A three-way ball valve works by using a rotating ball with a specifically shaped internal bore to divert, mix, or block fluid flow across three distinct ports. Managing multi-directional fluid flow in high-pressure systems often requires an over-complicated network of multiple two-way valves and connectors. When a system relies on outdated piping configurations, maintenance becomes a nightmare and leak points multiply across your infrastructure. Implementing a streamlined solution helps you understand how a three way ball calve work to optimize your hydraulic and industrial operations effectively.

What are the fundamental principles of how does a three way ball calve work?

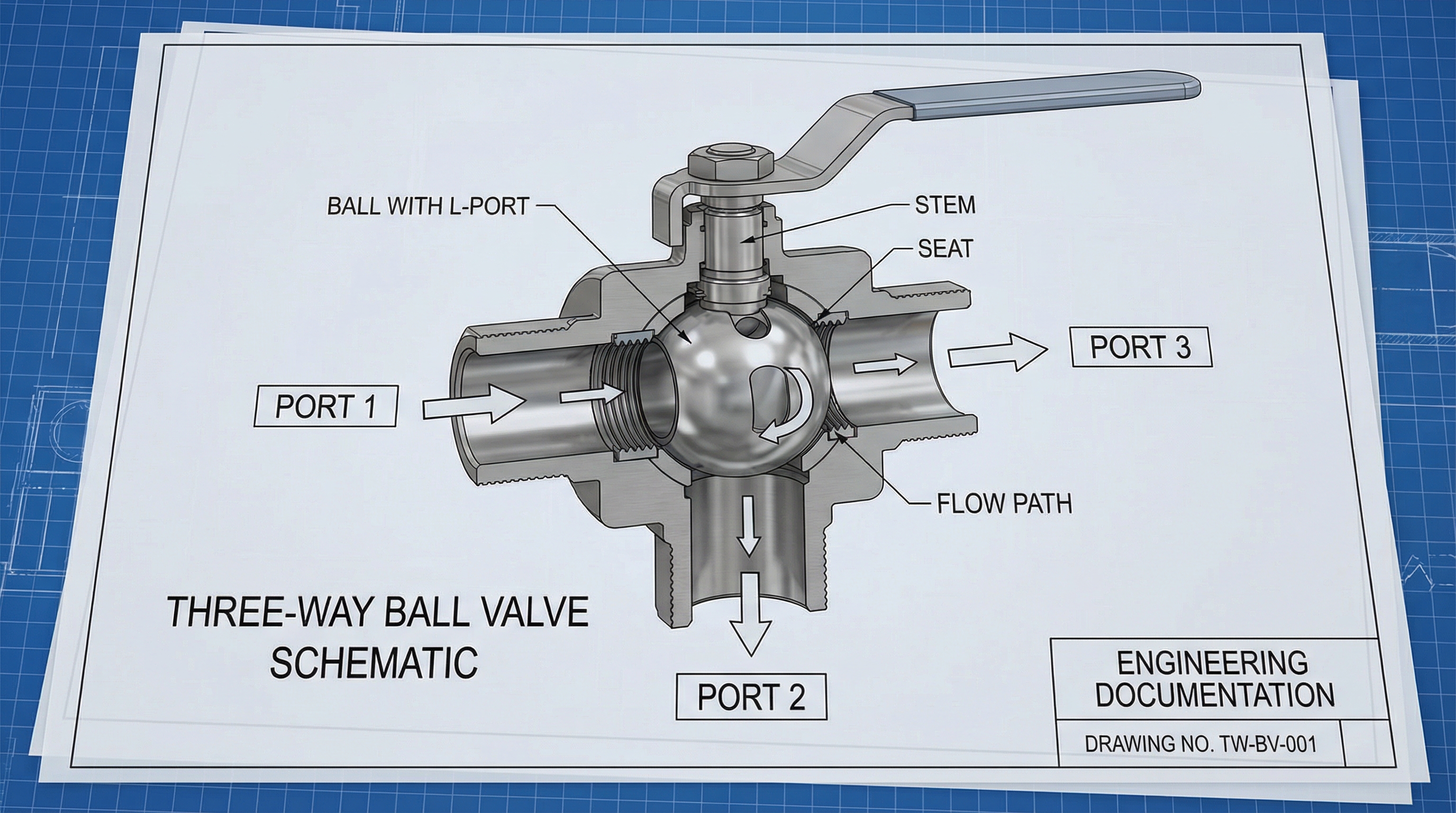

The core principle involves a spherical plug that rotates to align its internal channel with various inlet and outlet ports. Understanding the Three Way Ball Valve Work process is essential for anyone designing complex fluid circuits. You can explore how the three way ball calve work to improve your system efficiency immediately.

What is the port configuration?

The three-port design allows for one common inlet to interact with two different outlets simultaneously or sequentially. But that’s not all because these ports are typically arranged in a “T” or “L” shape.

- Port 1: Typically the primary inlet.

- Port 2: Often used for diverting.

- Port 3: Secondary outlet or mixing input.

How does the ball rotate?

The internal sphere contains a bore that aligns with specific ports to direct fluid based on the handle position. Here is the kicker: a simple 90-degree turn can completely change the direction of your fluid.

- Quarter-turn operation for speed.

- Precision alignment for flow control.

- Full-bore designs for low pressure drop.

What are the flow path basics?

Flow enters through one port and is directed through the internal channel to exit through another selected port. What’s more, you can transition from a standard line into the valve body for seamless integration.

- Smooth internal surfaces reduce turbulence.

- Directional arrows often guide installation.

- Multiple configurations support diverse needs. Correct port alignment is the foundation of all efficient multi-directional fluid systems.

| Component | Function | Material |

| Ball | Directs fluid flow | Stainless Steel |

| Ports | Entry/Exit points | Carbon Steel |

| Bore | Internal flow path | L or T Shaped |

The physical arrangement of ports determines the maximum number of flow combinations available to the operator.

Which internal components affect how does a three way ball calve work?

Internal components like the perforated ball and the stem interface dictate the physical limits of the valve’s operation. When you study Three Way Ball Valve Work, you realize that every seal and gasket must withstand extreme pressures.

Why does the bore shape matter?

The shape of the hole drilled through the center of the ball determines if the valve mixes or diverts. Believe it or not, the L-shape and T-shape are not interchangeable in most systems.

- L-Port for simple diversion.

- T-Port for complex mixing.

- Vertical bores for specialized drainage.

How does the stem transfer torque?

The stem acts as the bridge between your manual handle and the internal ball mechanism. Think about it: the stem must be strong enough to overcome the friction of the seats under high pressure.

- Blowout-proof stem designs for safety.

- Low-torque interfaces for easy turning.

- Heavy-duty mounting for actuators.

What is the role of seals?

High-quality seals prevent cross-port leakage and ensure that fluid only goes where you intend. It gets better because modern synthetic materials can last for thousands of cycles without failing.

- O-rings prevent external leaks.

- Seats provide the internal shut-off.

- Packing nuts maintain stem tension. High-quality internal components are the primary defense against unexpected system downtime and fluid loss.

| Part | Critical Feature | Impact |

| Stem | Torque resistance | Operational ease |

| Bore | Flow geometry | Control type |

| Gaskets | Chemical resistance | Longevity |

The synergy between the stem and the ball bore ensures that your manual or automated input results in precise flow control.

How does an L-Port change how does a three way ball calve work?

An L-Port configuration is specifically designed to divert flow from one source to one of two different destinations. This specific Three Way Ball Valve Work setup ensures that you can never accidentally mix the two outlet streams.

How is the diverter function used?

The L-port directs flow from a common inlet, usually the center port, to either the left or right outlet. Wait, there is more, as this prevents any “dead-heading” of your pumps during the transition.

- Two-way switching capability.

- No-mixing safety feature.

- Clear flow path indication.

Why use 90-degree operation?

A simple quarter-turn is the standard for switching paths in an L-pattern valve. Interestingly enough, this allows for very fast response times in emergency diversion scenarios.

- Fast manual switching.

- Easy automation setup.

- Visual handle confirmation.

Where are L-ports common?

You will find these valves in systems that require switching between two different storage tanks or processing lines. But that’s not all, as they are also perfect for selecting between a primary and a standby filter.

- Fuel system tank selection.

- Cooling water bypass lines.

- Chemical reagent switching. L-Port valves are the industry standard for applications requiring reliable diversion without the risk of cross-contamination.

| Feature | L-Port Specification |

| Positions | 2 Positions |

| Switching Angle | 90 Degrees |

| Mixing Ability | None |

The L-shaped bore provides a “one-or-the-other” flow logic that simplifies complex piping layouts significantly.

How does a T-Port design influence how does a three way ball calve work?

T-Port designs offer the most flexibility because they allow for mixing, diverting, and even all-port flow.

How does mixing work?

The T-shaped bore allows fluid from two different inlets to merge into a single outlet simultaneously. Here is the kicker: you can precisely control the ratio of the mix by adjusting the handle position slightly.

- Dual inlet blending.

- Temperature control mixing.

- Concentration adjustment.

Can all ports be open?

Unlike the L-port, the T-port has a specific position where all three ports are connected at once. What’s more, this allows for complete system circulation or pressure equalization across all lines.

- Maximum flow capacity.

- System-wide flushing.

- Pressure balancing.

Are they compatible with fittings?

Ensuring that your valves match the standards of your piping is critical for a leak-free system. Believe it or not, using the wrong thread type can cause catastrophic failure in high-pressure T-port setups.

- Compatibility with various standards.

- High-flow internal geometry.

- Secure mounting options. T-Port valves provide the versatile flow logic needed for complex blending and multi-directional distribution systems.

| Feature | T-Port Specification |

| Positions | 4 Positions |

| Switching Angle | 90 to 360 Degrees |

| Mixing Ability | High |

The T-bore geometry allows for sophisticated flow patterns that are impossible to achieve with a standard L-bore.

What role does rotation play in how does a three way ball calve work?

Rotation is the physical action that changes the state of the valve and determines which ports are active. In the context of Three Way Ball Valve Work, the degree of rotation dictates the available flow paths. You can master how the three way ball calve work by coordinating rotation with system pressure demands.

What is 180-degree travel?

Some three-way valves allow for 180 degrees of rotation to access more flow combinations than a standard 90-degree valve. Think about it: this extra range of motion opens up a third or fourth flow state.

- Multiple switching points.

- Extended control range.

- Specialized port logic.

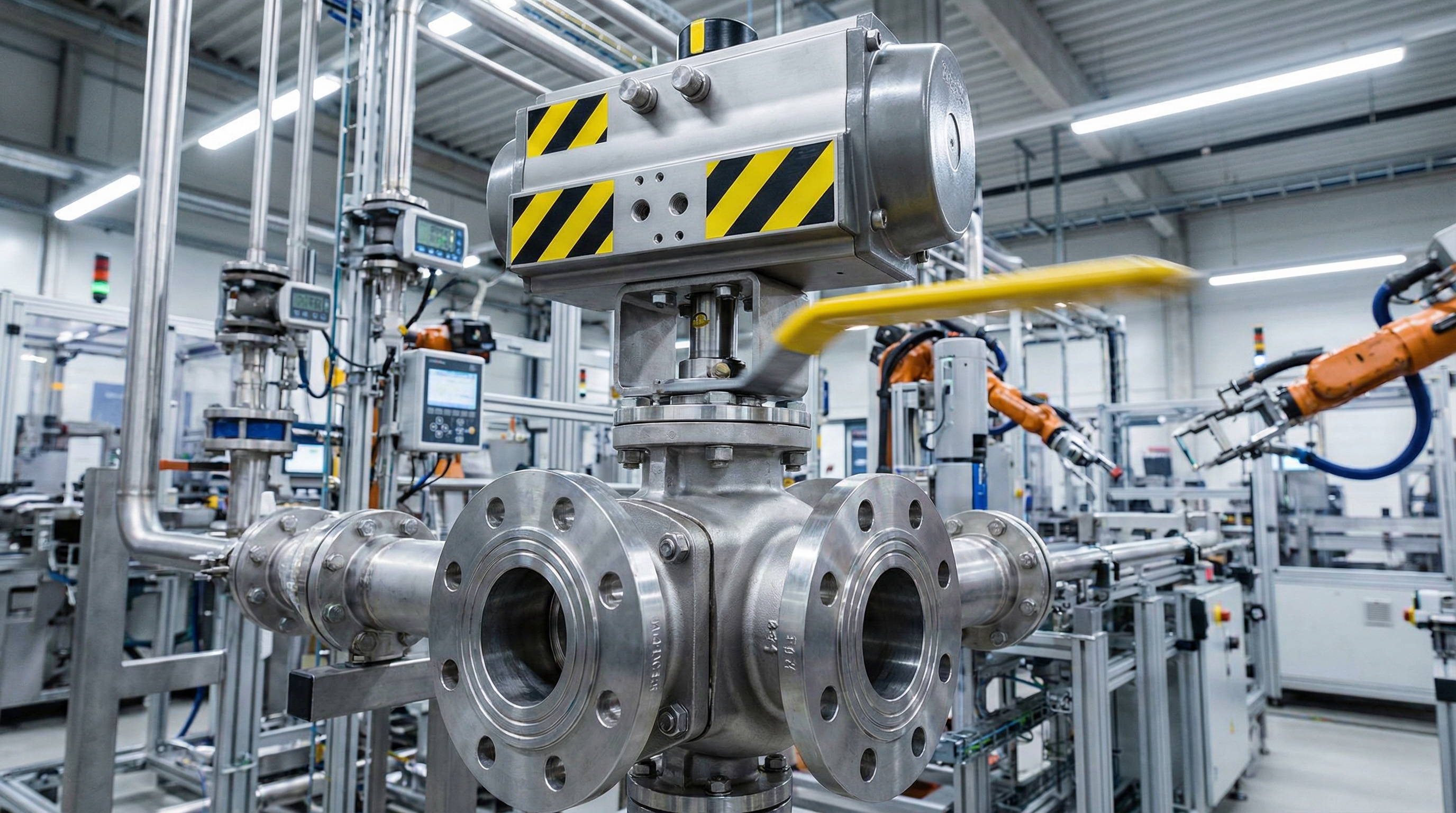

How does automation help?

Pneumatic or electric actuators can provide the precise rotation needed for remote or high-speed operations. It gets better because you can integrate these into a central control system for fully hands-off management.

- Remote flow switching.

- Precise positioning.

- Continuous operation.

Why are stops important?

Mechanical stops prevent the ball from over-rotating and causing unintended flow paths or “dead-heading.” Keep in mind that a single degree of misalignment can lead to internal turbulence or pressure drops.

- Precise port alignment.

- Safety against over-torque.

- Clear positional feedback. Precision rotation controlled by robust actuators ensures your fluid system remains responsive and accurate under all conditions.

The method and accuracy of rotation are the primary factors in how quickly and safely you can switch flow paths.

Why is seat material critical to how does a three way ball calve work?

Seat material determines the temperature, pressure, and chemical compatibility of the valve unit. Your understanding of Three Way Ball Valve Work must include the material science behind the seal interfaces.

When to use PTFE seats?

Soft seats made from PTFE or Teflon provide a bubble-tight seal in low-to-medium temperature environments. But that’s not all, as they also offer incredible chemical resistance against most industrial solvents.

- Low friction for easy turning.

- Excellent chemical inertness.

- Cost-effective for most uses.

Are metal seats better?

Hardened metal seats are necessary when you are dealing with abrasive fluids or extreme thermal conditions that would melt plastic. Here is the kicker: metal-to-metal seals require much higher torque to operate effectively.

- High-temperature stability.

- Abrasion resistance.

- Extreme pressure handling.

How does friction affect torque?

The choice of material directly impacts the force you need to apply to the handle or actuator. What’s more, higher friction materials might require larger, more expensive actuators to function.

- Operational cost impact.

- Seal wear rates.

- Maintenance frequency. Selecting the correct seat material is the most important decision for ensuring the long-term sealing integrity of your valve.

| Material | Temp Range | Seal Quality |

| PTFE | -50°C to 200°C | Bubble-Tight |

| PEEK | -50°C to 250°C | Excellent |

| Metal | Up to 500°C+ | Industrial Tight |

The environmental conditions of your application must dictate the material selection for all internal sealing surfaces.

In what industries is it vital how does a three way ball calve work?

How are chemicals handled?

In refining and chemical plants, managing the flow of corrosive fluids requires precision that standard valves cannot provide. Believe it or not, a three-way valve can replace several gate valves in a single manifold.

- Reduction in leak points.

- Safer chemical diversion.

- Streamlined plant layouts.

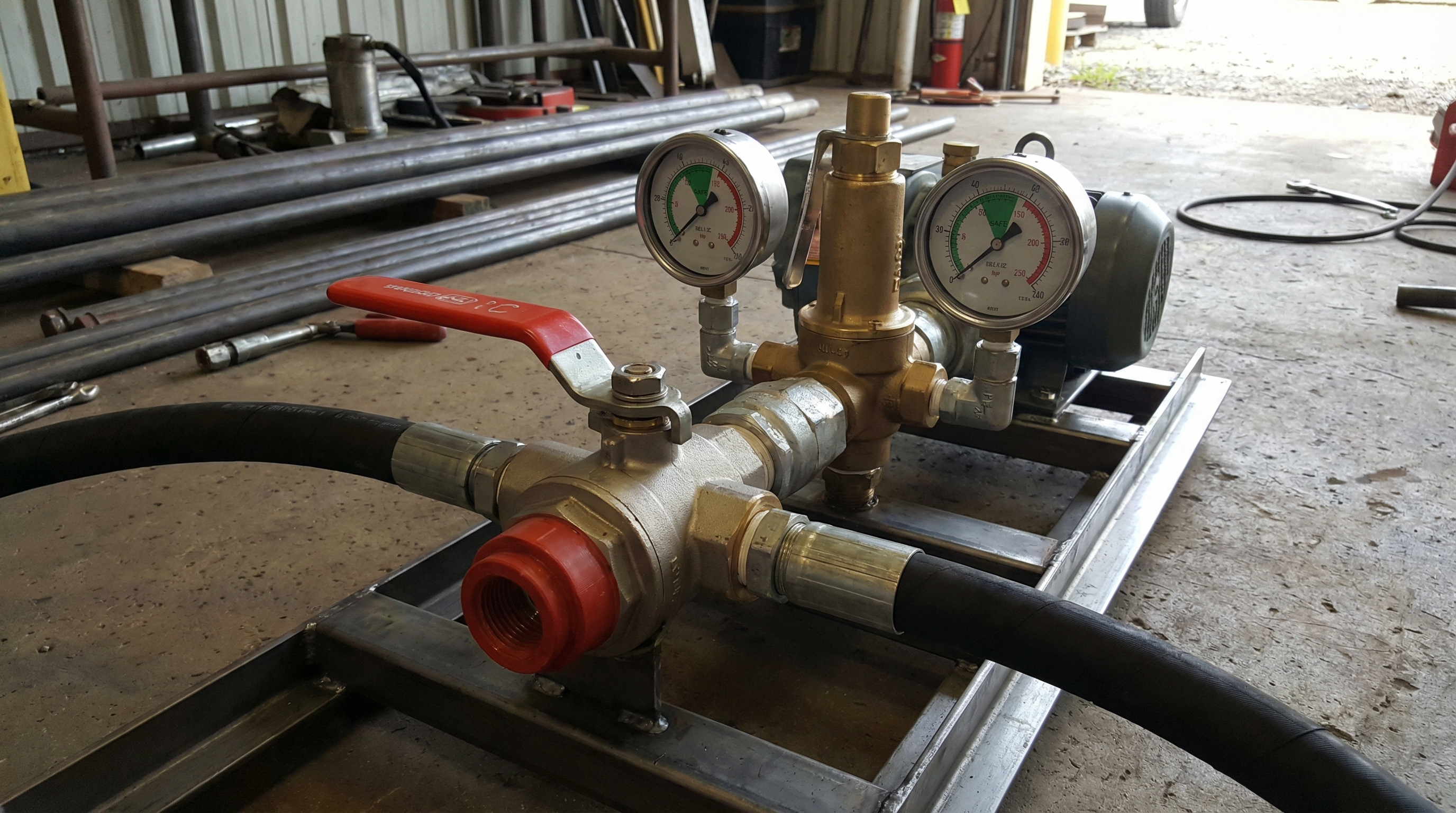

What about hydraulic power?

Hydraulic power units use these valves to direct high-pressure oil to different cylinders or return lines. It gets better because the robust construction of these valves allows them to handle thousands of PSI without flinching.

- Heavy machinery control.

- System pressure regulation.

- Efficient oil return paths.

Is industrial expertise necessary?

Drawing from years of experience in the field, we understand that every industrial sector has unique technical demands. Wait, there is more, as our commitment to fluid power standards ensures every component meets rigorous safety checks.

- Adherence to ISO standards.

- Custom engineering support.

- Comprehensive technical data. The widespread use of three-way valves across various sectors highlights their versatility as a core component of modern fluid engineering.

| Industry | Primary Use | Critical Requirement |

| Chemical | Corrosive diversion | Material compatibility |

| Hydraulic | Cylinder control | High pressure rating |

| Oil & Gas | Manifold switching | Explosion-proof |

Industrial success depends on selecting valves that are engineered for the specific rigors of your unique operating environment.

How can experts optimize how does a three way ball calve work?

Optimization involves a combination of regular maintenance and using the right diagnostic tools.

Why replace seals early?

Developing a schedule to replace O-rings and seats before they fail under pressure prevents catastrophic leaks. Interestingly enough, most valve failures are the result of neglected soft components.

- Prevention of cross-leakage.

- Protection of the ball surface.

- Reduced downtime costs.

How to care for the stem?

Ensuring that the moving parts remain lubricated prevents the stem from seizing due to oxidation or debris buildup. But that’s not all, as a well-maintained stem requires significantly less torque to operate.

- Smoother manual operation.

- Reduced actuator wear.

- Prevention of stem snapping.

Can you detect bypass leaks?

Identifying internal “bypass” leaks where fluid slips between ports requires specialized pressure testing equipment. Here is the kicker: an internal leak can be just as damaging to your process as an external one.

- Pressure drop monitoring.

- Acoustic leak detection.

- Regular cycle testing. Proactive maintenance and regular inspections are the only ways to guarantee the continued performance and safety of your valves.

| Maintenance Task | Frequency | Benefit |

| Lubrication | Quarterly | Lower torque |

| Seal Inspection | Bi-annually | Leak prevention |

| Cycling | Monthly | Prevents seizing |

A consistent maintenance routine transforms a standard valve into a long-term reliable asset for your fluid control system.

What safety protocols depend on how does a three way ball calve work?

Safety protocols like pressure relief and lockout procedures are built around the valve’s mechanical positions. High-pressure three way ball valve work requires strict adherence to safety standards to protect operators. You can verify how the three way ball calve work within integrated safety manifolds.

How is pressure relieved?

Using the third port as a return-to-tank line prevents over-pressurization during system malfunctions. What’s more, this setup acts as a manual override for automatic relief valves.

- Overpressure protection.

- Emergency fluid dumping.

- Controlled system venting.

What are LOTO procedures?

Lock-Out Tag-Out procedures ensure the valve is secured in a neutral or safe position during system maintenance. Think about it: a valve that can’t be accidentally turned is a life-saving feature for maintenance crews.

- Locking handle accessories.

- Clear “Off” position indicators.

- Tamper-proof mounting.

How to prevent cavitation?

Proper valve sizing and operation prevent the formation of vapor bubbles that can erode internal metal surfaces. Believe it or not, cavitation can destroy a high-quality ball in just a few weeks of operation.

- Correct flow sizing.

- Gradual switching speeds.

- Anti-cavitation trim options. Integrated safety features and strict operational protocols are non-negotiable when dealing with high-pressure fluid systems.

| Safety Feature | Purpose | Operational Impact |

| Locking Handle | Prevents accidents | High |

| Relief Port | Prevents bursts | Critical |

| Position Indicator | Visual safety | Moderate |

The safety of your entire production line often rests on the reliable performance of a single three-way valve.

Frequently Asked Questions

Can I use a three-way ball valve to completely shut off all flow?

It depends on the port configuration you choose. An L-port valve usually has a position where flow is blocked from the center port to the side ports, but it is primarily designed for switching rather than total isolation. Special “shut-off” three-way valves or four-seated designs are available if you require a complete zero-leakage shut-off in all directions.

What’s the best way to determine if I need an L-port or T-port?

You should evaluate whether you ever need to mix two fluids or have all three ports open at once. If your answer is yes, you must select a T-port. If your goal is simply to send fluid from one source to one of two different lines without any chance of mixing, an L-port is the standard and safer choice for your application.

How do I know if my valve is correctly aligned with the actuator?

You can check the visual indicator on top of the actuator or the flats on the valve stem to ensure they match the bore direction. Most professional-grade actuators feature a standard ISO 5211 mounting pad that ensures a keyed, foolproof connection. Always perform a dry cycle test before introducing pressurized fluid to verify that the ports open and close as expected.

Can I automate a three-way ball valve after it is already installed?

Yes, provided your valve was manufactured with an integrated mounting pad for an actuator. This modular design allows you to bolt on a pneumatic or electric motor without having to remove the valve body from your piping system. It is a cost-effective way to upgrade a manual system to a fully automated one as your production needs grow.

How do I know if the seat material is compatible with my fluid?

You must consult a chemical compatibility chart for your specific fluid and the seat material, such as PTFE, PEEK, or metal. Soft seats like PTFE are excellent for most chemicals but can fail if your fluid contains abrasive particles or operates at extreme temperatures. If you are dealing with steam or high-viscosity slurries, metal-to-metal seats are typically the only reliable option.