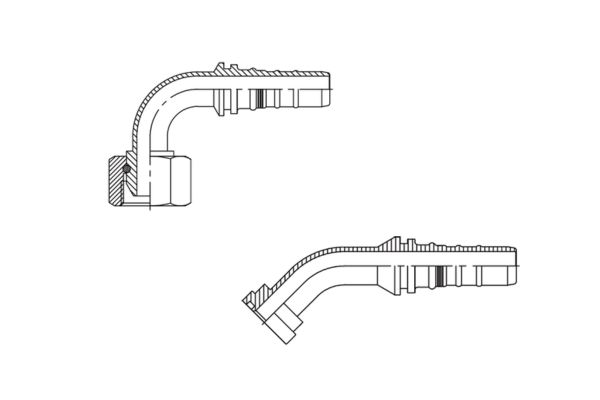

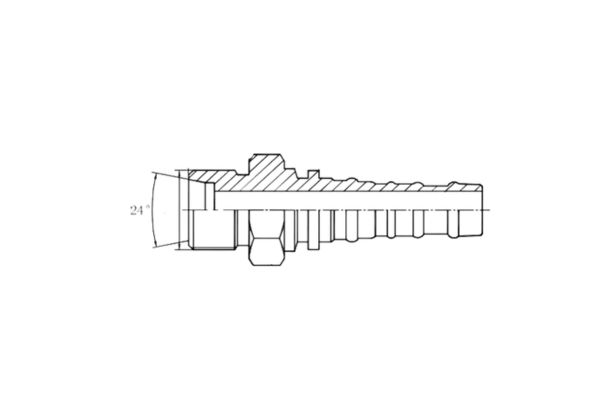

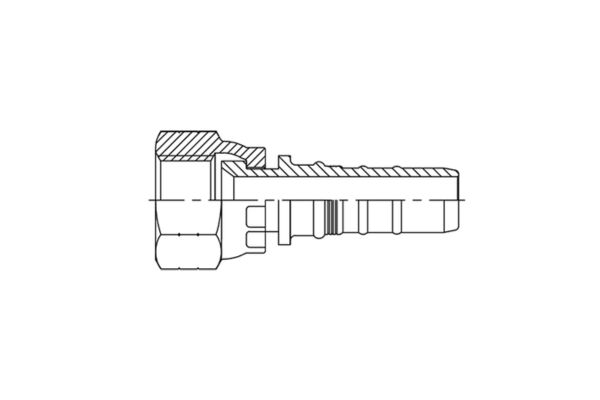

Swivel Hose End An Fitting

Swivel hose end fitting has swivel end on both ends, they are easy to operate and install. Topa can supply all size and color AN fuel line fitting , you can check the pictures below.

If you have any questions of An hose fittings, please contact us!

Swivel Hose End An Fitting Video

This video is about the details of Topa swivel hose end fitting.

Swivel hose end An fittings are made of high-quality aluminum. They are used to connect braided fuel lines. Topa can offer all kinds of an hose connectors.

Please contact with us if you have any questions about hydraulic An hose fitting or other products.

An Fitting Catalog

This catalog is about An fittings.

Topa can offer all kind of hydraulic An hose fittings, and our catalog also including all of them.

Please contact us If you need more information of An hydraulic hose fittings, or would like some free samples.