Different Types of Brass Fittings: A Detailed Guide

Table of Contents

Introduction

Brass fittings play a crucial role in various industries due to their durability, versatility, and corrosion resistance. They are essential components in plumbing, gas, HVAC systems, and numerous industrial applications. This guide aims to provide a comprehensive overview of the different types of brass fittings, helping you choose the right ones for your specific needs.

Understanding Brass as a Material

Properties of Brass

Brass is an alloy primarily composed of copper and zinc, which can be adjusted in varying proportions to achieve desired mechanical and chemical properties. This versatility makes brass a preferred material for a wide range of applications. The unique combination of copper and zinc results in a material that is both strong and malleable.

Strength: Brass possesses significant tensile strength, allowing it to withstand high pressures and heavy loads without deformation. This makes it ideal for fittings in high-stress environments such as plumbing and industrial systems.

Malleability: One of the standout properties of brass is its malleability. It can be easily shaped and fabricated into various forms without cracking, which is crucial for manufacturing complex fitting designs. This property also enables the creation of precise and intricate components required in specific applications.

Corrosion Resistance: Brass exhibits excellent corrosion resistance, particularly from water and various chemicals. This resistance is a result of the protective oxide layer that forms on its surface, preventing further oxidation. Consequently, brass fittings are highly durable and maintain their integrity over long periods, even in harsh environments.

Thermal Conductivity: Brass has good thermal conductivity, making it an ideal material for heat exchangers and radiator components. This property ensures efficient heat transfer, which is essential in HVAC systems and other thermal applications.

Electrical Conductivity: While not as conductive as copper, brass still offers decent electrical conductivity, which is beneficial in certain electrical fittings and components where both mechanical strength and electrical performance are required.

Common Types of Brass Fittings

Brass fittings come in a variety of types, each designed for specific purposes and applications. Selecting the right fitting is crucial for ensuring the efficiency, safety, and durability of the system in which it is used. This chapter provides an in-depth look at some of the most common types of brass fittings, highlighting their unique features and typical uses.

Compression Fittings

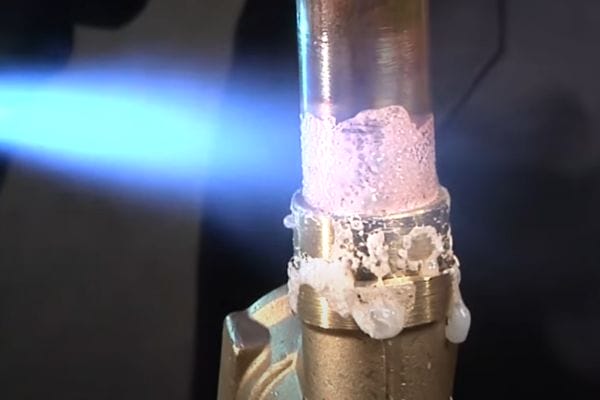

Compression fittings are widely used in plumbing and gas systems due to their reliability and ease of installation. These fittings consist of three main components: a nut, a compression ring (ferrule), and a fitting body. When the nut is tightened, it compresses the ring onto the pipe, creating a secure, leak-proof seal.

Components and Mechanism:

Nut: The nut is screwed onto the fitting body and tightened to compress the ring.

Compression Ring (Ferrule): The ring compresses around the pipe when the nut is tightened, forming a tight seal.

Fitting Body: The body of the fitting houses the pipe and holds the other components in place.

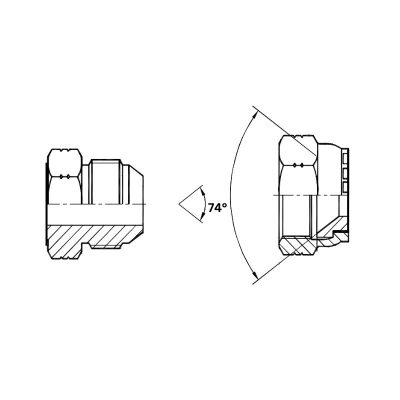

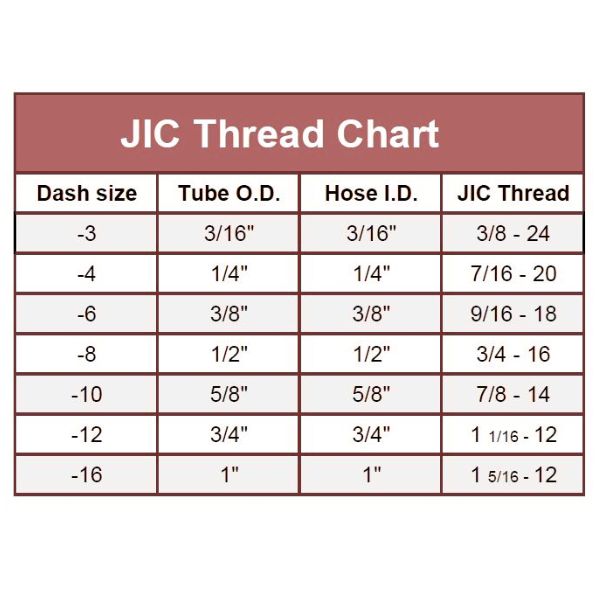

Flare Fittings

Flare fittings are specifically designed to provide robust, leak-proof connections in high-pressure environments, such as gas and refrigeration systems. These fittings are integral to systems where safety and reliability are paramount, as they prevent gas or refrigerant leaks that could lead to hazardous situations or system inefficiencies. The mechanism of flare fittings involves the end of the pipe being flared outward into a cone shape, allowing the fitting to create a strong seal when the flare nut is tightened.

Components and Mechanism

Flared Pipe End:

The process of creating a flared pipe end involves using a flaring tool to expand the pipe’s end into a 45-degree cone shape. This flare provides a larger surface area for the fitting to make contact with, ensuring a secure and tight seal.

Flare Nut:

The flare nut is threaded and designed to be screwed onto the fitting body. It has a tapered interior that matches the cone angle of the flared pipe end.

As the flare nut is tightened, it compresses the flared pipe end against the conical seat of the fitting body, creating a gas-tight seal.

The flare nut’s design ensures that the pipe end remains securely in place, preventing any movement that could disrupt the seal and cause leaks.

Fitting Body:

The fitting body houses the conical seat that matches the angle of the flared pipe end. This seat is precision-engineered to ensure a perfect fit with the flared pipe.

The fitting body typically includes a male or female threaded end to connect with other system components, providing versatility in various applications.

The conical seat in the fitting body plays a crucial role in creating the seal. When the flare nut is tightened, the flared pipe end is pressed firmly against this seat, ensuring a leak-proof connection.

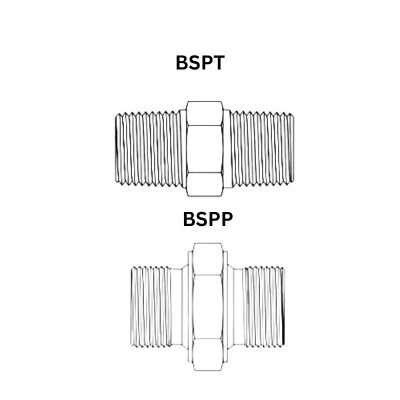

Threaded Fittings

Threaded fittings are among the most versatile and widely used types of brass fittings, offering secure, threaded connections for a broad range of applications. These fittings are essential in systems where reliable, strong connections are required, such as in plumbing, gas lines, and industrial processes. Threaded fittings come in various standards, including NPT (National Pipe Thread) and BSP (British Standard Pipe), each with specific thread profiles and applications.

Components and Mechanism

Male Threads:

Male threads are the external threads on the fitting that screw into the internal threads of another fitting or pipe. These threads are precisely cut to match the thread standard, ensuring a tight fit.

Male threads can be tapered (as in NPT) or straight (as in BSP), with tapered threads creating a seal as they are tightened and the threads compress.

Female Threads:

Female threads are the internal threads that receive the male threads. These threads are cut into the interior surface of a fitting or pipe.

Like male threads, female threads can be tapered or straight, depending on the thread standard and application.

The interaction between male and female threads creates a secure connection that can handle significant pressure and mechanical stress.

Sealant:

Sealants, such as thread seal tape (commonly known as PTFE tape) or pipe dope (thread sealant compound), are often used to ensure a leak-proof connection.

Thread Seal Tape: This thin, flexible tape is wrapped around the male threads before they are screwed into the female threads. The tape fills any gaps between the threads, preventing leaks.

Pipe Dope: A thick paste applied to the threads, providing lubrication and sealing properties to ensure a tight, leak-proof connection.

Push-to-Connect Fittings

Push-to-connect fittings, also known as push fittings or quick-connect fittings, revolutionize the process of joining pipes and tubing by providing a simple, tool-free method for creating secure connections. The mechanism involves pushing the pipe into the fitting until it locks in place, creating a tight, reliable seal without the need for additional tools or complex procedures.

Components and Mechanism

Release Collar:

The release collar, sometimes referred to as the release ring, is an integral component that facilitates the easy disconnection of the pipe from the fitting. It is typically made from durable plastic or metal and is designed to be depressed or pulled to release the grip on the pipe.

When the release collar is engaged, it compresses the grip rings, allowing the pipe to be easily removed. This feature is particularly useful for maintenance, repairs, and system modifications, as it enables quick and effortless disassembly without damaging the pipe or fitting.

O-Ring:

Made from rubber or similar elastomeric material, the O-ring forms a tight seal around the pipe when it is inserted into the fitting.

The O-ring ensures a leak-proof connection by preventing fluid or gas from escaping. Its elasticity allows it to adapt to slight variations in pipe size and surface imperfections, maintaining a reliable seal even under pressure.

The material of the O-ring is selected based on the type of fluid or gas it will be in contact with, ensuring chemical compatibility and long-term durability.

Grip Rings:

Grip rings, also known as collets or teeth, are the components that hold the pipe securely in place within the fitting. These rings are typically made from metal or high-strength plastic and feature a series of sharp edges or barbs that dig into the pipe’s outer surface.

As the pipe is pushed into the fitting, the grip rings engage with the pipe, creating a strong mechanical connection that resists pulling and rotational forces. This grip ensures that the pipe remains securely attached, even under high pressure or mechanical stress.

The design of the grip rings allows for a firm hold without damaging the pipe, making them suitable for use with various pipe materials, including copper, PEX, CPVC, and more.

Hose Barb Fittings

Hose barb fittings are essential components in fluid handling systems, specifically designed to connect flexible hoses to pipes, tubing, or other fittings. Their unique design features a ridged, or barbed, end that grips the interior surface of the hose, ensuring a secure and leak-proof connection. These fittings are widely used in a variety of low-pressure applications, including water lines, fuel systems, and general fluid transfer.

Components and Mechanism

Barbed End:

The barbed end of the fitting is characterized by a series of ridges or barbs that taper towards the end of the fitting. These barbs are designed to penetrate the interior surface of the hose, providing a firm grip that resists pulling and pressure forces.

The barbs create a mechanical lock with the hose material, ensuring that the hose does not slip off the fitting under normal operating conditions. This grip is enhanced when the hose is secured with a hose clamp or crimp ring, providing additional security and preventing leaks.

Fitting Body:

The body of the hose barb fitting is typically cylindrical and connects to the barbed end. The opposite end of the body may have various connection types, including threaded ends (male or female), push-to-connect ends, or smooth ends for additional barbed fittings.

The body of the fitting is designed to be compatible with the hose’s internal diameter, ensuring a snug fit that optimizes the sealing and gripping properties of the barbed end.

Brass D.O.T. Fittings

Brass Department of Transportation (D.O.T.) fittings are specialized connectors designed to meet the stringent standards required for use in transportation applications, particularly in air brake systems of commercial vehicles. These fittings ensure safety and reliability, handling the high pressures and rigorous conditions associated with transportation systems.

Different Types of Brass D.O.T. Fittings

Push-to-Connect (Push-In) D.O.T. Fittings

Push-to-connect fittings, also known as push-in fittings, are designed for quick and easy installation without the need for additional tools. They provide a secure and reliable connection for air brake systems by simply pushing the tubing into the fitting.

Compression D.O.T. Fittings

Compression fittings are used to connect tubing by compressing a ferrule onto the tube as the nut is tightened. This creates a strong and reliable seal.

Swivel D.O.T. Fittings

Swivel fittings allow for rotational movement, making them ideal for applications where flexibility and movement are required.

Reusable Brass D.O.T. Fittings

Reusable brass D.O.T. fittings offer a practical and cost-effective solution for air brake systems and other pneumatic applications in the transportation industry. Their ability to be disassembled and reassembled multiple times without compromising performance makes them ideal for systems that require frequent maintenance or adjustments.

How to Choose the Right Brass Fitting

Choosing the right brass fitting for your application is crucial to ensure the efficiency, safety, and durability of your system. With various types of brass fittings available, it’s essential to consider several key factors to make an informed decision.

Factors to Consider

Pressure: Identify the maximum and minimum pressure levels the fitting will be subjected to. Brass fittings come with different pressure ratings, and selecting one that can handle your system’s operating pressure is essential to avoid leaks or failures.

Temperature: Consider the temperature range in which the fitting will operate. Brass fittings must withstand the operating temperature without degrading or losing their structural integrity. High-temperature applications may require fittings with special seals or materials.

Fluid Type: The type of fluid or gas flowing through the system can impact the suitability of a brass fitting. Ensure the fitting material and seals are compatible with the fluid to prevent corrosion, degradation, or contamination.

Material Compatibility: Ensure that the brass fittings are compatible with the materials of the pipes and other components in your system. Incompatible materials can lead to galvanic corrosion, where different metals in contact with an electrolyte (such as water) create a galvanic cell, leading to accelerated corrosion.

Seals and O-rings: The material of seals and O-rings used in brass fittings should be compatible with the fluid and temperature conditions. For example, EPDM seals are suitable for water and steam, while Viton seals are better for high-temperature applications and chemical resistance.

Chemical Compatibility: If the system involves chemicals or aggressive fluids, verify that the brass fittings and their components can resist chemical attacks. Refer to chemical compatibility charts to determine the suitability of brass for specific fluids.

Size and Configuration

Pipe Size: Select fittings that match the diameter of the pipes in your system. Using the correct size ensures proper fitment and sealing, preventing leaks and maintaining system integrity.

Configuration: Choose the appropriate fitting configuration (e.g., elbow, tee, coupling, reducer) based on the layout and requirements of your system. The right configuration ensures efficient flow and easy installation.

Conclusion

Brass fittings are essential components in many industries, offering durability, versatility, and corrosion resistance. This guide has covered the different types of brass fittings, their applications, and tips for choosing and maintaining them. By understanding the different types of fittings and their specific uses, you can ensure optimal performance and reliability. Consult with professionals to make informed decisions and select the best fittings for your needs.

FAQ

Brass fittings are commonly used in plumbing, gas lines, air brake systems, and industrial applications due to their durability, corrosion resistance, and ability to handle high pressures and temperatures.

To choose the right brass fitting, consider the application requirements, including pressure and temperature ratings, fluid type, compatibility with other materials, and the fitting’s size and configuration.

Yes, brass fittings are compatible with various piping materials, including copper, plastic (PVC, CPVC, PEX), and stainless steel. Always ensure material compatibility to avoid galvanic corrosion and ensure a secure connection.

For a leak-proof connection, ensure the fittings are properly tightened and use appropriate sealants such as thread seal tape or pipe dope for threaded fittings. Follow manufacturer guidelines for installation and maintenance.

Brass fittings can handle a wide range of temperatures, making them suitable for high-temperature applications. However, always check the specific temperature ratings of the fitting to ensure it meets your system’s requirements.

To maintain brass fittings, regularly inspect them for signs of wear, corrosion, or leaks. Ensure that connections remain tight and replace any damaged fittings. Using compatible fluids and materials will help extend the lifespan of your fittings.