Flat Face Hydraulic Coupler Leaking? Fix It with These Steps

Table of Contents

Introduction

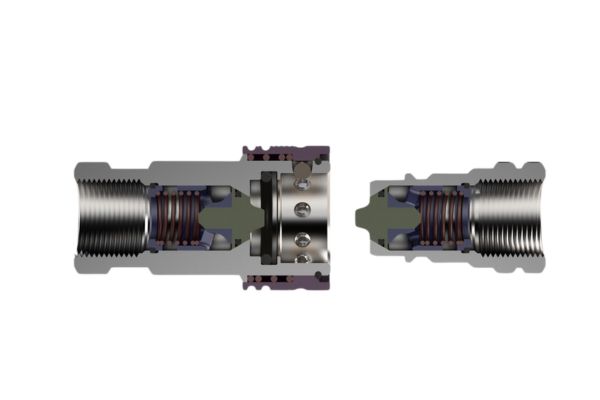

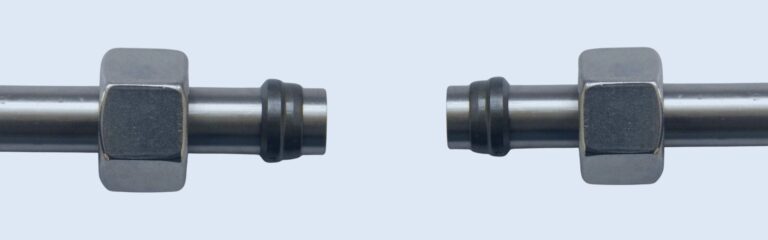

Flat-face hydraulic couplers are specialized connectors used in hydraulic systems to quickly and securely join hoses and components without significant fluid loss. These couplers are designed with a flat sealing surface that minimizes air inclusion and leakage during connection and disconnection. Addressing leaks in flat-face hydraulic couplers is essential for several reasons. Leaks can lead to significant risks and damages, including hydraulic fluid loss, which can cause environmental hazards and increase operational costs. Moreover, leaking couplers can compromise the performance and efficiency of the hydraulic system, leading to reduced pressure, inconsistent operation, and potential failure of machinery.

Identifying the Problem

Signs of a Leaking Flat Face Hydraulic Coupler

Visible Fluid Leaks

The most apparent sign of a leaking flat face hydraulic coupler is the presence of hydraulic fluid around the coupler or on the ground beneath it. This can manifest as puddles of hydraulic fluid, wet or oily patches on and around the coupler, or streaks of fluid running down the coupler body and nearby components. These visible leaks not only indicate a breach in the sealing system but also pose significant environmental hazards and safety risks. Hydraulic fluid can be slippery, creating slip hazards in the workplace, and potentially harmful if it comes into contact with skin or eyes. Prolonged exposure to hydraulic fluid can lead to dermatitis or other skin conditions. Additionally, spilled hydraulic fluid can contaminate soil and water sources, necessitating thorough cleanup efforts to prevent environmental damage. Regular visual inspections of the hydraulic system and surrounding areas can help in early detection of fluid leaks, allowing for prompt intervention and minimizing the risk of accidents and environmental contamination.

Decreased System Pressure

A significant drop in system pressure is a critical indicator of a hydraulic leak. Hydraulic systems rely on maintaining a consistent pressure to function correctly, and any loss of pressure suggests that fluid is escaping from the system. This pressure drop can affect the performance of hydraulic machinery, leading to slower response times, reduced force output, and inefficient operation. For example, a hydraulic press may not generate enough force to perform its intended function, or a hydraulic lift might struggle to elevate its load. Monitoring system pressure gauges regularly can help identify such leaks early on. If the pressure drops below the expected range, it’s essential to inspect the couplers and other components for potential leaks. In more advanced systems, pressure sensors and diagnostic software can provide real-time alerts and data logging, making it easier to track pressure changes and identify leaks quickly. Addressing pressure drops promptly helps maintain the efficiency and effectiveness of hydraulic systems, reducing downtime and preventing further damage to components.

Unusual Noises or Vibrations

Unusual noises or vibrations in the hydraulic system can also signal a leaking coupler. When hydraulic fluid escapes from the system, air can enter the hydraulic lines, causing cavitation or aeration. Cavitation occurs when air bubbles form and collapse within the fluid, resulting in noises such as whining, hissing, or knocking sounds, which are not typical during normal operation. These sounds indicate that the hydraulic fluid is not flowing smoothly through the system, leading to erratic performance. Additionally, vibrations may become more pronounced due to the inconsistent fluid flow and the presence of air bubbles in the hydraulic lines. These noises and vibrations can lead to further mechanical issues if not addressed promptly, as they can cause additional wear and tear on the hydraulic components. For instance, cavitation can damage pump impellers and other moving parts, while vibrations can loosen fittings and connections, exacerbating the leak. Using acoustic emission testing or vibration analysis tools can help diagnose the source of these issues, enabling targeted repairs and maintenance to restore smooth and efficient operation.

Identifying the Problem

Wear and Tear Over Time

One of the most common causes of leaks in flat face hydraulic couplers is wear and tear over time. Hydraulic systems are subjected to high pressures and frequent use, which gradually degrade the materials of the couplers. Metal surfaces can become scratched or worn, leading to an imperfect seal. The constant pressure fluctuations and mechanical stresses cause components to fatigue and fail. This natural degradation process can be exacerbated by environmental factors such as exposure to harsh chemicals, extreme temperatures, and abrasive particles.

Improper Installation

Improper installation is another frequent cause of leaks in flat-faced hydraulic couplers. When couplers are not installed correctly, it can lead to misalignments or inadequate sealing. Over-tightening can damage threads or seals, while under-tightening can result in loose connections that allow fluid to escape. Misalignment during installation can create uneven pressure distribution, leading to gaps and potential leak points. Additionally, using the wrong type of coupler or failing to follow manufacturer guidelines during installation can also contribute to leaks.

Contamination and Debris

Contamination and debris can significantly impact the integrity of flat face hydraulic couplers and lead to leaks. Hydraulic systems operate in environments where dirt, dust, and other particles can easily enter the system. When contaminants get lodged in the coupler, they can scratch or damage the sealing surfaces, creating pathways for fluid to leak. Debris can also interfere with the proper functioning of seals and O-rings, causing them to fail prematurely.

Damaged Seals or O-Rings

Damaged seals or O-rings are a typical cause of leaks in flat face hydraulic couplers. These components are crucial for maintaining a secure and leak-proof connection within the hydraulic system. Over time, seals and O-rings can degrade due to exposure to high pressures, temperatures, and hydraulic fluid chemicals. They may become brittle, cracked, or worn out, losing their ability to form a tight seal.

Step-by-Step Guide to Fixing Leaks

Safety Precautions

Depressurize the Hydraulic System

Before starting any repair work on a hydraulic system, it is crucial to ensure that the system is completely depressurized. This involves shutting down the hydraulic machinery and releasing any residual pressure in the system. Failure to depressurize can result in sudden releases of hydraulic fluid, which can cause serious injuries or damage to equipment. Use pressure gauges to verify that the system pressure is at zero before proceeding. Additionally, consult the machinery’s operation manual for specific depressurization procedures.

Ensure a Clean Working Environment

Working in a clean environment is essential to prevent contamination of hydraulic components. Contaminants such as dirt, dust, and debris can compromise the integrity of hydraulic seals and other components, leading to further leaks and system failures. Set up a clean workspace with minimal exposure to contaminants. Use clean tools and materials, and consider laying down clean mats or protective coverings to catch any dislodged debris during the repair process.

Inspecting the Coupler

Visual Inspection for Obvious Damage

Begin by visually inspecting the coupler for any obvious signs of damage. Look for cracks, dents, or deformities on the coupler surfaces and connections. Check for any signs of wear or abrasion that could compromise the seal. Pay close attention to the areas where the coupler connects to other hydraulic components, as these points are prone to damage from physical stress or improper handling.

Checking the Condition of Seals and O-rings

Seals and O-rings are critical components in preventing leaks. Inspect these parts for signs of wear, such as cracks, tears, or brittleness. Check for any deformation or flattening that could affect their ability to form a tight seal. If seals or O-rings appear damaged, they will need to be replaced to restore the coupler’s integrity. Use a magnifying glass or inspection light to get a detailed view of these small components.

Cleaning the Coupler

Removing Debris and Contaminants

Once the inspection is complete, proceed with cleaning the coupler. Use brushes and cleaning agents to remove any dirt and debris from the coupler surfaces. Pay particular attention to the sealing surfaces, as even small particles can prevent a proper seal. Ensure that all contaminants are thoroughly removed to avoid future leaks.

Using Appropriate Cleaning Agents

Choose cleaning agents that are suitable for hydraulic components. Avoid using harsh chemicals that could damage the metal surfaces or the seals. Mild detergents or specialized hydraulic component cleaners are recommended. Rinse the components with clean water if necessary and dry them completely before proceeding with reassembly.

Replacing Damaged Parts

Selecting the Correct Seal Kits and O-rings

Use manufacturer-recommended replacement parts to ensure proper fit and function. Refer to the equipment manual or consult with the manufacturer to obtain the correct seal kits and O-rings for your specific coupler model. Using the wrong parts can lead to improper sealing and further leaks.

Proper Installation Techniques

Follow proper techniques to install seals and O-rings. Ensure they are correctly positioned and seated in their grooves. Apply a thin layer of hydraulic fluid or assembly lubricant to the seals and O-rings to facilitate installation and prevent damage. Use appropriate tools to avoid overstretching or damaging the seals during installation.

Reassembling the Coupler

Ensuring All Components are Securely Fitted

Make sure all parts are correctly reassembled according to the manufacturer’s specifications. Align all components properly to ensure a secure fit. Tighten connections hand-tight first to ensure proper alignment before using tools.

Applying the Correct Torque Settings

Use a torque wrench to apply the correct amount of torque to ensure a secure and leak-free connection. Refer to the manufacturer’s specifications for the appropriate torque settings for each connection. Over-tightening can damage threads and seals, while under-tightening can lead to leaks.

Testing for Leaks

Repressurizing the System

Once reassembled, repressurize the hydraulic system to check for leaks. Gradually increase the system pressure while monitoring for any signs of leaks. This helps prevent sudden pressure spikes that could cause new leaks or damage.

Monitoring for Signs of New Leaks

Observe the coupler for any signs of new leaks during and after repressurization. Look for any fluid seepage, drops in system pressure, or unusual noises. Conduct a thorough inspection around the coupler and other components to ensure the repair was successful. If any leaks are detected, repeat the inspection and repair process as necessary.

By following these detailed steps, you can effectively diagnose and fix leaks in flat face hydraulic couplers, ensuring the continued performance and reliability of your hydraulic systems. Regular maintenance and proper handling are key to preventing leaks and maintaining optimal performance.

Preventative Maintenance Tips

Scheduled Checks for Wear and Damage

Implementing a regular inspection schedule is essential for maintaining the integrity of hydraulic systems. These scheduled checks should be designed to thoroughly examine the hydraulic couplers for any signs of wear and damage. This includes looking for scratches, dents, cracks, or deformities on the metal surfaces, as well as checking the seals and O-rings for signs of wear, brittleness, or damage. By identifying and addressing these issues early, you can prevent minor problems from escalating into major failures that could lead to costly repairs and downtime. Utilizing detailed checklists and logging inspection results can help ensure that no potential issues are overlooked during these routine checks.

Routine Cleaning and Lubrication

Keeping hydraulic couplers clean and well-lubricated is vital for preventing contamination and wear. Contaminants such as dirt, dust, and other particles can damage the sealing surfaces and lead to leaks. Routine cleaning should involve using appropriate cleaning agents to remove any buildup of debris or grime on the couplers. Additionally, regular lubrication of the moving parts and seals can help reduce friction, prevent wear, and ensure smooth operation. It’s important to use the correct type of lubricant specified by the manufacturer to avoid compatibility issues that could degrade the seals and other components. Establishing a consistent cleaning and lubrication routine can significantly extend the lifespan of the couplers and enhance the overall performance of the hydraulic system.

Conclusion

Leaks can lead to decreased system pressure, compromised performance, and potential environmental hazards. To effectively fix and prevent leaks, it is essential to follow a systematic approach: identify the problem through visual inspections and monitoring system performance; clean and maintain the couplers to prevent contamination; replace worn or damaged seals and O-rings using proper installation techniques; and ensure all components are compatible and installed according to manufacturer guidelines. By adhering to these practices, you can enhance the durability and reliability of your hydraulic equipment, reducing downtime and operational costs.

FAQ

Flat face hydraulic couplers are connectors used in hydraulic systems to join two hydraulic lines, providing a leak-free connection and minimizing fluid loss during connection and disconnection.

Common signs include visible hydraulic fluid leaks around the coupler or on the ground, decreased system pressure, and unusual noises or vibrations in the hydraulic system.

Prevent leaks by performing regular inspections for wear and damage, keeping the couplers clean and well-lubricated, following proper installation practices, and using compatible components.

If a leak is detected, depressurize the hydraulic system, inspect the coupler for damage, clean the components, replace any worn or damaged seals and O-rings, and reassemble the coupler according to manufacturer specifications.

Hydraulic couplers should be inspected regularly as part of a scheduled maintenance program. The frequency of inspections depends on the usage and operating conditions of the hydraulic system.

Common causes of leaks include wear and tear over time, improper installation, contamination and debris, and damaged seals or O-rings. Regular maintenance and proper handling can help mitigate these issues.

Contact Topa

Have a question or suggestion? Fill out the form below to get in touch with one of our experts.