Hydraulic systems are sophisticated power transmission assemblies that utilize incompressible fluids to transfer energy from a motor to an actuator to perform mechanical work. Imagine a high-output production line suddenly seizing because a minor seal failure caused a massive pressure drop in your primary press. This failure doesn’t just stop a machine; it creates a cascade of mounting downtime costs that can reach thousands of dollars per hour. You need a solution that prioritizes reliability and precision. Optimized Hydraulic Systems provide the robust force and control required to keep your operations running smoothly without these expensive interruptions.

What Define Modern Industrial Hydraulic Systems?

Modern industrial Hydraulic Systems are defined by their ability to generate immense force within a small footprint using pressurized oil. These systems integrate pumps, reservoirs, and actuators into a cohesive network designed for heavy-duty applications. You will find them in everything from manufacturing plants to aerospace equipment.

The Power Density Factor

Power density in these systems refers to the high ratio of power output relative to the size and weight of the components. This allows you to perform massive lifting or pressing tasks in confined spaces where electric motors might be too bulky.

But here is the kicker:

- High force-to-weight ratio.

- Precise speed and torque control.

- Inherent overload protection.

Versatility Across Sectors

Versatility is a hallmark of these systems because they can be adapted for linear or rotary motion with simple component changes. Whether you are operating a plastic injection molding machine or a massive construction crane, the fundamental physics remains the same.

| Feature | Industrial Benefit |

| High Pressure | Maximum force output |

| Variable Speed | Precise process control |

| Fluid Cooling | Continuous operation capability |

The data shows that power density is the primary reason industries choose hydraulic power over purely mechanical or electrical alternatives.

Why is Fluid Critical for Hydraulic Systems?

Fluid is critical for hydraulic systems because it acts as the primary medium for energy transfer while providing essential lubrication for internal parts. Without a high-quality, incompressible liquid, the system cannot build the pressure necessary to move heavy loads. You must select a fluid that matches your specific temperature and pressure requirements.

Functions of Hydraulic Oil

Hydraulic oil serves four primary functions: power transmission, lubrication, sealing, and cooling. As the fluid moves through the system, it carries away excess heat generated by friction and compression.

You might be wondering…

- Mineral-based oils for standard use.

- Synthetic fluids for extreme temperatures.

- Water-glycol for fire resistance.

Maintaining Fluid Integrity

Maintaining fluid integrity requires constant monitoring of viscosity and contamination levels. If the oil becomes degraded, your components will experience accelerated wear and potential failure.

| Fluid Property | Operational Impact |

| Viscosity Index | Performance across temperatures |

| Oxidation Stability | Fluid lifespan and sludge prevention |

| Anti-wear Additives | Protection of pumps and valves |

Selecting the correct fluid specification is the single most important factor in long-term system reliability.

How Do Pumps Drive Hydraulic Systems?

Pumps drive Hydraulic Systems by converting mechanical energy from an engine or motor into fluid power through flow generation. The pump creates a vacuum at its inlet to pull fluid from the reservoir and then pushes it into the system’s lines. You can learn more about specific models in our industrial hydraulic pumps guide .

Pump Types and Selection

Pump selection depends on your required flow rate and maximum operating pressure. Common types include gear, vane, and piston pumps, each offering different efficiency levels.

Think about this:

- Gear pumps for simple, low-pressure tasks.

- Vane pumps for quiet operation.

- Piston pumps for high-pressure industrial needs.

Efficiency and Output

Efficiency in pumps is measured by how much input power is successfully converted into fluid flow without being lost to heat. High-efficiency pumps reduce your energy costs and extend the life of your fluid.

| Pump Type | Typical Pressure Range | Common Application |

| External Gear | 1500 – 3000 PSI | Material handling |

| Axial Piston | 3000 – 6000+ PSI | Heavy construction |

| Internal Gear | 1000 – 2500 PSI | Machine tools |

Choosing the right pump architecture ensures your system has the flow capacity to meet cycle time requirements.

What is The Role of Cylinders in Hydraulic Systems?

Hydraulic cylinders in hydraulic systems serve as the primary actuators that convert fluid pressure into linear mechanical force. They are the components that actually “do the work,” such as lifting a bucket or pressing a mold. Proper upkeep is essential, and you should follow a strict hydraulic cylinders maintenance schedule to prevent leaks.

Hydraulic Cylinder Construction

A cylinder consists of a barrel, a piston, and a rod that extends or retracts based on fluid flow. High-strength steel and precision seals ensure the unit can withstand thousands of pounds of force.

In other words:

- Single-acting for one-way force.

- Double-acting for powered extension and retraction.

- Telescopic for long-stroke requirements.

Seal Performance

Seal performance determines how well a cylinder maintains pressure and prevents external contamination. If a seal fails, you lose power and risk environmental hazards from leaking oil.

| Component | Function |

| Piston Rod | Transmits force to the load |

| Wiper Seal | Keeps dirt out of the barrel |

| Cylinder Head | Secures the rod end of the barrel |

Effective cylinder design maximizes the longevity of the entire machine while ensuring operator safety.

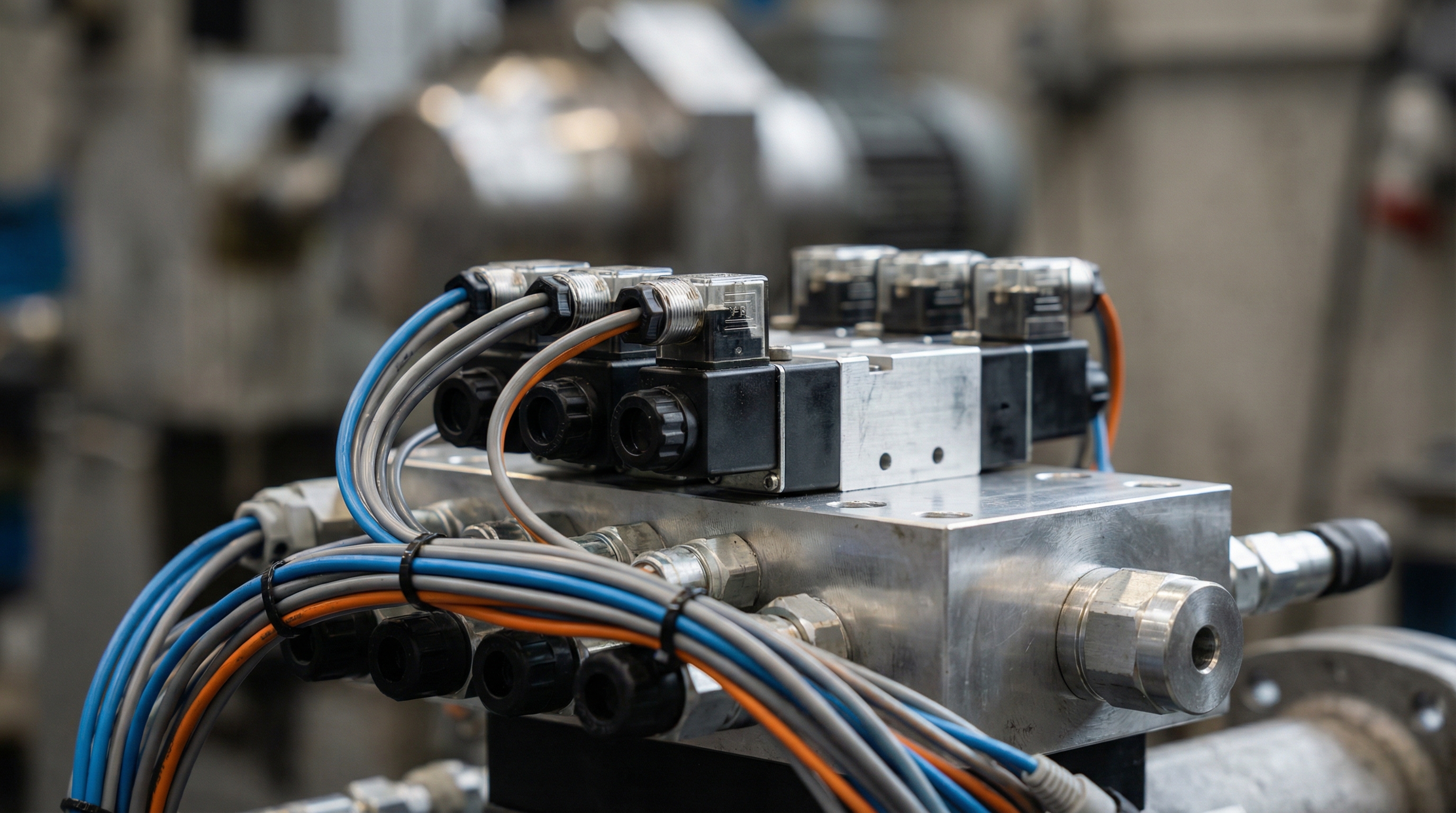

How Do Valves Control Hydraulic Systems?

Valves control hydraulic systems by directing fluid flow, regulating pressure, and managing the flow rate to various actuators. They act as the “brain” of the circuit, ensuring that every movement is timed and powered correctly. For assistance in choosing the right type, consult our hydraulic valves selection resource.

Directional Control Valves

Directional control valves determine where the fluid goes, allowing you to extend or retract cylinders at will. They can be operated manually, mechanically, or via electronic solenoids for automated processes.

Let’s dig deeper:

- Check valves for one-way flow.

- Spool valves for complex routing.

- Proportional valves for fine control.

Pressure and Flow Regulation

Pressure and flow regulation valves prevent your system from exceeding safe limits and control the speed of operation. These safety components are vital for protecting your hardware from catastrophic bursts.

| Valve Type | Primary Purpose |

| Relief Valve | Limits maximum pressure |

| Flow Control | Adjusts actuator speed |

| Solenoid Valve | Enables remote/automated control |

The integration of smart valves allows for modern automation that significantly increases factory throughput.

Why are Hoses Essential to Hydraulic Systems?

Hoses are essential to hydraulic systems because they provide the flexible pathways needed to transport high-pressure fluid between moving components. Unlike rigid piping, hoses can bend and flex, which is critical for machinery with moving arms or platforms. You must ensure your hoses are rated for both the pressure and the environmental conditions they will face.

Hose Construction Layers

A standard hydraulic hose features three layers: an inner tube for fluid compatibility, a reinforcement layer for strength, and an outer cover for protection. Steel wire braiding is commonly used to provide the necessary tensile strength.

It gets better:

- Braided hoses for high flexibility.

- Spiral-wire hoses for extreme pressure.

- Thermoplastic hoses for chemical resistance.

Routine Hose Inspection

Routine hose inspection is vital because a burst hose can cause severe injury and immediate machine shutdown. You should check for abrasions, kinks, or “weeping” at the connections during every shift.

| Hose Specification | Importance |

| Pressure Rating | Prevents catastrophic bursts |

| Bend Radius | Determines routing flexibility |

| Temperature Range | Ensures material integrity |

Proper hose management prevents the most common cause of hydraulic system failure and downtime.

How Do Hydraulic Fittings Secure Hydraulic Systems?

Fittings secure Hydraulic Systems by creating leak-proof connections between hoses, tubes, pumps, and valves. They must withstand the same high pressures as the rest of the system while allowing for easy assembly and maintenance. You can find the most durable options in our list of top hydraulic hose fittings .

Thread Types and Standards

Fittings come in various thread standards, such as JIC, NPT, and ORFS, to ensure compatibility across different manufacturers. Using the correct thread type is essential to prevent stripping or slow leaks that waste expensive fluid.

The best part?

- Flared fittings for high-pressure reliability.

- O-ring face seals for vibration resistance.

- Quick-disconnects for rapid tool changes.

Material Selection

Material selection for fittings often involves carbon steel or stainless steel to prevent corrosion and handle mechanical stress. In harsh environments, such as offshore drilling, stainless steel is the preferred choice for its longevity.

| Fitting Style | Key Advantage |

| JIC 37-Degree | Standardized and easy to install |

| O-Ring Face Seal | Superior leak prevention |

| NPT Pipe Thread | Common for low-pressure auxiliary lines |

Standardizing your fittings across your facility simplifies inventory and speeds up emergency repairs.

How to Ensure Filtration in Hydraulic Systems?

Ensuring filtration in Hydraulic Systems involves using specialized filters to remove microscopic particles that can damage sensitive pumps and valves. Contamination is the leading cause of hydraulic component failure, making a robust filtration strategy a top priority. You must monitor filter indicators to know exactly when a replacement is needed.

Levels of Filtration

Systems typically employ suction strainers, pressure line filters, and return line filters to capture debris at various stages. This multi-stage approach ensures that even the smallest metal shavings or dirt particles are trapped.

Make no mistake:

- Suction filters protect the pump intake.

- Pressure filters protect sensitive valves.

- Return filters clean fluid before it enters the tank.

Importance of Oil Analysis

Oil analysis complements physical filtration by identifying chemical changes or invisible contaminants in the fluid. By analyzing samples regularly, you can predict potential failures before they happen.

| Micron Rating | Contaminant Type |

| 5 – 10 Microns | Silt and fine dust |

| 10 – 25 Microns | General industrial debris |

| 40+ Microns | Large metal particles |

A well-maintained filtration system can triple the life of your hydraulic components by reducing abrasive wear.

How to Perform Diagnostics on Hydraulic Systems?

Performing diagnostics on hydraulic systems requires a combination of sensory inspection and high-precision electronic measurement tools. You should start by checking for unusual noises, excessive heat, or sluggish actuator response. Modern technicians use digital flow meters and pressure transducers to pinpoint exact internal issues without dismantling the entire machine.

Using Pressure Gauges

Pressure gauges are the most basic diagnostic tool, allowing you to see if the pump is hitting its relief setting or if pressure is dropping across a valve. Consistent readings are a sign of a healthy, stable circuit.

Here is the truth:

- Listen for “aeration” (snorting sounds).

- Check for “cavitation” (metallic banging).

- Use thermal cameras to find internal leaks.

Digital Diagnostic Tools

Digital diagnostic tools can log data over time, helping you identify intermittent faults that only occur during specific cycles. This data-driven approach takes the guesswork out of complex troubleshooting.

| Symptom | Probable Cause |

| Slow Operation | Low pump flow or internal bypass |

| Overheating | Clogged cooler or high friction |

| Erratic Motion | Air in the fluid or damaged seals |

Investing in advanced diagnostic equipment pays for itself by reducing the time your machines spend offline.

What Are the Future Trends for Hydraulic Systems?

Future trends for hydraulic systems are centered on “smart” integration, energy efficiency, and hybrid electrification. You will see more systems using IoT sensors to provide real-time health monitoring and predictive maintenance alerts. These advancements are making hydraulics more competitive with all-electric systems in terms of precision and environmental impact.

Electrification and Hybridization

Hybrid systems combine the strength of hydraulics with the precision control of electric servo motors. This allows you to use power only when needed, drastically reducing your factory’s energy footprint.

Believe it or not:

- Smart pumps with variable frequency drives.

- Bio-degradable “green” hydraulic fluids.

- Integrated sensors for remote monitoring.

Increased Precision Control

Increased precision through advanced electronics allows these systems to perform tasks once reserved for delicate robotics. You can now achieve sub-millimeter accuracy even when handling multi-ton loads.

The future is “Electro-Hydraulic,” merging massive force with digital intelligence for peak productivity.

| Trend | Main Advantage |

| IoT Integration | Predictive maintenance |

| Digital Twin Tech | Virtual system optimization |

| High-Efficiency Seals | Zero-leakage sustainability |

Staying ahead of these trends ensures your facility remains competitive in a rapidly evolving industrial landscape.

FAQ

Can I mix different types of hydraulic fluid? No, you should never mix fluids as different chemical additives can react and cause sludge or seal damage.

What’s the best way to prevent hydraulic leaks? The best way is to maintain a strict inspection schedule for hoses and fittings while ensuring all components are properly torqued.

How often should I change my hydraulic filters? You should change filters whenever the differential pressure indicator signals a bypass or during your scheduled annual maintenance.

Can hydraulic systems operate in freezing temperatures? Yes, but you must use a low-viscosity fluid specifically rated for cold starts to prevent pump cavitation.

How do I know if my hydraulic pump is failing? Signs include increased noise levels, excessive heat generation, and a noticeable decrease in the speed of your actuators.