What is SAE Fitting: Everything You Need to Know

Introduction

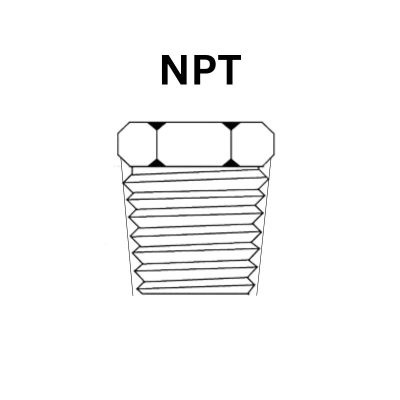

Among the array of fitting types tailored to diverse hydraulic needs — including JIC, NPT, and ORFS fittings — SAE fittings occupy a prominent position. Developed under the auspices of the Society of Automotive Engineers (SAE), these fittings adhere rigorously to standardized dimensions and specifications. In essence, the adoption of SAE fittings underscores a commitment to operational excellence and safety within hydraulic systems. Their standardized construction minimizes the risk of fluid leakage and system downtime, thereby enhancing overall reliability and efficiency.

Introduction to SAE Fittings

SAE fittings, integral components in hydraulic systems, adhere to standards established by the Society of Automotive Engineers (SAE), ensuring uniformity and reliability across industries. This section provides a comprehensive overview, highlighting the definition, historical context, and distinctive advantages of SAE fittings compared to other hydraulic fitting types.

Definition of SAE Fittings

SAE fittings refer to hydraulic connectors designed according to standards set by the SAE, governing dimensions, materials, and performance criteria. These fittings facilitate secure connections between hydraulic components, ensuring efficient fluid transfer and system functionality.

Historical Background and Evolution of SAE Standards

The evolution of SAE standards in hydraulic fittings traces back several decades, evolving alongside technological advancements and industry needs. Initially developed to standardize fitting dimensions and performance, SAE standards have continuously adapted to incorporate innovations in materials, sealing techniques, and manufacturing processes. This evolution reflects ongoing efforts to enhance fitting reliability, compatibility, and safety in diverse hydraulic applications.

Key Features and Advantages of SAE Fittings

SAE fittings offer several key features and advantages that distinguish them from other types:

Interchangeability: SAE fittings are designed to be interchangeable across various hydraulic systems and equipment brands, promoting ease of maintenance and component replacement.

Sealing Mechanisms: They incorporate reliable sealing mechanisms such as flared connections, O-ring seals, and face seals, ensuring leak-free performance under high-pressure conditions.

Durability: Constructed from robust materials like stainless steel, brass, or aluminum, SAE fittings withstand corrosion, abrasion, and mechanical stresses, enhancing longevity and operational reliability.

Standardization: Adherence to SAE standards ensures uniformity in fitting dimensions, thread types, and performance specifications, facilitating compatibility and reducing assembly errors.

SAE fittings’ widespread adoption across industries such as automotive, aerospace, and manufacturing underscores their reliability and performance in critical hydraulic applications. Their standardized design and engineering precision contribute to efficient fluid power management, operational safety, and overall system integrity.

Types of SAE Fittings

SAE fittings encompass various types, each designed to meet specific hydraulic system requirements and operational demands across various industries. Prominent among these are fittings defined by standards such as SAE J514 for hydraulic tube fittings and SAE J1926 for straight thread O-ring boss fittings. These standards delineate precise specifications regarding thread forms, sealing methods, and material composition, ensuring reliable performance in critical applications.

SAE J514 Hydraulic Tube Fittings

SAE J514 fittings, also known as JIC (Joint Industry Council), are widely used in hydraulic systems due to their versatility and robust design. These fittings feature a 37-degree flare seating surface and a straight thread with a rounded crest and roots, optimized for high-pressure applications. The flare connection provides a metal-to-metal seal that enhances resistance to vibration and shock, crucial for industries such as construction, agriculture, and industrial machinery.

SAE J1926 Straight Thread O-Ring Boss (ORB) Fittings

SAE J1926 fittings utilize a straight thread with an O-ring seal to prevent leakage under high-pressure conditions. These fittings are commonly used where a reliable, leak-tight seal is essential, such as in hydraulic pumps, valves, and cylinders. The O-ring boss design ensures effective sealing without the need for additional sealants, simplifying assembly and maintenance procedures. This type of fitting is favored in aerospace, automotive, and marine applications where reliability and performance are paramount.

SAE 45 Degree Fittings

SAE 45-degree fittings are a specific type of hydraulic fitting designed to facilitate fluid connections at a 45-degree angle. SAE 45-degree fittings feature a cone-shaped seating surface with a 45-degree flare angle. This design allows for a secure connection between the fitting and tubing, typically using a flare nut to compress the tubing against the fitting body. The flare angle ensures a metal-to-metal seal, enhancing resistance to vibration and reducing the risk of leakage, which is critical in applications where hydraulic fluids are under pressure.

Application Specificity

Each type of SAE fitting is tailored to specific hydraulic applications, offering distinct advantages in terms of sealing efficiency, pressure tolerance, and compatibility with hydraulic fluids. Engineers and designers select fittings based on operating pressure, temperature range, and environmental conditions to ensure optimal system performance and reliability. The standardized nature of SAE fittings enables interchangeability across different equipment and facilitates streamlined procurement and maintenance processes.

Industry Adoption

SAE fittings have gained widespread adoption across industries globally due to their proven performance and adherence to stringent standards. They play a critical role in maintaining system integrity and operational safety in applications ranging from heavy machinery and construction equipment to precision aerospace components. Engineers rely on SAE fittings to provide durable, leak-resistant connections that withstand the rigors of continuous operation and harsh environments, ensuring long-term reliability and performance.

Design and Construction of SAE Fittings

SAE fittings are engineered with precision and durability to meet stringent performance requirements in hydraulic systems. This section delves into the detailed anatomy of SAE fittings, the materials used in their construction, and the critical role of precision engineering in their design.

Detailed Anatomy of SAE Fittings

Components:

Nut: The nut of an SAE fitting is typically hexagonal and serves to secure the fitting to the mating component, such as tubing or a port.

Body: The body houses the fitting’s internal components and features the threading that facilitates connection with other hydraulic components.

Seals: Various types of seals, such as O-rings, metal seals, or gaskets, are used depending on the fitting type to prevent leaks and maintain hydraulic fluid integrity.

Locking Mechanisms: Some fittings include locking mechanisms to ensure the fitting remains securely fastened under operational vibrations and pressures.

Types of Connections:

Flare Fittings: Utilize a conical seat and flare nut to create a seal, commonly used in SAE J514 fittings.

O-Ring Boss (ORB) Fittings: Feature a straight thread with an O-ring seal, ensuring a reliable, leak-free connection, as seen in SAE J1926 fittings.

Face Seal Fittings: Employ a flat face with an O-ring seal for high-pressure applications where vibration resistance and reliable sealing are crucial.

Applications of SAE Fittings

SAE fittings are integral components in a wide array of applications across various industries, leveraging their versatility, reliability, and standardized design to ensure efficient fluid power management and operational safety.

Hydraulic Machinery:

In hydraulic machinery, SAE fittings play a crucial role in connecting hydraulic hoses, tubes, and components. They facilitate the transmission of pressurized hydraulic fluid, enabling precise control and power transmission in equipment such as excavators, loaders, and hydraulic presses.

Automotive Steering Systems:

SAE fittings are extensively utilized in automotive steering systems to connect hydraulic lines that assist in steering control. These fittings ensure the reliable transmission of hydraulic power from the steering pump to the steering gear or rack, enabling responsive and smooth vehicle maneuverability.

Marine Propulsion:

In marine applications, SAE fittings are employed in hydraulic systems that power propulsion mechanisms, steering systems, and winches aboard ships and vessels. These fittings withstand the corrosive effects of saltwater environments while maintaining tight seals to prevent hydraulic fluid leakage. Their ability to handle varying pressures and temperatures makes them ideal for maritime operations, ensuring reliable performance and maneuverability of marine equipment across commercial shipping, offshore drilling, and naval applications.

Manufacturing Industry:

SAE fittings support critical functions in manufacturing processes, where hydraulic systems operate machinery such as injection molding machines, CNC machining centers, and assembly lines. These fittings enable precise control of hydraulic actuators and tools, contributing to the efficiency and productivity of manufacturing operations.

Agricultural Equipment:

In agriculture, SAE fittings are employed in hydraulic systems that power equipment such as tractors, harvesters, and irrigation systems. These fittings facilitate the operation of hydraulic cylinders, motors, and valves essential for tasks such as lifting, steering, and controlling implements.

Installation and Maintenance of SAE Fittings

Proper installation and diligent maintenance of SAE fittings are critical to ensuring reliable performance and longevity in hydraulic systems. These practices involve meticulous attention to detail to prevent leaks, maintain system integrity, and optimize operational efficiency across various industrial applications.

Installation Best Practices

Torque Application: Proper torque application is essential during installation to achieve optimal sealing and prevent fittings from loosening under operational pressures. Using a torque wrench calibrated to manufacturer specifications ensures uniform tightening of fittings without over-stressing or damaging components.

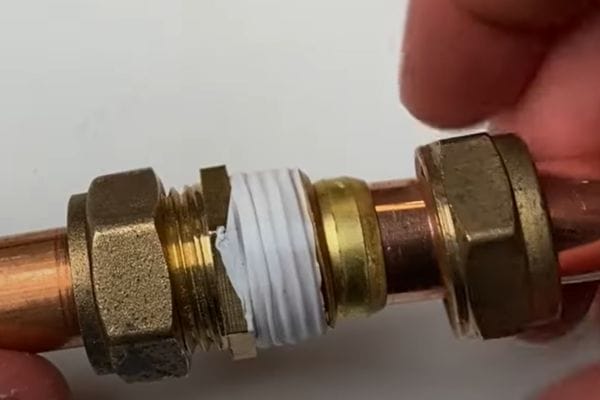

Thread Engagement: Ensuring adequate thread engagement between the fitting and mating components is crucial for establishing a secure connection. Proper alignment and threading prevent cross-threading, which can compromise sealing integrity and lead to leaks.

Cleanliness: Maintaining cleanliness during installation minimizes the risk of contamination that can compromise hydraulic fluid and damage internal components. Thoroughly clean fittings, hoses, and tubing ends before assembly to remove dirt, debris, and residual fluids that could impair sealing effectiveness.

Use of Sealants and Lubricants: Applying appropriate sealants and lubricants on threads and sealing surfaces enhances sealing performance and facilitates assembly. Care should be taken to use compatible sealants recommended for hydraulic applications to prevent chemical reactions or degradation of sealing materials.

Maintenance Tips

Periodic Inspections: Regular inspections of SAE fittings and hydraulic connections are essential to detect signs of wear, corrosion, or leaks early on. Visual inspections should include checking for visible leaks, loose fittings, and abnormal wear patterns that may indicate potential issues.

Replacement of Worn Components: Timely replacement of worn fittings, seals, and O-rings is crucial to prevent leaks and maintain system reliability. Components subjected to high pressures and repetitive use should be inspected according to maintenance schedules and replaced as necessary to avoid unexpected failures.

Seal Integrity Checks: Periodically check the integrity of seals and O-rings within SAE fittings to ensure they remain pliable and capable of forming effective seals. Replace seals that show signs of cracking, hardening, or deformation to prevent leakage and maintain hydraulic fluid containment.

Pressure Testing: Conduct pressure testing as part of routine maintenance to verify the integrity of hydraulic connections and fittings. Pressure tests help identify potential leaks or weaknesses in fittings under operating conditions, allowing for preemptive repairs or replacements before they escalate into critical failures.

Choosing the Right SAE Fitting

Selecting the appropriate SAE fitting is critical to ensuring efficient and reliable operation within hydraulic systems. The process involves a thorough evaluation of several key factors tailored to specific operational requirements and industry standards.

Factors to Consider

Pressure Ratings: Evaluate the maximum operating pressure that the fitting will encounter within the hydraulic system. SAE fittings are rated to withstand specific pressure ranges, and selecting a fitting with an appropriate pressure rating ensures safety and performance under operational conditions.

Temperature Tolerances: Consider the temperature range in which the hydraulic system operates. SAE fittings are designed to withstand varying temperatures, and choosing fittings that match the system’s temperature requirements prevents issues such as material degradation or loss of sealing effectiveness in extreme temperature environments.

Compatibility with Hydraulic Fluids: Assess compatibility with the type of hydraulic fluid used in the system, including considerations for chemical compatibility and resistance to fluid degradation. Different hydraulic fluids can have varying properties that may affect the material and seal performance of SAE fittings, making compatibility a crucial factor in ensuring long-term reliability.

Material Selection: SAE fittings are available in various materials such as stainless steel, brass, and aluminum, each offering unique advantages in terms of strength, corrosion resistance, and compatibility with specific applications. Select materials that align with environmental conditions and operational requirements to enhance durability and performance.

Customization Options: Explore customization options offered by manufacturers to tailor fittings to specific application needs. Custom fittings may include variations in thread configurations, sizes, and sealing methods to optimize fit and function within unique hydraulic systems.

Consultation with Experts

Seeking expert advice from hydraulic system engineers or SAE fitting manufacturers can provide valuable insights and recommendations. Experts can offer technical guidance on selecting fittings based on detailed application specifications, ensuring compatibility with existing system components and adherence to industry standards.

Conclusion

SAE fittings represent a cornerstone in hydraulic system design, combining standardized excellence with adaptability to evolving industry needs. As technology advances, future innovations promise further enhancements in performance and efficiency, reinforcing the pivotal role of quality fittings in sustaining system integrity and operational success.

FAQ

What are SAE Fittings?

SAE Fittings refer to hydraulic connectors that adhere to standards set by the Society of Automotive Engineers (SAE). They are used to connect pipes, fittings, and other hydraulic components in systems, designed with precision for high strength and reliable sealing performance across various industrial and commercial applications.

What types of SAE Fittings are there?

SAE Fittings include various types such as SAE J514 (JIC), SAE J1926 (ORB), and SAE J1453 (ORFS), among others. Each type features specific thread types, sealing methods, and applications tailored to different operational needs.

What are the main advantages of SAE Fittings?

The primary advantages of SAE Fittings include standardized design, ease of installation, high-pressure resistance, excellent sealing capabilities, and a variety of material options. They provide stable connections and performance under demanding conditions.

Which industries use SAE Fittings?

SAE Fittings are widely used in industries such as hydraulic machinery, automotive systems, aerospace, and industrial manufacturing. They play a crucial role in ensuring precise control and reliability in critical applications.

How do I choose the right SAE Fitting?

Selecting the appropriate SAE Fitting involves considering factors like operating pressure, temperature range, compatibility with hydraulic fluids, and specific application requirements. Consulting with industry experts or manufacturers based on technical specifications and standards is recommended for optimal selection.

What should I consider during the installation and maintenance of SAE Fittings?

During installation, ensure proper torque application, correct thread engagement, and cleanliness to prevent leaks and maintain system integrity. Regular inspections and replacement of worn components are essential for ensuring long-term reliability and operational efficiency.

Contact Topa

Have a question or suggestion? Fill out the form below to get in touch with one of our experts.