A standardized metric hex profile allows for easy wrench engagement, improving grip and preventing tool slippage during installation or maintenance. This design ensures consistent torque application, reducing the risk of overtightening or under-tightening, and speeds up service work in the field or workshop.

The specially engineered internal geometry significantly lowers the insertion force needed to seat the fitting onto the hose. This not only speeds up the assembly process but also reduces operator fatigue, particularly when working with larger hose sizes or multiple assemblies in a production environment.

Available in premium carbon steel for standard hydraulic use or stainless steel for corrosive, marine, or chemical processing environments. Both materials are precision-machined for dimensional accuracy, offering extended service life even under high vibration, high load, and extreme pressure conditions.

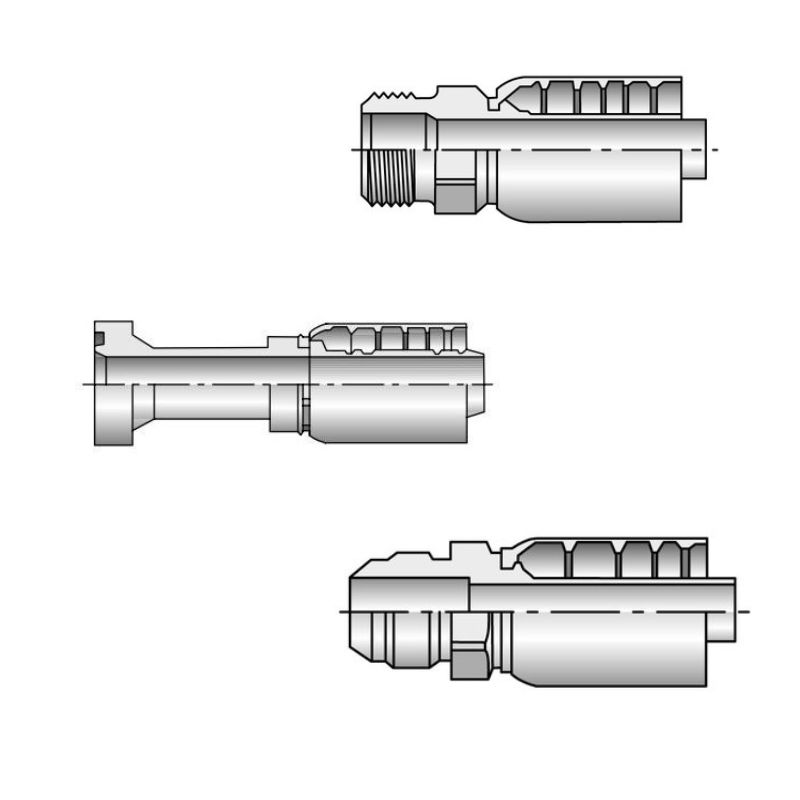

The one-piece design eliminates the need for additional adapters or multiple connection points. This reduces potential leak paths, simplifies system design, and enhances overall connection strength.

Fully compatible with 77 series crimp fittings’s No-Skive hoses, this design removes the need to strip the outer cover before crimping. The result is a faster, cleaner assembly process, reduced preparation time, and a lower risk of hose damage during assembly.

Internal flow paths are designed to minimize turbulence, reduce heat build-up, and maintain consistent pressure throughout the system. This efficiency not only improves equipment performance but also extends the life of hydraulic components by reducing stress and energy loss.

Available from ¼″ to 2″ inside diameter, covering everything from compact equipment hose assemblies to large-bore, high-flow hydraulic lines. This flexibility ensures a precise fit for virtually any high-pressure system requirement.

Designed for use with petroleum-based hydraulic oils, lubricants, and compatible industrial fluids. Material options such as stainless steel further expand compatibility to cover more demanding fluid and environmental conditions.

With over 500 configurations available — including straight, 45°, and 90° elbows; multiple port types (JIC, NPTF, SAE Code 61/62, DIN, ORFS) — the 77 Series offers unparalleled adaptability to suit different system designs and space constraints.

Specifically rated for high-pressure hydraulic systems (up to 5,000 psi), making them ideal for heavy-duty applications such as construction, mining, oil & gas, forestry, and industrial manufacturing where operational safety and system integrity are critical.