NPSM Thread Meaning: Unraveling the Basics

Table of Contents

Introduction

NPSM threads, characterized by their straight (non-tapered) profile, offer specific advantages in certain types of connections where sealing is achieved through means other than thread interference. In this post, readers will gain a comprehensive understanding of NPSM threads, including their definitions, history, technical specifications, and applications. We will delve into the basic characteristics that set NPSM threads apart, explore their evolution and industry adoption, and provide detailed technical insights.

What is NPSM?

Definition of NPSM

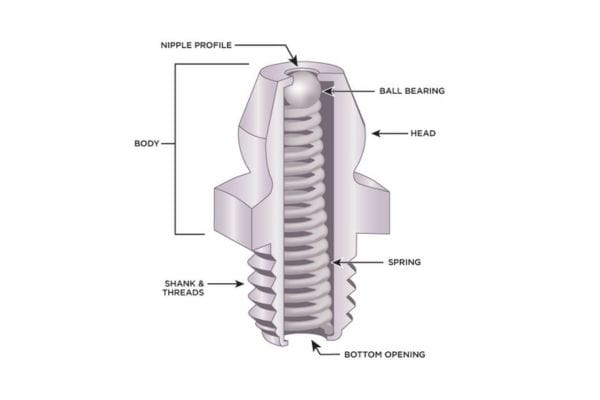

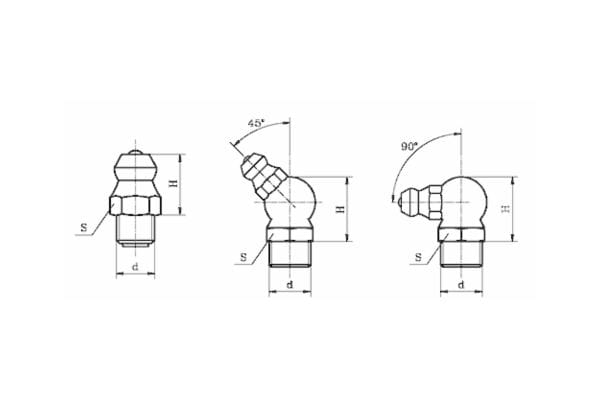

NPSM stands for National Pipe Straight Mechanical. It refers to a type of straight (non-tapered) thread used primarily in mechanical and hydraulic systems. Unlike tapered threads, which gradually decrease in diameter, NPSM threads maintain a consistent diameter throughout their length. This characteristic makes them ideal for certain types of connections where sealing is achieved through other means, such as O-rings or gasket seals, rather than thread interference.

Full Form of NPSM

National Pipe: Refers to the standardization of pipe threads in the United States, ensuring consistency and compatibility across various applications and industries.

Straight Mechanical: Indicates that the threads are straight, as opposed to tapered, and are designed for mechanical connections where the primary function is to hold components together rather than to create a pressure-tight seal through thread deformation.

Basic Characteristics and Specifications

Thread Design: NPSM threads are designed with a parallel profile, meaning the thread crests and roots are consistent in diameter along the length of the thread.

Pitch: The distance between adjacent threads is uniform, ensuring a consistent and reliable fit.

Flank Angle: The angle between the threads is standardized to ensure compatibility with other NPSM components.

Brief History of NPSM Threads

NPSM threads have their roots in the early 20th century, developed as part of the effort to standardize industrial components. As industries grew, so did the need for uniform threading standards to ensure compatibility and interchangeability. This drive towards standardization led to the creation of various thread types, including NPSM. The National Pipe Straight Mechanical thread was developed to offer a reliable and leak-proof connection specifically for mechanical and hydraulic applications. Its design catered to the needs of industries requiring robust, high-pressure-resistant connections without the use of sealing compounds.

Origin and Standardization Process

The standardization of NPSM threads was driven by the American National Standards Institute (ANSI) and later incorporated into various international standards. This standardization process involved rigorous testing and validation to ensure that NPSM threads met the necessary criteria for strength, durability, and reliability. The adoption of NPSM threads by key industries helped solidify its place as a standard, ensuring that components from different manufacturers could be used interchangeably, thus facilitating global trade and industrial expansion.

Industries Using NPSM Threads

NPSM threads are widely used across various industries due to their reliable, leak-proof connections and ease of use. Some of the key industries include:

Automotive: NPSM threads are commonly found in hydraulic systems, brake lines, and fuel systems where secure, high-pressure connections are vital.

Aerospace: The aerospace industry uses NPSM threads in hydraulic and fuel systems, as well as in various mechanical assemblies that require high precision and reliability.

Manufacturing: In manufacturing, NPSM threads are used in machinery, hydraulic presses, and equipment that relies on fluid power for operation.

Construction: Heavy machinery and hydraulic tools in the construction industry often use NPSM threads for their robustness and ease of maintenance.

Oil and Gas: NPSM threads are used in pipelines, drilling equipment, and other high-pressure applications where leak prevention is critical.

Compatibility and Interchangeability

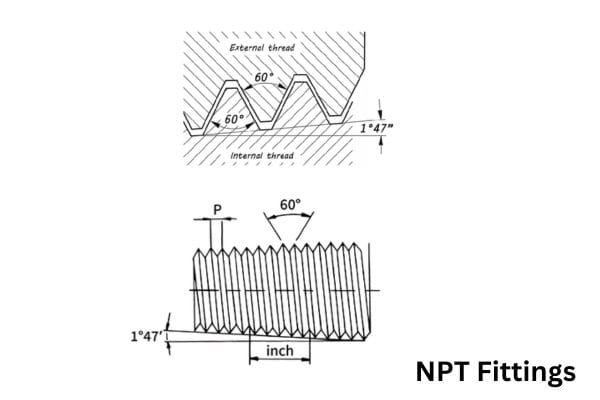

NPSM vs NPT

NPSM threads are straight threads designed for mechanical connections, relying on a gasket or O-ring to create a seal. In contrast, NPT threads are tapered, meaning the thread diameter decreases along the length, which helps create a seal through thread deformation and often requires a sealing compound like Teflon tape. While NPSM threads can connect to NPT threads, a leak-proof connection is not guaranteed without a gasket, as NPSM does not create a mechanical seal on its own. Therefore, understanding the differences is crucial for ensuring the proper application and avoiding potential leaks.

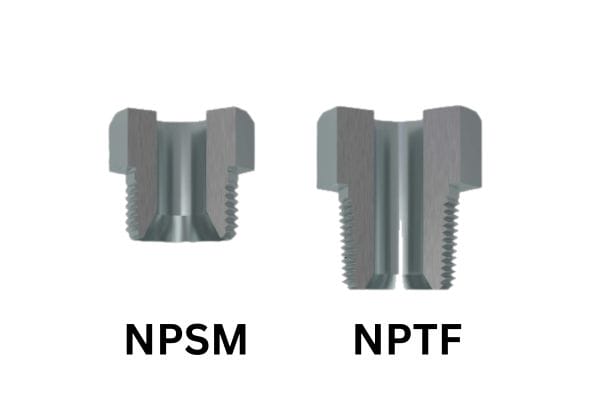

NPSM vs NPTF

NPSM threads differ significantly from NPTF threads. NPTF threads, like NPT, are tapered but are designed to create a dry seal without the need for sealants, thanks to their precision machining. The threads deform to create a metal-to-metal seal, which is especially useful in fuel systems where contaminants from sealants must be avoided. NPSM threads, being straight, require an additional sealing mechanism and do not offer the same sealing capabilities as NPTF threads. Therefore, while NPTF threads can often replace NPT in critical applications, NPSM threads require careful consideration to ensure a proper seal.

NPSM vs BSP

NPSM and BSP threads both serve essential roles in mechanical and hydraulic systems, but they differ in design and application. NPSM threads are straight, maintaining a consistent diameter along their length, while BSP threads come in two types: BSPP (parallel) and BSPT (tapered). Both NPSM and BSPP are parallel threads, but they have different thread angles and pitch dimensions, making them incompatible without adapters.

NPSM threads are commonly used in applications where a mechanical connection is required, and the seal is achieved through other means like O-rings or gaskets, making them ideal for low-pressure systems in hydraulic and pneumatic equipment. BSP threads, on the other hand, are prevalent in plumbing and industrial fluid transfer systems, particularly in Europe and Asia. BSPT’s tapered design allows it to form a seal through thread interference, making it suitable for higher-pressure applications.

NPSM vs JIC

NPSM and JIC threads cater to different needs in hydraulic systems. While NPSM threads are straight and primarily rely on external seals, JIC threads are 37-degree flared fittings designed to create a metal-to-metal seal, offering superior leak resistance in high-pressure environments. The primary distinction lies in their sealing mechanism and application suitability.

Compatibility between NPSM and JIC threads requires careful consideration. NPSM threads can connect with other straight threads or fittings designed for O-ring seals, while JIC fittings require a matching 37-degree flare to ensure a proper seal. Adapters are often needed to bridge these systems. JIC fittings are preferred in high-pressure applications like hydraulic lines in heavy machinery and aviation, where a robust, leak-proof connection is critical. NPSM fittings, meanwhile, are suited for lower-pressure applications where external sealing mechanisms can be effectively utilized.

Challenges and Considerations

Common Problems Encountered with NPSM Threads

One of the most common issues with NPSM threads is improper sealing, especially in high-pressure applications. Since NPSM threads are straight and do not seal through thread interference, they rely instead on external seals like O-rings or gaskets. Any damage or misalignment of these seals can lead to leaks. For instance, if the O-ring is not seated correctly or is damaged, the integrity of the seal is compromised, resulting in fluid leakage.

Another frequent problem is thread galling during installation. Galling occurs when friction between the threads causes them to seize or weld together. This is particularly problematic during assembly and disassembly, as galling can make it extremely difficult to separate the components without causing damage to the threads. This issue is often exacerbated in stainless steel and aluminum fittings, where the material’s tendency to gall is higher.

Solutions and Preventative Measures

To address sealing issues, it is essential to ensure that the O-rings or gaskets used with NPSM threads are of high quality and compatible with the fluids and pressures involved. Regular inspection and replacement of these seals can prevent leaks. For example, using O-rings made from materials resistant to the specific chemicals in the hydraulic system can significantly enhance seal longevity and performance. Additionally, ensuring proper seating and alignment during installation can help maintain seal integrity.

To mitigate thread galling, applying appropriate lubricants during installation can reduce friction and prevent seizing. High-quality thread lubricants or anti-seize compounds specifically designed for use with hydraulic fittings are recommended. These lubricants create a barrier between the mating surfaces, reducing metal-to-metal contact and minimizing the risk of galling. Additionally, using tools and techniques specifically designed for NPSM threads can help maintain proper alignment and avoid damage. For instance, employing a torque wrench to apply precise torque values can ensure that the threads are not over-tightened, which is a common cause of galling.

Installation and Maintenance Tips

Best Practices for Installation

When installing NPSM threads, it is crucial to ensure that the threads and seals are clean and free from debris. Contaminants can compromise the connection and lead to leaks or thread damage. Therefore, thoroughly cleaning both the internal and external threads before assembly is essential.

Lubricate the threads to reduce friction and prevent galling. Using a suitable thread lubricant helps ensure a smooth assembly process. Align the components carefully to avoid cross-threading, which can damage the threads and compromise the connection. Cross-threading often occurs when the parts are not aligned correctly, leading to improper thread engagement.

Tighten the components according to the manufacturer’s specifications, typically using a torque wrench to ensure consistent and accurate application of force. Over-tightening or under-tightening can both lead to sealing issues and thread damage. Using proper tools designed for NPSM threads can also help achieve a secure and reliable connection. For example, wrenches and fittings specifically made for hydraulic systems are designed to apply the correct amount of force without damaging the threads.

Regular Maintenance Routines

To maintain the integrity of NPSM-threaded connections, implement a routine maintenance schedule that includes regular inspections for signs of wear, corrosion, or damage to the threads and seals. Visual inspections should focus on checking for leaks, which can indicate a failing seal, and looking for any signs of thread damage or deformation.

Replace any worn or damaged O-rings or gaskets promptly to prevent leaks. Over time, seals can degrade due to exposure to hydraulic fluids, temperature fluctuations, and mechanical stress. Regular replacement of these components ensures the continued reliability of the connection.

Periodically re-torque the connections to the recommended specifications to ensure they remain tight and secure. Vibration and thermal expansion can cause fittings to loosen over time, so periodic checks are necessary to maintain the correct torque levels.

Keeping a detailed maintenance log can help track the condition of each connection and identify any recurring issues that may need addressing. Documenting maintenance activities, including inspections, component replacements, and re-torquing events, provides valuable data that can be used to improve maintenance practices and predict potential problems before they lead to system failures.

Selecting the Right NPSM Threads

Material Compatibility

Choosing the correct material for NPSM threads is crucial for ensuring compatibility with the fluids and chemicals used in your hydraulic system. NPSM threads are available in a variety of materials, including stainless steel, brass, and carbon steel. Stainless steel is highly resistant to corrosion and is ideal for applications involving water, chemicals, or food-grade environments. Brass is often used in applications requiring good conductivity and corrosion resistance in mild environments. Carbon steel, while strong and durable, requires protective coatings to prevent rust in corrosive environments. It’s important to match the material of the threads with the specific requirements of the system to prevent chemical reactions that could weaken the connection or cause contamination.

Environmental Conditions

The operating environment plays a significant role in selecting the right NPSM threads. Consider factors such as exposure to corrosive substances, temperature extremes, and humidity levels. In corrosive environments, such as those involving saltwater or industrial chemicals, materials like stainless steel or brass with appropriate corrosion-resistant coatings are preferable. For applications exposed to high temperatures, selecting materials that can withstand thermal stress without deforming or losing strength is critical. Similarly, in extremely cold conditions, materials must be able to maintain their integrity without becoming brittle. Environmental factors can significantly affect the longevity and reliability of the threaded connection, so it is essential to choose materials and coatings that are well-suited to the specific conditions.

Pressure and Temperature Ratings

Understanding the pressure and temperature ratings of NPSM threads is essential for ensuring safety and performance in hydraulic systems. Each material and design of NPSM threads has specific pressure ratings, which indicate the maximum pressure the threads can safely withstand. These ratings are typically provided by manufacturers and should be matched to the operating conditions of your system. For example, high-pressure hydraulic systems require threads with high-pressure ratings to prevent leaks and failures. Similarly, the temperature rating indicates the range of temperatures within which the threads can operate effectively. Exceeding these ratings can lead to thread deformation, leaks, and potential system failures. Always consult manufacturer specifications to ensure that the NPSM threads selected meet or exceed the operational requirements of your application.

Conclusion

In this post, we explored the fundamentals of NPSM threads, including their definition, characteristics, and applications. By understanding the unique attributes and requirements of NPSM threads, you can make informed decisions that enhance system performance and prevent potential issues. We encourage you to apply the knowledge gained from this post to select the appropriate threads for your specific applications, ensuring long-lasting and secure connections.

FAQ

NPSM stands for National Pipe Straight Mechanical. These are straight (non-tapered) threads commonly used in mechanical and hydraulic systems.

Unlike NPT threads, which are tapered and seal through thread interference, NPSM threads are straight and rely on external seals such as O-rings or gaskets for sealing.

NPSM threads are often used in low-pressure systems, hydraulic equipment, and mechanical connections where external seals are utilized to ensure a leak-free joint.

NPSM threads can be made from a variety of materials, including stainless steel, brass, and carbon steel, depending on the application’s requirements and environmental conditions.

Common issues include improper sealing due to damaged or misaligned seals and thread galling during installation. Using high-quality seals and proper lubrication can mitigate these problems.

Regular inspections for wear, corrosion, and damage, along with routine replacement of O-rings or gaskets and periodic re-torquing of connections, are essential for maintaining the integrity of NPSM-threaded connections.