How to Measure BSP Hydraulic Fittings

Table of Contents

Introduction

BSP fittings are widely used in various industries for connecting hydraulic components. Accurate measurement of these fittings is crucial to ensure proper fitting and functionality, preventing leaks and maintaining system efficiency. BSP fittings come in two types: BSPP (British Standard Pipe Parallel), which seals with a washer or an O-ring, and BSPT (British Standard Pipe Tapered), which seals with mating male and female threads. This guide aims to provide a comprehensive step-by-step process for measuring BSP hydraulic fittings, helping you choose the correct fittings and avoid common measurement errors.

Understanding BSP Fittings

Definition and History of BSP Fittings

BSP (British Standard Pipe) fittings are standardized thread types used to connect and seal pipes and hoses in various applications. The BSP standard was developed in the early 20th century to ensure compatibility and reliability in hydraulic and plumbing systems across different industries. These fittings are distinguished by their precise thread specifications, which allow for secure and leak-free connections.

Explanation of BSPP and BSPT Threads

BSP fittings come in two main types: BSPP (British Standard Pipe Parallel) and BSPT (British Standard Pipe Tapered).

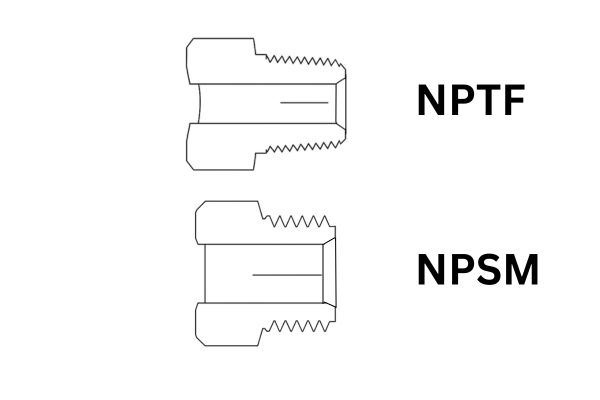

BSPP (Parallel): These threads are parallel, meaning the thread diameter remains consistent along its length. BSPP fittings rely on a sealing washer or an O-ring to create a leak-proof seal. This type of fitting is commonly used in low-pressure applications where precision and tightness are crucial.

BSPT (Tapered): In contrast, BSPT threads taper along their length, meaning the thread diameter decreases from one end to the other. This design allows the threads to create a mechanical seal by wedging together as they are tightened. BSPT fittings are often used in high-pressure applications due to their robust sealing capabilities without the need for additional sealing materials.

Common Applications of BSP Fittings

BSP fittings are prevalent in various industries due to their reliability and standardization. Some of the common applications include:

Hydraulics: Used extensively in hydraulic systems for machinery and equipment, ensuring secure connections in high-pressure environments.

Plumbing: Utilized residential and commercial plumbing for connecting pipes and fixtures, ensuring leak-free installations.

Oil and Gas: Employed in pipelines and equipment within the oil and gas sector, where durable and reliable connections are essential.

Manufacturing: Applied in manufacturing processes for machinery and equipment, supporting fluid and air systems that require precise and secure fittings.

Automotive: Used in various automotive applications, including fuel and brake systems, where robust and reliable fittings are necessary.

Step-by-Step Measurement Process for BSP Hydraulic Fittings

Step 1: Identify the Thread Type

BSPP (British Standard Pipe Parallel):

- Thread Characteristics: The threads on BSPP fittings are parallel, maintaining a constant diameter along their entire length. This uniformity ensures that the fitting can be screwed in and out easily without any tapering resistance.

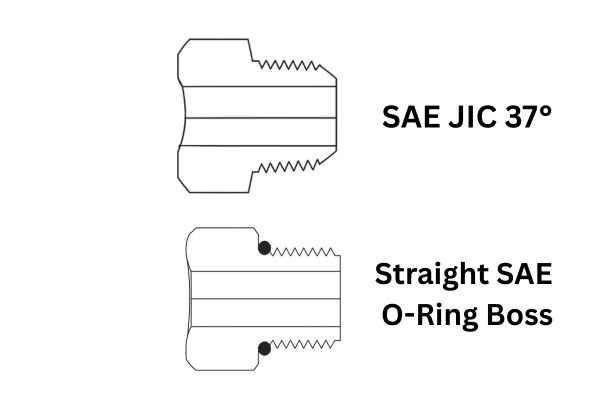

- Sealing Method: BSPP fittings typically require a sealing washer or an O-ring to create a secure seal. This is because the parallel threads do not naturally seal as they tighten. The washer or O-ring is placed between the mating faces of the fittings, which provides the necessary seal to prevent leaks.

- Visual Cues: To identify a BSPP fitting, look for the presence of a washer or an O-ring near the base. Additionally, check the threads visually or with a caliper to confirm that they are parallel and not tapered.

BSPT (British Standard Pipe Tapered):

- Thread Characteristics: BSPT fittings have tapered threads, meaning the thread diameter decreases from the end of the fitting towards the base. This taper allows the threads to wedge together, creating a mechanical seal as they are tightened.

- Sealing Method: Unlike BSPP fittings, BSPT fittings do not require additional sealing elements like washers or O-rings. The tapering of the threads themselves creates the seal when the male and female threads are tightened together.

- Visual Cues: To identify a BSPT fitting, examine the threads to see if they taper. You can measure the diameter at different points along the threads using a caliper; a decreasing diameter indicates a tapered thread. Also, the lack of sealing elements such as washers or O-rings suggests a BSPT fitting.

Checking for Sealing Methods

BSPP Sealing:

- Washer or O-Ring: Look for a washer or O-ring near the base of the fitting. These sealing elements are crucial for BSPP fittings as they rely on the washer or O-ring to form a leak-proof seal between the mating faces.

- Assembly: During assembly, ensure that the washer or O-ring is correctly positioned and not damaged. This ensures that the parallel threads are properly sealed to prevent fluid leakage.

BSPT Sealing:

- Thread Tapering: Inspect the threads to confirm they are tapered. A tapered thread will gradually decrease in diameter from one end to the other, which can be verified by measuring at different points.

- Mechanical Seal: Note that BSPT fittings do not use additional sealing elements like washers or O-rings. The tapered threads themselves create a tight seal when the fittings are screwed together, making additional seals unnecessary.

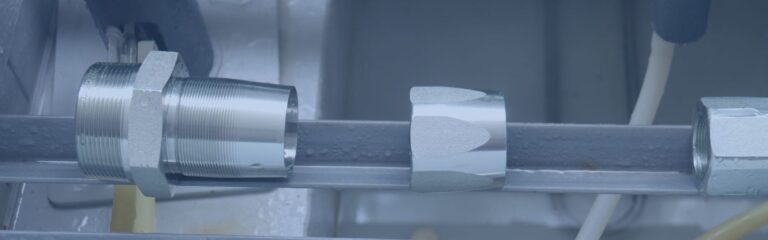

Step 2: Measure the Outer Diameter (OD)

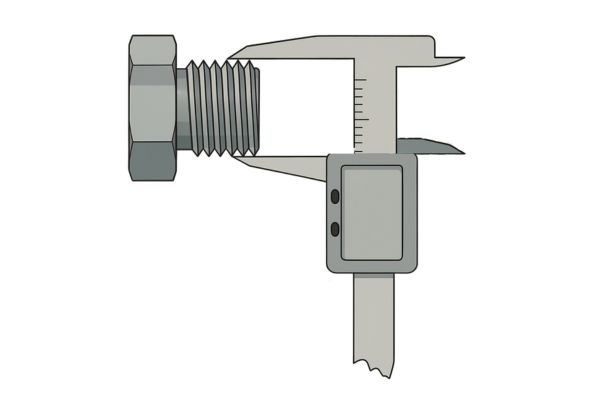

How to Use a Caliper to Measure the OD:

Open the Caliper:

Start by fully opening the jaws of the caliper to accommodate the size of the fitting.

Place Around the Outermost Thread:

Position the caliper around the outermost thread of the fitting. Ensure the jaws are parallel to the thread to avoid angled measurements.

Close the Caliper Gently:

Close the caliper jaws until they just touch the threads. Apply minimal pressure to avoid compressing the threads, which could lead to inaccurate readings.

Read the Measurement:

Ensure the caliper is perpendicular to the fitting for an accurate measurement. Read the value displayed on the caliper scale. For digital calipers, read the digital display; for analog calipers, read the scale.

Tips for Accurate Measurement

Clean the Fitting:

Remove any debris, dirt, or oil from the fitting before measuring. Contaminants can affect the accuracy of the measurement.

Measure Multiple Points:

Take measurements at several points around the circumference of the fitting. This helps to ensure that the fitting is not out of round and that your measurement is consistent.

Use a Digital Caliper:

For greater precision, use a digital caliper. Digital calipers provide more accurate and easier-to-read measurements compared to analog ones.

Example Calculation

Measured OD:

Suppose the measured outer diameter (OD) is 1 inch.

Conversion to Nominal Thread Size:

To convert the OD to the nominal thread size, subtract 25% from the measured OD.

Calculation: 1 inch (OD) – 0.25 inch (25% of OD) = 0.75 inch.

Result: The nominal thread size is ¾ inch.

Step 3: Count the Threads per Inch (TPI)

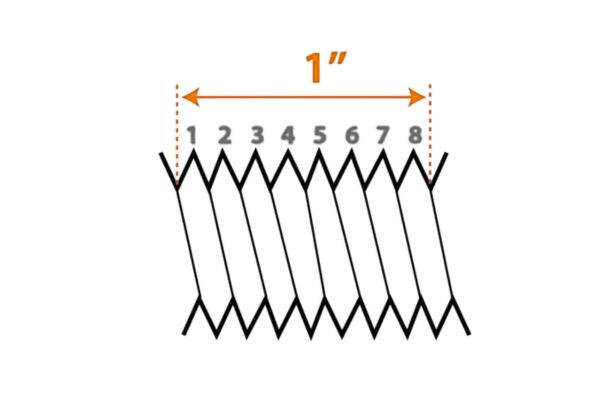

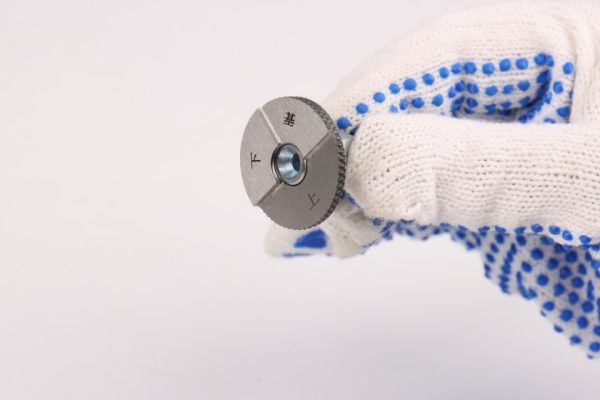

Using a Thread Pitch Gauge to Count TPI

Select a Thread Pitch Gauge:

Choose a thread pitch gauge with a range of thread sizes suitable for BSP fittings. Ensure the gauge covers the common BSP thread pitches.

Match the Gauge to the Threads:

Place the gauge against the threads of the fitting. Adjust it until the gauge fits perfectly into the threads without any gaps or overlaps. The teeth of the gauge should nestle into the valleys of the threads seamlessly.

Count the Threads:

Count the number of threads within a 1-inch section of the fitting. This count gives you the TPI (threads per inch). If your fitting is shorter than an inch, follow the instructions below.

Detailed Instructions for Measuring Short Sections and Converting to TPI:

Measure Shorter Sections:

If the fitting is too short to measure a full inch, measure a smaller section accurately. Common sections used are ¼ inch or ½ inch.

Count the Threads:

Count the number of threads in the measured section. Ensure your count is precise to avoid errors in TPI calculation.

Convert to TPI:

Multiply the thread count by the factor needed to scale up to a full inch. For example, if you measure a ¼-inch section, multiply the thread count by 4. If you measure a ½-inch section, multiply by 2.

Example: If you count 7 threads in a ¼-inch section, multiply 7 by 4 to get 28 TPI.

Examples of Common TPI for Various BSP Sizes:

1/4″ BSP: 19 TPI

3/8″ BSP: 19 TPI

1/2″ BSP: 14 TPI

3/4″ BSP: 14 TPI

1″ BSP: 11 TPI

By accurately counting the TPI using a thread pitch gauge and following these detailed steps, you can ensure that you have the correct thread measurements for your BSP fittings. This precision is crucial for ensuring compatibility and functionality in hydraulic systems.

Match Measurements to Standard BSP Thread Table

How to Use BSP Thread Tables for Verification

Gather Your Measurements:

Ensure you have accurately measured the outer diameter (OD) and counted the threads per inch (TPI) of your fitting.

Locate the Appropriate Thread Table:

Find a reliable BSP thread table from industry sources such as manufacturer specifications or industry standards. BSP thread tables are available from many hydraulic fitting suppliers and technical resources online.

Match the OD and TPI:

Compare your measured OD and TPI with the values listed in the BSP thread table. Look for a match in both the OD and TPI columns to identify the correct fitting size.

Example: If your fitting has an OD of 20.99 mm (0.825 inches) and a TPI of 14, match these measurements to the corresponding BSP size in the table.

Common Mistakes to Avoid

Misidentifying Thread Type

One of the most common mistakes is confusing BSPP (parallel) with BSPT (tapered) threads. BSPP threads maintain a consistent diameter along their length and require a washer or O-ring for sealing, while BSPT threads taper and seal through the tightening of the threads themselves. Ensure you visually and physically check the thread characteristics to avoid this error.

Inaccurate Outer Diameter (OD) Measurement

Incorrectly measuring the outer diameter can lead to selecting the wrong fitting size. Ensure that the caliper is perpendicular to the fitting and that it measures the outermost thread accurately. Additionally, clean the fitting of any debris that could affect the measurement and measure at multiple points around the circumference for consistency.

Incorrect Thread Per Inch (TPI) Calculation

Errors in counting TPI can result from not using a thread pitch gauge properly or measuring a short section inaccurately. Always ensure the gauge fits perfectly into the threads without gaps. If measuring a short section, multiply the thread count appropriately (e.g., threads in ¼ inch multiplied by 4).

Relying on Single Measurement Points

Measuring only one point on the fitting can lead to inaccuracies, especially if the fitting is not perfectly round. Always take multiple measurements around the circumference to ensure consistent and accurate readings.

Ignoring Wear and Tear

Old or worn fittings may have damaged threads that can affect measurement accuracy. Inspect the fittings for wear and tear before measuring and consider replacing severely worn parts to ensure accurate measurement.

Misinterpreting Thread Tables

When matching your measurements to BSP thread tables, ensure you are using the correct table and understand the conversions. Misinterpreting these tables can lead to selecting the wrong fittings. Always double-check your findings against multiple sources if unsure.

Overlooking Thread Pitch Variations

Some fittings may have non-standard pitches. Always verify the TPI against the specific standards and variations that might exist within BSP fittings to ensure compatibility.

Conclusion

Accurately measuring BSP hydraulic fittings is critical to ensuring proper installation and preventing leaks in your hydraulic system. With this guide, you can confidently measure and identify BSP fittings to ensure compatibility and functionality. For more help, see detailed tables and resources from reliable industry sources or Topa.

FAQ

What is the difference between BSPP and BSPT threads?

BSPP (British Standard Pipe Parallel) threads are parallel and require a washer or O-ring for sealing. BSPT (British Standard Pipe Tapered) threads taper along their length and seal through the tightening of the threads.

How do I measure the outer diameter (OD) of a BSP fitting?

Use a caliper to measure the OD at the outermost thread, ensuring the caliper is perpendicular to the fitting for accuracy. Read the measurement directly from the caliper scale.

How can I count the threads per inch (TPI) on a BSP fitting?

Use a thread pitch gauge to match the gauge teeth with the threads on the fitting. Count the number of threads within a 1-inch section or measure a shorter section and multiply accordingly to find the TPI.

What tools do I need to measure BSP fittings accurately?

You will need a caliper for measuring the OD, a thread pitch gauge for counting TPI, and a clean workspace to ensure accurate readings.

Why is it important to measure multiple points around the fitting?

Measuring at multiple points ensures consistency and accuracy, accounting for any irregularities or out-of-round conditions in the fitting.

Where can I find BSP thread tables for validation purposes?

BSP thread tables can be found in manufacturer specifications, industry standards, and online technical resources. Or contact Topa directly and we’ll help you!