How to Install PTFE Fittings

Introduction

Proper installation is crucial to ensure that these fittings perform optimally and maintain their integrity over time. Incorrect installation can lead to leaks, system failures, and costly downtime, especially in industries where safety and precision are paramount. This guide will cover everything you need to know about PTFE fittings, from understanding their properties and selecting the right tools to preparing the components and executing the installation.

Understanding PTFE Fittings

What are PTFE Fittings?

PTFE (Polytetrafluoroethylene) fittings are specialized components designed to create secure and reliable connections within piping and tubing systems. PTFE is a synthetic fluoropolymer known for its exceptional non-reactivity, low friction, and high resistance to heat. This material’s properties make it ideal for use in harsh environments where traditional materials might fail.

Description of PTFE Material and Its Properties

PTFE is a white, waxy polymer that is chemically inert, meaning it does not react with most chemicals. This characteristic makes it particularly useful in environments where exposure to corrosive substances is common. PTFE has one of the lowest coefficients of friction of any solid material, which contributes to its excellent non-stick properties. Additionally, PTFE can withstand a wide range of temperatures, from as low as -200°C to as high as 260°C, making it suitable for use in extreme thermal conditions. The combination of chemical resistance, temperature stability, and low friction makes PTFE an indispensable material in many industrial applications.

Types of PTFE Fittings

There are several types of PTFE fittings, each designed for specific applications:

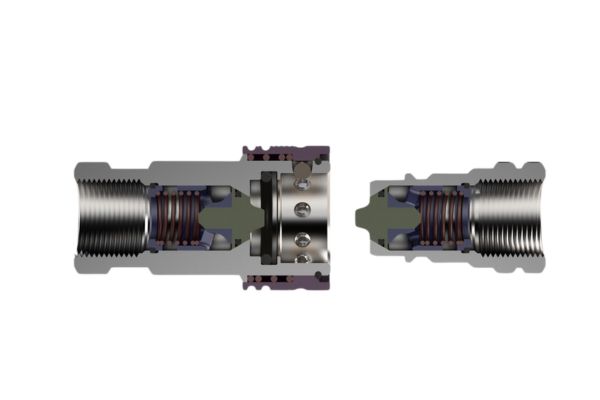

Compression Fittings: These fittings work by compressing a PTFE sleeve around the pipe or tube as the fitting is tightened, creating a secure, leak-proof connection. They are commonly used in applications where disassembly and reassembly of the system are required, such as in laboratory settings.

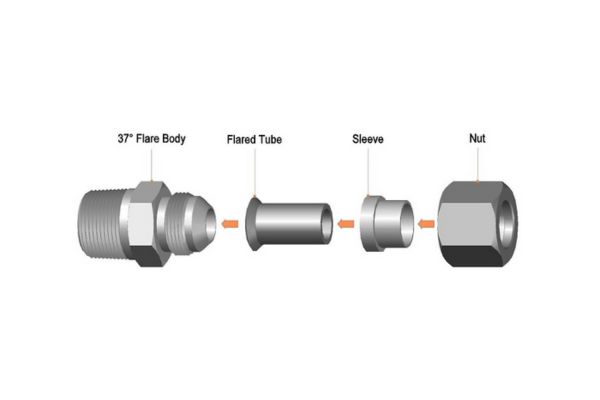

Flare Fittings: Flare fittings involve the flaring of the tubing end before connecting it to the fitting, creating a larger surface area for sealing. This type of fitting is often used in high-pressure applications where a robust connection is necessary.

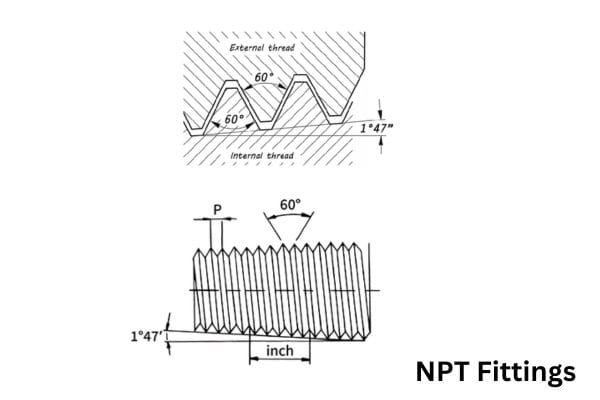

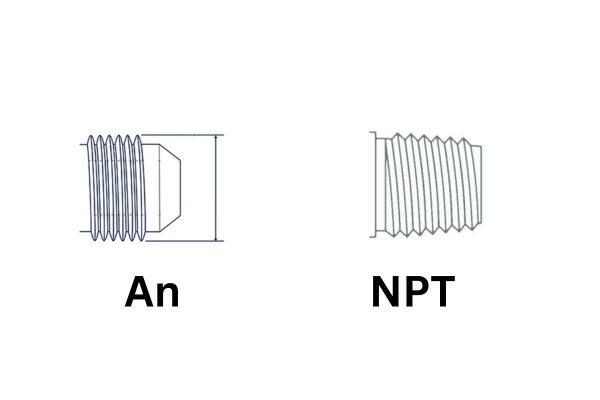

Threaded Fittings: These fittings are designed with threads that match corresponding pipes or tubing, ensuring a tight and secure fit. PTFE tape or thread sealant is typically used to enhance the seal and prevent leaks. Threaded fittings are commonly used in applications involving liquid and gas transfer.

Preparing for Installation

Safety Precautions

Safety Guidelines to Follow During Installation

When installing PTFE fittings, following strict safety guidelines is essential to ensure both the safety of the installer and the integrity of the system. The first step is to thoroughly understand the materials you are working with, including the potential hazards associated with PTFE and any chemicals or fluids the system may contain. It is crucial to work in a well-ventilated area, especially if working with substances that could emit harmful fumes or require special handling procedures. Always ensure that the system is depressurized and free of hazardous fluids before beginning installation to avoid accidents.

Another critical safety measure is to secure the workspace. This means stabilizing the pipes or tubes to prevent them from moving unexpectedly during installation, which could cause injury or damage to the components. Additionally, any tools or equipment should be used as per the manufacturer’s instructions to prevent misuse that could lead to accidents or compromised fittings.

Inspection of Components

How to Inspect Fittings, Hoses, and Other Components Before Installation

Before installing PTFE fittings, it is crucial to thoroughly inspect all components to ensure they are in good condition and free of defects. Start by examining the PTFE fittings themselves. Look for any cracks, deformities, or irregularities in the material that could compromise the seal or connection. The fittings should be smooth and consistent, with no visible signs of wear or damage.

Next, inspect the hoses or pipes that will be connected to the PTFE fittings. Check for any signs of wear, such as cracks, abrasions, or soft spots that could indicate material degradation. The ends of the hoses should be cleanly cut and free from fraying or uneven edges that could prevent a secure fit with the fittings.

Identifying and Addressing Defects or Damage

If any defects or damage are identified during the inspection, they must be addressed before proceeding with the installation. Damaged PTFE fittings should be replaced, as even minor imperfections can lead to leaks or system failures. For hoses, any section showing signs of wear should be cut off, and if the damage is extensive, the entire hose should be replaced.

In some cases, fittings may have accumulated residue from previous use or storage. If this is the case, clean the fittings thoroughly before installation. Additionally, ensure that any O-rings or seals that are part of the assembly are in good condition, with no cracks or flattening that could affect their performance.

Cleaning and Preparing Surfaces

Importance of Clean Surfaces for a Secure Fit

Clean surfaces are critical for ensuring a secure and leak-proof fit when installing PTFE fittings. Any contaminants, such as dirt, grease, or debris, can prevent the fitting from seating properly, leading to leaks or system inefficiencies. Furthermore, even microscopic particles can interfere with the integrity of the seal, especially in high-precision or high-pressure systems.

Cleaning Techniques for Both Fittings and Hoses

To prepare the surfaces of both the PTFE fittings and the hoses, start by wiping down all components with a clean, lint-free cloth to remove any visible debris. For more thorough cleaning, especially in cases where oils or other residues are present, use a solvent that is compatible with PTFE and the materials being connected. Isopropyl alcohol or acetone can be effective, but it is essential to ensure that the cleaning agent will not react with the PTFE or the hose material.

Step-by-Step Installation Guide

Preparing the Fittings

Proper Handling of PTFE Fittings

Before beginning the installation process, it is important to understand the correct way to handle PTFE fittings to avoid damaging them or compromising their performance. PTFE, while durable, can be sensitive to rough handling. Avoid dropping the fittings or subjecting them to unnecessary stress, such as bending or twisting, which could lead to micro-cracks or deformation. Handle the fittings with clean, dry hands, or use gloves to prevent contamination. Additionally, store the fittings in a clean, dry place before use to protect them from environmental factors like dust and moisture, which could affect their performance during installation.

Applying PTFE Tape or Thread Sealant (If Required)

In some cases, particularly with threaded PTFE fittings, applying PTFE tape or thread sealant is necessary to ensure a secure, leak-proof connection. PTFE tape, also known as plumber’s tape, is a thin film used to seal pipe threads. It helps to fill any gaps between the threads, preventing leaks. To apply PTFE tape:

Begin by cleaning the threads of the fitting with a lint-free cloth to remove any debris or oils.

Hold the fitting in one hand and the tape in the other. Start at the base of the threads and wrap the tape around the threads in the direction of the thread rotation (usually clockwise).

Overlap the tape slightly with each wrap, covering the threads completely. Typically, two to three layers of tape are sufficient.

Press the tape firmly into the threads and smooth it out to ensure it is well-adhered.

If a thread sealant is preferred or required by the manufacturer, apply it according to the manufacturer’s instructions, usually by applying a thin, even layer to the male threads before connecting the fitting.

Connecting PTFE Fittings to Tubes/Hoses

Detailed Steps for Connecting Compression Fittings

Compression fittings are widely used for PTFE connections due to their ability to create a tight, leak-proof seal without the need for welding or soldering. Here’s how to connect a PTFE compression fitting:

Prepare the Tube: Cut the PTFE tube to the desired length using a sharp tube cutter. Ensure the cut is clean and square, with no burrs or uneven edges. If necessary, use a deburring tool to smooth the edges.

Slide the Compression Nut: Place the compression nut onto the tube, followed by the compression ring (ferrule). Ensure that the components are positioned correctly, with the nut closest to the end of the tube.

Insert the Tube into the Fitting: Push the tube into the body of the compression fitting until it bottoms out. The tube should be fully seated in the fitting to ensure a proper seal.

Tighten the Compression Nut: Using a wrench, tighten the compression nut onto the fitting body. As the nut tightens, it compresses the ferrule onto the tube, creating a tight seal. Typically, tighten the nut by hand until it is snug, then use a wrench to turn it an additional quarter to half turn.

Step-by-Step Guide for Flare Fittings Installation

Flare fittings are commonly used in high-pressure applications where a strong, reliable connection is required. To install a PTFE flare fitting:

Prepare the Tube: As with compression fittings, start by cutting the PTFE tube to the desired length, ensuring a clean, square cut. Deburr the edges if necessary.

Flare the Tube End: Place the appropriate flaring tool on the tube and flare the end of the tube to the specified angle, typically 37 degrees for most PTFE applications. The flaring tool will expand the tube end, creating a larger surface area for sealing.

Slide the Flare Nut onto the Tube: Before flaring, don’t forget to slide the flare nut onto the tube. Once the tube is flared, the nut should be positioned so that it can be threaded onto the fitting body.

Insert the Tube into the Fitting: Place the flared end of the tube into the flare fitting. Ensure that the flared end sits flush against the fitting’s seat.

Tighten the Flare Nut: Thread the flare nut onto the fitting body by hand, then use a wrench to tighten it securely. The flare should compress against the fitting seat, creating a strong seal.

Instructions for Threaded PTFE Fittings

Threaded PTFE fittings are straightforward to install but require careful handling to ensure a leak-proof connection:

Prepare the Threads: Clean both the male and female threads with a cloth to remove any contaminants. If using PTFE tape or thread sealant, apply it as described in the earlier section.

Align the Fittings: Align the male and female threads to ensure they will engage properly. Misalignment can cause cross-threading, which can damage the fittings and lead to leaks.

Hand-Tighten: Begin threading the fittings together by hand, ensuring they engage smoothly and are not cross-threaded. Continue hand-tightening until snug.

Final Tightening: Use a wrench to tighten the fitting securely. Be careful not to overtighten, as this can strip the threads or crack the fitting. A general rule is to tighten the fitting by an additional one to two turns after it is hand-tight, depending on the size and type of fitting.

Tightening and Securing Connections

Proper Techniques for Tightening Fittings Without Causing Damage

When tightening PTFE fittings, it is crucial to apply the correct amount of torque to avoid damaging the fittings or compromising the seal. Over-tightening can lead to cracked fittings, stripped threads, or deformed sealing surfaces, while under-tightening may result in leaks.

Use the Right Tools: Always use the appropriate size and type of wrench for the fitting. Avoid using pliers or adjustable wrenches, as they can slip and cause damage to the fitting surfaces.

Apply Even Pressure: Tighten the fitting evenly by applying steady pressure to the wrench. If using a torque wrench, follow the manufacturer’s recommended torque specifications to ensure the fitting is tightened to the correct level.

Avoid Overtightening: When you feel resistance increasing as you tighten the fitting, be cautious not to exceed the recommended torque. If you are unsure, it is better to slightly under-tighten and then check for leaks, adjusting as needed.

Tools and Methods to Ensure a Leak-Proof Connection

To ensure a leak-proof connection, consider using the following tools and methods:

Torque Wrench: A torque wrench is essential for applying the correct amount of torque to threaded fittings. It ensures that fittings are neither under nor over-tightened, helping to maintain the integrity of the seal.

Thread Sealants: If the manufacturer recommends, use PTFE tape or a suitable thread sealant to fill any gaps in threaded connections and prevent leaks.

Pressure Testing: After installation, perform a pressure test to check for leaks. Gradually increase the system pressure while monitoring the connections for any signs of leakage.

Final Inspection and Testing

Steps to Check for Leaks and Ensure Proper Installation

Once all fittings are installed, it is important to conduct a thorough inspection to ensure that the installation was successful and that there are no leaks. Follow these steps:

Visual Inspection: Inspect all connections visually for signs of misalignment, improper tightening, or damage. Ensure that all fittings are properly seated and that there are no visible gaps or uneven connections.

Leak Detection: Apply a leak detection solution (or soapy water) to each connection. If bubbles form, this indicates a leak that needs to be addressed. Alternatively, use an electronic leak detector for more sensitive applications.

Tighten as Needed: If any leaks are detected, carefully tighten the affected fittings using a wrench, but avoid overtightening. Repeat the leak detection test to confirm that the leak has been eliminated.

Pressure Testing and Adjustments if Necessary

Pressure testing is a crucial step to ensure the integrity of the entire system after the installation of PTFE fittings:

Gradual Pressure Increase: Slowly pressurize the system to the working pressure, monitoring the pressure gauge and connections closely. Do not exceed the system’s rated pressure.

Monitor for Leaks: During the pressure test, watch for any drop in pressure, which could indicate a leak. If a drop is observed, shut down the system, depressurize, and inspect the fittings for leaks.

Make Necessary Adjustments: If any leaks are detected, depressurize the system and make the necessary adjustments, such as tightening fittings or replacing faulty components. Retest the system to ensure that the issue has been resolved.

Final Pressure Test: Once all adjustments are made, perform a final pressure test at the system’s operating pressure to confirm that all fittings are secure and leak-free.

Conclusion

Precision and care during installation are essential for maintaining the performance and safety of your system. Using quality materials, adhering to manufacturer guidelines, and taking the necessary precautions during each step of the installation will ensure that your PTFE fittings perform optimally and provide long-lasting service.

FAQ

PTFE tape is used to seal threaded connections, filling any gaps between the threads to prevent leaks.

Yes, PTFE fittings can often be reused, but they should be inspected for damage before reinstallation.

PTFE fittings should be tightened according to the manufacturer’s torque specifications to avoid leaks or damage.

If a leak is detected, depressurize the system, inspect the fitting, and retighten or replace it as needed.

PTFE fittings are resistant to most chemicals, but it’s important to check chemical compatibility charts for specific applications.

A torque wrench, pipe cutter, and thread sealant (or PTFE tape) are essential tools for installing PTFE fittings properly.