Are you torn between the flexibility of field repairs and the speed of factory production? Choosing the wrong hydraulic fitting type leads to wasted money, time, and effort.

Your choice depends entirely on your work environment. Reusable fittings are two-piece designs for on-the-spot repairs with hand tools. One-piece fittings are single units that require a crimping machine for fast, high-volume production in a workshop, offering unmatched speed and consistency.

What Defines a Reusable Hydraulic Fitting?

Reusable hydraulic fittings are specialized connectors that allow hoses to be assembled, disassembled, and reassembled multiple times. Unlike permanent crimp fittings, they can be removed from a worn hose and installed on a new one, provided the fitting remains undamaged. This makes them especially valuable for field service, where quick repairs are needed, and downtime must be minimized. They are popular in industries such as agriculture, construction, and small repair shops.

Construction

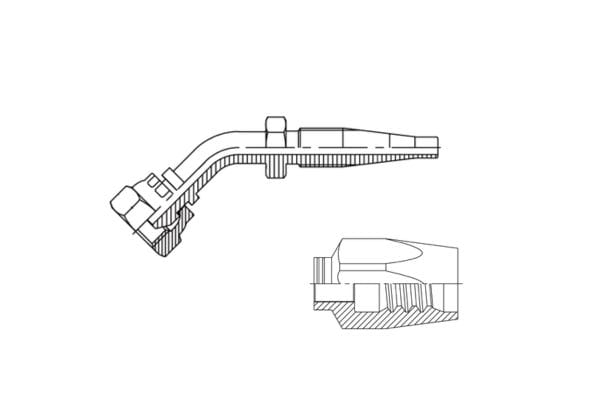

Reusable fittings typically feature two main components:

Socket (outer sleeve): The socket grips the outer cover of the hose. It creates mechanical strength by threading down over the hose, compressing the cover for a secure hold.

Insert (inner nipple): The insert fits tightly inside the hose bore, aligning with the socket. Its barbs or serrations help grip the inner tube and create a seal against fluid leakage.

These two parts are joined with a threaded connection. The installer threads the socket over the hose and onto the insert. Tightening them together creates a secure, leak-resistant joint. No crimping machine is required—only standard hand tools like wrenches.

Pros and Cons for Field Operations

✅ Pros

- Allows quick field repairs without special equipment.

- Reduces downtime for tractors, excavators, and logging machines.

- Avoids the high cost of emergency service calls.

- Fittings can be disassembled and reused on new hoses.

- Adds long-term value through reusability.

❌ Cons

- Higher initial cost compared to one-piece crimp fittings.

- Slower assembly process than hydraulic crimping.

- Requires careful installation to avoid leaks.

What Makes a One-Piece Fitting Different?

Do you need to build hundreds of identical hose assemblies for your products every single week? Is speed, consistency, and a low cost-per-assembly your top priority?

A one-piece fitting is the engine of mass production. It combines the ferrule (the outer sleeve) and the stem (the part that goes inside the hose) into a single, integrated unit.

The Crimping Process Explained

The assembly process for a one-piece fitting is completely different. It relies on a specialized machine. First, you push the fitting’s stem into the hydraulic hose until it seats properly. Then, you place the entire assembly into a hydraulic crimper fitted with the correct set of dies for that specific hose and fitting size. When you activate the machine, the dies close and compress the outer ferrule with immense force, squeezing it down to a precise, pre-determined diameter. This action permanently deforms the ferrule, binding it to the hose reinforcement and creating a secure, 360-degree seal. The process is extremely fast, often taking less than 30 seconds per end.

Benefits and Drawbacks for the Workshop

✅ Benefits

- High production speed, enabling hundreds of assemblies per day.

- Machine-controlled crimp diameter ensures consistency and reliability.

- Eliminates human error common in manual assembly.

- Lower unit cost compared to reusable fittings.

❌ Drawbacks

- Cannot be serviced in the field.

- Requires a crimping machine for every assembly.

- Entire hose assembly must be replaced if it fails in the field.

Reusable vs One-Piece: A Detailed Comparison

Choosing between reusable and one-piece hydraulic fittings involves weighing various factors. There is no single right answer; the optimal choice depends on specific application needs.

Key Differences at a Glance

| Feature | Reusable Fittings | One-Piece Fittings |

| Installation | Hand tools only, no crimp machine needed | Requires crimping machine and dies |

| Reusability | Can be removed and reused on new hoses | Single-use, discarded with the hose |

| Pressure Rating | Medium pressure range | Handles higher pressure and impulse loads |

| Size and Weight | Bulkier, takes more space | Compact, fits better in tight areas |

| Skill Requirement | Easy for basic repairs | Requires trained operator for crimping |

| Field Repair | Ideal for quick repairs in remote areas | Limited, machine access is needed |

| Industry Preference | Agriculture, maintenance, small shops | Construction, mining, manufacturing plants |

How to Install Each Type

Installing Reusable Fittings

- Cut hose cleanly Always begin by cutting the hose squarely. Use a hydraulic hose cutter or a fine-tooth hacksaw. A rough or angled cut may leave uneven edges that prevent proper sealing. Remove any rubber dust or wire fragments after cutting. Clean ends help the fitting seat tightly and reduce the chance of leaks during operation.

- Insert nipple into hose bore Next, push the insert (nipple) into the inner bore of the hose. Make sure the barbed shank or serrated surface is fully inside. This design locks against the inner tube to prevent slippage under pressure. Push firmly until the nipple bottoms out. If resistance is high, apply a small amount of approved lubricant to ease installation.

- Thread socket onto hose cover Slide the socket over the hose’s outer cover, aligning it with the nipple. Begin threading it carefully by hand to avoid cross-threading. The socket threads bite into the rubber cover, gripping it securely. Once it catches, continue rotating until it draws down over the nipple, clamping the hose between both parts.

- Tighten with wrenches until secure Finally, use two wrenches to complete the connection. Hold the nipple steady with one wrench while turning the socket with the other. Tighten until the fitting feels snug and secure. Do not overtighten, as this can strip threads, crush the hose, or weaken the seal. After tightening, visually inspect the joint to confirm proper alignment and thread engagement.

Installing One-Piece Fittings

- Cut hose squarely Start by cutting the hose with a hose saw designed for hydraulic lines. The cut must be perfectly straight across, not angled. A clean, square edge ensures the fitting slides in smoothly and crimps evenly. Remove debris, rubber dust, or exposed wire before moving to the next step.

- Insert fitting into hose Push the one-piece fitting into the hose bore until it is fully seated. The hose should cover the entire shank of the fitting without gaps. Check that the inner tube has not folded back or twisted during insertion. A correct fit at this stage is critical for sealing and long-term performance.

- Place assembly in crimping machine Position the hose and fitting in the crimping dies. Align the fitting shoulder with the die face to prevent uneven crimping. Misalignment can create weak spots or leaks. Make sure the hose is centered and the fitting is straight before beginning the crimp cycle.

- Crimp to specified diameter Activate the crimping machine until the fitting is compressed to the manufacturer’s recommended diameter. Always check the finished crimp with a caliper or a go/no-go crimp gauge. Correct measurement guarantees a strong, uniform seal. If the crimp is too loose or too tight, replace the hose and repeat the process—never reuse a mis-crimped fitting.

How to Decide Which Type to Use

Consider System Pressure

- Low to medium pressure Reusable fittings are reliable for applications under moderate operating pressures. They are often used in tractors, loaders, and small hydraulic tools where heavy loads are uncommon. These fittings balance cost and performance, making them ideal for farming, workshop repairs, and routine maintenance tasks.

- High pressure One-piece fittings are engineered for extreme demands. They handle the high-pressure spikes found in excavators, drilling rigs, and mining equipment. Their crimped design creates a permanent seal, which reduces the risk of sudden hose failure in dangerous or high-load environments.

Think About Repair Needs

- Frequent field repairs Reusable fittings shine in remote areas where downtime is costly and replacement parts are scarce. A hose can be cut, fitted, and reinstalled with simple hand tools. This makes them popular among farmers, contractors, and mobile service teams who need quick, reliable fixes.

- Fixed installations One-piece fittings are preferred for systems that run continuously, such as factory machinery or hydraulic presses. Since hoses are not replaced often, the one-time crimp connection provides long-term stability. It also reduces the risk of leaks that could disrupt production lines.

Budget and Tools

- Small shops or mobile service units Reusable fittings are cost-effective for businesses with limited budgets. They eliminate the need to purchase crimping machines or dies. Standard wrenches are all that’s required for installation. This makes them practical for repair shops or on-site service vehicles.

- Large factories or assembly lines One-piece fittings are better suited for large-scale operations. While the upfront investment in crimping equipment is higher, the long-term benefits are significant. Faster assembly, uniform crimps, and fewer leaks improve productivity and reduce labor costs. Over time, these savings outweigh the initial expense.

| Factor | Reusable Fittings | One-Piece Fittings |

| System Pressure | Low to medium pressure, tractors, loaders, small tools | High pressure, excavators, drilling rigs, mining equipment |

| Repair Needs | Frequent field repairs, quick fixes with hand tools | Fixed installations, long-term stability in factories |

| Budget & Tools | Cost-effective, no crimp machine needed, wrenches only | Higher upfront cost, needs crimping machine, efficient in bulk |

Common Mistakes to Avoid

With Reusable Fittings

- Using on high-pressure systems beyond rating Reusable fittings are generally built for low- to medium-pressure applications. When they are exposed to extreme hydraulic pressures, the threaded connection may not withstand the force. This can lead to hose separation, fluid spraying, or complete system failure. Before installation, always compare the fitting’s rated pressure with the system’s maximum operating pressure, including possible spikes.

- Reusing damaged fittings Over time, fittings can show signs of wear such as stripped threads, deformed barbs, or small cracks in the body. Reusing these parts creates weak points that compromise sealing performance. Even if the fitting appears usable, microscopic damage may lead to leaks under pressure. Always inspect fittings before reuse, and discard any that show visible wear, corrosion, or thread damage.

- Skipping thread seal checks One of the most common errors with reusable fittings is failing to properly tighten and inspect the threaded connection. A loose socket may appear sealed but will allow fluid to escape under load. On the other hand, cross-threading can damage both the socket and hose. Always thread the socket by hand first to confirm proper alignment, then finish tightening with wrenches.

With One-Piece Fittings

- Using the wrong die size Each hose type requires a precise die set for crimping. Using the wrong die results in uneven compression of the fitting, leading to weak joints or crushed hose reinforcement. This mistake often happens when technicians try to “make do” with a similar die instead of the correct one. Always refer to the hose manufacturer’s crimp chart and verify the die size before beginning.

- Under- or over-crimping If a fitting is under-crimped, it will not grip the hose firmly enough. This can cause the fitting to loosen or leak during operation. Over-crimping, however, damages the hose reinforcement and can cut into the inner tube, shortening hose life. Both errors are costly and dangerous. To prevent this, always use a calibrated crimping machine and confirm the final diameter with a crimp gauge or caliper.

- Failing to pressure-test the assembly Even if a crimp looks perfect, hidden defects may exist. Small cracks, uneven crimps, or internal damage can remain undetected until the hose is under pressure. Skipping the testing stage means these flaws could cause failure in the field, risking safety and downtime. Every newly assembled hose should undergo a proof or burst test according to manufacturer or industry standards before being approved for use.

| Fitting Type | Mistake | Consequence | Solution |

| Reusable | Using on high-pressure systems beyond rating | Hose separation, fluid leaks, system failure | Always check pressure ratings; use only in low- to medium-pressure systems |

| Reusing damaged fittings | Weak seal, leaks, sudden failure | Inspect before reuse; replace fittings with visible wear or thread damage | |

| Skipping thread seal checks | Loose connection, leaks, cross-thread damage | Hand-thread first; tighten with wrenches and confirm proper alignment | |

| One-Piece | Using the wrong die size | Uneven crimp, crushed hose, poor sealing | Match die size with hose manufacturer’s crimp chart before crimping |

| Under- or over-crimping | Loose fittings, leaks, or hose damage | Use a calibrated crimping machine; check final diameter with a gauge | |

| Failing to pressure-test the assembly | Hidden defects, leaks, unsafe failures | Perform proof or burst tests before use, per industry standards |

At Topa, we offer a full range of hydraulic fittings, all manufactured to global standards. Whether you require couplings for field repairs, heavy machinery, or large-scale production, we have you covered. Make Topa your trusted hydraulic coupling partner—order now to ensure your systems run smoothly and reliably!

FAQ

When should I choose reusable hydraulic fittings?

Reusable fittings are ideal for low- to medium-pressure systems and frequent field repairs where quick installation is needed.

Why are one-piece fittings better for high pressure?

One-piece fittings use a permanent crimp design that holds under extreme pressure and impulse, reducing the risk of leaks or hose blowouts.

Do reusable fittings require special equipment?

No. They can be installed with simple hand tools like wrenches, making them practical for on-site or emergency repairs.

What tools are needed for one-piece fittings?

One-piece fittings require a hydraulic crimping machine and the correct die set to ensure proper installation and sealing.

Which fitting type saves more money in the long run?

Reusable fittings save costs for small shops and repairs, while one-piece fittings are more cost-effective for factories and bulk production.

Can I use both types in the same hydraulic system?

Yes. Many businesses keep both on hand—reusable for emergency repairs and one-piece for permanent, high-pressure installations.