Your new hose assembly failed far too soon, causing a leak and stopping work. That unexpected downtime is expensive, and a high-pressure leak is a serious safety risk for everyone nearby.

The secret is installing the hose correctly by working with its natural properties, not against them. Proper installation respects the hose’s natural bend, uses the right fitting angles, and ensures the correct length to prevent all stress, which is the key to a long, reliable service life.

What is a Hose’s Natural Bend Direction?

You are trying to force a hose into position, but it seems to fight back. This creates hidden stress points that you can’t see, which will eventually lead to a premature leak or burst.

Every hose has a natural curve from being coiled during manufacturing and storage. This is its natural bend direction. Installing the hose along this curve eliminates internal stress and is the first step toward a long-lasting, reliable assembly.

Think of it like the grain in a piece of wood. You can work with the grain for a smooth finish, or you can work against it and cause splintering. A hydraulic hose is no different. Forcing it to bend against its natural curve twists the internal wire reinforcement, creating fatigue points. Simply identifying this natural bend and using it to your advantage will significantly increase the assembly’s service life.

Why Do Hoses Have a Natural Bend?

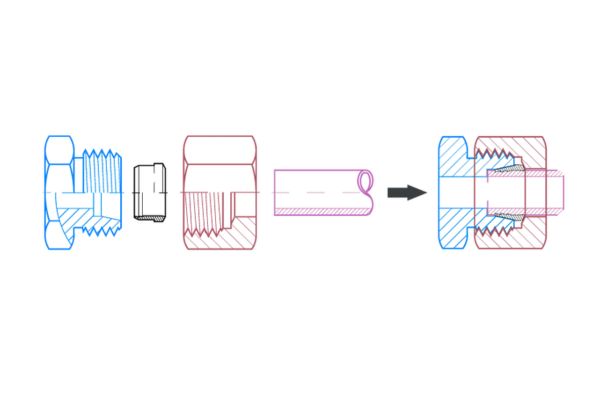

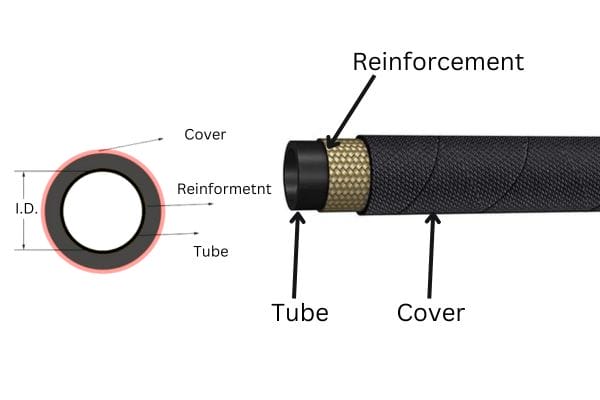

Hydraulic hose is constructed in long, continuous lengths and then stored in large coils. This coiling process imparts a permanent, gentle curve into the hose structure. Even after it is cut and assembled, this “memory” remains. It’s not a defect; it’s an inherent property of the product. The goal of a good installation is to accommodate this property rather than fight it.

How to Identify the Natural Bend Plane

The method is very simple. Lay the hose assembly on a flat, level surface and let it rest freely. The plane it naturally lies on is its horizontal reference plane, and the curve it forms is its natural bend direction. When planning your installation route, you should aim to have the primary bend of the hose follow this natural curve.

The High Cost of Ignoring the Natural Bend

When you bend a hose against its natural curve, you are not just bending it; you are also twisting it. This torsional stress puts uneven strain on the steel wire reinforcement layers. Under pressure, the hose will try to unwind itself. This constant internal friction and stress on the wires leads to metal fatigue, which is a leading cause of premature hose failure. The hose might look fine on the outside, but it’s being destroyed from within.

How Do You Configure Bent Hose End Fittings?

You have a hose with an angled fitting, but you aren’t sure which way it should point. Guessing wrong can twist the hose, creating a hidden failure point that will cause problems later on.

To prevent twisting, you must use standard fitting configurations. These configurations define the orientation of the bent fitting in relation to the hose’s natural bend plane, ensuring a stress-free connection in any direction.

When we manufacture a hose assembly with a bent fitting, we need to know its final orientation. This is specified using a clear and simple system. This system ensures that the hose you receive is built to be installed without any twist. Understanding these configurations is vital when ordering or installing assemblies with one or two bent ends, as it is the key to preventing torsional stress.

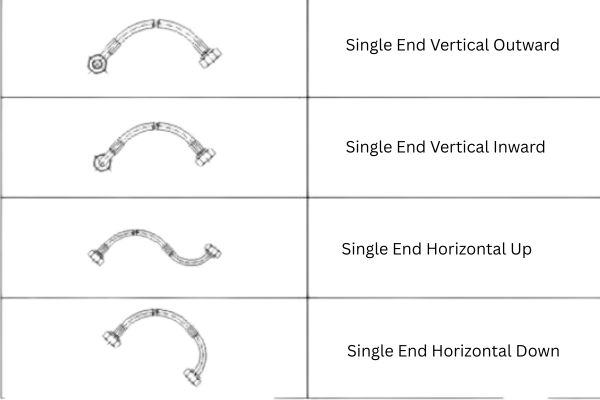

Assemblies with One Bent Fitting

When one end is a straight fitting and the other is a bent fitting (like a 45° or 90° elbow), there are four standard positions. These are defined relative to the hose’s natural bend plane.

| Configuration | Description |

| Position 1 (Up) | The bent fitting points upward, perpendicular to the natural bend plane. |

| Position 2 (Down) | The bent fitting points downward, perpendicular to the natural bend plane. |

| Position 3 (Right) | The bent fitting points to the right, parallel with the natural bend plane. |

| Position 4 (Left) | The bent fitting points to the left, parallel with the natural bend plane. |

Choosing one of these four standard options when ordering ensures the hose will fit perfectly without being forced.

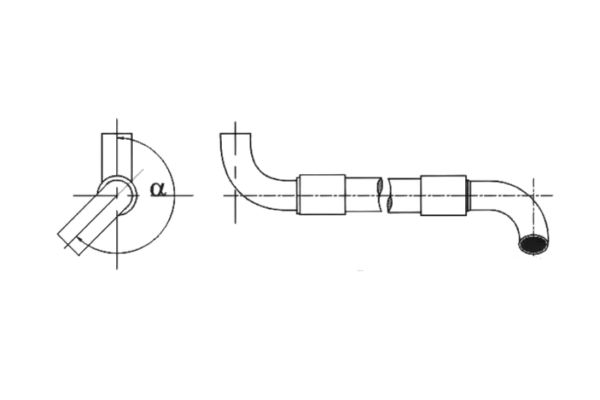

Assemblies with Two Bent Fittings

When both ends have bent fittings, we need to know their angle relative to each other. This is called the “assembly angle” or “V-angle.” It is measured by holding the near fitting pointing straight up (this is the 0° position) and then measuring the angle to the far fitting in a clockwise direction. There are ten common standard configurations for these assemblies.

Why is the Hose Fitting Angle So Critical?

A slightly twisted hose assembly does not look like a big problem. But that small amount of twist is a silent killer, slowly destroying the hose’s reinforcement from the inside every time the system is pressurized.

The fitting angle’s only job is to prevent twisting. A twisted hose will try to unwind violently under pressure, which causes the internal wire layers to rub against each other and leads to fatigue. A correctly specified angle ensures the hose only bends in one plane, totally eliminating this destructive force.

Bending vs. Twisting: The Key Difference

It is crucial to understand that bending and twisting are not the same.

- Bending: This is a natural and expected function of a hose. A hose is designed to be flexible and bend around corners. This is a safe movement.

- Twisting (Torsion): This is a rotational stress along the hose’s length. Hoses are not designed to handle torsion. A twist of even 7 degrees can reduce a hose’s service life by up to 90%.

How We Measure the Assembly Angle (V-Angle)

The V-angle is the industry standard for specifying the orientation between two bent fittings. The process is precise:

- The hose assembly is held straight.

- The “near” fitting is oriented so it is pointing vertically upwards. This is the 0-degree reference point.

- Looking at the “far” fitting, we measure its angle clockwise from the 0-degree reference.

An angle of “V90” means the far fitting is at a 90-degree angle clockwise from the near one. An angle of “V180” means it is pointing in the opposite direction

Common V-Angle Configurations

| V-Angle | Description |

| V0° | Both fittings are parallel and pointing in the same direction. |

| V90° | The fittings are oriented at a right angle to each other. |

| V180° | The fittings are parallel but point in opposite directions. |

| V270° | The fittings are at a right angle, with the far fitting pointing left. |

How Do You Calculate the Correct Hose Length?

Your replacement hose is too short and is being pulled tight, or it’s too long and is rubbing against the machine’s frame. Both of these scenarios will cause the hose to fail very quickly.

You must calculate the correct hose length using a formula that accounts for the straight sections, the bend radius, and the fittings. For moving applications, you must also add extra length to accommodate the full range of motion. This prevents stress from tension and damage from abrasion.

A hose that is too short is under constant tension. This pulls on the fittings and can cause the hose to fail at the crimp. A hose that is too long will sag and rub against other components, wearing away the outer cover and exposing the reinforcement wires to damage. Taking a few moments to calculate the proper length before ordering is a simple step that prevents these common and costly failures.

Calculating Length for Fixed Installations

For a hose that connects two fixed points with a single 90-degree bend, use the following formula to find the overall length (L).

Formula: L = A + B + (π/2 * R)

| Parameter | Description |

| L | Total required length of the hose assembly. |

| A | Length of the first straight section. |

| B | Length of the second straight section. |

| R | The bend radius of the installation route. This must be equal to or greater than the hose’s specified minimum bend radius. |

Important Note: You must also add sufficient straight hose length at each end (at least 1.5 times the hose outside diameter) before the bend begins. This ensures the bend doesn’t put stress on the fitting.

Calculating Length for Dynamic Applications

When a hose is connected to a moving part, like the boom of a crane, you must account for this movement. The calculation is similar, but you must add extra length to prevent the hose from being stretched at the limits of travel.

Formula: L’ = A + B + (π/2 * R) + D

The new parameter is:

- D (Displacement Length): The extra length needed to accommodate the full travel distance of the component. You must measure the hose length required at both the minimum and maximum points of travel and use the longest dimension to ensure there is never any tension on the assembly.

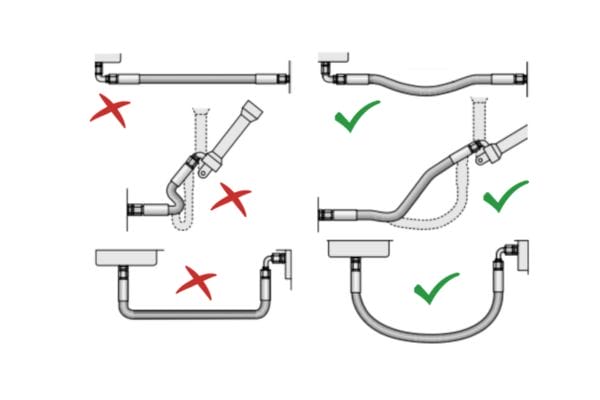

What Are the Most Common Installation Mistakes?

You installed a new hose assembly, and the machine is running fine. But a hidden routing mistake is already working to destroy that new part, guaranteeing you will be replacing it again much sooner than expected.

The most common installation mistakes are easy to avoid once you know what to look for. These include twisting the hose during tightening, bending it too sharply, poor routing that causes abrasion, and creating tension by making it too short.

Mistake 1: Twisting During Tightening

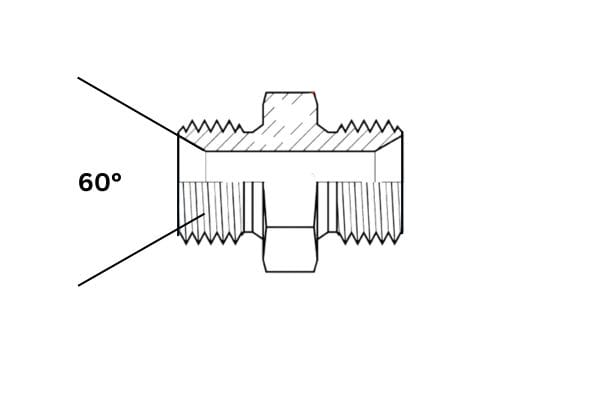

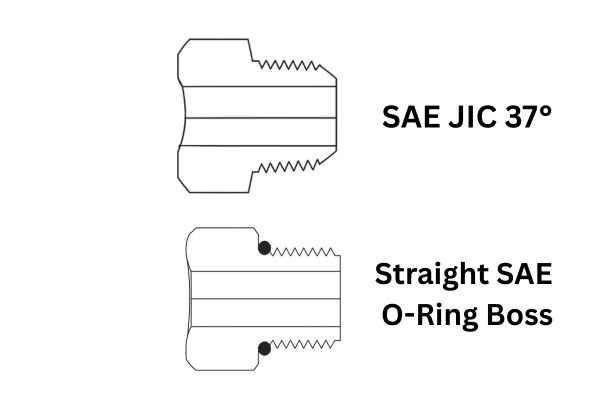

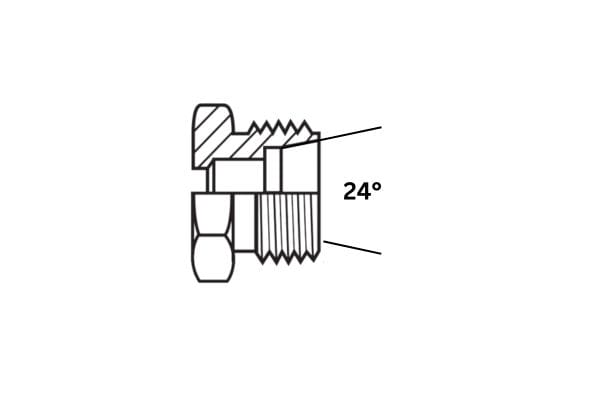

This often happens when tightening a JIC or other swivel fitting. The user tightens the nut but allows the hose itself to twist.

Solution: Always use two wrenches. One wrench to hold the hose and fitting steady, and a second wrench to turn only the swivel nut. This ensures all tightening force is rotational and does not translate into torsional stress on the hose.

Mistake 2: Violating the Minimum Bend Radius

Every hose has a specified minimum bend radius. Bending it sharper than this limit will cause the hose to kink. This restricts flow and puts extreme stress on the reinforcement at the outer edge of the bend, leading to a burst.

Solution: Always know the minimum bend radius of your hose and ensure your routing is well above this limit.

Mistake 3: Abrasion and Heat

Routing a hose where it can rub against a machine frame, another hose, or a sharp edge is a guarantee of failure. The abrasion will wear through the cover and compromise the wire reinforcement. Similarly, routing a hose too close to an engine exhaust or other heat source will cook the rubber, making it brittle.

Solution: Use clamps to secure hoses and maintain proper spacing. Use protective sleeves or guards in areas with high abrasion risk.

Mistake 4: Tension

A hose that is pulled perfectly straight between two points is a hose under tension. Hydraulic hoses are designed to have some slack. They can contract or expand slightly in length as they are pressurized. A taut hose has no room for this, which puts immense stress on the crimped fittings.

Solution: Always ensure there is a visible, slight sag in the hose.

| Mistake | Description | Solution |

| Twisting During Tightening | Hose twists when nut is tightened, adding torsional stress. | Use two wrenches: one to hold hose steady, one to tighten nut. |

| Violating Minimum Bend Radius | Hose bent too sharply, causing kinks and stress on reinforcement. | Follow hose’s minimum bend radius and route accordingly. |

| Abrasion and Heat | Hose rubs against surfaces or is too close to heat sources, damaging cover. | Secure with clamps, keep spacing, use sleeves/guards. |

| Tension | Hose pulled straight with no slack, stressing fittings under pressure. | Leave a slight sag to allow for expansion/contraction. |

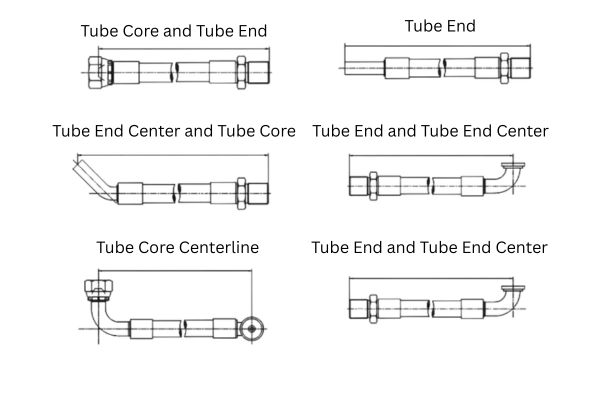

How Do You Measure a Hose Assembly Properly?

You need to re-order a complex hose assembly. You measure it quickly, but when the new part arrives, it doesn’t fit because you measured from the wrong points.

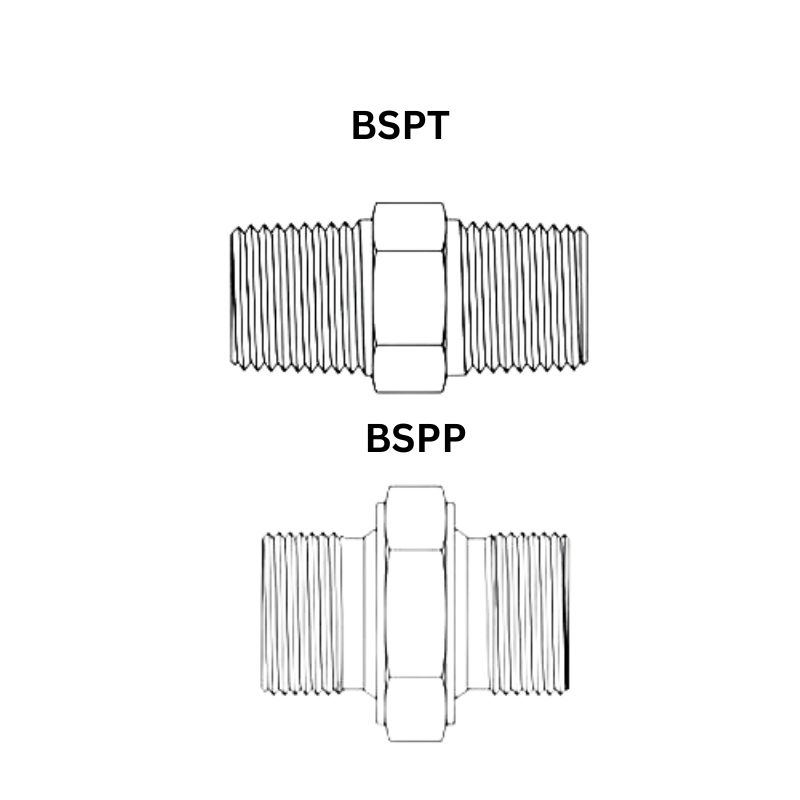

You must measure a hose assembly using industry-standard reference points. For straight fittings, you measure from the end of the sealing surface. For bent fittings, you measure from the centerline of the fitting’s bore. Adhering to these standards ensures the replacement you order is an exact match.

Accuracy is everything when ordering a replacement. As a manufacturer, we build parts to the precise length and tolerance requested by our customers. Using the correct measurement technique eliminates errors and ensures you get the right part on the first try, saving you time and the cost of shipping returns. It’s about speaking the same language as your supplier.

Standard Measurement Points

- Straight Fittings (e.g., JIC, ORFS): The overall length (L) is measured from the end of the fitting on one side to the end of the fitting on the other side.

- Bent Fittings (e.g., 45° or 90° Elbows): The overall length (L) is measured from the centerline of the sealing surface on one end to the corresponding point (end face or centerline) on the other.

Understanding Standard Length Tolerances

No manufacturing process is perfect, so there are acceptable tolerances for hose assembly lengths. These tolerances vary based on the length of the hose.

| Hose Assembly Length (mm) | Tolerance (mm) |

| Up to 300 | +/- 3 |

| 300 to 600 | +/- 5 |

| 600 to 1200 | +/- 1% of length |

| 1200 to 6000 | +/- 1.5% of length |

| Over 6000 | +/- 2% of length |

Knowing these tolerances helps you understand the acceptable range for a new part and allows you to check if a supplied product meets quality standards.

Conclusion

Proper installation is not complicated. By respecting the hose’s natural bend, calculating the right length, using the correct fitting angle, and routing it carefully, you can guarantee a longer, safer service life for every hydraulic hose assembly you install.

Choose Topa for reliable hydraulic fittings, hoses, and couplings. Our products are built to international standards, offering durability, precision, and fast delivery. Contact us today to place your order and keep your equipment running at peak performance.

FAQ

How can I tell if a hose has been twisted during installation?

If the hose shows a spiral mark along its cover or resists natural movement when pressurized, it has likely been twisted.

What happens if a hose is too short for the installation?

A short hose creates constant tension, pulling on the fittings and increasing the risk of leaks or burst failures.

Why do hose assemblies sometimes fail even when the fittings are tight?

Failures often come from hidden issues such as twisting, over-bending, or abrasion—not just loose fittings.

Can protective sleeves really extend hose life?

Yes. Sleeves protect against abrasion, UV, and heat, helping the hose last much longer in harsh environments.

Do hydraulic hoses need slack in every installation?

Yes. A small amount of slack allows the hose to expand and contract under pressure without stressing the fittings.

What is the most reliable way to measure a hose assembly for replacement?

Always measure from the sealing surfaces of the fittings (straight or bent) according to industry standards to avoid errors.