Incorrect storage can significantly shorten the life of hydraulic hoses. Exposure to extreme temperatures, humidity, or physical stress can weaken the hose material, leading to cracks, leaks, and eventual failure. By storing hoses correctly, you can extend their service life and reduce the need for costly replacements.

Understanding the Basics of Hydraulic Hose Storage

Proper hydraulic hose storage is essential to maintaining the integrity and performance of hoses over time. Without following correct storage guidelines, even the highest quality hoses can experience damage that may compromise their functionality.

What constitutes “proper” hydraulic hose storage?

Proper storage of hydraulic hoses involves ensuring they are kept in a clean, dry, and temperature-controlled environment. This means placing hoses in areas free from harsh chemicals, excessive heat, moisture, or UV exposure. Also, hoses should be stored to prevent deformation, kinking, or crushing. This can be achieved by coiling or hanging hoses using appropriate racks or reels, avoiding pressure on the hose material.

Key factors to consider for long-lasting hoses

Several factors play a crucial role in prolonging the lifespan of hydraulic hoses:

Temperature: Excessive heat or cold can cause hoses to weaken or become brittle. Keeping the storage temperature within a controlled range (ideally between -15°C and +40°C) is essential for maintaining hose flexibility and integrity.

Humidity: High humidity levels can encourage the growth of mold or lead to rusting of metal fittings. Keeping hoses in a low-humidity environment prevents corrosion and material degradation.

Physical Stress: Hoses should never be stacked under heavy loads or subjected to physical stress that could deform them. Proper storage methods, such as coiling or suspending hoses, ensure they retain their shape and functionality.

The importance of controlled storage environments

A controlled storage environment is key to maintaining the quality and durability of hydraulic hoses. Storing hoses in an area with stable temperatures and low humidity prevents the most common types of hose damage, such as cracking, drying out, or warping. Additionally, storing hoses away from direct sunlight, extreme weather conditions, or corrosive chemicals protects the hose material from degradation, ensuring it performs effectively when needed.

Ideal Temperature and Humidity Conditions for Storing Hydraulic Hoses

The environment in which hydraulic hoses are stored plays a significant role in their longevity and overall performance. Both temperature and humidity must be carefully controlled to ensure hoses remain in optimal condition and can withstand the pressures they are designed for.

Recommended temperature range for hose storage

The recommended temperature range for storing hydraulic hoses is typically between -15°C and +40°C (5°F to 104°F). Storing hoses within this range helps preserve the flexibility and material integrity of the hose, reducing the risk of cracking or brittleness.

Too hot: Excessive heat can cause the rubber or synthetic materials to soften, which can lead to deformation, swelling, or accelerated wear. Heat can also break down the inner layers of the hose, reducing its pressure capacity and shortening its lifespan.

Too cold: Low temperatures can cause hoses to become rigid and brittle, increasing the likelihood of cracks when they are bent or manipulated. In extremely cold environments, hoses may become stiff to the point of failure if handled improperly.

Maintaining a stable, moderate temperature prevents these issues and ensures that hydraulic hoses stay flexible and ready for use.

How humidity affects hose integrity and performance

Humidity is another critical factor in hose storage. Excess moisture can lead to several issues:

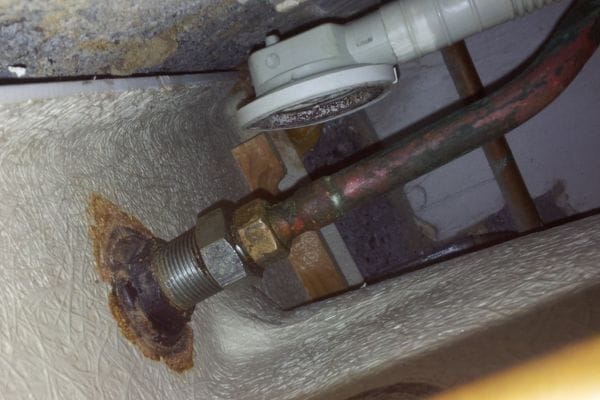

Corrosion: High humidity levels can promote rust or corrosion, particularly in metallic fittings or hose components. Even if the hose itself is not directly affected, corrosion on the metal parts can weaken the hose’s connection points, leading to leaks or failure.

Mold and mildew growth: Prolonged exposure to moisture can lead to the growth of mold or mildew on the outer surface of hoses, especially if the hoses are made from materials prone to absorbing water. This can compromise the hose’s structural integrity, reduce its flexibility, and cause contamination of the fluids being transported through the hose.

Accelerated degradation: Excess moisture can cause the rubber or synthetic materials in the hose to degrade faster, weakening the hose and reducing its lifespan.

To prevent these issues, it is essential to store hoses in a low-humidity environment, ideally below 80% relative humidity. This helps preserve the hose materials and ensures the fittings stay free of rust and corrosion.

Best practices for controlling environmental factors

Controlling the environment where hydraulic hoses are stored requires attention to both temperature and humidity. Here are some best practices:

Climate control: If possible, store hydraulic hoses in a climate-controlled space, such as a warehouse with air conditioning or heating. This ensures temperature consistency and protects the hoses from extreme fluctuations that could cause damage.

Ventilation: Ensure good airflow in the storage area. Proper ventilation helps control both temperature and humidity levels, preventing the buildup of moisture or stagnant air that could damage the hoses.

Humidity control: Use dehumidifiers or humidity-controlled storage units to keep moisture levels in check. For outdoor storage, ensure that hoses are kept in a dry, covered area to protect them from rain and humidity.

Thermal insulation: For areas with extreme temperature variations, consider using thermal insulation or climate-controlled covers for hose storage racks to maintain a stable temperature.

Proper Hose Coiling and Winding Techniques for Storage

Coiling and winding hydraulic hoses correctly is essential for preventing damage, maintaining their integrity, and ensuring their readiness for use when needed. Improper coiling can lead to kinks, twists, or pressure points that compromise the hose’s functionality.

How to coil hydraulic hoses without damaging them

Coiling hoses the right way is crucial to prevent damage during storage. Here’s how to do it properly:

Use a gentle, consistent coil: Avoid tight coils that can stress the hose material. Instead, coil the hose in a natural, loose curve that follows the hose’s natural bend. This reduces the risk of kinking or creating weak points that could lead to premature failure.

Avoid twisting the hose: When coiling, make sure not to twist or over-rotate the hose. Twists can cause internal damage to the hose’s structure and compromise its pressure integrity. Keep the hose as flat as possible while coiling.

Hand-coil rather than using mechanical tools: While automatic winding machines can help in some cases, hand-coiling is often the best method for hydraulic hoses. This allows for more control and minimizes the risk of tight spots or uneven coils that could damage the hose.

The proper coil size: Why diameter matters

The diameter of the coil is a critical factor when storing hydraulic hoses. Coiling the hose too tightly or with too small a radius can cause long-term damage. Here’s what you need to know:

Maintain a large enough coil diameter: Ideally, the diameter of the coil should be at least 15 times the inner diameter of the hose. For example, if your hose has an internal diameter of 25mm, the coil diameter should be no less than 375mm (15 x 25mm). This ensures that the hose maintains its natural flexibility and reduces the risk of kinks or pressure spots.

Why diameter matters: A smaller coil diameter can cause the hose to bend too sharply, leading to internal stress on the material. Over time, this can result in cracks or leaks. Large-diameter coils help maintain the hose’s flexibility and avoid permanent deformation.

Tips for preventing hose deformation and kinking

To ensure that hydraulic hoses remain in good condition and are easy to use, take steps to prevent common issues such as deformation and kinking:

Store coils off the ground: Always store hoses on a clean, flat surface or on racks that prevent them from being squashed or deformed under their own weight. Storing hoses off the ground also protects them from dust, moisture, and contaminants that could damage the material.

Avoid sharp bends: When coiling the hose, always aim for smooth, gradual curves. Sharp bends can cause the hose material to weaken at the bend points and lead to cracks or leaks over time.

Use hose supports or reels: For longer hoses, use hose reels or racks designed to keep the coil shape intact. Reels provide a controlled environment that helps prevent kinks or tangles, making it easier to deploy the hose when needed.

Avoid over-coiling: While storing hoses in coils is essential, be mindful of how long the hose has been stored in the same position. Over time, coiling the hose in the same position can create a permanent set, causing the hose to retain a bend or kink. Periodically rotate and uncoil hoses to prevent deformation.

Choosing the Right Storage Space for Your Hydraulic Hoses

Selecting the right storage space for your hydraulic hoses is crucial to ensuring their longevity and optimal performance. The right storage environment helps prevent damage, contamination, and environmental wear, which can affect hose quality and lifespan.

The importance of a clean, dry, and well-ventilated space

The condition of the storage space directly impacts the integrity of your hydraulic hoses. A clean, dry, and well-ventilated area is essential to prevent deterioration and ensure that hoses remain in optimal condition.

Cleanliness: A dirty storage area can expose hoses to dust, debris, and contaminants that may compromise the hose material or fittings. A clean space minimizes the risk of dirt or chemicals coming into contact with the hoses, reducing the chance of damage or failure.

Dry conditions: Moisture is one of the most significant contributors to hose deterioration. Excess moisture can cause rust on metal components, mold growth, and weakening of the hose material itself. Storing hoses in a dry environment helps prevent these issues.

Ventilation: Proper airflow is necessary to maintain a consistent temperature and humidity level in the storage space. Good ventilation reduces the risk of condensation, mold, or mildew buildup, and helps keep hoses dry and free of moisture.

Best locations for storing hoses: indoor vs. outdoor storage

Deciding where to store hydraulic hoses—whether indoors or outdoors—depends on several factors, such as the available space, environmental conditions, and the type of hoses being stored.

Indoor storage: Storing hydraulic hoses indoors is generally the best option. Indoor environments provide a more controlled atmosphere, where temperature and humidity can be regulated more effectively. It also offers protection from harsh weather, UV radiation, and airborne contaminants. Warehouses, storage rooms, or dedicated hose storage areas are ideal for keeping hoses protected.

Pros: Temperature control, low risk of moisture, protection from UV rays and chemicals, less physical wear.

Cons: Requires more space and may have limited room if the area is not adequately sized for your hose storage needs.

Outdoor storage: While outdoor storage may be more convenient or necessary in some cases, it comes with more risks. Hoses stored outdoors should be kept under shelter to protect them from rain, snow, or direct sunlight. Exposure to extreme temperatures or moisture can rapidly degrade hose material.

Best for: Large quantities of hoses that cannot fit indoors.

Protection: Use UV-resistant covers and tarps to shield hoses from sunlight and rain. Ensure the storage area is dry, and ideally elevated to prevent water pooling.

Protecting hoses from physical damage during storage

Physical damage is another common concern in hose storage. Proper handling and protective measures can prevent damage caused by crushing, kinking, or abrasion.

Use racks or reels: Storing hoses on racks or reels ensures they are not subject to crushing under their own weight or that of other materials. Racks and reels allow hoses to be stored in an organized manner, with minimal pressure on the hose material, and make it easier to coil or uncoil them when needed.

Avoid stacking heavy items on top of hoses: Hoses should never be stored under heavy equipment or materials, as this can deform the hose or damage fittings. If using racks, ensure that the hose is stored in a way that minimizes strain and avoids unnecessary weight.

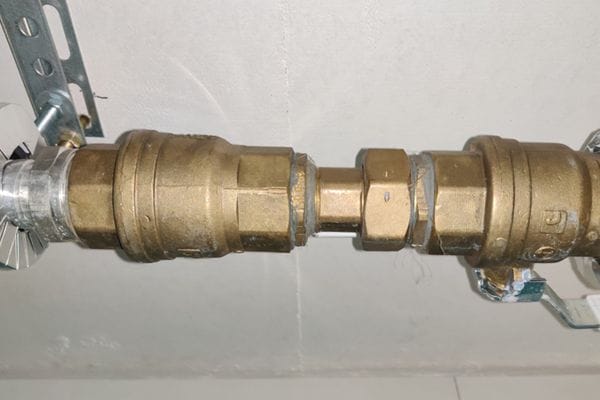

Protect the hose ends: The hose fittings should be protected from damage, especially if hoses are coiled or rolled up. Use caps or protective covers for the fittings to keep dirt, debris, and moisture out of the ends during storage.

Maintain clearance from walls or other structures: When storing hoses on the floor or in tight spaces, make sure there’s enough clearance around them to avoid accidental crushing or pinching. Hoses should not be pressed up against walls or shelves where they can be unintentionally damaged.

Best Practices for Storing Hydraulic Hoses in Harsh Environments

Storing hydraulic hoses in harsh environments—whether in extreme temperatures, outdoor settings, or locations with exposure to chemicals and moisture—requires special care. Harsh conditions can accelerate wear and tear on hoses, affecting their performance and safety.

Storing hoses in extreme temperatures or outdoor settings

Extreme temperatures can have a significant impact on the flexibility and durability of hydraulic hoses. Storing hoses in either very hot or very cold environments can cause them to degrade faster or lose their intended properties. Proper care is necessary to protect hoses from the harsh effects of temperature extremes.

Temperature considerations:

Cold temperatures: Hydraulic hoses can become brittle and stiff in cold environments, especially when temperatures drop below freezing. This makes the hose more prone to cracking and rupture when used.

Hot temperatures: Excessive heat can cause the hose material to soften, making it more susceptible to wear, swelling, or deformation. Prolonged exposure to heat can also damage the hose’s inner lining and compromise its ability to withstand high-pressure conditions.

Best practices for storing in extreme temperatures:

Temperature-controlled storage: Whenever possible, store hydraulic hoses in an area with regulated temperature conditions, ideally between -15°C and +40°C (5°F to 104°F). This prevents the hose material from becoming too rigid or too soft.

Outdoor storage protection: If hoses must be stored outdoors, use insulated covers or protective enclosures to shield them from extreme temperature fluctuations. For very cold areas, keep hoses off the ground to avoid frost buildup. For hot environments, consider storing hoses in shaded, ventilated areas to prevent overheating.

Use hose insulation: For outdoor or extreme temperature applications, use insulated hose covers to protect hoses from freezing or heat exposure. These covers help maintain a stable temperature for the hoses, preventing damage due to extreme environmental conditions.

Protecting hoses from industrial chemicals and corrosive substances

Industrial chemicals and corrosive substances pose a significant threat to hydraulic hoses, especially those exposed to harsh manufacturing or outdoor environments. Chemical exposure can lead to rapid degradation of the hose material, affecting its strength and safety.

Identifying harmful chemicals: Common industrial chemicals that may harm hydraulic hoses include solvents, oils, acids, and alkalis. These substances can cause the hose material to swell, crack, or break down, compromising the hose’s integrity.

Best practices for chemical protection:

Avoid contact with chemicals: Store hydraulic hoses in a location where they will not be exposed to industrial chemicals. This could include keeping hoses in dedicated storage rooms or on shelves where chemical spills or vapors won’t reach them.

Chemical-resistant coverings: When hoses must be used in environments where chemicals are present, consider using chemical-resistant sleeves or wraps to protect them. These protective layers provide an additional barrier to prevent direct contact with harsh substances.

Proper labeling and segregation: Ensure that hoses are clearly labeled for their intended use and are stored separately from incompatible materials. This prevents cross-contamination and ensures the right hose is used in the right environment.

Tips for storing hoses in high-humidity or freezing conditions

High humidity and freezing conditions can both affect hydraulic hoses in different ways. Humidity can lead to corrosion, mold, and mildew, while freezing conditions can cause the hoses to become brittle and more prone to cracking.

Storing in high-humidity environments:

Moisture control: Excess humidity can lead to rust on metallic parts and mold growth on the outer surface of the hose. Store hoses in a dry, well-ventilated space where humidity is kept below 80%.

Use dehumidifiers: In areas prone to high humidity, use dehumidifiers to help control moisture levels. Dehumidified storage areas are ideal for preventing mold and ensuring the hose material does not degrade from prolonged exposure to moisture.

Storing in freezing conditions:

Elevated storage: In freezing temperatures, store hoses off the ground to prevent water or snow from collecting around them. Water trapped in the hose can freeze, leading to cracks or ruptures when the hose is used.

Thermal protection: Use insulated covers to protect hoses from freezing temperatures. For very cold environments, store hoses in heated storage units or areas that maintain a stable temperature.

Pre-freeze inspection: Before using hydraulic hoses in freezing conditions, inspect them for brittleness or cracks. Ensure the hoses are flexible and in good condition to avoid sudden failure during operation.

Conclusion

Maintaining hydraulic hose quality starts with proper care and storage. Implementing the right storage practices now will help you avoid costly repairs and replacements later, while ensuring that your hoses remain functional, durable, and safe for use.

FAQ

What is the best temperature for storing hydraulic hoses?

The ideal storage temperature for hydraulic hoses is between -15°C to +40°C (5°F to 104°F). This range prevents the hoses from becoming too brittle in cold weather or soft and prone to wear in hot conditions.

Can hydraulic hoses be stored outdoors?

Yes, but outdoor storage requires extra protection. Hoses should be covered with UV-resistant tarps or stored under shelter to avoid exposure to the sun, rain, or extreme temperatures.

How should hydraulic hoses be coiled for storage?

Hydraulic hoses should be coiled loosely with a coil diameter at least 15 times the hose’s inner diameter to avoid kinks and deformation. Ensure the coil is not too tight or sharp.

Is humidity a concern for hydraulic hose storage?

Yes, high humidity can cause corrosion and mold. Store hoses in a dry, well-ventilated area to prevent moisture buildup that can damage the hose material.

Can I store hydraulic hoses in high-pressure environments?

Hydraulic hoses should be stored in low-pressure, relaxed conditions. High pressure during storage could lead to deformation or internal damage, affecting their performance.

How often should I rotate stored hydraulic hoses?

It’s recommended to rotate stored hoses at least once a quarter to prevent permanent deformations and ensure they are in good condition for use when needed.