What is the main difference between the 78 Series and other hydraulic fittings?

Can the 78 Series be used with any hydraulic hose?

What pressure ratings can the 78 Series handle?

Do I need to skive the hose before assembly?

What materials are available?

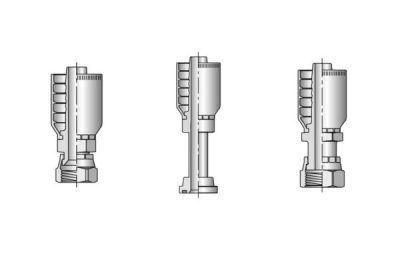

Are there different configurations available?