Camlock Fittings Specification: The Detailed Guide

Table of Contents

Introduction

Camlock couplings, also known as cam and groove couplings, are vital components in fluid handling systems, designed for quick and secure hose connections. These couplings play a crucial role in various industries by providing a reliable means to connect and disconnect hoses with minimal effort, ensuring efficient and safe fluid transfer. This guide aims to provide a comprehensive overview of camlock couplings, covering their technical specifications, various types, material options, and installation and maintenance best practices.

What Are Camlock Couplings?

Camlock couplings, also known as cam and groove couplings, are specialized connectors used to quickly and securely join hoses and pipes in various fluid transfer systems. These couplings are designed for ease of use, allowing for fast connections and disconnections without the need for tools. Their primary function is to provide a leak-proof connection between two hoses or a hose and a pipe, ensuring that fluids can be transferred efficiently and safely.

Definition and Functionality

Camlock couplings operate using a simple yet effective mechanism. The coupling consists of two main parts: the coupler (also known as the female part) and the adapter (the male part). The coupler features two cam arms that pivot open to accept the adapter. When the adapter is inserted into the coupler, the cam arms are pushed down, locking the adapter securely in place. This locking action creates a tight seal, preventing leaks and ensuring that the fluid flows smoothly through the connection. The design of camlock couplings allows for rapid connections and disconnections, making them ideal for applications where speed and efficiency are critical.

Key Components

Cam Arms: These are the levers on the coupler that are used to lock the adapter in place. When the cam arms are pulled down, they create a secure connection between the coupler and the adapter. The cam arms are typically made of durable materials to withstand repeated use and resist wear and tear.

Coupler: The coupler is the female part of the camlock coupling. It contains the cam arms and is designed to receive the adapter. The coupler’s internal design ensures a tight seal when the adapter is inserted and locked into place.

Adapter: The adapter is the male part of the camlock coupling. It is inserted into the coupler to form a connection. The adapter is designed to fit snugly within the coupler, and when the cam arms are engaged, it creates a secure and leak-proof seal.

Common Applications

Camlock couplings are used across a wide range of industries due to their versatility, reliability, and ease of use. Some of the most common industries where camlock couplings are utilized include:

Agriculture: In agriculture, camlock couplings are often used for irrigation systems, chemical transfer, and the handling of fertilizers and pesticides. Their ability to quickly connect and disconnect hoses makes them ideal for field use where efficiency is key.

Chemical Processing: The chemical industry relies on camlock couplings for the safe transfer of various chemicals. These couplings are compatible with a wide range of chemicals and can be made from materials that resist corrosion and chemical damage.

Oil and Gas: In the oil and gas industry, camlock couplings are used for the transfer of fuels, lubricants, and other hydrocarbons. Their durability and ability to handle high pressures and temperatures make them suitable for the demanding conditions of this industry.

Water Treatment: Camlock couplings are commonly used in water treatment facilities for connecting hoses and pipes that transport water and other fluids. Their quick-connect design allows for efficient maintenance and system adjustments.

Typical Fluids Handled

Camlock couplings are capable of handling a variety of fluids, making them a versatile choice for many applications. Some of the typical fluids that are commonly transferred through camlock couplings include:

Water: Whether in agriculture, construction, or water treatment, camlock couplings are frequently used to transfer water due to their reliability and ease of use.

Chemicals: Camlock couplings made from materials like stainless steel or polypropylene are often used in chemical processing to handle corrosive and hazardous fluids safely.

Fuels: In the oil and gas industry, camlock couplings are used to transfer fuels such as gasoline, diesel, and kerosene, where a secure and leak-proof connection is essential.

Types of Camlock Couplings

Camlock couplings come in various types, each designed for specific applications and configurations. Understanding these types is crucial for selecting the right coupling for your needs. Below is a detailed overview of the standard types, special variants, and a comparison of their advantages and disadvantages.

Standard Types

Type A

Description: Type A camlock couplings have a male adapter and a female threaded end. They are typically used to connect hoses to female threaded pipes or equipment.

Applications: Commonly used in applications where a secure threaded connection is required, such as connecting hoses to pumps or valves.

Type B

Description: Type B couplings feature a female coupler and a male threaded end. They are often used to connect hoses to male-threaded pipes or equipment.

Applications: Ideal for situations where hoses need to be attached to equipment with a male thread, such as in chemical processing or water transfer systems.

Type C

Description: Type C couplings have a female coupler and a hose shank. They are used to connect hoses with a camlock coupling at one end and a plain hose at the other.

Applications: Common in agriculture and water treatment, where quick hose connections are needed.

Type D

Description: Type D couplings consist of a female coupler with a female threaded end. They are used to connect male-threaded pipes or equipment to hoses.

Applications: Frequently used in chemical processing and oil and gas industries, where secure connections to threaded equipment are necessary.

Type E

Description: Type E camlock couplings have a male adapter with a hose shank. They are used to connect hoses to a female coupler.

Applications: Often found in applications requiring quick connections between hoses, such as in the transport of liquids.

Type F

Description: Type F couplings feature a male adapter with a male threaded end. They are used to connect hoses to female threaded pipes or equipment.

Applications: Suitable for environments where a hose needs to be connected to female-threaded equipment, like pumps or tanks.

Special Variants

Dust Caps and Dust Plugs

Overview: Dust caps (Type DC) and dust plugs (Type DP) are designed to protect camlock couplings when not in use. They prevent dirt, dust, and debris from entering the coupling, which could compromise the seal and cause leaks.

Specific Uses: These components are especially useful in environments with high cleanliness requirements or in outdoor applications where the couplings are exposed to harsh conditions.

High-Pressure Variants and Materials

Overview: For applications that involve extreme conditions, such as high pressures or temperatures, special camlock couplings are available. These variants are made from materials like stainless steel or brass, which offer enhanced durability and resistance to corrosion.

Specific Uses: High-pressure camlock couplings are commonly used in the oil and gas industry, chemical processing, and any application where standard couplings might fail due to high stress.

Type | Advantages | Disadvantages | Best Use Cases |

Type | Secure threaded connection; | Requires precise matching | Connecting hoses to |

Type | Versatile;easy to use | Limited to applications with | Attaching hoses to |

Type C | Quick connection to plain hoses | Requires hose clamps for secure fit | Agricultural and water treatment applications |

Type | Secure connection to male | Requires precise matching | Chemical processing,oil and |

Type E | Quick hose connection; versatile | Requires hose clamps for secure fit | Liquid transport,industrial applications |

Type F | Simple connection to female threads | Requires precise matching with female thread | Connecting hoses to female- threaded equipment |

Type DC | Protects against | Only for non-operational | Food processing,outdoor |

Type | Prevents dirt and damage | Only for non-operational | Hygiene-critical industries, |

Material Specifications

Choosing the right material for camlock couplings is critical for ensuring their performance, durability, and safety in various applications. Below is a detailed overview of the common materials used in camlock couplings, the selection criteria for these materials, and the importance of gasket materials in sealing performance.

Aluminum

Overview: Aluminum is one of the most widely used materials for camlock couplings due to its lightweight nature and good corrosion resistance.

Material Properties: Aluminum is resistant to corrosion, especially from water and certain chemicals. It has a moderate strength-to-weight ratio, making it suitable for applications where weight is a concern.

Compatibility: Aluminum camlock couplings are compatible with water, oils, and some chemicals, but they may not be suitable for highly acidic or alkaline fluids.

Stainless Steel

Overview: Stainless steel is known for its superior strength and resistance to corrosion, making it a preferred material in harsh environments.

Material Properties: Stainless steel offers excellent resistance to corrosion from a wide range of chemicals, as well as high temperatures. It is also highly durable and capable of withstanding high pressure.

Compatibility: Stainless steel camlock couplings are ideal for use with corrosive chemicals, oils, steam, and food-grade applications.

Brass

Overview: Brass is valued for its good corrosion resistance, machinability, and antimicrobial properties.

Material Properties: Brass has good corrosion resistance, especially in water-based applications. It is also relatively easy to machine, making it suitable for precision parts.

Compatibility: Brass camlock couplings are commonly used in applications involving water, petroleum products, and mild chemicals. However, brass is not recommended for use with ammonia or certain acids.

Polypropylene

Overview: Polypropylene is a lightweight, cost-effective plastic material that is resistant to many chemicals.

Material Properties: Polypropylene is resistant to many acids, bases, and solvents, but it has lower mechanical strength compared to metal couplings. It is also not suitable for high-temperature applications.

Compatibility: Polypropylene camlock couplings are typically used in agricultural applications, chemical processing, and low-pressure fluid handling systems.

Nylon

Overview: Nylon is another plastic material used for camlock couplings, offering higher strength than polypropylene.

Material Properties: Nylon has good mechanical strength, chemical resistance, and impact resistance. However, it can absorb moisture, which may affect its dimensions and performance.

Compatibility: Nylon camlock couplings are suitable for a wide range of chemicals, oils, and fuels, particularly in situations where lightweight and durable materials are needed.

Gasket Materials

Buna-N (Nitrile Rubber): Buna-N is a common gasket material known for its excellent resistance to petroleum-based fluids, oils, and some chemicals. It has good mechanical properties but limited temperature resistance.

EPDM (Ethylene Propylene Diene Monomer): EPDM offers excellent resistance to water, steam, and certain chemicals, especially in outdoor environments. It has a broad temperature range but is not suitable for petroleum-based products.

PTFE (Polytetrafluoroethylene): PTFE, also known as Teflon, is highly resistant to almost all chemicals and can withstand extreme temperatures. It provides excellent sealing performance, especially in aggressive chemical environments.

Sizing and Dimensions

Standard Sizes

Camlock couplings come in a range of standard sizes to accommodate various hose and pipe diameters. The most common sizes range from 1/2 inch to 6 inches, with each size corresponding to the internal diameter (ID) of the hose or pipe the coupling will connect to.

1/2″ and 3/4″: Often used in small-scale applications such as laboratories or small equipment connections.

1″ to 3″: Common in agriculture, chemical processing, and light industrial applications.

4″ and 6″: Typically used in larger industrial applications, such as oil and gas, where large volumes of fluid need to be transferred quickly.

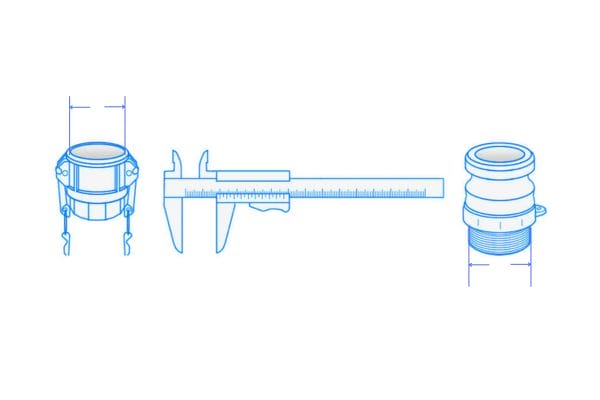

How to Measure Camlock Couplings Correctly

To ensure a proper fit, it’s important to measure camlock couplings accurately. Here’s a step-by-step guide:

Determine the Size: Measure the internal diameter (ID) of the hose or pipe that will connect to the camlock coupling. The coupling size should match this measurement.

Measure the Coupler and Adapter: The coupler’s internal diameter and the adapter’s external diameter should align with the hose or pipe size. Ensure that the cam arms fit securely around the adapter when locked.

Check Thread Size (if applicable): For couplings with threaded ends, measure the thread size using a thread gauge to ensure compatibility with the connecting equipment.

Verify Overall Length: Measure the total length of the coupling assembly to ensure it fits within the available space.

Interchangeability Across Sizes

Ensuring Compatibility

Camlock couplings are designed to be interchangeable across manufacturers, provided they conform to recognized standards. Standardization ensures that a camlock coupling from one manufacturer will fit and function correctly with a coupling from another manufacturer. To ensure compatibility:

Adhere to Standards: Use camlock couplings that comply with international standards such as ISO 7241, MIL-C-27487, or EN 14420-7. These standards define the dimensions and tolerances required for interchangeability.

Cross-Check Manufacturer Specifications: Verify that the couplings you are using match the specifications provided by the manufacturer, especially when mixing products from different sources.

Dimensional Tolerances

Importance of Precise Dimensions

Precise dimensions are critical for ensuring a leak-free connection. Even slight deviations from the standard dimensions can result in poor sealing, leading to leaks or coupling failure. Accurate dimensions also ensure that the cam arms lock securely, preventing accidental disconnection.

How Tolerances Are Maintained

Manufacturing Precision: High-quality camlock couplings are manufactured using precision machining processes that ensure tight dimensional tolerances. Computer Numerical Control (CNC) machining and quality control measures like coordinate measuring machines (CMM) help maintain these tolerances.

Quality Control: Regular inspections and adherence to quality management systems (e.g., ISO 9001) ensure that each coupling meets the required dimensional standards. This helps prevent issues related to misalignment or improper sealing.

Pressure and Temperature Ratings

Understanding Pressure Ratings

Pressure ratings for camlock couplings vary depending on the material and size of the coupling. These ratings indicate the maximum pressure the coupling can safely handle without failure.

Material Impact: Different materials have varying pressure ratings. For example, stainless steel camlock couplings typically have higher pressure ratings than polypropylene couplings due to the material’s strength.

Size Impact: Larger couplings generally have lower pressure ratings because the increased surface area can result in higher forces being exerted on the coupling.

Factors Affecting Pressure Ratings

Temperature: Higher temperatures can reduce the pressure rating of a coupling as materials tend to weaken when exposed to heat. For instance, a stainless steel coupling rated for 250 PSI at 70°F might only be rated for 200 PSI at 150°F.

Fluid Type: The type of fluid being transferred can also affect pressure ratings. Fluids with higher viscosities or those that are corrosive may require couplings with higher pressure ratings or those made from more resistant materials.

Temperature Limitations

Operating Temperature Ranges

Each material used in camlock couplings has a specific operating temperature range:

Stainless Steel: -150°F to 500°F

Brass: -50°F to 400°F

Aluminum: -50°F to 225°F

Polypropylene: 0°F to 150°F

Nylon: -20°F to 200°F

Impact on Material Selection and Performance

High-Temperature Applications: For applications involving steam or hot fluids, stainless steel or brass is preferred due to their high-temperature tolerance.

Low-Temperature Applications: For cold environments, materials like stainless steel and nylon are often used due to their durability and resistance to brittleness at low temperatures.

Testing and Certification

Standards and Testing Protocols

Camlock couplings must meet various industry standards to ensure their reliability under pressure and temperature conditions. Common standards include:

ISO 7241: Specifies performance requirements for hydraulic fluid power quick-action couplings.

MIL-C-27487: Military standard for camlock couplings, ensuring they meet stringent durability and performance criteria.

Testing Procedures

Pressure Testing: Couplings are tested at their rated pressure to ensure they can handle the maximum specified load without leaking or failing.

Temperature Testing: Materials are subjected to temperature extremes to verify that they maintain their integrity and performance under varying thermal conditions.

Importance of Certifications

Certifications from recognized bodies (e.g., ISO, ANSI, MIL-spec) assure that the camlock couplings have been tested and meet the required safety and performance standards. These certifications are crucial for ensuring the safety and reliability of fluid handling systems, especially in regulated industries such as chemical processing, oil and gas, and pharmaceuticals.

Conclusion

For optimum performance and safety, consider consulting an expert or supplier when selecting a cam locking fitting. We can provide advice tailored to your specific needs and help you understand the various options available. In addition, you can learn more about resources or products related to cam lock couplings. Whether you’re upgrading an existing system or planning a new installation, having the right knowledge and support is key to achieving a reliable and efficient fluid-handling system.

FAQ

Camlock couplings are used for quickly connecting and disconnecting hoses and pipes in fluid transfer systems across various industries, such as agriculture, chemical processing, and oil and gas.

Camlock couplings are commonly made from materials like aluminum, stainless steel, brass, polypropylene, and nylon, each suited for different fluids and environmental conditions.

To select the correct size, match the internal diameter (ID) of the camlock coupling to the hose or pipe it will connect to. Sizes typically range from 1/2 inch to 6 inches.

Yes, but the pressure and temperature ratings depend on the material of the coupling. For high-pressure or high-temperature applications, materials like stainless steel or brass are recommended.

Yes, camlock couplings that comply with industry standards (like ISO 7241 or MIL-C-27487) are generally interchangeable between different manufacturers.

Regularly inspect camlock couplings for wear and tear, clean them, and replace components like gaskets and cam arms as needed to ensure they remain leak-free and reliable.