Cam lock fittings are vital components in fluid transfer systems, ensuring secure and reliable connections. Proper installation is crucial not only to prevent leaks but also to maintain system performance, longevity, and safety. A correct installation ensures that the fittings work as intended and helps to avoid costly repairs or operational disruptions.

What Are Cam Lock Fittings?

Understanding the Basics of Cam Lock Fittings

Cam lock fittings, also known as cam and groove couplings, are versatile and user-friendly connectors designed to join hoses or pipes securely. These fittings are widely used across industries such as agriculture, construction, chemical processing, and fluid transfer systems due to their efficient design and functionality. Their primary purpose is to provide a reliable, quick, and leak-proof connection for the seamless transfer of liquids, powders, or gases.

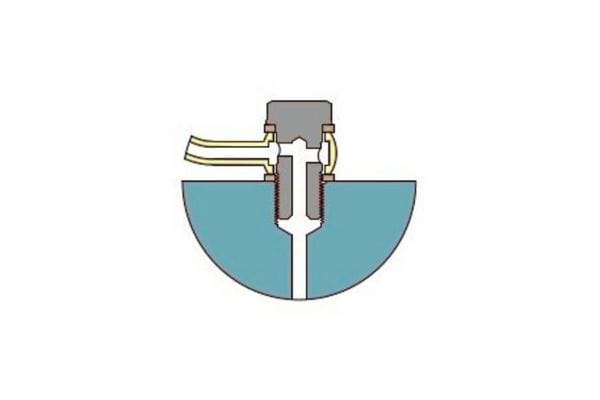

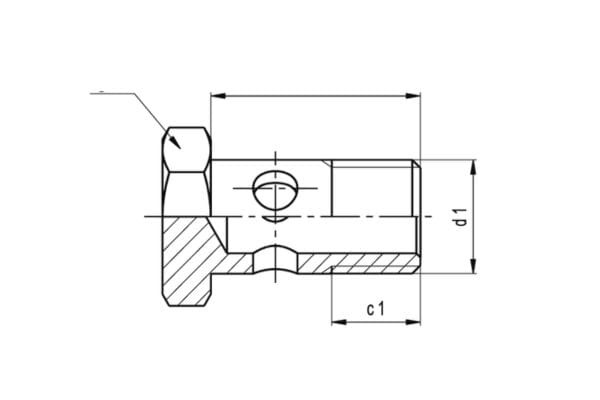

The structure of a cam lock fitting is straightforward yet highly effective. It comprises two main components:

Male Coupler (Adapter): This part inserts into the hose or pipe and forms one half of the connection.

Female Coupler (Coupling): Equipped with cam levers, the female coupler locks onto the male adapter, creating a secure seal.

The cam levers are integral to the design, allowing users to lock and unlock the connection by simply flipping the levers. This eliminates the need for complicated tools, making cam lock fittings an ideal choice for scenarios where speed and ease of operation are paramount.

Cam lock fittings are available in various materials, including stainless steel, aluminum, brass, and polypropylene. Each material is suited for specific applications depending on the type of fluid being handled, environmental conditions, and system requirements.

Why Choose Cam Lock Fittings for Your System?

Cam lock fittings have become a go-to solution for many industries because of their numerous benefits:

Ease of Use Unlike traditional threaded connectors, cam lock fittings do not require wrenches or other tools for installation. The quick-connect mechanism saves time and reduces labor, especially in systems requiring frequent assembly and disassembly.

Time-Saving Design Their quick-connect and disconnect functionality make them ideal for applications that demand efficiency. This feature is especially useful in industries such as agriculture and construction, where minimizing downtime is crucial.

Versatility Cam lock fittings are compatible with a wide range of hoses and pipes, making them suitable for diverse applications. They can handle liquids, gases, and even fine particles, catering to both high-pressure and low-pressure systems.

Reliable Seal The cam lock mechanism provides a tight, leak-proof seal, ensuring the safe transfer of fluids without spillage. This reliability is essential for preventing costly system failures or contamination.

Durability Depending on the material used, cam lock fittings can withstand harsh environmental conditions, corrosive chemicals, and high temperatures. For instance, stainless steel fittings are ideal for corrosive or high-pressure environments, while polypropylene is suited for lightweight, non-corrosive applications.

Applications of Cam Lock Fittings

The versatility and reliability of cam lock fittings make them indispensable in several industries:

Agriculture: Used for irrigation systems, pesticide transfer, and fertilizer distribution.

Chemical Industry: Ideal for transferring corrosive chemicals due to the availability of resistant materials like stainless steel and polypropylene.

Oil and Gas: Facilitates the safe transfer of fuel, oil, and gas in high-pressure systems.

Food and Beverage: Ensures hygienic transfer of liquids, such as milk or juice, with food-grade materials.

Construction: Useful for water distribution, concrete pumping, and other fluid transfer tasks on job sites.

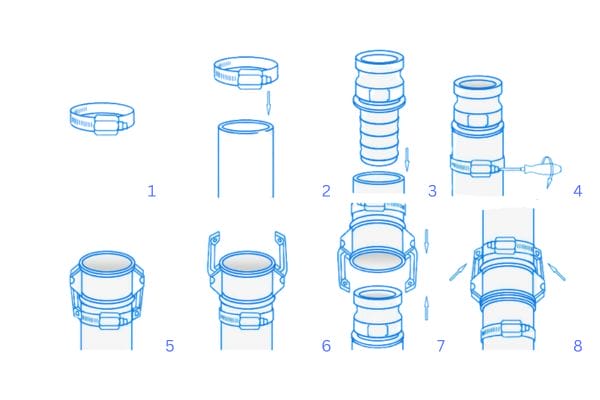

Step-by-Step Guide: How to Install Cam Lock Fittings Correctly

Preparing Your System for Installation

Before beginning the installation of your cam lock fittings, it’s essential to properly prepare the system to ensure a secure and leak-free connection. Here are the key steps for preparation:

Inspect the System: Check the pipes, hoses, or equipment where the fittings will be installed. Ensure that there are no cracks, corrosion, or other signs of damage that could compromise the integrity of the connection.

Clean the Fitting Surfaces: Any dirt, rust, or debris on the male or female coupling surfaces can interfere with the seal and result in leaks. Use a clean cloth or brush to wipe off the fittings and make sure the surfaces are free from contaminants. For more stubborn dirt, use an appropriate cleaning solution to disinfect and prepare the surfaces.

Check for Proper Size and Compatibility: Confirm that the cam lock fittings you are using are the correct size for the hoses or pipes. Mismatched sizes can prevent the fittings from locking properly, which may lead to leaks or disconnections under pressure.

Inspect O-Rings or Seals: The O-rings or seals are crucial for maintaining a leak-proof connection. Before installation, check that they are intact and in good condition. If they show any signs of wear or damage, replace them before proceeding.

Positioning and Aligning the Fittings

Proper alignment of the male and female coupling parts is critical to ensuring a secure and effective connection. Here’s how to correctly align the cam lock fittings:

Align the Male and Female Couplers: Position the male adapter (the part that attaches to the hose or pipe) into the female coupling. The male part should fit snugly inside the female part without any resistance. Both ends must be aligned straight to ensure that the cam lock mechanism works smoothly.

Ensure Proper Orientation: Make sure that both the male and female couplers are oriented in the correct direction. This means the cam levers should be positioned in such a way that they can be easily pulled and locked. Misalignment or improper orientation can make it difficult to secure the fittings and may lead to failures.

Double-Check for Obstacles: Ensure that no debris, dirt, or other materials are obstructing the connection. Even small particles can cause misalignment or prevent the couplings from locking properly.

Securing the Cam Lock Fitting in Place

Once the fittings are properly aligned, it’s time to lock them in place. This step ensures that the cam lock coupling is securely engaged and will not disconnect under pressure.

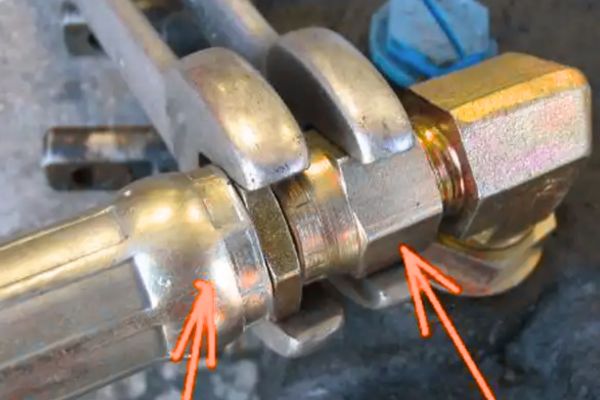

Use the Cam Levers to Lock the Fittings: Each cam lock fitting has one or two cam levers that need to be pulled down to lock the male and female parts together. With both parts aligned, grip the cam lever and pull it towards the fitting body. It should snap into place with a firm, but not forced, motion.

Check the Locking Mechanism: Once the cam lever is locked, make sure the fitting is securely attached. You should not be able to move or twist the couplings once they are locked. If the lever doesn’t engage smoothly, check for alignment issues or ensure that the fitting is properly seated.

Avoid Over-tightening: Cam lock fittings are designed to create a secure seal with just a firm pull on the cam lever. Over-tightening the levers can damage the fitting or deform the O-rings, leading to leaks or premature wear. A simple, firm pull should be enough to ensure the connection is secure.

Repeat for Additional Connections: If you are installing multiple cam lock fittings, repeat the alignment and securing process for each one. Ensure that each fitting is properly aligned and locked before moving on to the next.

Sealing Cam Lock Fittings: Ensuring a Leak-Free Connection

Importance of Proper Sealing in Cam Lock Fittings

Proper sealing is one of the most critical aspects of installing cam lock fittings. A tight, secure seal ensures that your system remains leak-free, preventing the potential for fluid or gas leaks, which could damage the system, cause costly downtime, or present safety hazards. In fluid transfer systems, a failure to properly seal cam lock fittings could lead to spills, contamination, and a pressure drop, which could compromise the system’s overall efficiency.

Cam lock fittings rely on seals such as O-rings, gaskets, and sealing compounds to create a reliable, leak-proof connection. Without these seals, or if they are improperly installed or damaged, leaks can occur around the connection point, leading to operational issues and safety risks.

By using the correct sealing methods and regularly maintaining them, you can ensure a durable, long-lasting, and safe system.

How to Properly Seal Your Cam Lock Fittings to Prevent Leaks

To ensure that cam lock fittings are sealed correctly and function as intended, follow these steps:

Use the Appropriate Sealing Method: Different types of cam lock fittings may require different sealing methods depending on the material and the pressure of the system. Always refer to the manufacturer’s instructions for the recommended sealing material. Common options include:

O-rings: These are the most common sealing method for cam lock fittings. Made of rubber or elastomeric materials, O-rings form a tight seal between the male and female parts of the fitting.

Gaskets: For larger or higher-pressure connections, gaskets may be used in addition to O-rings to prevent leaks.

Sealing Compounds: In certain applications, sealing compounds (such as PTFE tape or liquid sealants) may be applied to the threads or surfaces to ensure a leak-free connection.

Inspect the O-Rings and Seals: Before installation, always check the condition of the O-rings and seals. Ensure that the O-rings are not cracked, dry, or damaged. Worn-out O-rings should be replaced before connecting the fittings. A damaged seal will not provide adequate sealing, leading to leaks.

Lubricate the O-Rings (if needed): Some applications may benefit from lubricating the O-rings with an appropriate lubricant. This helps to ensure a smoother connection, minimizes wear and tear, and improves the seal’s effectiveness. Use a lubricant that is compatible with both the O-ring material and the fluid being transferred in your system. Always consult the manufacturer’s guidelines for lubricant recommendations.

Properly Seat the O-Rings: When connecting the fittings, ensure that the O-rings are properly seated in their grooves. Misaligned or improperly seated O-rings can create gaps in the seal, allowing fluid or air to escape. Gently press the O-ring into its seat to ensure it is uniformly positioned before locking the cam levers in place.

Double-Check the Fittings After Installation: After the cam lock fittings are secured, it is important to inspect the connection for any signs of leaks. Tighten the cam levers just enough to secure the fitting, but avoid over-tightening, which can deform or damage the O-ring and cause leaks. If you notice any leaks during testing or operation, stop the system and check the O-ring and sealing surface immediately.

Common Sealing Mistakes and How to Avoid Them

Even though cam lock fittings are relatively simple to install, several common sealing mistakes can cause leaks or damage to the system. Avoid these errors by following best practices:

Failing to Lubricate the O-Rings: One of the most common mistakes is failing to lubricate O-rings before installation. While not all O-rings require lubrication, lubricating them helps prevent damage during installation and ensures a better seal. If lubrication is needed, always use a lubricant that is compatible with the materials involved.

Using Worn or Damaged Seals: Never attempt to reuse O-rings or seals that show signs of wear, cracking, or aging. Worn seals lose their elasticity and will fail to form a tight seal, resulting in leaks. Always inspect the seals before installation and replace any that are worn out.

Over-tightening or Under-tightening the Cam Lock Levers: Over-tightening the cam levers can damage the O-rings, while under-tightening them can leave the fitting loose, causing leaks. Always follow the manufacturer’s recommended torque settings for tightening the cam levers and ensure they are securely locked in place.

Neglecting to Inspect the Sealing Surface: Another mistake is neglecting to clean the sealing surface before installation. Dirt, debris, or old sealant left on the mating surfaces can prevent a proper seal from forming. Always clean the surfaces thoroughly before fitting the components together.

Using the Wrong Type of Sealant: Using a sealing compound that is not compatible with the materials of the fitting or the fluid being transferred can result in leaks, damage to the fittings, or degradation of the sealant. Make sure to select a sealant that is appropriate for both the fitting material and the application

.

Common Mistakes to Avoid When Installing Cam Lock Fittings

Over-tightening and Under-tightening Fittings

One of the most common errors when installing cam lock fittings is failing to properly tighten them. Both over-tightening and under-tightening can lead to significant issues, including leaks, system inefficiency, and damage to the fittings.

Over-tightening: Applying excessive force when securing the cam lock fittings can cause damage to the fitting itself, such as cracking the coupler or distorting the sealing components (such as the O-rings). This can compromise the integrity of the seal and increase the risk of leaks. Over-tightening can also lead to undue stress on the system, potentially causing long-term damage.

Under-tightening: On the other hand, under-tightening the fittings can lead to loose connections, which are a common cause of leaks. If the cam lock is not tightened adequately, the coupling may not seal properly, and the fittings could easily come apart under pressure. This can be dangerous, especially in high-pressure systems.

Failing to Check for Proper Alignment

Alignment is key to ensuring that cam lock fittings function properly. If the male and female parts of the fitting are not aligned correctly before securing the cam levers, several issues can arise:

Improper Locking: If the male and female components are misaligned, the cam levers may not fully engage, which could lead to a partial connection. This can cause leaks or detachment of the coupling under pressure.

Damaged Seals: Misalignment can also cause uneven pressure on the seals, leading to premature wear or damage. Over time, this can result in leaks or even failure of the sealing components.

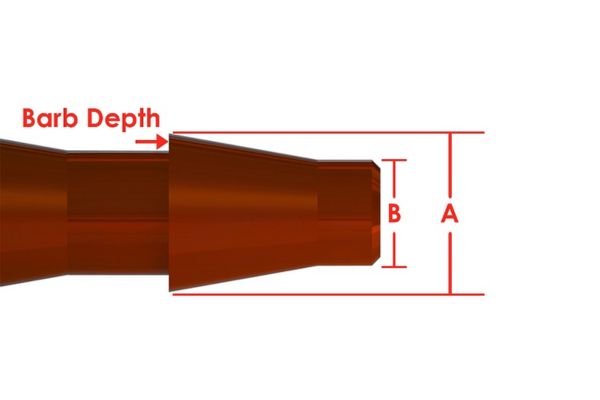

Using the Wrong Fitting Size

Choosing the wrong size cam lock fitting for your hoses or pipes is another frequent mistake that can lead to system failures. If the fitting is too small, it may not provide a tight enough seal, leading to leaks. On the other hand, a fitting that is too large can cause the coupling to be loose, which also increases the risk of a poor connection.

Too Large a Fitting: If the fitting is oversized, the connection may be unstable, causing the cam lock to fail when exposed to pressure or vibration. This can also put unnecessary strain on the entire system.

Too Small a Fitting: A fitting that is too small for the hose or pipe won’t create a proper seal, allowing leaks to occur. It could also lead to damage as the system tries to compensate for the misfit.

Troubleshooting Cam Lock Fitting Installation Issues

Identifying and Fixing Common Installation Problems

Several common installation issues can arise when working with cam lock fittings, but most of them are relatively easy to fix with a bit of attention to detail:

Misalignment: If the male and female parts of the fitting are not aligned correctly, they won’t lock properly, which can cause leaks or even detachment under pressure.

Solution: Before securing the cam levers, make sure the fittings are properly aligned. The male and female parts should be fully inserted and should line up straight, with no gaps or obstructions.

Incorrect Fitting Sizes: Using the wrong size fitting for the hose or pipe can lead to poor sealing and potential system failure.

Solution: Double-check the fitting sizes before installation. Use the correct size cam lock fittings for your system’s specifications to ensure a proper seal.

Damaged Seals: Worn or damaged seals, such as O-rings or gaskets, can cause leaks.

Solution: Inspect the seals before installation. If any seals are damaged, replace them immediately. Lubricating seals with an appropriate sealing compound can also improve the seal and prevent leaks.

Dealing with Hose Connection Issues

A common issue with cam lock fittings occurs when the hose isn’t properly seated in the fitting, which can cause leaks or instability in the connection. Here’s how to resolve this:

Ensure Proper Hose Seating: When attaching a hose to the cam lock fitting, ensure it is securely inserted into the fitting. The hose should fit snugly without any gaps.

Tighten Securely: If the hose is not seated properly, check to ensure it’s connected to the correct fitting and that there is no obstruction or misalignment. Tighten the cam lock fitting carefully, making sure the connection is secure.

What to Do When You Notice Leaks

Leaks can occur even after proper installation, often due to minor issues that can be easily corrected:

Stop the System: If you notice a leak during operation, immediately stop the system to prevent further damage or safety hazards.

Inspect for Misalignment: First, check for any misalignment between the male and female parts of the cam lock fitting. Misalignment can prevent the cam lock from engaging fully, resulting in a poor seal.

Check Seals and O-Rings: Leaks can also be caused by worn-out or damaged seals. Inspect the O-rings or gaskets for wear and tear. If damaged, replace them with new ones that match the specifications.

Retighten the Fitting: If the fitting is loose, gently retighten the cam lever. Be careful not to over-tighten, as this can cause damage to the fitting or seals.

Replace Damaged Parts: If you find any broken or damaged components (like a cracked coupler or worn-out seal), replace them with new parts to ensure a secure, leak-free connection.

Conclusion

By paying attention to detail and following best practices for cam lock fitting installation, you’ll keep your system running smoothly, efficiently, and safely. Regular inspections, proper sealing, and correct assembly will help you avoid common pitfalls and extend the lifespan of your fittings and the overall system.

FAQ

What are cam lock fittings used for?

Cam lock fittings are used to quickly and securely connect hoses or pipes in fluid transfer systems, ensuring leak-proof connections for a variety of industries, including agriculture, construction, and chemical processing.

How do cam lock fittings work?

Cam lock fittings consist of a male adapter and a female coupling with cam levers. The male part inserts into the female part, and the cam levers are pulled down to lock the fitting in place, creating a secure connection.

How do I prevent leaks when installing cam lock fittings?

To prevent leaks, ensure the fittings are properly aligned, use the correct size fittings, and check that seals (such as O-rings) are in good condition. Lubricate the seals if necessary, and follow the manufacturer’s installation guidelines.

Can I use cam lock fittings with any type of hose or pipe?

No, cam lock fittings must match the size and material of the hose or pipe. Always verify compatibility before installation to ensure a secure connection and prevent leaks or damage.

What should I do if I notice a leak after installation?

If you notice a leak, stop the system immediately. Inspect the fitting for misalignment, worn seals, or loose connections. Tighten the fittings or replace damaged components as needed.

How do I maintain cam lock fittings to ensure they last?

Regularly inspect the fittings for wear, check O-rings and seals for damage, and clean the fittings to remove debris. Lubricating the seals and replacing worn-out parts will help maintain a leak-free connection.