Hydraulic Flange Fitting Size Chart: Your Ultimate Guide

Table of Contents

Introduction

Hydraulic flange fittings play a crucial role in ensuring leak-free and efficient hydraulic systems. Understanding the correct sizing of these fittings is essential for system performance and safety. This guide aims to provide a comprehensive resource on hydraulic flange fitting size charts, helping you make informed decisions for your hydraulic applications.

Understanding Hydraulic Flange Fittings

Hydraulic flange fittings are essential for connecting pipes, hoses, and tubes in hydraulic systems. They provide secure, leak-free connections that withstand high pressures. Here are the primary types:

NPT/NPTF (National Tapered Pipe/Fuel)

SAE Code 61: Used for standard pressure applications, typically up to 3000 psi.

SAE Code 62: Designed for high-pressure applications, handling pressures up to 6000 psi.

ISO 6162: An international standard covering both Code 61 and Code 62 flange fittings, ensuring global compatibility and consistency.

These fittings are widely used across various industries, including automotive, aerospace, and manufacturing, due to their reliability and robustness.

SAE Code 61: These fittings are ideal for lower to medium-pressure hydraulic systems. They have a robust design that ensures a strong, leak-free connection. Common applications include mobile equipment, agricultural machinery, and industrial hydraulic systems.

SAE Code 62: These fittings are designed for high-pressure applications, making them suitable for more demanding hydraulic systems. They are used in heavy machinery, construction equipment, and high-pressure industrial applications. Their ability to withstand higher pressures makes them indispensable in situations where system integrity and safety are critical.

ISO 6162: This standard encompasses both SAE Code 61 and Code 62 fittings, providing a unified specification that ensures compatibility across different regions and manufacturers. ISO 6162 fittings are versatile and widely accepted in international markets, facilitating global trade and system standardization.

Importance of Accurate Sizing

Selecting the correct size for hydraulic flange fittings is crucial to maintaining system integrity and efficiency. Incorrect sizing can lead to leaks, system failures, and significant safety hazards. Ensuring the right size offers several key benefits:

Optimal System Performance: Properly sized fittings maintain the desired pressure levels and fluid flow, enhancing overall system efficiency.

Extended Lifespan: Correct sizing minimizes wear and tear on components, reducing the need for frequent replacements and maintenance.

Enhanced Safety and Reliability: Accurate sizing prevents leaks and bursts, ensuring a safer working environment and reliable system operation.

Preventing System Failures

Incorrectly sized hydraulic flange fittings can compromise the entire hydraulic system. When the fitting is too small, it restricts fluid flow, leading to increased pressure and potential system overload. Conversely, an oversized fitting may cause connections to be loose, resulting in leaks. Both scenarios can cause significant operational disruptions and costly repairs.

Safety Hazards

Safety is paramount in any hydraulic system. Leaks resulting from improperly sized fittings can lead to hazardous working conditions, including the risk of hydraulic fluid exposure and potential fire hazards. Ensuring that fittings are correctly sized mitigates these risks, providing a safer environment for operators and technicians.

Tips for Ensuring Accurate Sizing

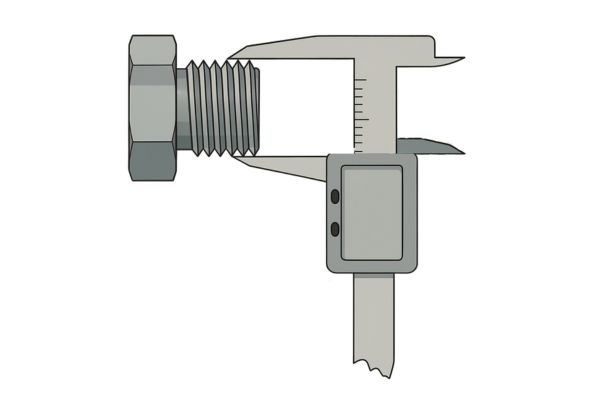

Measure Precisely: Use accurate tools like calipers to measure the diameter, bolt circle diameter, and other critical dimensions of your fittings.

Consult Size Charts: Refer to detailed hydraulic flange fitting size charts to match your measurements with the correct fitting size.

Consider Application Requirements: Ensure the fitting size matches the specific needs of your application, including pressure and flow requirements.

Verify Standards Compliance: Ensure the fittings adhere to industry standards such as SAE or ISO to guarantee compatibility and performance.

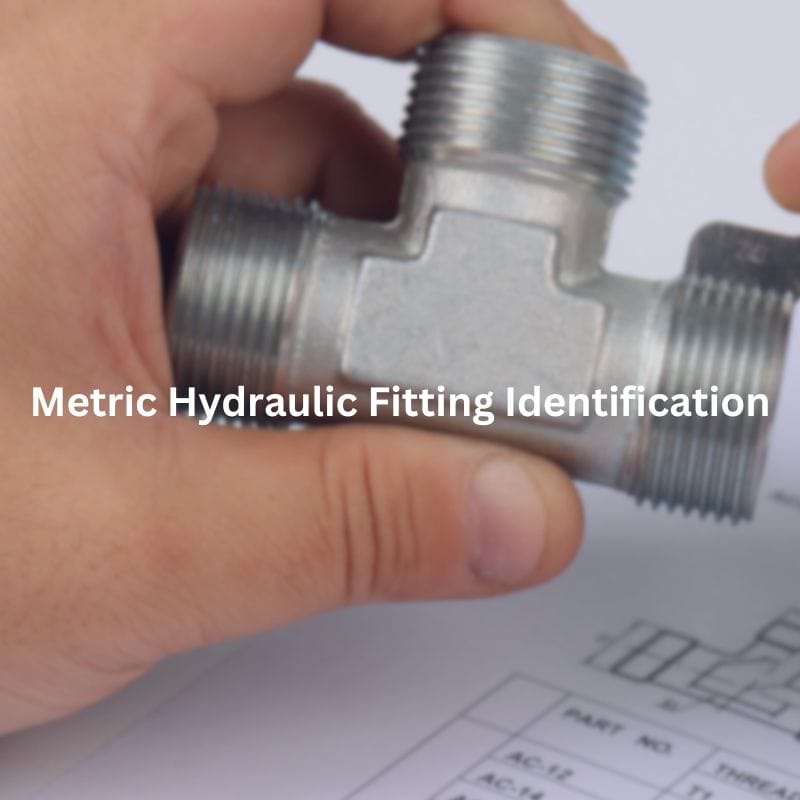

Components of a Hydraulic Flange Hose Fitting Size Chart

A hydraulic flange hose fitting size chart is essential for ensuring the correct selection and compatibility of fittings in hydraulic systems. Here’s a detailed breakdown of the key components identified from the provided image:

Part Number:

A unique identifier for each fitting type facilitates precise selection and ordering.

Flange Size:

The nominal size of the flange, typically measured in inches, indicates the fitting’s general size category.

Hose I.D. (Inner Diameter):

The internal diameter of the hose is crucial for ensuring the hose fits properly with the fitting and maintains optimal flow capacity.

Dimensions:

Length:

The overall length of the fitting from end to end, is measured in both inches and millimeters. This measurement is crucial for determining the fitting’s reach and ensuring it fits within the system’s spatial constraints.

Flange Diameter:

The diameter of the flange face is critical for matching the fitting to the system’s flange specifications. This ensures a proper seal and secure connection.

Bolt Circle Diameter:

The distance between the centers of the bolt holes is essential for aligning the flange fitting correctly and securing it tightly to prevent leaks and maintain system integrity.

Additional Material Options:

Information indicating the availability of fittings in different materials, such as stainless steel, is important for applications requiring specific material properties for durability, corrosion resistance, and compatibility with various hydraulic fluids.

Measurement Steps

Follow these steps to measure each dimension of the hydraulic flange fitting:

Measuring Hose End Inner Diameter (Hose I.D.)

Prepare the Hose: Lay the hose flat, ensuring it is not compressed or deformed.

Measure with a Caliper: Use a vernier caliper to measure the inner diameter of the hose. Open the caliper’s jaws and insert them inside the hose. Ensure the caliper’s jaws are touching the inner walls of the hose.

Record the Measurement: Note down the measurement for future reference.

Measuring Length

Position the Flange Fitting: Place the flange fitting flat on a level surface, making sure it is fully extended.

Use a Measuring Tape or Ruler: Measure the total length of the flange fitting from one end to the other using a measuring tape or a steel ruler.

Record the Measurement: Write down the measured length accurately.

Measuring Flange Diameter

Position the Flange: Place the flange flat on a level surface.

Measure with a Caliper or Ruler: Use a vernier caliper or a steel ruler to measure the outer diameter of the flange at its widest point.

Record the Measurement: Note down the flange diameter measurement.

Measuring Bolt Circle Diameter

Position the Flange: Lay the flange flat on a level surface.

Identify Bolt Holes: Locate two opposite bolt holes on the flange.

Measure with a Measuring Tape: Use a measuring tape to measure the distance between the center points of the two opposite bolt holes.

Record the Measurement: Write down the bolt circle diameter measurement.

Practical Tips for Choosing the Right Flange Fitting

Consider Pressure Rating

Maximum Pressure

When selecting a hydraulic flange fitting, it is critical to ensure that the fitting can handle the highest pressure your system will encounter. This involves understanding the system’s maximum operating pressure and comparing it to the pressure rating of the fitting. Using a fitting that cannot withstand the required pressure can result in leaks or catastrophic failures, posing serious safety risks and potentially causing extensive damage to the system.

System Fluctuations

Hydraulic systems often experience pressure spikes and fluctuations. It is essential to account for these variations by choosing a fitting with a safety margin above the regular operating pressure. This buffer helps accommodate unexpected surges and ensures that the fitting remains secure and functional under varying pressure conditions. Selecting a fitting with a higher pressure rating than the maximum operating pressure provides an additional layer of safety and reliability, helping to prevent failures and maintain system integrity.

Detailed Considerations

Pressure Rating Labels:

Always check the manufacturer’s specifications for the pressure rating, typically labeled in psi (pounds per square inch) or bar. These ratings indicate the maximum pressure the fitting can safely withstand.

Safety Margins:

Implement a safety margin of at least 1.5 to 2 times the system’s normal operating pressure. For instance, if your system operates at 3000 psi, consider fittings rated for at least 4500 to 6000 psi.

Pressure Testing:

Regularly test your system under controlled conditions to ensure that fittings perform well within the expected pressure ranges. Periodic testing can help identify potential weaknesses before they lead to failures.

Material Compatibility

Hydraulic Fluid

When choosing fittings, ensure they are made from materials compatible with the specific type of hydraulic fluid used in your system. Different fluids can react differently with various metals. For example, some hydraulic fluids may be corrosive to aluminum but not to stainless steel. Compatibility is crucial to prevent chemical reactions that can lead to corrosion, degradation, and system failure.

Operating Environment

Consider environmental factors such as temperature, exposure to chemicals, and humidity. Material selection should account for these conditions:

Stainless Steel: Ideal for corrosive environments and high-humidity areas due to its excellent resistance to rust and chemical reactions.

Carbon Steel: Suitable for less demanding conditions where corrosion resistance is not as critical. It is often used in standard industrial applications.

Brass or Bronze: Can be used in situations where metal flexibility and corrosion resistance to specific chemicals are needed.

Installation Practices

Proper installation of hydraulic flange fittings is essential to ensure a secure and leak-free connection. Here are some best practices to follow:

Alignment

Proper Alignment: Ensure that fittings are properly aligned during installation. Misalignment can cause undue stress on the fittings and lead to potential leaks or system failures. Use alignment tools if necessary to maintain precision.

Torque Specifications

Manufacturer’s Specifications: Always adhere to the torque specifications provided by the manufacturer. Over-tightening bolts can damage fittings and threads, while under-tightening can result in insufficient sealing and leaks. Use a calibrated torque wrench to achieve the correct torque.

Even Tightening

Crisscross Pattern: Tighten bolts in a crisscross pattern to ensure even pressure distribution across the flange. This method prevents warping or uneven sealing, which can compromise the integrity of the connection. Start by tightening bolts to a fraction of the final torque, then gradually increase to the full torque in multiple passes.

Detailed Considerations

Pre-Installation Checks:

Inspect all components for damage or defects before installation.

Ensure that all surfaces are clean and free of debris to prevent contamination and ensure a proper seal.

Use of Lubricants:

Apply appropriate lubricants to bolts and threads to achieve accurate torque readings and prevent galling (seizing or sticking of metal parts).

Post-Installation Inspection:

After installation, conduct a thorough inspection to verify the correct alignment and torque. Check for any signs of leaks or misalignment and rectify them immediately.

Additional Tips

Temperature Ratings

Operating Temperatures: Ensure that the fitting material can withstand the operating temperatures of your system without degrading or losing integrity. Different materials have varying levels of temperature resistance, so select accordingly.

Maintenance and Inspection

Regular Inspections: Routinely check your fittings for signs of wear, corrosion, or damage. Early detection of issues can prevent minor problems from escalating into major failures.

Timely Maintenance: Replace worn or damaged fittings promptly to maintain the system’s performance and safety. Regular maintenance helps in extending the lifespan of the hydraulic components and ensures consistent operation.

Conclusion

In this guide, we have explored the critical aspects of hydraulic flange hose fittings, including the importance of accurate sizing, understanding key components of the size chart, adhering to common standards and specifications, practical tips for selecting the right fittings, and best practices for installation and maintenance. Apply the knowledge gained from this guide to select and maintain your hydraulic fittings effectively, enhancing your hydraulic system’s longevity and functionality.

FAQ

What are hydraulic hose flanges?

Hydraulic hose flanges are fittings used to connect hoses in hydraulic systems, ensuring a secure and leak-free connection capable of withstanding high pressures.

How do I measure a hydraulic flange?

Use calipers or a measuring tape to measure the flange diameter, bolt circle diameter (BCD), bolt size, and port size.

What is the difference between SAE Code 61 and Code 62?

SAE Code 61 is for medium-pressure applications, while Code 62 is for high-pressure applications.

What materials are hydraulic flanges made from?

Common materials include stainless steel, carbon steel, and alloy steel, chosen based on compatibility with hydraulic fluids and environmental conditions.

Why is proper alignment important during installation?

Proper alignment prevents undue stress and potential leaks, ensuring a secure and efficient connection.

How often should I inspect my hydraulic flange fittings?

Regular inspections should be conducted to check for signs of wear, corrosion, or damage, ideally during routine maintenance schedules.