In the controlled calm of a test bench, almost any hydrulic fitting can hold pressure. But out in the field—on a mining truck buried in red dust, a harvester working through freezing dawn, or a drilling rig exposed to salt and spray—the story changes completely.

The Foundation: Why Environmental Testing Is Non-Negotiable

In real operations, hydraulic fittings are constantly attacked by corrosion, vibration, dust, and temperature extremes.

A high pressure rating alone cannot guarantee reliability.

True durability is proven only when a fitting survives environmental simulation — the process that exposes it to the same abuse it will face in the field.

Moving Beyond the Pressure Rating

A fitting’s rated pressure is measured under ideal laboratory conditions — clean, dry, and temperature-controlled.

But once installed on a bulldozer, harvester, or offshore crane, that same fitting faces:

- Salt and humidity that corrode metal surfaces

- Heat and UV exposure that degrade seals and plating

- Vibration and shock that loosen threads and fatigue metal

Ignoring these factors leads to premature wear, unexpected leaks, and costly downtime.

| Condition | Real-World Example | Typical Effect on Fitting |

| Corrosion (Salt, Moisture) | Coastal and marine sites | Rust, seal degradation |

| Extreme Temperature | Desert or arctic operation | Brittle metal, seal hardening |

| Vibration and Impact | Mobile machinery | Loosening, fatigue cracks |

| Dust and Dirt | Mining, construction | Abrasion and contamination |

Simulating a Lifetime of Abuse

Environmental testing compresses years of field use into hours or days of laboratory exposure.

Through salt spray, thermal cycling, and vibration endurance, engineers can precisely predict how long a fitting will perform before degradation begins.

This accelerated testing gives manufacturers a quantifiable way to validate quality — and gives users confidence that every fitting can survive the world’s harshest job sites.

The Role of International Standards

Organizations such as ISO and SAE establish clear procedures for testing durability.

By following these standards, test results become measurable, repeatable, and comparable across manufacturers.

| Standard Body | Example Test | Focus Area |

| ISO 9227 / ASTM B117 | Neutral Salt Spray Test | Corrosion resistance |

| ISO 19879 | Vibration & Pressure Cycling | Mechanical endurance |

| ISO 16750 | Environmental Conditions for Road Vehicles | Temperature and shock |

| SAE J514 / J1453 | Hydraulic Fitting Performance Tests | Seal and connection integrity |

When a fitting is certified to these standards, it’s not just a claim — it’s proof of verified durability.

The Primary Enemy: The War Against Corrosion

Corrosion is the most persistent threat to steel hydraulic fittings. Once it begins, it weakens structural integrity, damages sealing surfaces, and leads to leaks or system failure. The only way to prove true durability is through controlled corrosion testing—especially salt spray testing.

The Gold Standard: Salt Spray Testing

The neutral salt spray (NSS) test, defined by ISO 9227 and ASTM B117, is the global benchmark for evaluating plating performance. During this test:

- Fittings are placed in a sealed chamber.

- A fine mist of 5% sodium chloride (NaCl) solution is sprayed continuously.

- The temperature is kept at 35 ± 2°C.

- Examiners check the samples at regular intervals.

This simulates harsh marine or industrial environments and measures how well the plating protects the base metal.

White Rust vs. Red Rust

| Rust Type | What It Means | Material Affected | Significance |

| White Rust | Early corrosion of zinc coating | Zinc layer only | Acceptable in early stages |

| Red Rust | Corrosion of the base steel | Steel substrate | Signals coating failure |

Performance is defined by how many hours pass before red rust appears. The higher the hour count, the better the plating protection.

The Evolution of Protective Plating

| Plating Type | Composition | Typical Hours to Red Rust | Advantages | Common Use |

| Zinc Plating | Pure Zn | 72–96 hours | Basic corrosion resistance | Light-duty fittings |

| Zinc-Nickel (Zn-Ni) | 12–15% Ni alloy | 720–1000+ hours | Excellent corrosion protection, high adhesion | High-performance fittings, marine and industrial environments |

Modern zinc-nickel plating provides superior protection by forming a stable, passive barrier that resists corrosion far longer than traditional zinc coatings. It’s the preferred choice for fittings used in agriculture, mining, construction, and offshore applications.

The Trial by Fire & Ice: Thermal Performance Testing

Hydraulic systems operate everywhere — from arctic mining trucks to desert drilling rigs. In these extremes, fittings must perform flawlessly despite constant expansion, contraction, and material stress. Thermal testing proves that a fitting can endure both intense heat and freezing cold without losing its sealing integrity or mechanical strength.

Thermal Shock: The Ultimate Stress Test

Among all environmental trials, thermal shock testing is one of the harshest.

A fully pressurized fitting assembly is rapidly cycled between extreme low and high temperatures, often swinging from -40°C to +120°C within minutes.

This process simulates real-world conditions such as a frozen machine suddenly returning to operation or a hose line exposed to sun-heated oil after an overnight freeze.

These rapid transitions test the bond between dissimilar materials—the steel body, zinc-nickel plating, and elastomer seals. Each expands and contracts at different rates, which can cause microscopic gaps, cracks, or seal extrusion if the design or material quality is inadequate.

Only fittings with high-quality plating adhesion and precision-engineered sealing grooves can withstand repeated thermal cycling without leaking.

Endurance at High Temperatures

Constant exposure to heat is another silent enemy of hydraulic systems.

During high-temperature endurance testing, fittings are pressurized and soaked at their maximum rated temperature—often 100°C or higher—for extended durations.

This prolonged thermal stress reveals how well the elastomer seals can retain their flexibility, compression, and shape under load.

Inferior seal materials may harden, shrink, or extrude under heat and pressure, causing gradual loss of sealing force and eventual leaks.

Quality fittings use temperature-stable elastomers such as NBR, FKM (Viton), or HNBR, each carefully selected to match the intended operating range.

A well-tested fitting maintains its shape, finish, and torque retention even after long-term exposure to high heat, confirming its ability to perform in demanding environments like steel mills or hydraulic presses.

Performance in the Deep Freeze

At the opposite extreme, low-temperature performance is just as critical.

When hydraulic fittings are exposed to sub-zero conditions, metals contract and rubber seals become stiff, threatening the tight seal required to contain pressurized fluid.

In low-temperature testing, assemblies are cooled to -40°C or below while pressurized to working load.

Engineers observe whether the seals retain elasticity and whether the fitting body shows any micro-cracking or plating separation.

A fitting that passes this test demonstrates its reliability in polar mining, wind turbine maintenance, or winter road equipment, where failure could lead to oil leaks, equipment shutdown, and costly downtime.

The Value of Thermal Testing

Thermal performance testing goes beyond qualification—it validates real-world endurance.

It ensures that every fitting, regardless of where it’s installed, can withstand the full spectrum of temperature extremes without losing strength or sealing capability.

From blistering heat to biting cold, fittings that survive these tests prove one thing above all:

They’re engineered not just to hold pressure, but to hold up against the planet’s harshest climates.

| Test Standard Example | Test Name / Purpose | Procedure Summary | Primary Failure Mode Tested |

| ISO 9227 / ASTM B117 | Neutral Salt Spray (NSS) | Continuous exposure to an atomized 5% NaCl solution in a heated chamber. | Corrosion of the base metal (red rust), indicating a breach of the protective plating. |

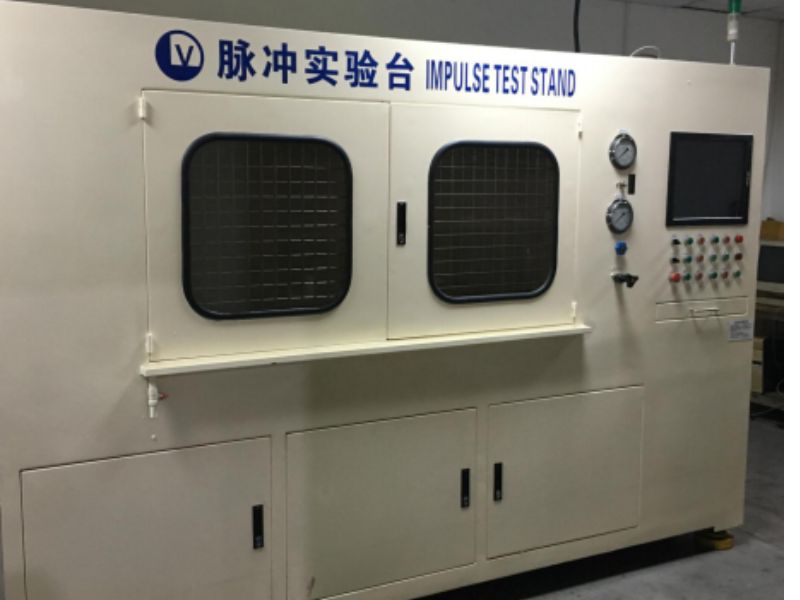

| ISO 18752 | Impulse Testing | Subjecting a hose assembly to repeated pressure cycles (impulses) at elevated temperatures. | Fatigue failure of the hose or the hose/fitting interface due to dynamic pressure loading. |

| SAE J1644 | Thermal Cycle Test | Pressurized assemblies are repeatedly cycled between extreme low and high temperatures. | Leakage caused by the different thermal expansion/contraction rates of metal and elastomer seals. |

| ISO 19879 | Combined Pressure/Vibration Test | The fitting is pressurized and simultaneously subjected to vibration on multiple axes. | Loosening of the threaded connection or fatigue failure due to resonant frequencies and mechanical stress. |

The Unseen Force: Vibration and Fatigue Resistance

Vibration is an invisible but relentless threat to hydraulic fittings, especially in mobile and heavy-duty machinery. Continuous vibration can loosen threads, wear out seals, and even cause fatigue cracks in the fitting body. That’s why vibration resistance testing is essential for any fitting designed for tough environments.

Simulating Real-World Vibration

Using multi-axis shaker tables, fittings are exposed to a spectrum of vibration frequencies that replicate the harsh movements of excavators, loaders, tractors, and forestry machines.

These tests identify weak points in the design and highlight resonant frequencies that can amplify stress on the connection.

| Test Type | Description | Purpose |

| Single-Axis Test | Vibration applied in one direction | Basic endurance check |

| Multi-Axis Test | Simulates combined motion in X, Y, and Z axes | Realistic machine environment |

| Resonance Sweep | Frequency range testing | Detects critical vibration points |

Endurance Under Combined Stresses

The most advanced testing procedures — such as those defined in ISO 19879 — combine vibration with internal hydraulic pressure.

This dual-stress approach measures how well a fitting maintains sealing integrity and mechanical strength under real operational conditions.

Key Evaluation Points:

- No leakage or loosening during vibration

- No visible thread wear or fatigue cracks

- Maintains torque and seal after pressure cycling

| Parameter | Standard Reference | Evaluation Focus |

| Vibration Frequency Range | 10–2000 Hz | Realistic dynamic stress simulation |

| Hydraulic Pressure | Working + Peak loads | Combined stress conditions |

| Test Duration | 20–50 hours continuous | Long-term endurance |

| Pass Criteria | No leakage, loosening, or cracking | Verified mechanical stability |

Engineering Against Vibration

Design improvements often come directly from these endurance tests.

Common vibration-resistant features include:

- 37° cone (JIC) fittings – robust mechanical metal-to-metal seal.

- ORFS fittings – soft O-ring face seal that absorbs vibration.

- DIN 24° fittings – precision machining for repeatable alignment and torque.

These geometries, when paired with correct assembly torque, provide the stability required to prevent loosening and extend system life.

The Ultimate Proof: Combined and Cyclic Testing

Individual tests are revealing, but the ultimate proof of a fitting’s reliability comes from tests that combine multiple stressors. Cyclic tests, which simulate the repetitive on/off, hot/cold, high/low pressure nature of real work, are a true measure of long-term durability.

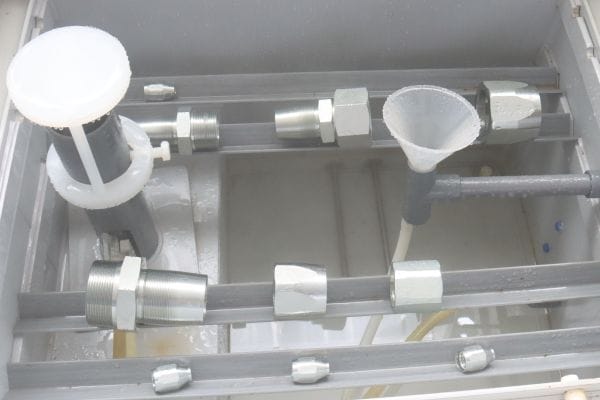

Pressure Impulse Testing

This is a critical fatigue test for a complete hose assembly. The assembly is subjected to hundreds of thousands—or even millions—of rapid pressure cycles, often at elevated temperatures. It validates the integrity of the hose-to-fitting crimp, which is a common failure point.

The Power of Combined Testing

Standards like SAE J1475 outline combined tests that might include pressure, vibration, and thermal cycling in a single, complex sequence. Passing such a test is a clear indicator that the fitting is robustly designed to handle the multi-faceted challenges of a demanding application.

Leakage vs. Burst: Defining Failure

In many of these tests, a catastrophic burst is not the only definition of failure. Any visible leakage from the connection is considered a failure. This high standard ensures that a fitting is not just strong, but that it maintains its primary function: providing a secure, leak-free seal.

| Fitting Type | Sealing Mechanism | Vibration Resistance | Primary Advantage |

| JIC (SAE J514 37° Flare) | Metal-to-metal seal between the 37° male flare and the female cone seat. | Good | Globally popular, wide availability, good for high-pressure applications. |

| ORFS (SAE J1453 O-Ring Face Seal) | Elastomer O-ring compressed between two flat faces. | Excellent | Virtually leak-proof performance, outstanding resistance to vibration & pressure spikes. |

| DIN (Metric / BSPP O-Ring) | Elastomer O-ring seal, often in a retaining ring (e.g., EO-2) or on the male stud. | Excellent | Very high pressure capabilities, dominant standard in Europe, excellent sealing reliability. |

| NPT (National Pipe Taper) | Metal-to-metal seal formed by deforming threads as they are tightened. Sealant required. | Poor | Inexpensive and common for low-pressure, static plumbing. Not recommended for high-vibration hydraulics. |

Validating Quality: The Role of Traceability and Certification

Rigorous testing is meaningless if the parts you receive are not the same ones that were tested. A robust quality system, complete with traceability and transparent certification, is the final and most critical link in the chain of reliability.

Traceability: Knowing What You Get

Reputable manufacturers mark their fittings with a name or code and a part number. This traceability ensures that the fitting can be traced back to a specific manufacturing batch, material certificate, and set of quality control test results, providing ultimate accountability.

Demanding Full Certification

When specifying fittings for a critical application, ask for the data. A quality manufacturer can provide certificates of conformance and detailed test reports that prove their products have passed the industry-standard tests for corrosion resistance, vibration, and pressure impulse.

Building a Partnership on Trust

Ultimately, choosing a hydraulic fitting supplier is about more than just the product; it’s about choosing a partner in reliability. Select manufacturers who are transparent about their testing processes and can provide the documentation to back up their performance claims.

Conclusion

Reliable hydraulic fittings are not defined by their pressure rating, but by their ability to withstand real-world punishment — salt, dust, heat, cold, and time. Manufacturers who commit to full ISO and SAE testing, detailed traceability, and transparent certification give their customers more than components; they deliver peace of mind.

FAQ

How long should a zinc-nickel plated fitting last in a salt spray test?

Leading manufacturers of high-performance zinc-nickel plated fittings typically certify their products for a minimum of 720 hours to red rust, with many exceeding 1,000 hours.

Can I use a fitting from one brand with a hose from another?

This is strongly discouraged. Manufacturers test their hose and fittings as a matched system to guarantee crimp integrity. Mixing and matching components, even if they seem compatible, voids any warranty and introduces a significant, unverified risk of failure.

What is the most reliable fitting for a high-vibration application?

O-Ring Face Seal (ORFS) fittings are generally considered the most reliable choice for extreme vibration due to their soft-seal design. The elastomer O-ring absorbs vibration and prevents the mechanical loosening that can affect metal-to-metal seal fittings.

My fitting passed pressure testing but is still corroding in the field. Why?

This highlights the importance of environmental testing. The fitting’s pressure rating is unrelated to its corrosion resistance. The plating has likely failed, indicating it was not specified or tested for the corrosive environment (e.g., salt exposure, chemical fumes) it is in.

Are stainless steel fittings always better?

Not necessarily. While stainless steel offers excellent corrosion resistance, it is more expensive and has different pressure ratings and temperature limitations compared to carbon steel. For many applications, a high-quality, zinc-nickel plated carbon steel fitting is the most cost-effective and reliable solution.

What does “type approval” from a certification body like DNV or ABS mean?

Type approval means the certification body has reviewed the manufacturer’s designs, witness-tested the products according to their stringent standards (which often exceed ISO/SAE), and audited the manufacturing facility.