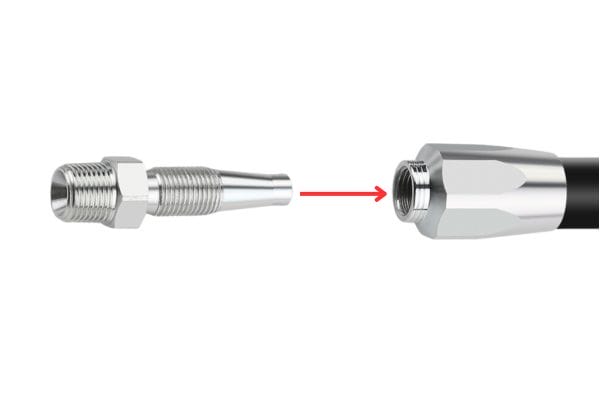

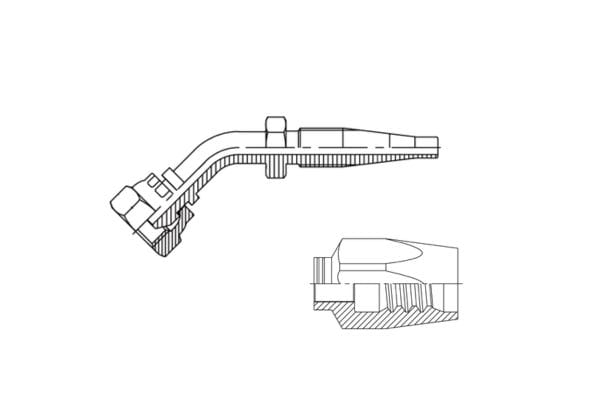

The science behind reusable hydraulic fittings lies in mechanical engineering, not brute force. They use a dual-threaded design and opposing forces to create a secure, leak-proof seal. A threaded socket grips the hose externally while a nipple expands it internally, forming a powerful compression lock.

The genius of the reusable fitting is its simplicity, but that simplicity is built on some very clever engineering principles. It’s not just a nut and a bolt. It’s a carefully designed system.

How Do Reusable Fittings Create a High-Pressure Seal Without Crimping?

Confused about how a fitting assembled with a wrench can be as strong as one made with a hydraulic press? This doubt can make technicians hesitate or assemble them incorrectly.

A reusable fitting creates a seal using the principle of opposing mechanical forces. A left-hand threaded socket screws onto the hose cover, while a right-hand threaded nipple pushes into the hose tube. This action simultaneously compresses and expands the hose, forming a 360-degree mechanical lock.

The real science here is in the distribution of force. A crimped fitting applies a massive radial force from the outside only. It’s a brute-force crush. A reusable fitting uses a more elegant, multi-directional method.

The Role of the Socket

The socket is the first piece of the puzzle. It has an internal, left-hand (counter-clockwise) thread. This is intentional. When you screw it onto the hose, the sharp threads are designed to cut through the outer rubber cover and bite directly into the steel wire reinforcement braid. This creates a powerful grip that prevents the hose from pulling out under pressure. Turning it counter-clockwise is also a key safety and design feature, ensuring it does not loosen when the right-hand threaded nipple is installed.

The Role of the Nipple

The nipple is the second piece. It has a standard right-hand (clockwise) thread. As you screw it into the socket, its tapered nose enters the hose’s inner tube. This action does two things:

- It forces the soft inner tube material tightly against the inside of the hose reinforcement.

- It pushes the hose reinforcement outwards, forcing it hard against the threads of the socket that are already biting from the outside.

This creates a “pincer” effect, locking the hose between the two metal components. The final seal is metal-to-metal at the tapered end of the nipple, but the strength of the assembly comes from this powerful mechanical grip on the hose itself.

What Role Does Material Science Play in Fitting Reliability?

Do you assume all steel fittings are the same? Choosing a fitting made from inferior materials can lead to premature failure from corrosion or cracking, right when you need it most.

Material science is critical. Reusable fittings are typically made from specific grades of carbon steel or stainless steel for strength and durability. They are then plated with materials like zinc or zinc-nickel alloy to provide essential corrosion resistance, extending their service life significantly.

The Science of Plating

However, raw steel rusts easily. This is where plating science comes in. Corrosion isn’t just ugly; it’s dangerous. A rusted fitting can have its structural integrity compromised, and rust flakes can contaminate the hydraulic system.

- Zinc Plating (Trivalent Chromate): This is the industry standard. A layer of zinc is electroplated onto the steel fitting. The zinc acts as a sacrificial anode, meaning it corrodes first, protecting the steel underneath. The chromate conversion coating applied over the zinc provides another layer of protection and gives it the common silver or yellow-gold appearance.

- Zinc-Nickel Alloy: This is a superior, high-performance plating we offer for harsh environments. By alloying the zinc with nickel (typically 12-15% nickel), the corrosion resistance is dramatically improved. These fittings can withstand salt spray tests for hundreds of hours longer than standard zinc plating.

Material Hardness

The hardness of the material, measured on the Rockwell scale, is also crucial. The fitting must be hard enough to resist thread deformation under tightening torque and pressure pulsation but not so brittle that it cracks. We perform rigorous testing to ensure our fittings meet the precise hardness specifications required for safe, long-term use.

Why Is the Thread Design So Critical for Performance?

Think all threads are just for screwing things together? The specific design and quality of the threads on a reusable fitting are the difference between a secure seal and a high-pressure leak.

The thread design is a work of precision engineering. The specific pitch, angle, and sharpness of the threads on both the socket and nipple are calculated to maximize grip and sealing pressure without damaging the hose’s structural integrity or the fitting itself.

In my experience, the details make all the difference, and this is especially true for threads. A poorly machined thread with incorrect angles or a dull profile simply won’t perform.

The Socket’s Left-Hand “Wave” Thread

The internal thread on the socket isn’t like a normal bolt thread. It’s often designed as a “wave” or “rope” thread. It’s sharp enough to bite into the hose cover but broad enough not to sever the critical wire reinforcement braids. The left-hand direction is also a crucial design choice. When the right-hand nipple is tightened, it creates a rotational force. The opposing thread direction of the socket ensures that this force tightens the socket’s grip on the hose rather than loosening it.

The Nipple’s Sealing Threads

The threads on the nipple perform two jobs.

- Mechanical Engagement: They engage with the socket’s threads to pull the two pieces together, creating the compression force.

- Sealing Path: For some fitting types (like NPT), the threads themselves form part of the seal (a tapered thread seal). For others (like JIC or ORFS), the threads provide the mechanical force, while a separate surface (a flare or an O-ring) creates the primary seal.

Here is a simplified table of thread functions:

| Thread Location | Primary Function | Scientific Principle |

| Internal Socket Thread | Grip the hose reinforcement | Mechanical interference and friction |

| External Nipple Thread | Engage with socket | Application of axial force via screw mechanics |

| Connection End Thread | Connect to other components | Provides mechanical connection and/or sealing path |

The precise geometry ensures that tightening torque is converted into optimal clamping force. This is why using a torque wrench, while not always practical in the field, is the technically ideal way to ensure this force is applied correctly.

How Do Fittings Affect Hydraulic Fluid Flow and Pressure?

Ever consider how a fitting might disrupt the flow inside your hose? A poorly designed fitting can create turbulence, leading to pressure drops, heat generation, and reduced system efficiency.

A well-designed reusable fitting minimizes flow disruption. Its internal passages are smooth, with gradual tapers and no sharp edges. This maintains a laminar (smooth) flow of hydraulic fluid, preventing turbulence that can rob the system of pressure and generate unwanted heat.

This is a more advanced aspect of hydraulics, but it’s important for performance. Every component in a hydraulic system contributes to the overall pressure drop. While a single fitting has a small effect, a system with many poorly designed fittings can become inefficient.

Laminar vs. Turbulent Flow

- Laminar Flow: Think of fluid moving in smooth, parallel layers. It’s efficient and quiet, with minimal energy loss.

- Turbulent Flow: The fluid moves in chaotic, swirling eddies. This creates friction, which manifests as a pressure drop and generates heat. It wastes energy.

Sharp corners, abrupt changes in diameter, and rough internal surfaces inside a fitting will trip laminar flow into turbulence. A quality reusable fitting nipple is designed with a smooth, bore-matched internal diameter and a gradual taper to ensure the fluid can move through it with minimal disruption.

Bernoulli’s Principle

Bernoulli’s principle states that as the speed of a fluid increases, its pressure decreases. When the internal diameter of a fitting is smaller than the hose, the fluid must speed up to pass through it, causing a temporary pressure drop. Our goal at Topa is to design fittings where the internal passage is as close to the hose’s inside diameter as possible, minimizing this effect and preserving the power and efficiency of your hydraulic system.

What Does the Science of Failure Teach Us About Reusable Fittings?

Are you replacing fittings without understanding why they failed? Simply swapping a broken part without learning from the failure leads to repeat problems and ongoing expenses.

The science of failure analysis shows that reusable fittings typically fail from predictable causes: metal fatigue due to pressure pulsations, incorrect assembly (over/under-tightening), or corrosion. Understanding these mechanisms is key to preventing them through proper installation and inspection.

Metal Fatigue

This is failure from repeated stress cycles. Every time your hydraulic system pressurizes, the fitting is stressed. When it depressurizes, the stress is relieved. Over millions of these cycles (pressure pulsations), microscopic cracks can form at points of high stress concentration, like the root of a thread or a sharp corner. These cracks slowly grow until the part fails. We combat this by using quality materials and designing fittings with rounded corners and smooth transitions to reduce stress concentration points.

The Physics of Torque

Overtightening is a common failure mode. When you apply too much torque with a wrench, you can exceed the material’s elastic limit.

- Elastic Deformation: The material stretches but returns to its original shape. This is normal.

- Plastic Deformation: You stretch the material so much that it’s permanently damaged. The threads are stripped or the body cracks. This fitting is now scrap.

Under-tightening is also bad, as it won’t create enough clamping force to seal properly or grip the hose, leading to leaks or blow-offs. The “gap” method of tightening is a practical way to achieve the correct preload without needing a torque wrench.

How Do Temperature Extremes Affect a Reusable Fitting’s Performance?

Worried about your equipment working in a freezing winter or a blazing summer? Extreme temperatures can cause materials to expand and contract, potentially compromising the seal on your hydraulic fittings.

Temperature extremes affect fittings due to thermal expansion and contraction. Metals and the rubber hose expand or shrink at different rates. A well-designed fitting accounts for this, but very low temperatures can make the hose less flexible, while high heat can accelerate aging and reduce seal effectiveness.

Cold Temperatures

In extreme cold, the rubber compounds in a hydraulic hose become hard and less pliable. This can make assembly more difficult. More importantly, if the seal relies on the flexibility of the rubber, its effectiveness can be reduced. The metal of the fitting will also contract, which can slightly alter the clamping forces. This is why using hoses and fittings rated for low-temperature service is critical in cold climates.

High Temperatures

High heat is also an enemy.

- Reduced Oil Viscosity: Hot hydraulic fluid becomes thinner, making it more likely to find small leak paths.

- Material Aging: Heat accelerates the aging of the rubber hose, making it brittle over time.

- Expansion: Both the hose and fitting expand. Because they expand at different rates, the tightness of the connection can be affected.

A quality reusable fitting is designed with tolerances that can accommodate these changes within its specified operating range. However, operating equipment far outside that range is asking for trouble.

Conclusion

The reliability of reusable hydraulic fittings is not accidental; it is the result of deliberate science in engineering, material selection, and fluid dynamics, designed for powerful, repeatable performance.

At Topa, we are passionate about this science. We manufacture fittings that are not only competitively priced but are built on a foundation of quality materials and precision engineering. Our fast, responsive team is ready to deliver these reliable solutions to you, anywhere in the world.

Ready to put the science of reliable fittings to work for you? Contact the Topa team for a quote and experience the difference that quality engineering makes.

FAQ

How do reusable hydraulic fittings seal without crimping?

They use opposing mechanical forces— a left-hand threaded socket grips the hose externally while a right-hand threaded nipple expands it internally, creating a strong compression seal.

Why is material selection important for fitting reliability?

High-quality carbon steel or stainless steel with zinc or zinc-nickel plating resists corrosion, cracking, and wear, ensuring long-term durability even in harsh environments.

What makes the thread design critical for performance?

Precision-engineered threads create proper grip and sealing pressure. Left-hand threads prevent loosening, while right-hand threads apply the compression force needed for a secure connection.

How does fitting design affect hydraulic fluid flow?

Well-designed fittings maintain smooth internal passages and consistent diameters to ensure laminar flow, reducing turbulence, pressure loss, and heat buildup in the system.

What are the most common causes of fitting failure?

Failures often result from overtightening, corrosion, or metal fatigue caused by pressure cycles. Proper assembly and inspection can prevent these issues.

How do temperature extremes impact reusable fittings?

Extreme cold hardens rubber hoses, while high heat accelerates aging and expansion. Quality fittings are engineered to handle thermal changes within rated operating ranges.