Hydraulic hoses play a pivotal role in transmitting fluid power safely and efficiently. They are the lifelines of hydraulic systems, allowing machinery to perform demanding tasks such as lifting, moving, and pressing. The quality of hose fabrication directly impacts how well these hoses function and how long they last.

Understanding Hydraulic Hose Fabrication

What is Hose Fabrication?

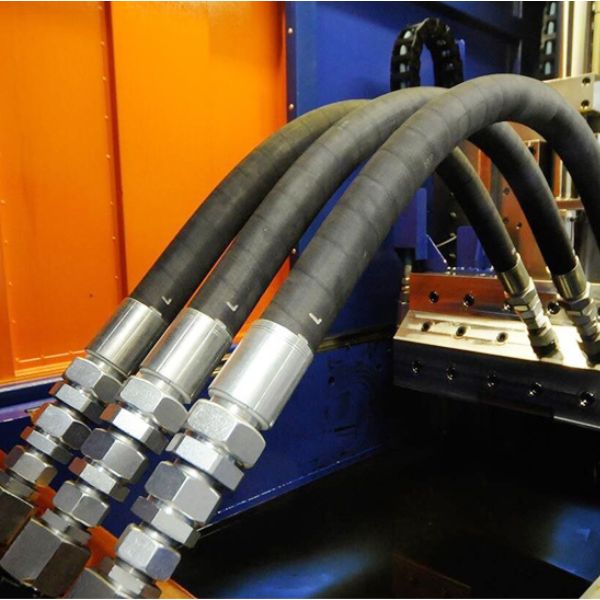

Hydraulic hose fabrication is the process of assembling and preparing hydraulic hoses to meet the specific needs of a hydraulic system. This process involves several critical stages, including cutting, assembling, fitting, and testing, each designed to ensure the hose is durable, leak-proof, and capable of handling the pressures and fluids that are part of hydraulic operations.

Cutting: The first step in hose fabrication is cutting the hose to the required length. Precision is key here, as a poorly cut hose can lead to weak points that could cause leaks or failure. The hose must be cut according to the exact specifications of the system for optimal performance.

Assembly: After cutting, the next step is the assembly of the hose with the necessary fittings and connectors. This can involve crimping or swaging (pressing) fittings onto the hose ends to form a secure, tight seal that prevents leaks.

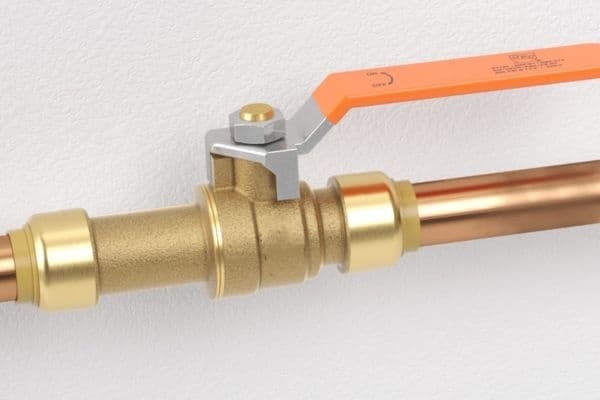

Fitting: Fittings are used to connect the hose to the rest of the hydraulic system. The process of fitting involves selecting and attaching the correct fittings, such as couplings, clamps, and adaptors, to ensure that the hose is securely connected to the system components. This process often includes tightening fittings to the proper torque specifications.

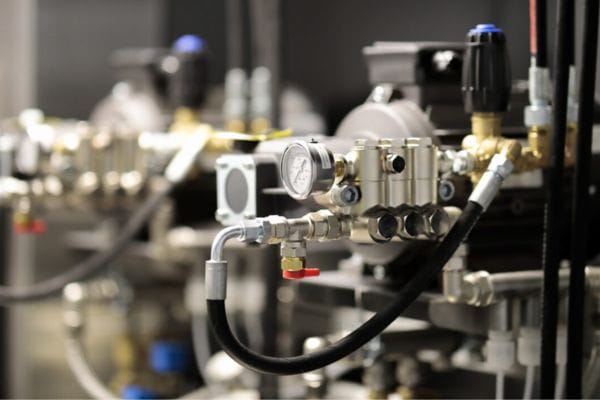

Testing: After assembly, hydraulic hoses must undergo rigorous testing to ensure they can handle the pressure and conditions they will face in operation. This often involves pressure testing, where the hose is subjected to high pressure to simulate real-world conditions. Leaks, weak spots, and potential failure points are identified during this phase.

The importance of selecting the right materials during fabrication cannot be overstated. Hoses are made from various materials, such as rubber, thermoplastic, or braided stainless steel, and the choice of material depends on the application’s demands. The right material ensures the hose will withstand pressure, temperature fluctuations, and environmental factors such as exposure to chemicals or UV rays. Fittings, ferrules, and other components must also be carefully selected for compatibility with the hose material and the specific system’s pressure and fluid type.

Why Hose Fabrication Matters

The process of hose fabrication plays a crucial role in maintaining system reliability and ensuring safe and efficient hydraulic operations. Properly fabricated hoses are designed to provide leak-proof connections and ensure that the system pressure remains stable throughout operation. A hose that is poorly fabricated can suffer from weak spots, which can lead to leaks, bursts, or even complete system failure.

Leak-Proof Connections: Hydraulic hoses carry fluid under high pressure, and any leak can cause loss of pressure, contamination, and unsafe operating conditions. A leak can quickly disrupt the operation of the hydraulic system, leading to increased downtime and expensive repairs. Proper fabrication ensures that all connections are tight, and no fluid escapes the system.

Maintaining System Pressure: In hydraulic systems, pressure is key to performance. If the hydraulic hoses are not correctly fabricated, the system may experience pressure loss, reducing efficiency and effectiveness. A properly fabricated hose assembly ensures that pressure is maintained consistently and safely.

Prevention of Failures and Inefficiencies: Poor fabrication can lead to various failures and inefficiencies in the system. For example, improperly crimped hoses may have weak connections that fail under pressure. Additionally, improper selection of materials or components may result in hoses that degrade prematurely, causing costly maintenance and potential safety hazards. Ensuring proper fabrication from the start eliminates the likelihood of these failures and minimizes downtime.

Key Components of a Hydraulic Hose Assembly

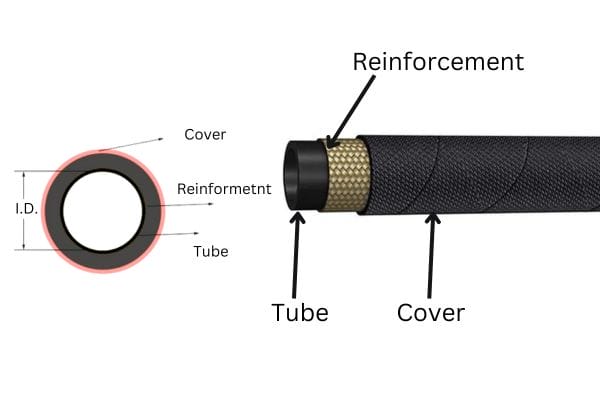

A hydraulic hose assembly is made up of several components, each contributing to the performance and safety of the system:

The Hose: The hose is the main component in a hydraulic assembly. It is responsible for carrying the fluid under pressure. The hose is usually made from a synthetic rubber or thermoplastic material, reinforced with layers of steel or braided fibers for added strength. The choice of hose material depends on the fluid type, temperature, and pressure in the system.

Fittings: Fittings are used to connect the hose to other system components. These can be swivel fittings, straight fittings, elbow fittings, or threaded connectors, and they ensure that the hose remains securely attached. Fittings come in various materials, including steel, brass, or aluminum, and are chosen based on the application’s specific requirements.

Ferrules: Ferrules are metal sleeves that are used to secure the hose to the fitting. When the fitting is crimped onto the hose, the ferrule provides additional compression, ensuring a tight and secure seal. Ferrules help prevent leaks and maintain the integrity of the assembly under pressure.

End Connections: These are the connectors that link the hose to the equipment or machinery. Depending on the system’s needs, end connections can include couplings, adapters, or flanges. These must be carefully chosen to ensure compatibility with the hose and system pressure.

The Role of Quality Materials in Fabrication

Choosing the Right Hose Material

One of the most critical aspects of hose fabrication is the selection of the right hose material. The material chosen must meet the specific demands of the hydraulic system, including pressure tolerance, flexibility, and resistance to wear chemicals and environmental factors. Several materials are commonly used for hydraulic hoses, each with unique characteristics that influence their performance in various applications.

Rubber: Rubber is one of the most widely used materials for hydraulic hoses. It is known for its flexibility, resilience, and ability to absorb shock. Rubber hoses are suitable for applications that require flexibility and resistance to weathering. However, they may be less resistant to certain chemicals or extreme temperatures. Specialized rubber formulations can be used to enhance these properties, making rubber hoses a versatile option in a range of industries.

Thermoplastic: Thermoplastic hoses are known for their lightweight nature and high chemical resistance. These hoses are often used in environments where flexibility, pressure resistance, and the need for a lighter hose are essential. Thermoplastic hoses are commonly used in industries like automotive, food processing, and pharmaceuticals. Their superior resistance to abrasion, oil, and fuel, combined with their ability to handle high pressure, makes them ideal for harsh environments.

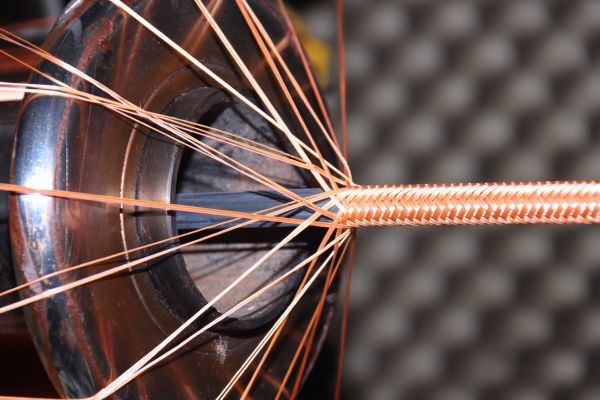

Metal Braided: Metal braided hoses are made from a rubber or thermoplastic core that is reinforced with a woven metal layer, usually made of stainless steel. These hoses are typically used in high-pressure applications and offer excellent abrasion resistance and burst strength. They are highly durable and resistant to wear, making them ideal for demanding applications like industrial machinery and heavy-duty equipment. Their metal braiding also provides additional protection against physical damage from external factors.

PTFE (Polytetrafluoroethylene): PTFE hoses are known for their high chemical resistance and ability to withstand extreme temperatures. These hoses are often used in industries where the fluid being transported may be highly corrosive or exposed to high heat. PTFE hoses offer exceptional performance when exposed to chemicals, acids, and extreme temperatures, making them ideal for the chemical, pharmaceutical, and food processing industries.

The selection of hose material impacts the durability, flexibility, and performance of the hose. For example, a hose that will be exposed to high temperatures or aggressive chemicals will need to be made from a material specifically designed to resist these conditions. Additionally, the flexibility of the material is important for applications where the hose will need to bend or move during operation, such as in robotics or manufacturing equipment.

Fitting Materials and Their Importance

While the hose material is crucial, the choice of materials for the fittings is just as important. Fittings are the connectors that join the hose to the other components of the hydraulic system. The material of the fittings can significantly affect the system’s overall integrity, longevity, and resistance to corrosion or damage.

Steel: Steel is one of the most common materials used for hydraulic fittings, thanks to its strength, durability, and resistance to high pressure. Steel fittings are often used in high-pressure systems where strength and reliability are crucial. However, steel is susceptible to corrosion if exposed to moisture or certain chemicals, which can compromise the integrity of the fitting over time.

Brass: Brass fittings are often used in systems that require excellent corrosion resistance and malleability. Brass is highly resistant to corrosion from water, salt, and a variety of fluids, making it ideal for use in systems exposed to harsh environments. While brass is generally not as strong as steel, it offers good performance in low to medium pressure systems and provides excellent resistance to chemical damage.

Stainless Steel: Stainless steel fittings offer superior corrosion resistance and are highly resistant to both high pressure and extreme temperatures. They are the preferred choice for applications in industries such as pharmaceuticals, food processing, and petrochemicals, where both cleanliness and strength are required. Stainless steel also offers excellent wear resistance, ensuring the longevity of the fitting even under the harshest conditions.

The choice of fitting material directly impacts the reliability of the hydraulic system. Corrosion or damage to the fittings can lead to leaks, reduced pressure, or even system failure. Fittings that corrode or weaken over time can result in costly maintenance, downtime, and, in the worst case, hazardous failures. Therefore, choosing the right fitting material that complements the hose material and system conditions is essential for ensuring the long-term reliability of the system.

The Impact of Quality Control on Fabrication

Ensuring material quality during hose fabrication is essential to prevent failures and extend the service life of the hoses. High-quality materials help to avoid weaknesses that could lead to cracks, leaks, or hose bursts under pressure. Poor-quality materials, or materials that are not suited for the specific conditions of the hydraulic system, can cause premature hose wear and lead to costly downtime or safety risks.

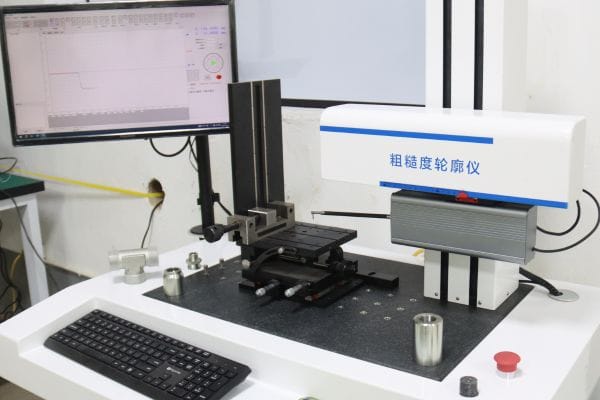

Material Testing and Inspection: Before being used in fabrication, raw materials must undergo rigorous testing and inspection to ensure they meet the required specifications. This includes testing for strength, flexibility, temperature resistance, and chemical compatibility. The material must also meet relevant industry standards and certifications to ensure it is fit for use in hydraulic systems.

Quality Standards and Certifications: There are several quality standards that guide the fabrication of hydraulic hoses, including ISO 9001, SAE (Society of Automotive Engineers) standards, and DIN (Deutsches Institut für Normung) certifications. These standards ensure that the materials used in hose fabrication are of the highest quality and can withstand the pressure and conditions required by the system. Additionally, quality certifications often require that the entire fabrication process, from material selection to testing, is performed according to specific guidelines to guarantee safety and reliability.

Testing the Finished Product: Once the hydraulic hose is fabricated, it undergoes further quality control through pressure testing, visual inspection, and functional tests. These checks ensure that the hose assembly meets the design specifications and can perform safely under working conditions. Quality control ensures that only hoses that meet or exceed industry standards are delivered to customers.

Key Fabrication Processes for System Reliability

Cutting and Preparing Hoses

The first crucial step in hose fabrication is cutting the hose to the correct length. Proper cutting is essential to avoid stress points that could weaken the hose and make it prone to failure during operation. A poorly cut hose can have jagged edges that may lead to early wear, leaks, or even hose rupture. Precision in cutting ensures that the hose will fit correctly into the system and that the connectors can be securely attached without any additional strain on the hose.

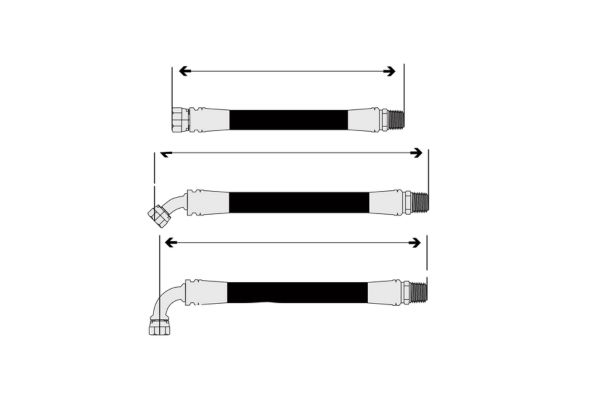

Correct Length: The length of the hose must be accurate because both too long or too short hoses can cause problems. If the hose is too long, it may introduce unnecessary slack, which can lead to friction and premature wear. If the hose is too short, it may put strain on the connections, causing leaks or premature failure. The length must accommodate the operational environment and system layout.

Techniques for Cutting: Hydraulic hoses are typically cut using rotary cutting tools or band saws, which provide clean, precise cuts. This helps avoid the creation of stress points at the ends of the hose. In some cases, laser cutting can be employed for extreme precision. After cutting, the ends of the hoses may be subject to further preparation to ensure they are ready for assembly.

Preparing Hose Ends: After the hose is cut, the ends must be prepared for fitting. This often involves deburring the edges of the hose to remove any roughness or burrs that may have formed during the cutting process. Cleaning is also necessary to remove any debris, dust, or oil residues that might affect the integrity of the fittings. This is typically done using solvents or specialized cleaning equipment, ensuring that the hose ends are free from contamination.

Proper cutting and preparation lay the foundation for strong, leak-proof hose assemblies and ensure that the hydraulic system performs efficiently without risk of failures.

Assembly of Hoses and Fittings

Once the hose has been cut and prepared, the next step is the assembly of the hose and its associated fittings. This process ensures that the hose is securely attached to other components of the hydraulic system and can safely handle the pressures and conditions of the system. There are several methods used for this assembly:

Crimping: One of the most common methods for attaching fittings to hoses is crimping, where a fitting is pressed tightly onto the hose using a crimping machine. The crimping process involves the use of crimp ferrules, which are metal sleeves that compress around the hose and fitting to create a tight, leak-proof connection. The use of crimping ensures that the hose and fitting are securely bonded, providing reliable performance under high pressure. The crimping process must be done accurately to ensure the right amount of compression and avoid damaging the hose or fitting.

Swaging: Similar to crimping, swaging involves the use of a hydraulic press to deform a ferrule or fitting around the hose. This method is commonly used for high-pressure systems and results in a tight, secure fit. Swaging is particularly useful for larger hoses or industrial applications where maximum strength is required. Like crimping, swaging requires careful precision to ensure the hose assembly meets the correct pressure and performance standards.

Push-On Fittings: For certain applications, push-on fittings can be used. These fittings simply slide onto the hose and are held in place by a tight friction fit. While they are typically used in low-pressure systems, push-on fittings offer a quick, easy, and efficient way to assemble hydraulic hoses. However, they may not provide the same level of pressure resistance as crimped or swaged fittings.

Reusable Fittings: In some instances, reusable fittings are used to allow for disassembly and reassembly of hose assemblies. These fittings are particularly beneficial in applications where the hoses need to be replaced frequently or reconfigured. Reusable fittings are designed to maintain their integrity over multiple uses, reducing costs and increasing system flexibility.

Pressure Testing and Quality Assurance

After the hose is assembled, it must undergo pressure testing to ensure it is capable of withstanding the operational demands of the hydraulic system. Pressure testing is essential for checking the structural integrity of the hose assembly and verifying that it can handle the expected pressure without leaks or failures.

Testing for Leaks: One of the primary objectives of pressure testing is to identify potential leaks. Leaks can lead to significant issues in hydraulic systems, including loss of pressure, contamination, and inefficiency. During pressure testing, the hose is subjected to a specific pressure value, often higher than its normal operating pressure, to identify any weak points where fluid may escape. If any leaks are found, the hose is rejected, and the issue is addressed before proceeding.

Simulating Real-World Conditions: Pressure testing simulates real-world operating conditions, helping to identify potential weak spots or failure points that may not be visible during the assembly process. This test is crucial for ensuring that the hose will perform reliably under high pressure, extreme temperatures, and the specific fluid conditions of the hydraulic system.

Testing for Pressure Tolerance: In addition to leak testing, pressure testing also checks the hose’s pressure tolerance. Hydraulic hoses are designed to withstand a range of pressures depending on the system, and failure to properly test this tolerance could result in catastrophic failure during operation. Testing ensures that hoses meet the required safety margins and are suitable for the intended application.

Heat Treatment and Resistance Testing

Once the hydraulic hose has passed pressure testing, it may undergo heat treatment and resistance testing to ensure the hose assembly can perform under extreme conditions.

Heat Treatment: Some hydraulic hoses undergo heat treatment to improve their strength, flexibility, and resistance to thermal degradation. Heat treatment processes involve subjecting the hose or its materials to high temperatures in a controlled environment, which alters the material’s properties to improve its performance. For example, rubber hoses may undergo vulcanization, a heat-based process that strengthens the material and improves its ability to resist wear and environmental factors.

Testing for Temperature Extremes: Hydraulic hoses are often exposed to a wide range of temperatures, from extreme heat to subzero conditions. Temperature resistance testing is essential to ensure that the hose can maintain its integrity under these extreme conditions without failing. The hose is tested under both high and low temperatures to assess its flexibility and resistance to thermal degradation.

Abrasion Resistance and Flexibility: In addition to heat treatment, hoses are also tested for abrasion resistance and flexibility. Hoses that are frequently exposed to abrasive surfaces or rough conditions must be able to resist wear and tear. Similarly, hoses used in systems where movement or bending occurs need to remain flexible without cracking or breaking. Resistance testing helps ensure the hose can stand up to these environmental stresses while maintaining its integrity.

Conclusion

To ensure optimal system performance, it is crucial to invest in high-quality hose fabrication. This means choosing certified professionals who understand the intricacies of hydraulic systems and the importance of precision in hose assembly. When selecting a hose fabrication provider, ensure they adhere to industry standards and use quality materials for assembly, while also offering pressure testing and quality assurance services.

FAQ

What is hydraulic hose fabrication?

Hydraulic hose fabrication is the process of assembling hydraulic hoses by cutting, crimping, and attaching fittings to ensure they are secure, leak-proof, and capable of withstanding high pressures in hydraulic systems.

Why is proper hydraulic hose fabrication important?

Proper fabrication ensures the reliability, safety, and efficiency of hydraulic systems. It helps prevent leaks, pressure loss, and equipment failure, ultimately minimizing downtime and maintenance costs.

What materials are commonly used in hydraulic hose fabrication?

Common materials include rubber, thermoplastic, metal braided, and PTFE hoses. Each material offers different benefits like durability, flexibility, and resistance to various environmental conditions.

How do I choose the right hydraulic hose for my system?

The right hose depends on factors such as pressure, temperature, fluid type, and the environmental conditions the hose will be exposed to. It’s essential to consult with a professional to ensure compatibility.

What is the role of pressure testing in hose fabrication?

Pressure testing ensures the hose assembly can handle the operating pressure without leaks or failures. It simulates real-world conditions to guarantee system integrity and prevent potential breakdowns.

How can I ensure the longevity of my hydraulic hoses?

Regular maintenance, proper installation, and using high-quality hose assemblies are key to extending the hose lifespan. Routine inspections for wear, cleaning, and replacing damaged hoses when necessary can prevent costly failures.