks by reassembling the fittings with additional sealant if necessary.

Common tools needed for assembly include adjustable wrenches, thread sealant (PTFE tape or liquid), a torque wrench for precise tightening, and inspection tools such as a magnifying glass and thread gauges to check for thread integrity.

Replace your fittings if you notice signs of wear, damage, or deformation during routine inspections. Regularly check for leaks, corrosion, and thread wear. If the fittings are damaged or no longer provide a reliable seal, replace them with new, compatible components to maintain system integrity.