What is FIP Thread?

Introduction

Threaded fittings are integral components in hydraulic systems, serving crucial roles in connecting various parts to ensure fluid containment and operational efficiency. Understanding different thread types, such as FIP (Female Iron Pipe), NPT (National Pipe Thread), and BSP (British Standard Pipe), is essential for selecting compatible fittings that prevent leaks and ensure optimal performance. This knowledge not only facilitates seamless assembly but also minimizes downtime and maintenance costs, highlighting the critical role of thread standards in hydraulic engineering.

Understanding Thread Basics

Definition of Threads in Mechanical and Hydraulic Applications

In mechanical and hydraulic systems, threads refer to the helical ridges or grooves on the inside or outside of cylindrical surfaces. These threads enable the connection of components by providing a means to secure fittings, valves, and pipes together. Threads serve a dual purpose: they facilitate the assembly of components while ensuring a tight seal to prevent leaks in pressurized systems.

Threads are standardized based on parameters such as size, pitch (distance between each thread), and shape (tapered or parallel). These parameters determine how well threads from different manufacturers or countries can interconnect, highlighting the importance of adhering to recognized thread standards.

Importance of Thread Compatibility and Standards:

Thread compatibility is crucial in hydraulic applications to ensure the integrity and reliability of connections. Mismatched threads can lead to leaks, improper fitting alignment, and potentially catastrophic failures in hydraulic systems. Therefore, adherence to international standards such as ANSI/ASME, ISO, and DIN is essential.

Standardization not only ensures compatibility between components sourced from different suppliers but also simplifies maintenance and replacement procedures. It allows engineers and technicians to select fittings and adapters confidently, knowing they will fit and function correctly within the system.

Understanding thread basics and their significance in hydraulic systems lays the foundation for reliable and efficient operation. By selecting and maintaining threads according to established standards, manufacturers and maintenance providers can optimize system performance while minimizing risks associated with component failure.

Definition of FIP Thread

FIP, or Female Iron Pipe, thread is a type of threaded connection used primarily in plumbing and hydraulic systems. It is characterized by its tapered threads designed to create a tight seal when engaged with a corresponding Male Iron Pipe (MIP) thread. The taper of FIP threads helps to ensure a secure fit and seal as the threads are tightened, making it suitable for applications where leak prevention is critical.

History and Development of FIP Thread Standards:

The development of FIP thread standards can be traced back to the early advancements in plumbing and fluid handling industries. Over time, standards such as those set by ANSI/ASME have standardized the dimensions, pitch, and taper angles of FIP threads, ensuring uniformity and compatibility across different manufacturers and applications.

The evolution of FIP thread standards reflects ongoing efforts to improve thread performance and reliability in diverse environments. These standards have been pivotal in enabling the widespread adoption of FIP threads across various industries, providing engineers and technicians with confidence in their application and longevity.

Detailed Analysis of FIP Thread Standards

ANSI/ASME Standards for FIP Threads:

FIP (Female Iron Pipe) threads adhere to standards set by ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers). These standards define the dimensions, tolerances, and performance requirements for FIP threads to ensure compatibility and reliability across applications. ANSI/ASME standards provide a framework that manufacturers and engineers rely on to produce and specify FIP threaded components with confidence in their performance and interchangeability.

Dimensions and Specifications of FIP Threads:

FIP threads are characterized by their taper and specific dimensions:

Taper: FIP threads typically have a taper of 1 in 16 on the diameter, meaning the diameter decreases by 1 unit per 16 units of length.

Pitch: The pitch refers to the distance between threads measured along the axis of the thread. Standard pitches for FIP threads are defined by ANSI/ASME to ensure uniformity.

Sizes: FIP threads are available in various sizes, ranging from smaller diameters suitable for residential plumbing to larger sizes used in industrial applications. Common sizes include 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, and larger.

These specifications are crucial in determining the compatibility of FIP threaded fittings with pipes, valves, and other components in hydraulic and plumbing systems. Proper adherence to these dimensions ensures a secure fit and effective sealing to prevent leaks and maintain system integrity.

Application Areas Where FIP Threads are Commonly Used

FIP threads find widespread application in various industries and environments, including:

Plumbing: FIP threads are commonly used in plumbing systems for connecting fixtures, faucets, and pipe fittings. Their tapered design facilitates a tight seal, preventing water leaks.

Hydraulics: In hydraulic systems, FIP threads are utilized for connecting pipes, hoses, and fittings. Their reliability and compatibility make them suitable for applications requiring high pressure and fluid containment.

Industrial Equipment: FIP threads are found in industrial machinery and equipment where threaded connections are necessary for fluid transfer, pneumatic systems, and other mechanical operations.

Construction: FIP threads are used in construction for connecting pipes in HVAC (heating, ventilation, and air conditioning) systems, fire suppression systems, and other building infrastructure.

Understanding the application areas of FIP threads helps in selecting the appropriate fittings and components that meet specific operational requirements and environmental conditions. Whether in residential, commercial, or industrial settings, FIP threads play a critical role in ensuring the reliability and functionality of fluid handling systems.

Differences Between FIP and Other Thread Types

Comparison with NPT

Design:

FIP Threads: FIP threads have a taper of 1 in 18, meaning the diameter decreases by 1 unit per 18 units of length.

NPT Threads: NPT threads have a taper of 1 in 16, which is more abrupt compared to FIP threads.

Function:

FIP Threads: Designed primarily for plumbing and hydraulic applications, FIP threads create a tight seal through the taper when engaged with a male thread.

NPT Threads: Widely used in the United States, NPT threads also utilize taper for sealing and are preferred for their interference fit that prevents leaks in plumbing, air compression, and hydraulic systems.

Application Suitability:

FIP Threads: Commonly found in North America and selected global industrial applications, FIP threads excel in environments requiring reliable sealing under pressure, such as in hydraulic fittings and plumbing systems.

NPT Threads: Ideal for applications where a secure, leak-resistant seal is crucial, NPT threads are standardized across various industries in the US and are known for their robust performance in fluid and gas handling systems.

Comparison with BSP

Design:

FIP Threads: Tapered design facilitates a tight seal without additional sealants, suitable for applications where a secure, leak-free connection is paramount.

BSP Threads: Parallel threads require sealants or washers to achieve a seal, offering ease of assembly and disassembly.

Function:

FIP Threads: Specifically engineered for sealing efficiency, FIP threads rely on the taper to enhance sealing effectiveness during assembly.

BSP Threads: Commonly used in Europe, Australia, and Asia, BSP threads provide versatility in fluid and gas handling applications with straightforward installation and maintenance procedures.

Application Suitability:

FIP Threads: Well-suited for environments demanding high sealing integrity, FIP threads are favored in hydraulic systems and industrial settings where reliability is critical.

BSP Threads: Suitable for environments requiring frequent assembly and disassembly, BSP threads accommodate applications in hydraulic fittings, pneumatic systems, and industrial equipment across diverse global markets.

Comparison with MIP Threads

Design and Function:

FIP Threads (Female Iron Pipe):

Design: FIP threads have a tapered internal thread designed to create a tight seal when engaged with a corresponding MIP thread.

Function: FIP threads are typically found on fittings and connectors where they mate with MIP threads, ensuring a secure and leak-resistant connection in plumbing and hydraulic systems.

MIP Threads (Male Iron Pipe):

Design: MIP threads have external tapering designed to fit into FIP threads, creating a tight seal when assembled.

Function: MIP threads are commonly used on pipes, valves, and fittings where they engage with FIP threads, providing a reliable connection that prevents leaks under pressure.

Application Suitability:

FIP Threads:

Suitability: FIP threads are suitable for applications where a secure, leak-free seal is essential, such as in plumbing fixtures, hydraulic fittings, and industrial piping systems.

MIP Threads:

Suitability: MIP threads complement FIP threads by providing a male counterpart that ensures a snug fit and effective sealing, making them integral in various plumbing and hydraulic applications.

Key Differences:

Design: FIP threads have a tapered internal design, while MIP threads have a tapered external design, facilitating a reliable seal when connected.

Function: FIP and MIP threads work together to create a robust, leak-resistant connection crucial in maintaining system integrity in hydraulic and plumbing systems.

Understanding the interplay between FIP and other threads is essential for selecting and assembling fittings and components that ensure efficient fluid handling and minimize the risk of leaks and system failures.

Installation and Maintenance of FIP Threads

Best Practices for Installing FIP Threads

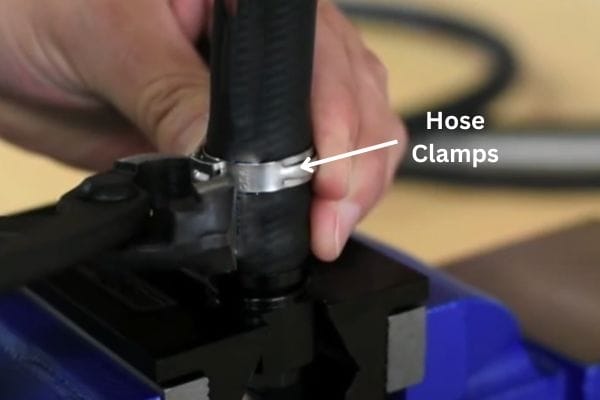

Cleanliness: Ensure that all threads, including those on fittings and pipes, are clean and free of debris or contaminants before installation. Use appropriate cleaning agents and tools to achieve a smooth mating surface.

Thread Sealant: Apply a suitable thread sealant or tape on the male threads before assembling with FIP threads. This helps in achieving a secure and leak-free connection. Avoid over-application of sealant to prevent excess material from entering the hydraulic system.

Proper Alignment: Align the threads carefully to prevent cross-threading, which can damage the threads and compromise the seal. Start threading by hand to ensure threads engage properly before using tools.

Torque Control: Use a torque wrench to tighten FIP threaded connections to the manufacturer’s recommended torque values. Over-tightening can distort threads or damage fittings, while under-tightening may lead to leaks.

Inspection: After installation, visually inspect the connection for any signs of leaks. Perform a pressure test if necessary to verify the integrity of the seal under operating conditions.

Maintenance Tips

Regular Inspections: Periodically inspect FIP threaded connections for signs of wear, corrosion, or damage. Replace fittings or components showing signs of deterioration to prevent leaks and system failures.

Sealant Renewal: Reapply thread sealant or tape as necessary during maintenance intervals or when reinstalling fittings. Ensure compatibility with hydraulic fluids and operating temperatures.

Surface Protection: Protect exposed FIP threads from environmental elements, such as moisture and chemicals, that can accelerate corrosion. Use protective coatings or covers where applicable.

System Flushing: Periodically flush hydraulic systems to remove contaminants that could accumulate around threaded connections and compromise seal integrity.

Documentation: Maintain records of installation dates, torque values, and maintenance activities related to FIP threaded connections. This documentation aids in troubleshooting and ensures compliance with maintenance schedules.

Troubleshooting Common Issues with FIP Threads

Leakage: If leaks occur at FIP threaded connections, check for insufficient thread engagement, damaged threads, or inadequate sealant application. Reassemble with proper alignment and sealant to rectify leaks.

Cross-threading: Misaligned threads can lead to cross-threading, causing damage and leaks. Inspect threads carefully before assembly and correct alignment issues to prevent cross-threading.

Corrosion: Monitor FIP threads for signs of corrosion, especially in corrosive environments. Use corrosion-resistant materials or coatings and perform regular inspections and maintenance to mitigate corrosion effects.

Thread Damage: Examine threads for signs of wear or damage, such as galling or stripping. Replace damaged fittings promptly to avoid compromising system integrity.

Temperature and Pressure Considerations: Ensure that FIP threads are rated for the temperature and pressure conditions within the hydraulic system. Inadequate thread ratings can lead to premature failure under operational stresses.

Adhering to these installation, maintenance, and troubleshooting practices enhances the reliability and longevity of FIP threaded connections in hydraulic systems. Proper care and attention to detail contribute to minimizing downtime, reducing maintenance costs, and optimizing system performance.

Conclusion

Looking ahead, FIP threads are expected to continue playing a pivotal role in hydraulic and plumbing systems globally. Their tapered design and adherence to robust standards make them a preferred choice for applications requiring high sealing integrity and reliability. As industries evolve and demand for efficient fluid handling solutions grows, FIP threads are poised to maintain their relevance and contribute to enhanced system performance and operational efficiency.

FAQ

FIP (Female Iron Pipe) threads are tapered threads on the inside of fittings or connectors. They are designed to create a tight seal when connected with a corresponding Male Iron Pipe (MIP) thread.

FIP threads are commonly found in female fittings such as couplings, elbows, and valves in plumbing, hydraulic systems, and industrial applications.

Yes, FIP threads typically require sealant on the male threads to ensure a proper seal and prevent leaks. This is especially important in pressurized systems.

FIP threads come in various sizes ranging from small diameters used in residential plumbing to larger sizes used in industrial applications. Common sizes include 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, and larger.

FIP threads can be used interchangeably with compatible male threads, such as MIP (Male Iron Pipe) threads, as long as sizes and thread pitches match. Proper sealant application is crucial for a secure connection.

FIP threads provide a reliable seal due to their tapered design, which increases sealing effectiveness as the threads are tightened. They are suitable for applications requiring leak prevention and secure connections.

Contact Topa

Have a question or suggestion? Fill out the form below to get in touch with one of our experts.