Why does the material matter so much? Well, different materials offer distinct advantages, such as corrosion resistance, durability, and compatibility with certain fluids and environments. For example, brass is a solid choice for water systems, while bronze excels in high-temperature conditions. With that in mind, we’ll explore the specific differences between bronze and brass ball valves next, giving you the insight needed to choose the best material for your application.

What Are Bronze Ball Valves?

Bronze ball valves are a type of valve made primarily from an alloy of copper, tin, and other elements like phosphorus, aluminum, and silicon. Known for their robustness and reliability, these valves are frequently used in industrial, commercial, and residential systems where durability and corrosion resistance are critical.

Unlike other valves, which may be made from a single material, bronze ball valves offer a perfect blend of strength, corrosion resistance, and wear resistance, making them a go-to option for many demanding applications. Whether it’s controlling water flow in a plumbing system or regulating gas in an industrial plant, bronze ball valves provide the reliability and performance that many systems require.

Composition and Properties of Bronze

Bronze is an alloy composed primarily of copper and tin, with varying amounts of other metals added to enhance specific properties. The exact composition of bronze can vary, but typical ratios include around 88% copper and 12% tin. Other elements such as phosphorus, aluminum, and silicon may also be included to improve its performance in certain environments.

Key Properties of Bronze Include:

Corrosion Resistance: Bronze is highly resistant to corrosion, especially in marine or freshwater environments. It is resistant to rust and oxidation, which makes it ideal for use in water systems or outdoor applications.

Strength and Durability: Bronze offers excellent tensile strength and hardness. It’s highly resistant to wear and tear, meaning that bronze ball valves can withstand rough handling and extreme conditions.

Thermal Conductivity: Bronze has a good level of thermal conductivity, making it suitable for high-temperature environments where metal parts may be exposed to heat.

Malleability: Compared to other metals like cast iron, bronze is more malleable, making it easier to form into precise shapes, which is important for creating tight seals in ball valves.

Resistance to Fatigue: Bronze has excellent resistance to fatigue under cyclic stresses, which means it can handle frequent operation without weakening or failing over time.

Common Applications of Bronze Ball Valves

Bronze ball valves are widely used in various industries due to their strength, corrosion resistance, and reliability. Some of the most common applications include:

Plumbing Systems: Bronze ball valves are frequently used in residential and commercial plumbing systems for controlling the flow of water. Their corrosion resistance makes them an excellent choice for systems that handle drinking water or household fluids.

Marine and Offshore Applications: In marine environments, where exposure to saltwater is a concern, bronze ball valves are essential for controlling water flow in shipboard systems, docks, and other marine equipment. Their ability to resist corrosion in saltwater makes them ideal for these demanding conditions.

Industrial Systems: In manufacturing plants, chemical processing, and power plants, bronze ball valves are used to control the flow of a variety of fluids, gases, and chemicals. Their durability and resistance to corrosion make them a go-to choice in environments where harsh chemicals or high temperatures are involved.

HVAC Systems: For heating, ventilation, and air conditioning (HVAC) systems, bronze ball valves are used to regulate the flow of fluids in boilers, cooling towers, and other critical components of these systems. Their reliability and ease of maintenance ensure optimal performance in these often complex systems.

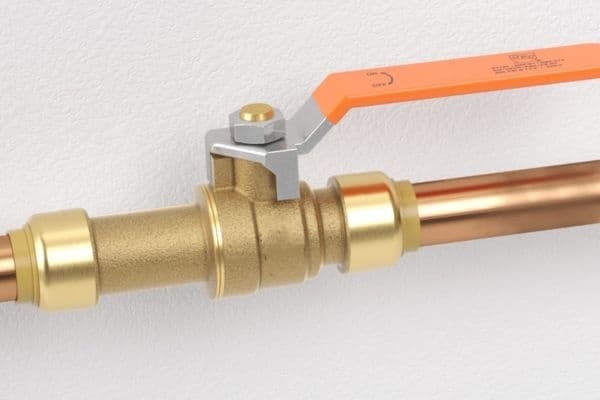

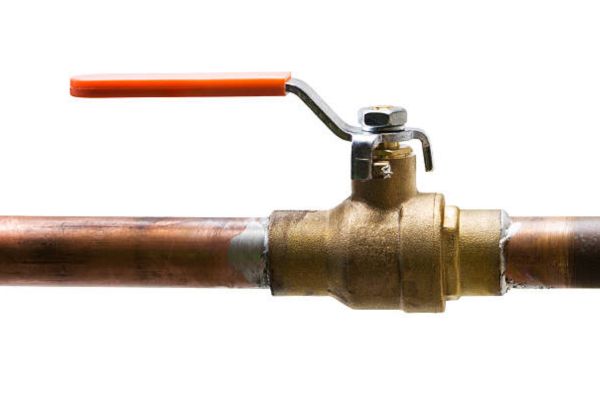

What Are Brass Ball Valves?

Brass ball valves are valves made from a copper-zinc alloy known as brass. This alloy is commonly used for its combination of strength, corrosion resistance, and excellent machinability. Brass ball valves are widely used in both residential and industrial applications where reliable flow control is necessary. Much like bronze ball valves, they are designed to control the flow of fluids through pipes but tend to offer different benefits depending on the application, environment, and specific needs of the system.

The material composition and the resulting properties of brass make it ideal for a variety of applications, offering a reliable and cost-effective solution in many systems. Brass is often favored for its affordability compared to other metals like bronze or stainless steel.

Composition and Properties of Brass

Brass is an alloy primarily made from copper and zinc, with varying amounts of other elements like lead, tin, or iron, depending on the intended application. Brass compositions typically contain 60% to 90% copper, with the remainder being zinc and small amounts of other metals that enhance specific properties.

Key Properties of Brass Include:

Corrosion Resistance: Brass has a natural resistance to corrosion, particularly in environments that involve water or humid conditions. While not as resistant to corrosion as bronze in certain extreme environments, brass offers solid protection against rust, making it suitable for many plumbing and water systems.

Strength and Durability: While brass is not as hard as bronze, it still provides excellent strength, which makes it a good option for controlling high-pressure flows. Brass ball valves are durable enough to last in most residential and commercial applications.

Malleability and Machinability: Brass is a highly malleable and ductile material, which means it can be easily shaped, machined, or cast into precise valve components. This makes brass a cost-effective material for creating high-quality ball valves.

Thermal Conductivity: Brass has a moderate level of thermal conductivity, which allows it to perform well in moderate temperature conditions. While not as heat-resistant as bronze, it can still handle standard operating conditions in most applications.

Low Friction: Brass exhibits low friction, which is particularly beneficial in ball valve operation, ensuring smooth movement of the ball and providing reliable sealing performance over time.

Common Applications of Brass Ball Valves

Brass ball valves are used in a wide range of applications due to their durability, cost-effectiveness, and ease of use. Some of the most common uses of brass ball valves include:

Residential Plumbing Systems: Brass ball valves are widely used in plumbing systems to control the flow of water in household pipes, faucets, and fixtures. Their low cost and corrosion resistance make them an excellent choice for residential applications where moderate pressure is present.

Natural Gas and Propane Systems: Brass ball valves are frequently employed in residential and commercial natural gas systems. Their ability to resist corrosion from natural gas makes them ideal for controlling the flow of gas into appliances and heating systems.

HVAC Systems: Brass ball valves are commonly used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of water or refrigerants. The material’s resistance to corrosion and ease of installation make it a good fit for these systems, where precision and long-term reliability are essential.

Irrigation Systems: Brass ball valves are often used in agricultural irrigation systems due to their ability to control water flow efficiently. Their resistance to corrosion from water and ability to handle medium pressures make them well-suited for these systems.

Corrosion Resistance: Which Material Wins the Battle?

When choosing the right material for ball valves, corrosion resistance is one of the most important factors to consider. Both bronze and brass have their strengths when it comes to resisting corrosion, but each material performs differently depending on the specific environment or substance they come into contact with. Both bronze and brass are alloys that offer corrosion resistance, but their performance can vary significantly when exposed to certain chemicals or environmental factors. Let’s take a closer look at how each material responds to common substances.

Bronze: Corrosion Resistance in Aggressive Environments

Saltwater & Marine Environments: Bronze is highly resistant to corrosion from saltwater, making it ideal for use in marine or coastal environments. It resists oxidation and corrosion from saltwater exposure far better than most other metals, which is why bronze is commonly used in shipbuilding, offshore platforms, and underwater pipelines.

Acidic and Alkaline Solutions: Bronze performs well in mild to moderately acidic or alkaline solutions. However, in highly acidic environments, bronze may start to corrode due to the degradation of copper. This is less of an issue in neutral pH solutions, such as water systems.

Oxidation and Patina: Over time, bronze develops a patina (greenish layer) when exposed to air and moisture. While this is a sign of oxidation, it actually acts as a protective barrier, preventing further corrosion. This makes bronze especially durable in outdoor and industrial settings.

Brass: Corrosion Resistance in Various Chemical Environments

Water Systems: Brass has strong corrosion resistance in freshwater systems, but it is more vulnerable than bronze in salty or chlorinated water. Brass can suffer from dezincification—a process in which zinc is leached out of the alloy, leaving behind porous copper, which weakens the material.

Acidic & Alkaline Conditions: Brass is more sensitive to highly acidic or alkaline solutions, especially when the solution contains chlorides or sulfur. It can suffer from stress corrosion cracking, which can cause leaks and failures under certain conditions.

Sulfuric and Hydrochloric Acid: Brass is highly susceptible to corrosion when exposed to sulfuric acid or hydrochloric acid, leading to accelerated degradation. This limits its use in chemical processing industries where such acids are present.

Valve Performance: Which Material Handles High-Pressure and Extreme Temperatures?

When selecting a ball valve for any application, especially in industries dealing with high-pressure or extreme-temperature environments, performance becomes a critical factor. Both bronze and brass offer solid performance, but their ability to handle intense conditions varies depending on the material’s inherent properties.

Comparing Strength and Sturdiness

Strength and sturdiness are key factors that influence the performance of a ball valve in high-pressure systems. Both bronze and brass are durable materials, but their physical properties differ in a way that impacts their ability to withstand pressure and maintain integrity over time.

Bronze: Superior Strength in Heavy-Duty Applications

High Tensile Strength: Bronze typically has a higher tensile strength than brass, which means it can withstand greater forces before deforming. This makes bronze the preferred material for high-pressure systems that require consistent and reliable performance under stress.

Resistance to Fatigue: Bronze excels in resisting fatigue under repeated cycles of pressure, which makes it ideal for heavy-duty industrial applications where valves may need to operate under pressure for extended periods.

Impact Resistance: Bronze is also more resistant to impact stress compared to brass, which is important in environments where the valve may experience sudden surges of pressure or mechanical shocks.

Brass: Adequate for Moderate Pressure, but Limited Under Extreme Stress

Moderate Tensile Strength: While brass is durable and has good strength, it generally falls short when compared to bronze in high-pressure systems. Brass is typically used in applications that do not exceed moderate pressure limits.

More Prone to Deformation: In high-stress environments, brass is more likely to deform under heavy loads or extreme forces. For example, brass valves can experience creep deformation in sustained high-pressure conditions.

Lower Fatigue Resistance: Brass is more susceptible to material fatigue over time in high-pressure systems, especially if subjected to constant cycles of stress.

Brass vs Bronze for High-Pressure Systems

High-pressure systems are prevalent in industries like oil and gas, water treatment, chemical processing, and steam distribution. These systems require valves that can reliably control the flow of fluids without failing under intense pressure.

Bronze in High-Pressure Systems

Preferred for Industrial Applications: Bronze is the preferred material for ball valves in high-pressure industrial systems, including those in power plants, steam boilers, and heavy machinery. Its superior strength, impact resistance, and ability to resist deformation make it ideal for these high-demand environments.

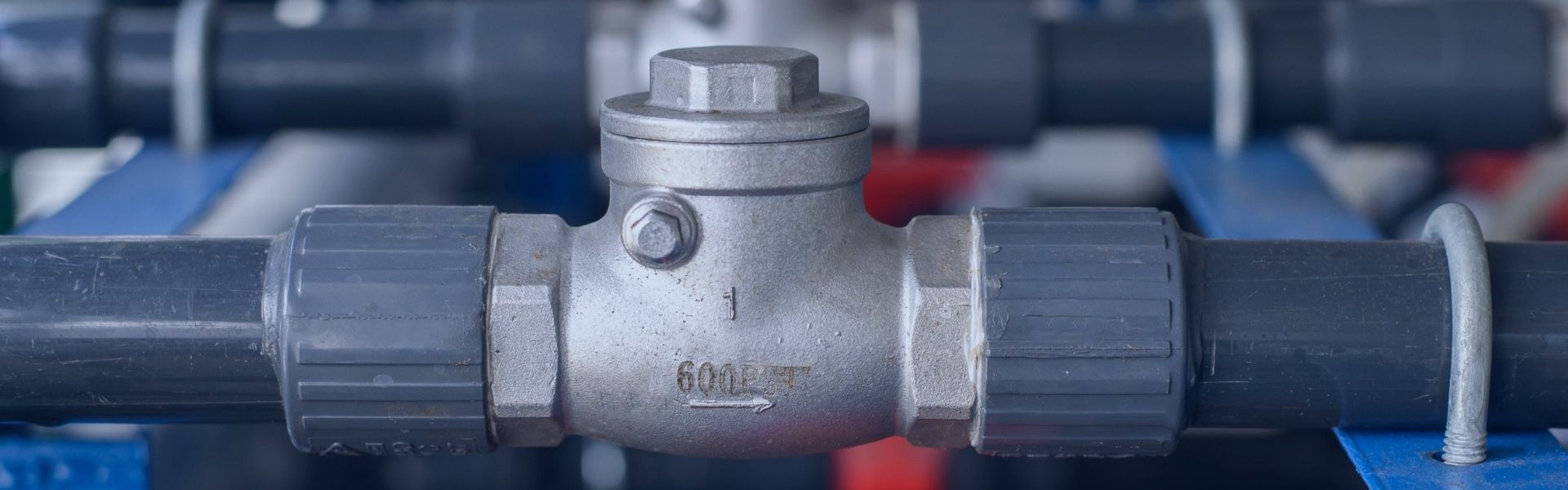

Valve Performance under Pressure: In high-pressure systems, bronze ball valves can handle pressures up to 600 PSI and beyond, depending on the specific grade of bronze used. This makes bronze particularly effective in applications that deal with fluids like steam, oils, and high-viscosity liquids.

Long-Term Reliability: Bronze ball valves are less likely to leak or fail under high-pressure conditions, ensuring consistent operation and reducing downtime in industrial settings.

Brass in High-Pressure Systems

Limited High-Pressure Performance: Brass is typically used for low to medium pressure systems. While it performs well in systems with pressures up to 300-400 PSI, brass is not suitable for high-pressure environments due to its comparatively lower strength and risk of deformation.

Risk of Stress Cracking: In high-pressure applications, brass ball valves can be prone to stress corrosion cracking (SCC), especially in environments where the valve is exposed to chemicals or high-temperature fluctuations. This limits its use in more demanding industries where valves need to endure extreme pressure for extended periods.

Performance in Extreme Temperature Environments

In many industries, ball valves are exposed to extreme temperature ranges, whether in hot water systems, steam boilers, cryogenic tanks, or industrial furnaces. The ability of a valve to maintain its performance under such conditions is crucial for the safety and efficiency of the system.

Bronze in Extreme Temperature Environments

High-Temperature Resistance: Bronze excels in high-temperature environments, especially in systems where temperatures exceed 300°F (150°C). This makes it suitable for steam systems, heating systems, and applications involving hot gases or liquids. Bronze ball valves can typically withstand temperatures as high as 400°F to 600°F (200°C to 315°C), depending on the specific grade of bronze used.

Low-Temperature Performance: Bronze also performs well at low temperatures, maintaining its structural integrity even in cryogenic environments. However, its performance in freezing conditions is not as strong as some other materials, like stainless steel, which is better for ultra-low temperatures.

Thermal Expansion: Bronze has a low coefficient of thermal expansion, which means it is less likely to warp or deform when subjected to rapid temperature fluctuations.

Brass in Extreme Temperature Environments

Moderate Temperature Range: Brass, on the other hand, can handle moderate to high temperatures but starts to lose its structural integrity when temperatures exceed 200°F (93°C) to 300°F (150°C). In applications where temperature changes are significant or where the system operates under high-heat conditions, brass may soften and deform, leading to potential leaks or valve failure.

Temperature Sensitivity: Brass is more sensitive to thermal cycling than bronze. Repeated exposure to high temperatures can cause brass to become brittle or develop cracks, particularly when it is under pressure or subjected to mechanical stress.

Poor Low-Temperature Performance: Brass is not recommended for applications where extremely low temperatures are involved, as it tends to become brittle and prone to cracking when exposed to freezing conditions.

Conclusion

Bronze is the better choice for demanding conditions, while brass offers a budget-friendly solution for less intense applications. By evaluating the specific needs of your project—whether it’s the type of fluid, pressure requirements, or system longevity—you can select the material that ensures optimal performance and cost-efficiency.

FAQ

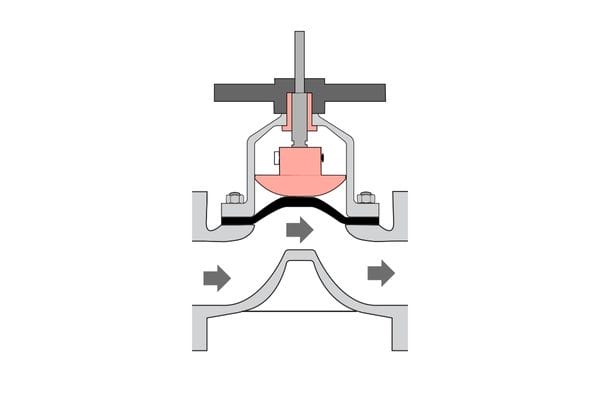

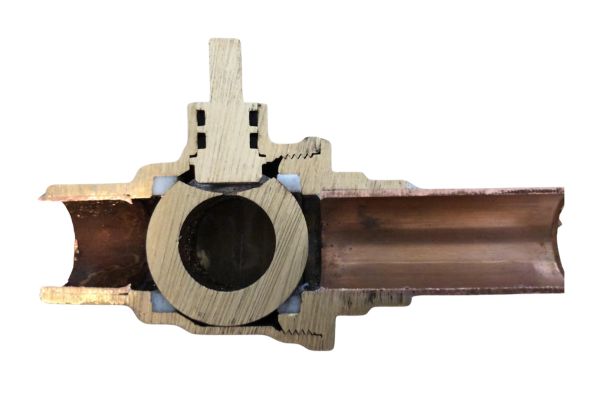

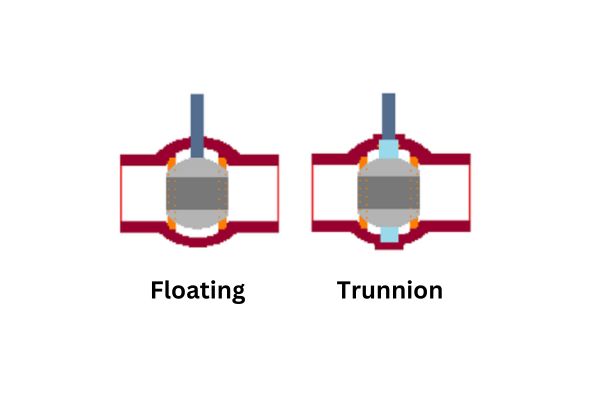

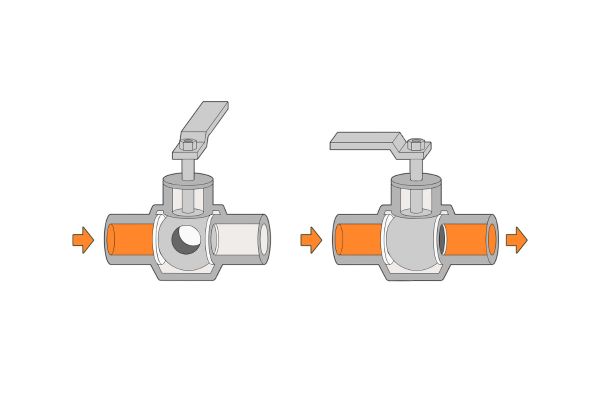

What is a ball valve?

A ball valve is a valve that controls the flow of a fluid or gas through a pipe using a spherical ball with a hole in the center. When the valve is open, the hole aligns with the pipe, allowing fluid to pass through. When closed, the hole is not aligned, stopping the flow.

What is the difference between bronze and brass ball valves?

Bronze is stronger and more corrosion-resistant than brass, making it ideal for high-pressure, high-temperature, and chemically aggressive environments. Brass is more cost-effective and commonly used in moderate-pressure applications like residential plumbing.

Which material is better for plumbing systems: bronze or brass?

Brass is often the better choice for residential plumbing because it is affordable, easy to work with, and performs well under moderate pressure. However, for systems exposed to harsher conditions or chemicals, bronze may be a more durable and corrosion-resistant option.

Can ball valves be used in high-temperature systems?

Yes, ball valves made from bronze are particularly well-suited for high-temperature applications. Bronze can withstand elevated temperatures better than brass, making it ideal for industrial systems dealing with steam, hot water, or oils.

How do I know which material to choose for my ball valve?

The choice depends on factors like the system’s pressure, temperature, fluid type, and environmental conditions. Brass is cost-effective for low-pressure systems, while bronze is a better option for high-pressure or chemically aggressive environments.

Are bronze ball valves more expensive than brass?

Yes, bronze ball valves tend to be more expensive than brass ball valves due to their superior strength, durability, and corrosion resistance. However, in the long run, bronze can provide better value in harsh or high-pressure environments, as it may require less maintenance and last longer.