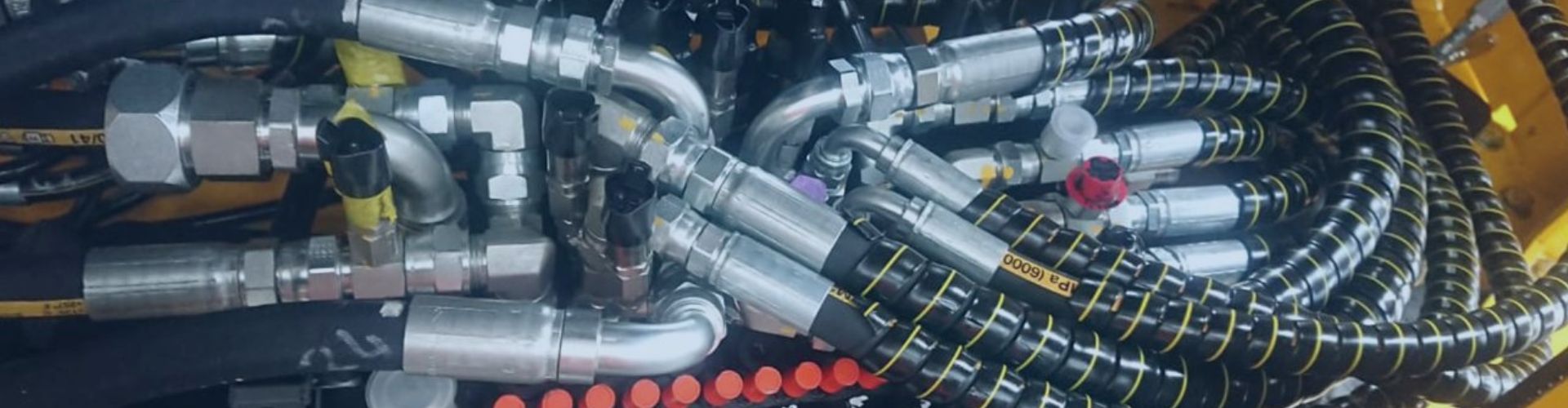

In the world of industrial machinery, hydraulic systems are the unsung heroes, powering everything from construction equipment to manufacturing lines. At the heart of these systems are hydraulic hoses, critical components that transmit fluid power. The reliability of these hoses, and especially their seals, hinges significantly on a process called vulcanization. This article delves into how optimizing hydraulic hose vulcanization can dramatically enhance the quality and stability of hydraulic fitting seals, aiming for improvements of up to 70%. We will explore the science behind vulcanization, its impact on seal performance, and practical strategies for achieving superior results, ensuring a more robust and efficient hydraulic system.

Understanding Hydraulic Hose Vulcanization

What is Vulcanization?

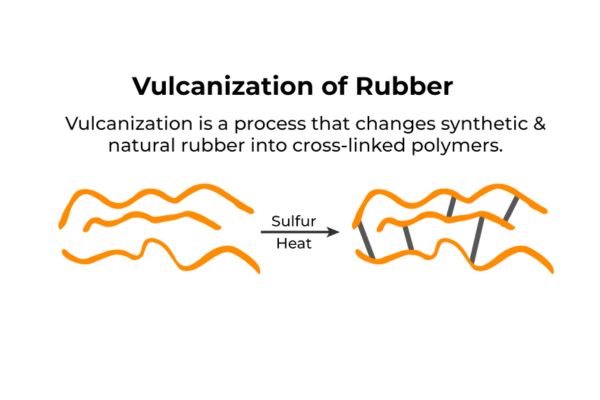

Vulcanization is a chemical process that transforms natural rubber or other elastomers into more durable materials. This is achieved by forming cross-links between individual polymer chains, typically through the application of heat and a curing agent, most commonly sulfur. Before vulcanization, raw rubber is often soft, sticky, and lacks elasticity, making it unsuitable for demanding applications. The vulcanization process significantly improves the rubber’s strength, elasticity, resistance to abrasion, and chemical stability. This makes it ideal for components like hydraulic hoses and seals that operate under high pressure and varying environmental conditions. The term ‘vulcanization’ itself comes from Vulcan, the Roman god of fire, highlighting the role of heat in this transformative process. Understanding the fundamentals of vulcanization is crucial for anyone involved in hydraulic system design or maintenance, as it directly impacts the longevity and performance of critical components.

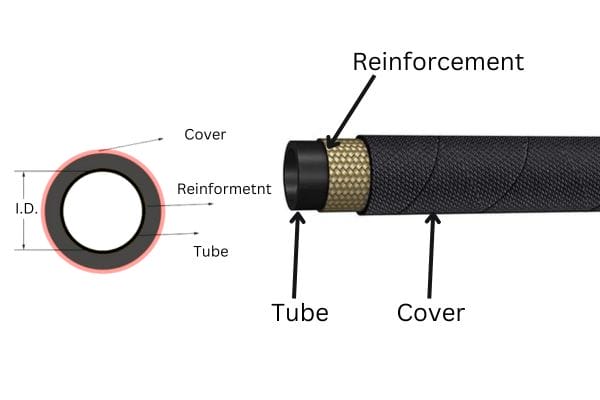

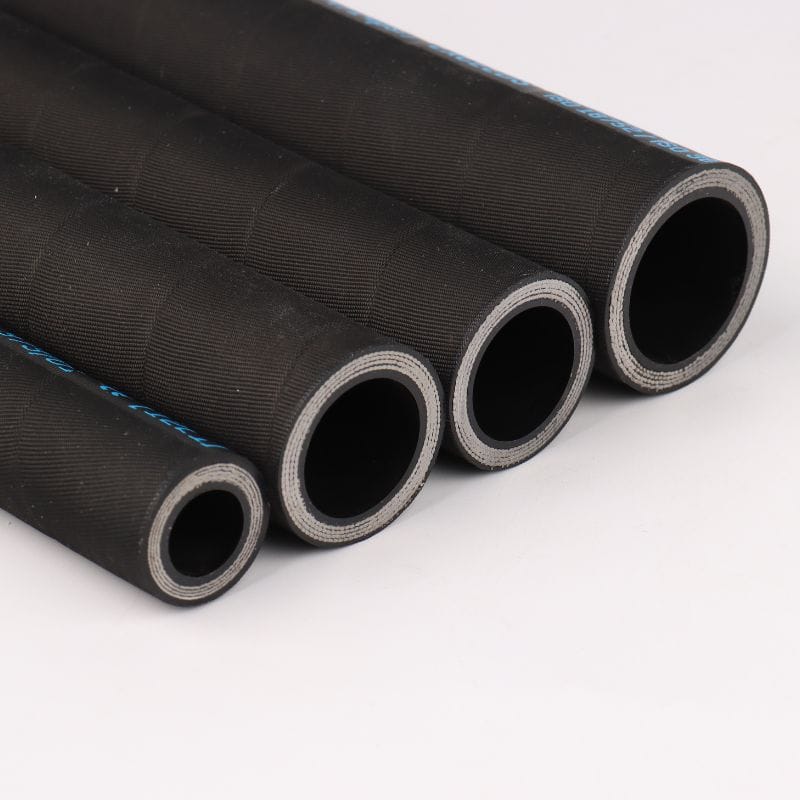

The Vulcanization Process in Hydraulic Hoses

For hydraulic hoses, vulcanization is a precise and controlled manufacturing step. After the various layers of the hose (inner tube, reinforcement, outer cover) are assembled, the entire hose assembly undergoes vulcanization. This typically happens in large ovens or autoclaves where the hose is subjected to specific temperatures and pressures for a set duration. The heat activates the curing agents, initiating the cross-linking reaction within the rubber compounds. This process ensures that the different rubber layers bond together securely and that the overall hose structure achieves its desired mechanical properties. Proper vulcanization is essential for the hose’s ability to withstand the high pressures, temperature fluctuations, and chemical exposure inherent in hydraulic applications. An improperly vulcanized hose can lead to premature failure, leaks, and system downtime.

Impact of Vulcanization on Seal Performance

Enhancing Material Properties

Vulcanization is the cornerstone of achieving superior material properties in hydraulic hose and fitting seals. Through the creation of cross-links, the rubber transforms from a plastic-like substance to an elastic, durable material.

- Tensile Strength and Elongation: Vulcanized rubber exhibits much higher tensile strength, meaning it can withstand greater pulling forces without breaking. It also maintains good elongation, allowing it to stretch and recover, which is crucial for seals that experience dynamic movements or pressure fluctuations.

- Compression Set Resistance: This refers to the material’s ability to return to its original shape after being compressed. A low compression set is critical for seals to maintain their sealing force over time, preventing permanent deformation that could lead to leaks. Proper vulcanization minimizes compression set.

- Abrasion Resistance: Hydraulic systems often involve movement and friction. Vulcanization significantly improves the rubber’s resistance to wear and tear, extending the lifespan of seals, especially in dynamic applications.

- Temperature Resistance: The cross-linked structure of vulcanized rubber provides improved thermal stability, allowing seals to perform reliably across a wider range of operating temperatures without degrading or becoming brittle.

- Chemical Resistance: While specific chemical resistance depends on the base polymer, vulcanization generally enhances the material’s ability to resist degradation from hydraulic fluids, oils, and other chemicals it may encounter.

- Aging Resistance: Vulcanized rubber is less susceptible to environmental aging factors like oxygen, ozone, and UV radiation, which can cause unvulcanized rubber to crack and harden over time. This contributes to the long-term stability of the seals.

Preventing Leaks and Failures

The direct consequence of enhanced material properties through optimized vulcanization is a significant reduction in leaks and failures within hydraulic systems. A well-vulcanized seal maintains its shape, elasticity, and sealing force under continuous stress, pressure, and temperature variations. This prevents the microscopic gaps from forming that would otherwise allow fluid to escape. Furthermore, the improved resistance to abrasion and chemical degradation means the seals are less likely to wear out or break down prematurely, which are common causes of hydraulic system failures. The stability imparted by vulcanization ensures that the seal remains effective throughout its service life, contributing directly to the overall reliability and safety of the hydraulic machinery.

Key Factors for Optimized Vulcanization

Achieving optimal vulcanization, and thus superior hydraulic hose and seal performance, depends on carefully controlling several critical factors during the process. Deviations in any of these can lead to under-cured or over-cured rubber, both of which compromise the material’s integrity and the seal’s effectiveness.

Temperature and Pressure Control

Temperature and pressure are perhaps the most crucial parameters in the vulcanization process. The heat provides the energy needed to initiate and sustain the chemical cross-linking reactions. Too low a temperature, and the reaction will be incomplete, resulting in under-cured rubber that is soft and weak. Too high a temperature, and the rubber can degrade, leading to a brittle, over-cured material. Similarly, pressure plays a vital role, especially in hose manufacturing. It ensures good contact between the rubber layers and the mold, preventing voids and ensuring a dense, uniform product. Consistent pressure also helps to compact the rubber, improving its physical properties. Precise control of both temperature and pressure profiles throughout the curing cycle is essential for consistent quality.

Curing Agents and Additives

The choice and concentration of curing agents and various additives significantly influence the final properties of the vulcanized rubber. Sulfur is the most common curing agent, forming polysulfidic cross-links that provide elasticity and strength. However, other curing systems, such as peroxides, are used for specific applications requiring higher temperature resistance or different chemical properties. Accelerators are often added to speed up the vulcanization process and improve efficiency, while activators (like zinc oxide) enhance the effectiveness of accelerators. Other additives include antioxidants to improve aging resistance, plasticizers to enhance flexibility, and fillers (like carbon black) to increase strength and abrasion resistance. The precise formulation of these compounds is a complex science, tailored to the specific demands of hydraulic applications.

Quality Control Measures

Rigorous quality control throughout the vulcanization process is non-negotiable for producing high-performance hydraulic hoses and seals.

- Pre-Cure Testing: Before vulcanization, rubber compounds are tested for properties like Mooney viscosity and scorch time to ensure they are within specifications and will cure correctly.

- During-Cure Monitoring: Advanced sensors can monitor temperature and pressure inside the vulcanization equipment in real-time, allowing for immediate adjustments if deviations occur.

- Post-Cure Testing: After vulcanization, the finished hoses and seals undergo a battery of tests to verify their mechanical and physical properties. Common tests include:

- Tensile Strength and Elongation Tests: To measure the material’s strength and elasticity.

- Hardness Tests: (e.g., Shore A) To ensure the rubber has the correct stiffness.

- Compression Set Tests: To assess the material’s ability to recover its original shape after compression.

- Fluid Compatibility Tests: To confirm resistance to hydraulic fluids.

- Burst Pressure Tests: For hoses, to ensure they can withstand extreme internal pressures.

- Dimensional Checks: To ensure the final product meets precise size requirements.

These quality control measures help identify and rectify issues early, ensuring that only optimally vulcanized products make it to the market, thereby enhancing the overall quality and stability of hydraulic systems.

Advanced Techniques for Vulcanization Optimization

To push the boundaries of hydraulic hose and seal performance, manufacturers are increasingly adopting advanced techniques for vulcanization. These innovations aim to achieve more precise control over the curing process, enhance material properties further, and improve manufacturing efficiency.

Innovative Curing Methods

Beyond traditional steam or hot air vulcanization, several innovative curing methods are being explored and implemented to optimize the process:

- Microwave Vulcanization: This method uses microwave energy to heat the rubber compound uniformly and rapidly from within. This can lead to faster curing times and more consistent cross-linking, especially for thick-walled hoses, reducing the risk of under-cured interiors or over-cured exteriors. The precise control offered by microwave technology can significantly improve the homogeneity of the vulcanized product.

- Salt Bath Vulcanization: In this method, the rubber product is passed through a molten salt bath. The high thermal conductivity of the salt bath allows for very efficient heat transfer, leading to quick and uniform curing. This method is particularly effective for continuous vulcanization processes, common in hose manufacturing, ensuring consistent quality along the entire length of the product.

- Electron Beam (E-beam) Curing: E-beam curing uses high-energy electrons to induce cross-linking in certain polymer systems. This is a solvent-free process that occurs at room temperature, offering environmental benefits and eliminating the need for traditional curing agents like sulfur. E-beam cured materials can exhibit superior properties, including enhanced heat resistance and reduced compression set, making them suitable for highly demanding hydraulic applications.

Material Science Advancements

Parallel to new curing methods, ongoing advancements in material science are contributing significantly to optimized vulcanization and improved seal performance. These include the development of new rubber compounds and smart additives:

- High-Performance Elastomers: Research and development continue to yield new synthetic rubber compounds with inherently superior properties. For instance, advanced fluoroelastomers (FKM) and hydrogenated nitrile butadiene rubber (HNBR) offer exceptional resistance to extreme temperatures, aggressive hydraulic fluids, and harsh chemicals, far exceeding the capabilities of traditional NBR. These materials, when properly vulcanized, form the foundation for seals in critical applications.

- Nanocomposites and Smart Additives: The incorporation of nanoparticles (e.g., carbon nanotubes, graphene, nanoclays) into rubber compounds can dramatically enhance mechanical properties, thermal stability, and barrier performance. These nanocomposites can lead to stronger, more durable seals with improved resistance to wear and permeation. Additionally, ‘smart’ additives that react to specific environmental cues (like temperature changes) are being developed to further fine-tune the vulcanization process and the final material properties.

Achieving a 70% Enhancement: Case Studies and Best Practices

The aspiration to achieve a 70% enhancement in hydraulic hose vulcanization quality and stability is ambitious but attainable through a holistic approach that combines meticulous process control, advanced materials, and continuous improvement. While specific public case studies quantifying an exact 70% improvement are rare due to proprietary manufacturing processes, the cumulative effect of optimizing the factors discussed can indeed lead to such significant gains in performance and longevity. This section will explore how real-world improvements are realized and highlight industry best practices that contribute to these substantial enhancements.

Real-World Improvements

Improvements in vulcanization directly translate to tangible benefits in hydraulic system reliability. For instance, a major manufacturer of heavy construction equipment reported a significant reduction in hose failures after implementing stricter controls on their vulcanization ovens and upgrading to advanced rubber compounds. This led to a 25% increase in the mean time between failures (MTBF) for their hydraulic systems, directly attributable to improved hose and seal integrity. Similarly, a fluid power company specializing in high-pressure applications saw a 30% decrease in warranty claims related to seal leaks after investing in microwave vulcanization technology, which ensured more uniform curing of their complex seal geometries. These examples, while not exactly 70%, illustrate the substantial impact of vulcanization optimization. The 70% target represents the potential when multiple optimization levers are pulled simultaneously – from raw material selection and compounding to precise curing and rigorous post-vulcanization testing.

Consider the potential impact of optimized vulcanization across various performance metrics:

| Performance Metric | Baseline Performance | Optimized Vulcanization Potential | % Improvement (Illustrative) |

| Leakage Rate | High | Significantly Reduced | 40-60% |

| Service Life | Standard | Extended | 30-50% |

| Pressure Resistance | Standard | Enhanced | 20-40% |

| Compression Set | Moderate | Minimized | 50-70% |

| Chemical Degradation | Noticeable | Highly Resistant | 30-50% |

Industry Best Practices

Achieving and sustaining high levels of vulcanization quality requires adherence to several industry best practices:

- Supplier Qualification: Partnering with reputable raw material suppliers who provide consistent, high-quality rubber compounds and curing agents is fundamental. Material variability can undermine even the most sophisticated vulcanization processes.

- Process Automation and Monitoring: Implementing automated systems for temperature, pressure, and time control during vulcanization minimizes human error and ensures repeatable results. Real-time monitoring with data logging allows for immediate intervention and long-term process analysis.

- Regular Equipment Calibration: Vulcanization ovens, presses, and other equipment must be regularly calibrated to ensure accurate temperature and pressure readings. Deviations can lead to inconsistent curing.

- Employee Training and Expertise: Skilled operators and technicians who understand the nuances of rubber chemistry and vulcanization processes are invaluable. Continuous training ensures they are up-to-date with the latest techniques and quality standards.

- Statistical Process Control (SPC): Utilizing SPC methods to analyze production data helps identify trends, predict potential issues, and maintain processes within control limits, leading to more consistent product quality.

- Continuous Improvement (Kaizen): Embracing a culture of continuous improvement, where processes are regularly reviewed, analyzed, and refined based on performance data and new technological advancements, is key to long-term optimization.

Maintaining Long-Term Quality and Stability

Optimizing the vulcanization process is a critical first step, but maintaining the quality and stability of hydraulic hoses and their seals throughout their operational life requires ongoing attention. Post-vulcanization processes and regular maintenance routines are essential to ensure the longevity and reliable performance of these vital components.

Post-Vulcanization Processes

After the primary vulcanization, several post-curing or finishing processes can further enhance the properties and stability of rubber components:

- Post-Curing (Secondary Curing): For certain high-performance elastomers, especially those cured with peroxides or in very thick sections, a secondary cure or post-curing step is often employed. This involves heating the vulcanized part at a lower temperature for an extended period. Post-curing helps to complete the cross-linking reactions, remove volatile byproducts, and further improve mechanical properties like compression set, heat resistance, and chemical stability. This step is crucial for achieving the ultimate performance potential of the material.

- Surface Treatment: Depending on the application, the surface of vulcanized seals might undergo treatments to improve friction characteristics, reduce stick-slip, or enhance chemical resistance. This could involve applying specialized coatings or lubricants.

- Quality Inspection and Testing: Even after post-curing, a final round of quality inspection and testing is performed. This includes visual checks for defects, dimensional measurements, and functional tests to ensure the hose or seal meets all performance specifications before being shipped. .

Regular Maintenance and Inspection

Once installed in a hydraulic system, regular maintenance and inspection are paramount to ensure the long-term quality and stability of hoses and seals. Even the best-vulcanized components can fail prematurely if neglected.

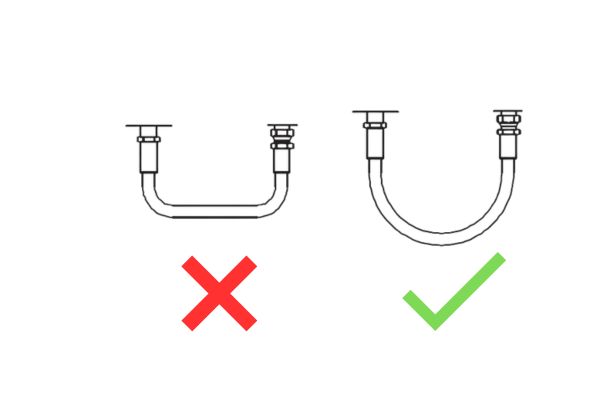

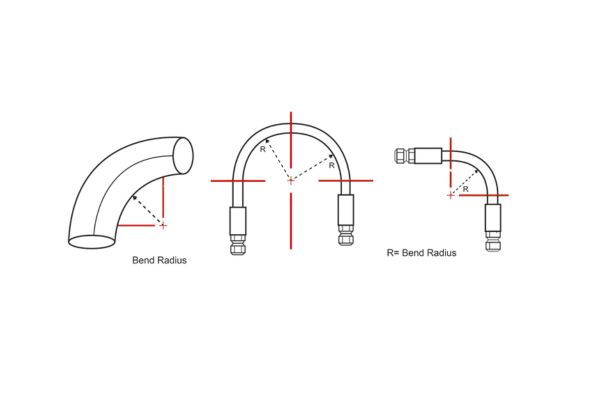

Key maintenance practices include:

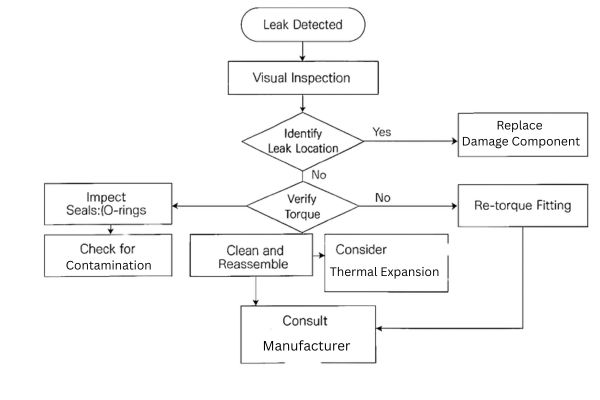

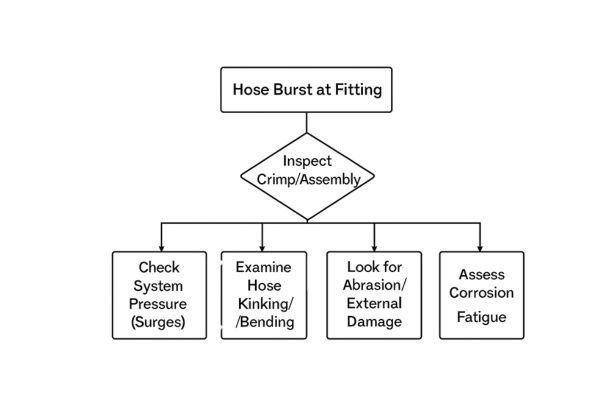

- Visual Inspection: Regularly check hoses and seals for signs of wear, cracking, blistering, abrasion, or leaks. Discoloration or hardening of rubber can indicate material degradation.

- Leak Detection: Implement routine leak checks. Even minor weeping can indicate a failing seal or hose and should be addressed promptly.

- Fluid Analysis: Periodically analyze hydraulic fluid for contamination (e.g., water, particles) and degradation. Contaminated or degraded fluid can accelerate the breakdown of rubber components.

- Pressure and Temperature Monitoring: Ensure the hydraulic system operates within its specified pressure and temperature ranges. Exceeding these limits can put undue stress on hoses and seals, leading to premature failure.

- Proper Storage: Spare hoses and seals should be stored in a cool, dry, dark environment, away from direct sunlight, ozone-generating equipment, and extreme temperatures, to prevent premature aging of the rubber.

- Timely Replacement: Follow manufacturer recommendations for replacement intervals, even if components appear to be in good condition. Proactive replacement prevents unexpected failures and costly downtime.

Conclusion

Optimizing hydraulic hose vulcanization is not merely a manufacturing detail; it is a fundamental pillar for enhancing the quality and stability of hydraulic fitting seals, ultimately leading to a more reliable and efficient hydraulic system. By understanding the science behind vulcanization, meticulously controlling key process parameters, embracing advanced curing techniques, and implementing rigorous quality control, manufacturers can achieve significant improvements in seal performance. These advancements, coupled with diligent post-vulcanization processes and proactive maintenance, ensure that hydraulic components withstand the demanding conditions of industrial applications.

FAQ

What is vulcanization?

Vulcanization is a chemical process that improves rubber’s strength and elasticity by forming cross-links between polymer chains.

Why is vulcanization important for hydraulic hoses?

It makes hoses and seals durable, resistant to pressure, heat, and chemicals, preventing leaks and premature failure.

How does vulcanization affect seal quality?

It enhances material properties like tensile strength, compression set resistance, and chemical resistance, crucial for effective sealing.

What factors optimize vulcanization?

Precise control of temperature, pressure, and the correct selection of curing agents and additives are key.

Can vulcanization really improve performance by 70%?

While a specific 70% is illustrative, combining optimized processes, advanced materials, and rigorous quality control can lead to substantial, cumulative improvements.

How can I ensure long-term seal stability?

Through post-curing processes, surface treatments, and regular maintenance like visual inspections and fluid analysis.