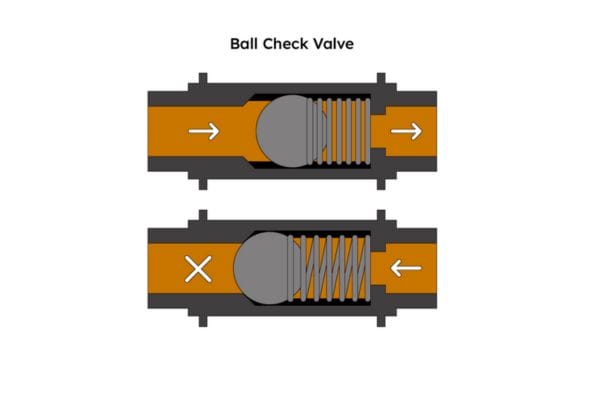

Ball valves use a spherical ball with a hole (or bore) in the center to control fluid flow: when the hole aligns with the flow path, the valve is open; when it rotates 90 degrees to a perpendicular position, the flow is blocked. This straightforward mechanism makes them a popular choice for on/off control, with some designs also capable of throttling flow.

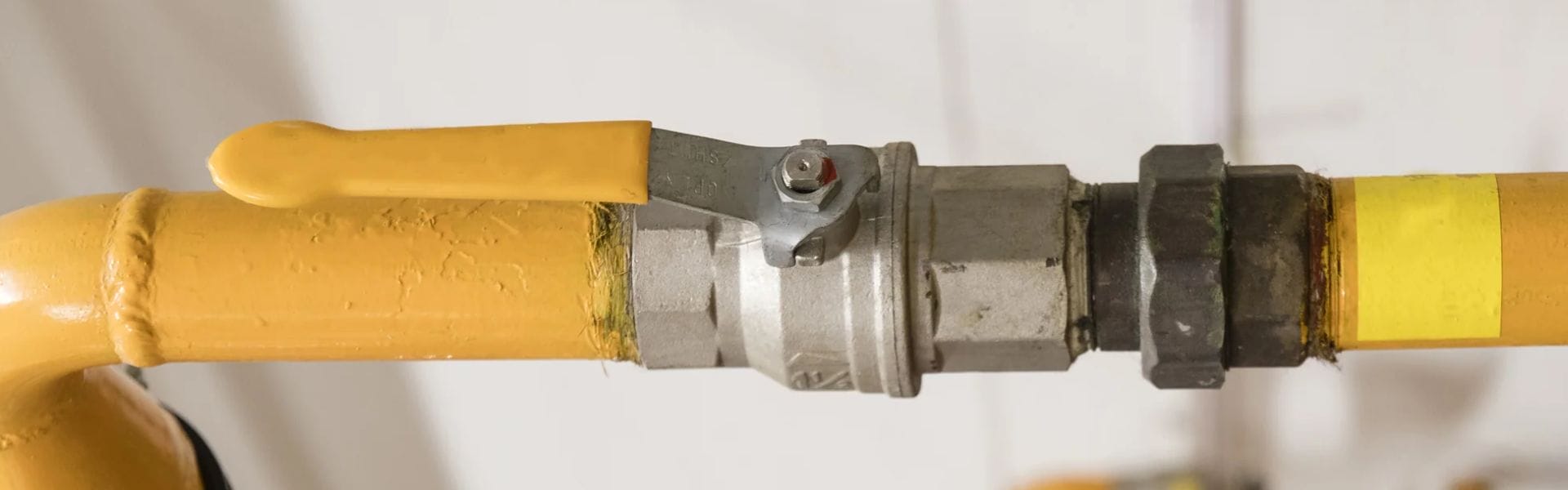

What is a Ball Valve?

A ball valve is a type of valve used to control the flow of fluids through a pipe or system. It operates using a spherical ball with a hole (or bore) in its center. The primary function of the ball valve is to regulate or stop the flow of liquid, gas, or vapor by rotating the ball within the valve body. When the hole aligns with the flow path, the valve is open, allowing fluid to pass. When the ball is rotated 90 degrees (a quarter-turn), the hole is perpendicular to the flow path, thereby blocking the flow completely. This on/off operation is highly effective for many applications where simple, quick fluid control is required.

Basic Components of a Ball Valve

The ball valve is made up of several key components that work together to regulate fluid flow:

Ball: The heart of the valve, the ball has a hole (bore) through its center. The position of the ball determines whether the valve is open or closed. The ball is typically made of durable materials such as stainless steel or brass, and its surface is often treated to resist corrosion.

Seats: The seats are the sealing surfaces that are in contact with the ball when it is in the closed position. Seats are generally made from materials like PTFE (Teflon), elastomers, or metal alloys depending on the application. These materials ensure a tight seal to prevent leakage.

Body: The body houses the ball and other components and is usually made from materials such as steel, stainless steel, or cast iron. It provides the structure and durability for the valve.

Stem: The stem connects the ball to the actuator or handle, transmitting the rotational motion needed to open or close the valve.

Handle: For manual ball valves, the handle allows the operator to rotate the ball and control the flow. In automated systems, the handle is replaced by an actuator.

Actuator: In automated ball valves, actuators (either electric, pneumatic, or hydraulic) control the movement of the ball. Actuators allow for remote or automatic operation of the valve, increasing efficiency and safety in industrial applications.

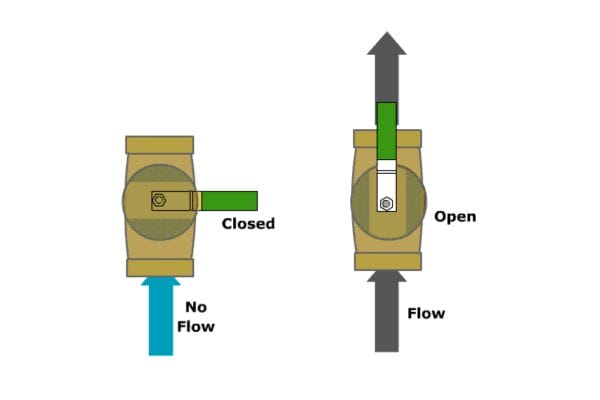

How It Works

Ball valves operate with a quarter-turn mechanism. When the valve is open, the hole in the ball is aligned with the flow path, allowing fluid to flow through. When the valve is closed, the ball is rotated 90 degrees so the hole is perpendicular to the flow, completely blocking the fluid. This simple and efficient mechanism allows for quick operation, with the valve shifting between open and closed positions in just a quarter turn.

Advantages of Ball Valves

Ball valves are highly favored in various industries due to several advantages:

Quick Operation: The quarter-turn mechanism allows for fast opening and closing, which is ideal for applications requiring swift responses.

Durability: Ball valves are built to last, with components that can withstand high pressures, temperatures, and harsh chemicals. The absence of rubbing parts reduces wear and tear, contributing to a long operational life.

Tight Shutoff: Ball valves provide a tight seal when closed, preventing leakage. This is essential for industries like oil and gas, water treatment, and chemical processing, where leakage can lead to significant safety concerns and operational inefficiencies.

Ball Valve Design Types

Ball valves come in various designs, each tailored for different flow control applications and operating conditions. The primary types of ball valves are floating ball valves and trunnion ball valves, but there are also several specialized designs, including V-port, multi-port, and 3-way ball valves. Each of these designs offers distinct advantages, depending on the system requirements such as pressure, flow rate, and application type.

Floating Ball Valves

Design Features and How They Work

A floating ball valve is the most common type of ball valve, where the ball is not fixed in place but is instead “floating” between the valve’s two seats. The ball is held in place by the pressure of the fluid on the inlet side, which forces the ball against the downstream seat, creating a tight seal. When the valve is open, the ball rotates to align the hole with the flow path. In the closed position, the ball rotates 90 degrees, sealing off the flow path.

Key Characteristics:

The ball is free to move within the body.

Pressure from the fluid forces the ball against the downstream seat for a tight seal.

Simplicity in design and cost-effective.

Typical Applications and Ideal Use Cases

Floating ball valves are ideal for low- to medium-pressure systems and smaller pipe diameters. They are widely used in industries such as water treatment, chemical processing, and food & beverage where the pressures are not extreme, and ease of maintenance is crucial. Since they are generally lighter and more affordable than other types, they are often chosen for cost-sensitive applications where high-pressure capabilities are not needed.

Pros and Cons Compared to Other Types

Pros:

Cost-effective: Typically more affordable than trunnion ball valves due to simpler design and construction.

Compact and lightweight: Suitable for applications with limited space and lower weight requirements.

Simple design: Easier to repair and maintain.

Cons:

Pressure limitations: Not ideal for high-pressure or high-flow applications, as the ball is not fixed and can shift under heavy pressure, potentially affecting sealing performance.

Potential leakage: In higher-pressure systems, leakage can occur if the ball does not remain tightly sealed against the downstream seat.

Trunnion Ball Valves

How the Design Differs

Unlike floating ball valves, trunnion ball valves feature a fixed ball that is supported at both the top and bottom by trunnions (extensions or shafts that support the ball). This design prevents the ball from floating under pressure and helps distribute the force more evenly. The trunnions are typically supported by bearings that allow the ball to rotate smoothly.

Key Characteristics:

Fixed ball, supported by trunnions on both ends.

Suitable for large, high-pressure systems where the ball needs additional support.

Generally larger and more complex than floating ball valves.

Ideal Applications

Trunnion ball valves are designed for high-pressure, high-flow, and large diameter systems. These valves are most commonly found in industries such as oil and gas, petrochemical, and power generation, where they manage large volumes of fluid or gas under high pressure. They are used in critical pipelines, reactors, and process systems that require reliable performance even under demanding conditions.

Benefits and Limitations

Benefits:

High-pressure tolerance: Can handle much higher pressures than floating ball valves because the trunnions provide additional support and stability.

Large flow capacity: Suitable for large diameter pipelines and systems with high flow rates.

Reduced wear: The fixed ball design reduces stress on the valve components, leading to longer service life.

Limitations:

More expensive: Due to their more complex design and materials, trunnion ball valves are generally more costly.

Larger size: These valves tend to be bulkier, requiring more space for installation.

Other Types of Ball Valves

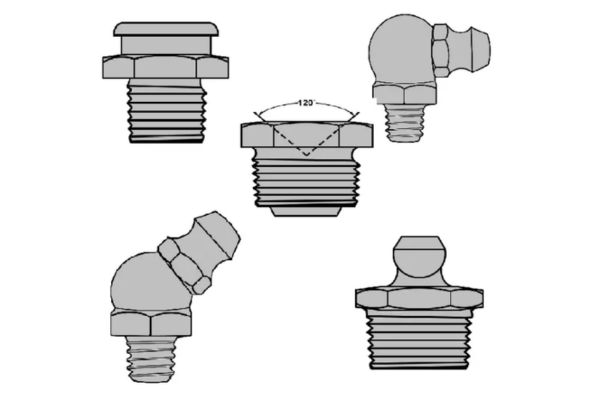

V-Port Ball Valves

A V-port ball valve has a ball with a V-shaped notch instead of a full bore. This design is specifically for throttling applications where precise control over the flow rate is needed. The V-notch allows for more controlled flow regulation and better performance in applications requiring variable flow.

Key Characteristics:

Provides flow regulation rather than just on/off control.

Ideal for systems where controlling the flow rate is crucial, such as in chemical dosing, mixing processes, or steam control.

Multi-Port Ball Valves

Multi-port ball valves have more than two ports, which enables the valve to divert or mix flows in multiple directions. These valves are commonly used in diverging or mixing flow paths, where one inlet can supply multiple outlets or multiple inlets need to be combined into a single outlet.

Key Characteristics:

Available in 3-port or 4-port configurations.

Used in mixing, diverting, or isolating different flow streams in a single valve.

3-Way Ball Valves

A 3-way ball valve is a specific type of multi-port valve that allows for three different flow paths. These valves are highly versatile and are often used for multi-directional flow control. In typical applications, a 3-way valve can combine or split two flow streams into different directions, making it ideal for systems like bypass systems, circulating systems, and diverting flow in multiple directions.

Key Characteristics:

Can redirect flow to three different ports, offering excellent control in complex systems.

Common in applications that require mixing or diverting fluids.

How to Choose the Appropriate Type

When selecting a ball valve design, several factors must be considered to ensure optimal performance:

Fluid Type: Different fluids (liquids, gases, slurries) may require different materials and designs to handle corrosiveness, viscosity, and other properties.

Pressure and Temperature: High-pressure and high-temperature applications typically require trunnion ball valves for added support, while floating ball valves may suffice for lower-pressure systems.

Flow Control Requirements: For simple on/off control, a floating or trunnion ball valve may be suitable. For variable flow control, consider V-port or 3-way ball valves.

Size and Space: If space is a constraint, floating ball valves are often preferred due to their compact design. For large pipelines, trunnion ball valves or multi-port valves may be more suitable.

Budget: Cost can be a factor in choosing between a floating and a trunnion ball valve, as the latter tends to be more expensive due to its complexity and additional features.

Key Factors in Ball Valve Design

The design and performance of ball valves are significantly influenced by the materials used in their construction, the quality of seals and seats, and the configuration of the flow path and valve porting. Understanding these key factors is crucial when selecting or designing a ball valve for a specific application. Let’s explore how these components contribute to the overall functionality and longevity of ball valves.

Materials of Construction

The materials chosen for ball valve components play a critical role in determining the valve’s performance, durability, and suitability for different fluids and operating conditions. The most common materials used in the construction of ball valves are stainless steel, brass, plastic, and carbon steel, among others. Each material offers specific advantages and is selected based on the following key factors:

Common Materials:

Stainless Steel: This is the most widely used material for ball valves, especially in applications that require high strength and corrosion resistance. Stainless steel is ideal for a broad range of industries, including oil and gas, water treatment, and chemical processing. It resists oxidation and corrosion from aggressive fluids, including acids and salts, making it highly suitable for harsh environments.

Brass: Brass is often used for smaller, low-pressure ball valves, typically found in residential, commercial, or HVAC applications. It is resistant to corrosion from water and air but is not as robust as stainless steel when exposed to harsh chemicals or extreme temperatures.

Plastic (PVC, CPVC, PVDF): Plastic ball valves, made from materials like PVC or CPVC, are commonly used in industries that handle corrosive chemicals or where cost is a significant factor. These materials are lighter than metal, offer excellent corrosion resistance, and are ideal for chemical processing or water treatment. However, they may not be suitable for high-temperature or high-pressure applications.

Carbon Steel: Used primarily in industrial applications, carbon steel ball valves are highly durable and can withstand moderate pressure and temperature. However, they are prone to corrosion, so they are typically coated or lined to prevent degradation when exposed to corrosive fluids.

Material Choice Considerations:

Corrosion Resistance: In aggressive environments, materials like stainless steel or plastics such as PVDF are preferred due to their superior corrosion resistance.

Pressure and Temperature Ratings: Stainless steel and carbon steel are generally chosen for high-pressure and high-temperature systems, while brass or plastic may be suitable for lower-pressure and lower-temperature systems.

Cost: Plastic materials are more affordable but may not perform as well in extreme conditions. Brass and carbon steel can be more cost-effective than stainless steel but may lack the durability required for certain industrial applications.

Seals and Seats

Seals and seats are essential for ensuring that the ball valve provides a tight shutoff and prevents leakage when the valve is in the closed position. These components directly influence the valve’s reliability, operational lifespan, and performance.

Importance of Seals and Seats:

Seals: The primary role of seals is to prevent leakage along the valve stem, where the ball is actuated. Seals are typically made from materials that provide a reliable seal while withstanding the pressures and temperatures of the system.

Seats: The seats, often positioned between the ball and the valve body, ensure a tight fit when the ball rotates to the closed position, preventing fluid from bypassing the valve. The material and design of the seats are critical in determining the leak-tightness of the valve.

Types of Seal Materials:

PTFE (Polytetrafluoroethylene): PTFE is the most common seal material due to its excellent chemical resistance, low friction, and ability to perform at a wide range of temperatures. It is ideal for valves used in chemical, pharmaceutical, and food-grade applications.

Metal Seals: Metal seals are used in high-temperature, high-pressure, or critical service applications where PTFE or elastomer seals would fail. They provide excellent durability but may require more maintenance due to wear over time.

Elastomers (e.g., Viton, EPDM): Elastomeric seals are used in systems requiring flexibility and resilience. They offer good sealing properties at low pressures and are often used in applications involving water, gases, or low-temperature fluids.

Impact of Seal Materials on Performance:

Durability: Seals made of PTFE or elastomers are typically softer and more susceptible to wear over time, especially in high-pressure or high-temperature environments. Metal seals, while more durable, may not offer the same flexibility or chemical resistance.

Leak Tightness: The seal material’s compatibility with the fluid and temperature directly affects the valve’s leak-tight performance. Inconsistent seal design or material choice can result in fluid leakage, compromising the system’s integrity.

Valve Life: A poor-quality seal or inappropriate material can cause valve failure, leakage, or the need for frequent replacements, thus affecting the valve’s operational life and maintenance costs.

Flow Path and Valve Porting

The flow path and porting configuration are critical elements that affect the flow rate, pressure drop, and overall flow efficiency of a ball valve. The design of the valve porting determines how the fluid flows through the valve, and choosing the right configuration is essential for meeting system requirements.

Port Configurations:

Full Port: A full port (or full bore) ball valve has an internal bore that matches the pipe diameter, ensuring minimal flow resistance and little to no pressure drop. Full port valves are typically used in applications that require high flow rates and low pressure loss, such as in large pipelines or HVAC systems.

Reduced Port: A reduced port valve has a smaller internal bore compared to the pipe size, creating a constriction in the flow path. This design is often used where space is limited or where flow rates do not need to be as high. The reduced port will create a pressure drop, but this may be acceptable in many standard applications, such as residential or commercial systems.

V-Port: A V-port valve features a V-shaped notch in the ball to provide precise flow control. This type of valve is used in throttling applications where the flow needs to be adjusted or regulated over time. The V-shaped opening allows for more gradual control of the flow rate compared to a standard full port.

How the Size of the Port Affects Flow Capacity:

The port size directly influences the flow capacity and pressure drop across the valve. A larger port allows for greater flow and lower pressure drop, making it suitable for high-flow applications. A smaller port restricts flow and increases the pressure drop but can be useful in applications where precise control of flow is needed, such as in throttling or mixing applications.

Choosing the Correct Port Configuration:

The choice between full port and reduced port configurations depends on several factors:

Flow Requirements: If high flow rates are required, full port ball valves are typically preferred. For moderate flow or low-flow systems, reduced port valves may be more economical.

Pressure Drop: Full port valves are ideal for maintaining low pressure drops, while reduced port valves are better suited for applications where the minor drop in pressure is acceptable.

Cost and Space Constraints: Full port valves are typically more expensive and bulkier than reduced port valves, so these considerations must be balanced based on system needs.

Ball Valve Actuation and Automation

Manual Actuation

The Role of a Lever or Handle

Manual actuation is the simplest and most traditional method of controlling a ball valve. A lever or handle is attached to the valve stem, and by turning the lever, the operator can rotate the ball inside the valve body to either open or close the valve. This rotation is a quarter-turn action, meaning the handle rotates 90 degrees to change the valve from an open to a closed position (or vice versa).

In manual ball valves, the handle is typically positioned to show the status of the valve (open or closed), providing a visual indication of the valve’s position. For smaller valves, this system offers a simple, cost-effective way to regulate fluid flow without requiring complex equipment.

Suitability for Smaller, Lower-Pressure Applications

Manual actuation is best suited for smaller, lower-pressure applications. These can include residential or commercial systems, HVAC installations, water treatment facilities, or smaller pipelines. Manual valves are often used in systems where frequent operation is not required and where the cost of automation is not justified. Additionally, they are ideal for situations where precise, remote control is not needed.

While manual ball valves are easy to install and maintain, they do require direct operator involvement, which can lead to inefficiencies in larger, more complex systems.

Automated Actuation

Pneumatic, Hydraulic, and Electric Actuators

Automated ball valves are controlled by external actuators, which are powered by pneumatic, hydraulic, or electric sources. Each type of actuator offers distinct advantages depending on the application’s power requirements and operating conditions.

Pneumatic Actuators: These actuators use compressed air to move the ball inside the valve. Pneumatic actuators are commonly used in systems that require quick, reliable operation and where compressed air is readily available. They are widely used in oil and gas or chemical processing industries, where fast shutoff and reliable operation are crucial.

Hydraulic Actuators: These actuators use hydraulic fluid (oil or water) to create the movement needed to open or close the valve. Hydraulic actuators are ideal for high-force applications, such as those in heavy industrial operations or power generation plants. They provide greater force compared to pneumatic actuators but require more complex systems.

Electric Actuators: Electric actuators use motors to turn the ball inside the valve. They are suitable for environments where a consistent power supply is available and where precise, controllable movements are required. Electric actuators are common in automation systems, including manufacturing, water treatment, and building management systems.

How Automation Impacts Performance, Efficiency, and System Control

Automating ball valves improves performance, efficiency, and system control in several ways:

Remote Control: Automated ball valves can be controlled remotely, making them ideal for systems that are difficult or dangerous to access. Operators can monitor and control valve positions from a central control room, minimizing the need for physical presence at each valve location.

Precise Control: Automated systems provide greater precision in adjusting the flow rate or pressure, especially when combined with flow meters or pressure sensors. This precision is particularly important in industries like chemical processing, where small changes in flow can have significant consequences on product quality or safety.

Operational Efficiency: Automation reduces the need for human intervention, streamlining processes and improving safety. In large systems, automated valves ensure that processes can continue to run smoothly without operator delays, contributing to higher throughput and reduced downtime.

Conclusion

In conclusion, choosing the right ball valve involves understanding the specific needs of your system, from flow requirements to pressure ratings and safety considerations. By carefully assessing the design and features of the valve, industries can ensure optimal performance, reduced downtime, and enhanced operational safety. If you need ball valves, please contact Topa now!

FAQ

What is a ball valve?

A ball valve is a type of valve that controls fluid flow using a spherical ball with a hole through its center. The ball rotates within the valve body to either allow or block the flow of fluid. It operates with a quarter-turn mechanism, meaning it opens or closes with a 90-degree rotation.

How does a ball valve work?

A ball valve works by rotating the ball inside the valve body. When the hole in the ball aligns with the flow path, the valve is open, allowing fluid to pass through. When the hole is perpendicular to the flow, the valve is closed, stopping the fluid.

What are the different types of ball valves?

The main types of ball valves are floating ball valves, which are used in low-pressure systems, and trunnion ball valves, which are designed for high-pressure applications and have trunnions (supports) to hold the ball in place.

What materials are ball valves made from?

Common materials for ball valves include stainless steel, brass, carbon steel, and plastics such as PVC. The choice of material depends on factors like corrosion resistance, temperature tolerance, and pressure requirements.

What’s the difference between full-port and reduced-port ball valves?

A full-port ball valve has an internal bore that matches the pipe diameter, offering minimal resistance to flow. A reduced-port ball valve has a smaller bore, which results in a higher pressure drop and reduced flow capacity, making it suitable for applications where flow rate is less critical.

Can ball valves be automated?

Yes, ball valves can be automated using pneumatic, hydraulic, or electric actuators. Automated ball valves provide benefits like remote operation, precise flow control, and enhanced safety features, such as fail-safe mechanisms for emergency shutoff.