Choosing the Right Hydraulic Hoses for Diesel Fuel

Introduction

Selecting the right hydraulic hose for diesel fuel is crucial for ensuring system efficiency and safety. Incompatible hoses can lead to leaks, contamination, and system failures, posing significant risks to operations. This post aims to guide you through the essential aspects of choosing the right hydraulic hose for diesel fuel applications. We will cover the basics of hoses, their compatibility with diesel fuel, key factors to consider, industry standards, installation and maintenance tips, case studies, and insights into future trends.

Understanding Hydraulic Hose

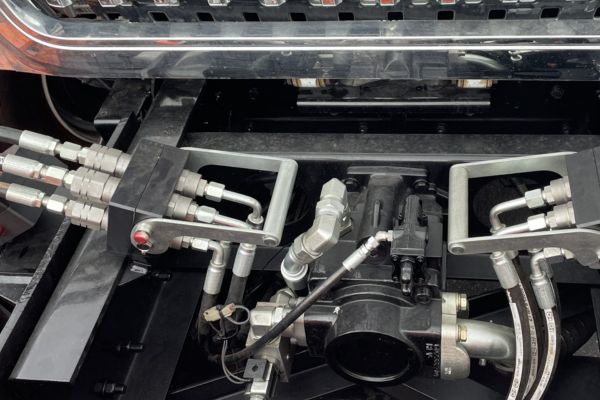

Hoses are essential components in hydraulic systems, acting as flexible conduits to transfer hydraulic fluid between various components like valves, actuators, pumps, and tools. Their flexibility and ability to withstand high pressure make them invaluable in many industrial applications, ranging from construction to manufacturing and beyond. To understand hoses better, it’s crucial to break down their structure and functionality.

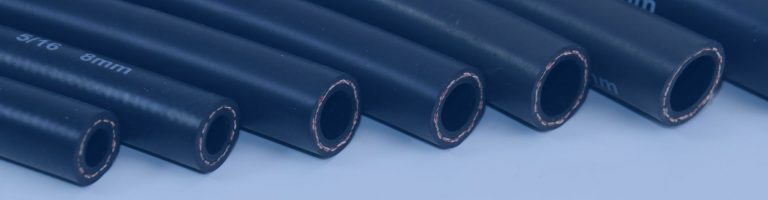

Components of Hoses

Inner Tube:

The inner tube of a hydraulic hose is the innermost layer that directly comes in contact with the hydraulic fluid. Its primary role is to carry the fluid efficiently without allowing it to leak or interact adversely with the hose material. The inner tube is typically made from materials that are chemically resistant to the types of fluids being conveyed.

Materials:

- Nitrile Rubber (NBR): Known for its excellent resistance to petroleum-based fluids, NBR is a common hose choice. It offers good tensile strength and flexibility, making it suitable for a wide range of temperatures.

- Fluorocarbon (FKM): FKM, also known as Viton, provides superior resistance to high temperatures and harsh chemicals. It’s used in applications where extreme environmental conditions are present.

Reinforcement:

The reinforcement layer is crucial for providing the necessary strength and flexibility to the hose. It enables the hose to withstand high pressures and prevents it from collapsing under vacuum conditions.

Construction:

- Braided Wire: This type of reinforcement uses woven wire braids that offer flexibility and strength. Braided hoses are typically used in medium-pressure applications.

- Spiral-Wound Wire: Consisting of multiple layers of wire spiraled around the inner tube, spiral-wound reinforcement is used in high-pressure applications. It provides greater strength and rigidity compared to braided wire.

Cover:

The cover is the outermost layer of the hose, designed to protect the inner tube and reinforcement from external damage. It shields the hose from environmental factors such as abrasion, chemicals, and weather conditions.

Materials:

- Synthetic Rubber: Often used for its durability and resistance to environmental damage, synthetic rubber covers can withstand harsh conditions and extend the hose’s lifespan.

- Thermoplastic: Offers excellent chemical resistance and is often used in hoses that are exposed to aggressive substances.

Compatibility with Diesel Fuel

Chemical compatibility is a critical factor when selecting hoses for diesel fuel applications. Using the wrong material can lead to severe consequences such as hose degradation, leaks, and even complete system failure. Ensuring that the hose material is compatible with diesel fuel is essential to maintain system integrity and operational efficiency.

What Is Diesel Fuel?

Diesel fuel is a type of refined petroleum product primarily used in compression ignition engines, common in industrial machinery, heavy-duty vehicles, agricultural equipment, and backup generators. Unlike gasoline, which ignites via spark, diesel combusts under pressure, requiring a fuel with high energy density and lubricating properties.

Chemically, diesel is composed of a complex mixture of hydrocarbons—mainly paraffins, naphthenes, and aromatic compounds—derived from the distillation of crude oil. Modern diesel formulations may also include additives for performance enhancement and bio-based components like fatty acid methyl esters (FAME), resulting in blends such as B5 (5% biodiesel) or B20 (20% biodiesel). While these bio-additives improve sustainability, they also increase the fluid’s tendency to oxidize, absorb water, and degrade hose materials not specifically rated for biodiesel compatibility.

Diesel fuel presents unique challenges for fluid transfer systems due to its chemical reactivity, temperature sensitivity, and potential for long-term permeation through incompatible hose materials. That’s why selecting the right hydraulic hose—resistant to swelling, hardening, or cracking in diesel environments—is essential to ensure reliable operation, minimize downtime, and extend service life.

Can Hydraulic Hose Be Used for Diesel Fuel?

Yes, hydraulic hoses can be used to transfer diesel fuel—but only if the hose is specifically rated for fuel service. Not all hydraulic hoses are compatible with diesel, especially modern diesel blends that may contain aggressive additives or bio-based components like biodiesel (FAME). Using the wrong hose can lead to premature failure, softening of the inner tube, fuel leakage, or even hose delamination.

✅ Key Considerations:

- Material Compatibility: The inner tube of the hose must be made from fuel-resistant compounds such as Nitrile (NBR), CPE, or FKM. Standard rubber compounds used in many hydraulic hoses may not resist the swelling effects of diesel fuel over time.

- Fuel Permeation Resistance: Diesel can slowly permeate through low-quality hose walls, leading to vapor loss, unpleasant odors, and environmental risks. Hoses rated for low-permeation or “fuel hose” applications should be selected.

- Pressure Rating: If diesel is being transferred in a pressurized system—such as fuel injection lines or return systems—ensure the hose meets the system’s PSI requirements, typically seen in SAE 100R6, SAE J30, or ISO 7840 rated hoses.

- Temperature Range: Diesel systems often operate between -20°C and +100°C. Make sure the hose can tolerate both cold starts and sustained high operating temperatures without hardening or cracking.

🚫 Common Mistakes to Avoid:

- Using a general-purpose hydraulic hose not designed for fuels

- Ignoring biodiesel compatibility in regions where B5–B20 blends are common

- Applying push-lock hoses in systems requiring crimped connections for pressure security

✅ Best Practices:

- Choose hoses clearly labeled for diesel, fuel oil, or biodiesel transfer

- Match the hose with fuel-resistant O-rings and compatible fittings

- Consult SAE J30 or ISO standards to ensure regulatory compliance

- When in doubt, request a chemical compatibility chart from your hose supplier

Common Materials Used in Diesel Fuel Hoses

Nitrile Rubber (NBR):

- Properties: NBR, also known as Buna-N, is a synthetic rubber renowned for its excellent resistance to petroleum-based fluids, including diesel fuel. It has good mechanical properties and provides a balance between flexibility and toughness.

- Applications: NBR is widely used in various applications, including fuel lines, gaskets, and seals, because of its affordability and effective performance in a range of temperatures. It can withstand temperature ranges from -40°C to +100°C, making it suitable for many operating conditions.

- Advantages: NBR offers good abrasion resistance and is relatively easy to produce, making it a cost-effective choice. Its ability to maintain flexibility at low temperatures is also beneficial for outdoor applications where temperature fluctuations are common.

Fluorocarbon (FKM):

- Properties: FKM, commonly known by the brand name Viton, is a high-performance material that provides superior chemical and temperature resistance. It can handle a wide range of aggressive chemicals and is particularly effective in environments where extreme temperatures are present.

- Applications: FKM is used in more demanding applications where hoses are exposed to harsh chemicals, high temperatures, and pressure fluctuations. It is common in industrial and automotive settings where reliability and longevity are critical.

- Advantages: FKM’s ability to withstand temperatures ranging from -20°C to +200°C and its resistance to fuels, oils, and other chemicals make it an ideal choice for heavy-duty applications. Although it is more expensive than NBR, its durability and performance justify the cost in high-risk environments.

Risks of Using Incompatible Hoses

Using hoses that are not chemically compatible with diesel fuel can lead to several issues:

- Swelling: When a hose material absorbs diesel fuel, it can swell. Swelling increases the hose’s internal volume and can lead to loosening of connections, resulting in leaks.

- Hardening: Some materials may harden upon exposure to diesel fuel, becoming less flexible and more prone to cracking under pressure or during movement.

- Cracking: Chemical reactions between the hose material and diesel fuel can cause the hose to crack, creating weak points that are susceptible to leaks and failures.

Case Examples:

- Swelling: A transport company used standard rubber hoses for their diesel fleet. Over time, the hoses absorbed the diesel, swelled, and started leaking at the connections, causing fuel spillage and increased maintenance costs.

- Hardening and Cracking: An agricultural business used hoses not rated for diesel fuel in their machinery. The hoses hardened and cracked under constant exposure to diesel, leading to frequent replacements and downtime during peak farming seasons.

Key Factors to Consider

When selecting a hydraulic hose for diesel fuel, several key factors must be considered to ensure optimal performance, safety, and longevity of the system. These factors include pressure rating, temperature rating, size and length, flexibility, and bend radius. Understanding and addressing these considerations can help prevent system failures and improve operational efficiency.

Pressure Rating

Ensuring the Hose’s Pressure Rating Matches System Requirements:

Hydraulic systems operate under varying pressures, depending on the application. It is crucial to choose a hose with a pressure rating that matches or exceeds the system’s requirements. Using a hose with an inadequate pressure rating can lead to leaks, ruptures, and catastrophic failures.

Understanding Burst Pressure vs. Working Pressure:

Burst Pressure: This is the maximum pressure a hose can withstand before it fails or bursts. Burst pressure is typically four times the maximum working pressure and is used as a safety benchmark.

Working Pressure: This is the maximum pressure at which the hose can operate safely continuously. It is essential to ensure that the working pressure of the hose is higher than the maximum pressure expected in the system. This ensures a safety margin and reduces the risk of hose failure.

Temperature Rating

Effects of Temperature on Hose Performance:

Hoses are exposed to various temperatures, both from the hydraulic fluid and the external environment. Extreme temperatures can affect the hose material, leading to hardening, softening, or cracking.

At high temperatures, hose materials may degrade more quickly, while at low temperatures, they may lose flexibility and become brittle.

Selecting Hoses for Extreme Temperature Conditions:

When selecting a hose, consider the temperature range of the application. For high-temperature applications, materials like Fluorocarbon (FKM) are ideal due to their superior heat resistance. For low-temperature applications, Nitrile Rubber (NBR) is often preferred for its flexibility in cold conditions.

It’s important to check the manufacturer’s specifications for the temperature limits of the hose and ensure that it can operate effectively within the expected temperature range.

Size and Length

Determining the Correct Hose Diameter and Length:

The diameter and length of the hose must be appropriate for the system design. The diameter affects the flow rate and pressure drop within the system. A hose that is too narrow can restrict fluid flow, causing inefficiency and increased pressure, while a hose that is too wide can result in a sluggish system response.

Length also plays a crucial role; an excessively long hose can cause pressure drops and may require more robust support to prevent sagging and damage.

Effects of Incorrect Sizing on System Performance:

Incorrectly sized hoses can lead to significant issues such as pressure drops, reduced efficiency, and potential damage to other components. Ensuring the hose is correctly sized according to the system’s requirements helps maintain optimal performance and reliability.

Flexibility and Bend Radius

Flexibility is Essential for Applications Requiring Frequent Movement:

In applications where hoses are subjected to frequent movement, flexibility is a critical factor. Flexible hoses can absorb movement and vibrations, reducing the risk of damage and extending the hose’s lifespan.

Stiff hoses may not bend or flex adequately, leading to kinks and cracks, especially in dynamic applications.

Adhering to Guidelines for Minimum Bend Radius:

The bend radius is the minimum radius a hose can be bent without kinking or damaging it. Adhering to the manufacturer’s guidelines for minimum bend radius is essential to prevent hose damage.

Bending a hose beyond its recommended radius can cause the inner tube to collapse, the reinforcement to fatigue, and the cover to crack. This can lead to leaks and hose failure.

Installation and Maintenance Tips

Proper installation and maintenance of hoses are critical to extending their lifespan and ensuring the safe and efficient operation of hydraulic systems. Adhering to best practices during installation and conducting regular maintenance can prevent common issues such as leaks, ruptures, and system failures.

Best Practices for Hose Installation

Avoid Over-Bending:

One of the most common mistakes in hose installation is over-bending. Hoses have a minimum bend radius, which is the smallest radius a hose can bend without kinking. Over-bending can lead to kinks and fatigue in the hose material, significantly reducing its lifespan.

To avoid over-bending, use proper routing techniques and supports such as clamps and brackets. This ensures the hose follows a natural bend without exceeding its minimum bend radius.

Proper Routing:

Improper routing can cause hoses to rub against sharp edges or surfaces, leading to abrasion and premature wear. Ensure hoses are routed away from high-traffic areas and moving parts.

Avoid twisting the hose during installation. Twisting can cause internal damage to the reinforcement layers, leading to reduced pressure capacity and potential failures.

Use elbows and adapters where necessary to achieve the correct routing without bending the hose excessively.

Securing Connections:

Ensure all hose connections are secure and properly tightened. Loose connections can lead to leaks and pressure drops. Use the correct type of fittings and connectors recommended by the hose manufacturer.

When securing hoses, avoid over-tightening, which can damage the fittings and the hose. Follow the manufacturer’s torque specifications to achieve the proper tightness.

Regular Maintenance

Inspect for Signs of Wear:

Regularly inspect hoses for signs of wear and damage. Common signs include abrasion, cuts, cracks, and blisters on the hose cover. Pay special attention to areas where the hose bends or is clamped, as these are more prone to wear.

Check the hose for any signs of deformation, such as swelling or flattening, which can indicate internal damage or chemical incompatibility.

Monitor for Leaks:

Leaks are a clear indication that a hose or connection may be failing. Regularly inspect all hose connections and the hose itself for signs of leaks. If a leak is detected, identify the source and address it immediately.

Small leaks can quickly escalate into major failures if not addressed promptly. Use appropriate leak detection methods such as visual inspection and, if necessary, pressure testing.

Ensure Connections are Secure:

Regularly check all hose connections to ensure they remain secure. Vibrations and thermal cycling can cause connections to loosen over time.

Re-tighten any loose connections according to the manufacturer’s specifications to prevent leaks and maintain system pressure.

Replace Damaged Hoses:

Replace hoses showing signs of damage immediately. Delaying replacement can lead to catastrophic failures, resulting in system downtime and potential safety hazards.

Keep a record of hose installation dates and their maintenance history. This helps in predicting hose life expectancy and planning proactive replacements before a failure occurs.

Conclusion

Selecting the right hydraulic hose for diesel fuel involves understanding compatibility, pressure and temperature ratings, industry standards, and proper installation and maintenance practices. By considering these factors and consulting with experts, you can ensure the efficiency and safety of your hydraulic systems. Investing time in choosing the right hose and supplier will pay off in reliable performance and reduced downtime. If you need hoses, just contact Topa!

FAQ

A hydraulic hose consists of three main components: the inner tube, reinforcement layer, and outer cover. The inner tube carries the hydraulic fluid, the reinforcement provides strength and flexibility, and the outer cover protects against environmental damage.

Chemical compatibility is crucial because diesel fuel can cause certain hose materials to degrade, leading to swelling, hardening, cracking, and ultimately, hose failure. Using a chemically compatible hose material ensures longevity and reliability.

To determine the correct pressure rating, you should consider the maximum operating pressure of your hydraulic system. Ensure the hose’s working pressure rating exceeds this maximum pressure to avoid system failures. Burst pressure, which is typically four times the working pressure, is also an important consideration for safety.

Signs that a hydraulic hose needs replacement include visible wear such as abrasion, cuts, cracks, blisters, deformation like swelling or flattening, and any leaks at the hose or connections. Regular inspections can help identify these issues early.

Proper installation involves avoiding over-bending, ensuring correct routing away from sharp edges and moving parts, securing connections properly without over-tightening, and using supports like clamps and brackets to prevent kinking and abrasion.

Regular maintenance practices include inspecting hoses for wear and damage, monitoring for leaks, ensuring connections are secure, replacing damaged hoses promptly, and using hose guards or sleeves for added protection. Establishing a preventive maintenance schedule can also help in early identification of potential issues.