Selecting the Camlock Couplings: Key Factors to Consider

Table of Contents

Introduction

Choosing the right Camlock coupling is not just a matter of convenience; it directly impacts the performance and longevity of the entire system. Selecting an inappropriate coupling can lead to leaks, operational downtime, and even safety hazards, underscoring the importance of making informed choices.

Understanding Camlock Fittings

Camlock fittings, also known as cam and groove couplings, are a type of quick-connect fitting used to connect or disconnect hoses and pipes efficiently. They are commonly employed in various industries for their ease of use and reliability. The design of a Camlock coupling consists of a male adapter (the “cam”) that fits into a female coupler (the “groove”). The cam arms on the coupler are then folded down, securing the connection tightly without the need for additional tools.

These couplings are particularly valued in industries where time and efficiency are critical. In agriculture, for instance, Camlock fittings are used for connecting irrigation systems, while in manufacturing, they facilitate the quick transfer of liquids or powders between tanks and equipment. In the oil and gas industry, they are essential for connecting hoses that transport fuels, chemicals, and other hazardous materials, ensuring secure and leak-proof connections.

Types of Camlock Fittings

Camlock fittings come in various types, each designed for specific applications:

Type A: Male adapter with a female thread. This type is typically used where the hose or pipe has a male thread, providing a secure connection.

Type B: Female coupler with a male thread. Type B is commonly used to connect a hose to a threaded pipe.

Type C: Female coupler with a hose barb. This type is ideal for connecting hoses directly to a pipe or another hose.

Type D: Female coupler with a female thread. Type D is used when both the hose and the pipe have male threads.

Type E: Male adapter with a hose barb. Type E allows direct connection of a hose to a pipe or another hose.

Type F: Male adapter with a male thread. This type is used when the hose or pipe has a female thread, providing a secure and leak-proof connection.

Dust Cap: A protective cap used to cover the open end of a male adapter when it is not in use, preventing contamination and damage.

Each type of Camlock coupling serves a specific purpose, allowing for flexibility and customization based on the requirements of the application. For example, Type C and Type E are often used together to connect two hoses, while Type B and Type D are used to connect hoses to pipes or tanks.

Benefits of Using Camlock Couplers

Camlock fittings offer several advantages that make them a preferred choice in many industrial applications:

Ease of Use and Quick Connection: One of the primary benefits of Camlock fittings is their simplicity. The cam and groove mechanism allows for quick and easy connection and disconnection of hoses without the need for tools. This feature is particularly valuable in situations where time is of the essence, such as in emergency spill containment or rapid equipment changes.

Versatility Across Multiple Applications: Camlock fittings are versatile and can be used in a wide range of industries, including agriculture, chemical processing, food and beverage, and oil and gas. They are compatible with various materials, such as liquids, gases, and powders, making them suitable for different types of media.

Durability and Long-Service Life: Made from materials such as stainless steel, brass, aluminum, and polypropylene, Camlock fittings are designed to withstand harsh conditions and prolonged use. Their robust construction ensures a long service life, reducing the need for frequent replacements and minimizing downtime.

Material Considerations

Selecting the right material for Camlock fittings is crucial to ensuring their performance and longevity in various industrial applications. Different materials offer distinct advantages and limitations, making them suitable for specific uses.

Aluminum

Pros:

Lightweight: Aluminum Camlock fittings are easy to handle and install due to their low weight, making them ideal for applications where frequent connection and disconnection are required.

Cost-Effective: Aluminum is relatively inexpensive compared to other metals, providing a budget-friendly option without compromising on durability.

Corrosion Resistance: While not as resistant as stainless steel, aluminum offers a decent level of corrosion resistance, particularly in non-corrosive environments.

Cons:

Limited Chemical Resistance: Aluminum is not suitable for use with highly corrosive chemicals or acidic substances, as it can corrode over time.

Lower Strength: Compared to stainless steel, aluminum has a lower tensile strength, making it less suitable for high-pressure applications.

Best Use Cases:

Aluminum Camlock fittings are best used in applications where weight is a concern, such as in agricultural settings for irrigation or manufacturing for lightweight fluid transfer systems.

Brass

Pros:

Excellent Corrosion Resistance: Brass offers superior resistance to corrosion, particularly from water, making it ideal for marine and plumbing applications.

Good Ductility: Brass is easily machined and formed, allowing for precise and reliable connections.

Durable: Brass has a good balance of strength and flexibility, ensuring a long service life in various applications.

Cons:

Higher Cost: Brass is more expensive than aluminum and some plastics, which may be a consideration for cost-sensitive projects.

Weight: Brass is heavier than aluminum, which can make it less desirable in applications where weight is a critical factor.

Best Use Cases:

Brass Camlock fittings are well-suited for water systems, marine applications, and environments where corrosion resistance is paramount, such as in plumbing and HVAC systems.

Stainless Steel

Pros:

Superior Strength: Stainless steel offers the highest tensile strength among the common materials used for Camlock fittings, making it ideal for high-pressure and heavy-duty applications.

Excellent Corrosion Resistance: Stainless steel is highly resistant to corrosion, even in harsh environments, such as those involving chemicals, saltwater, or extreme temperatures.

Longevity: Stainless steel couplings are extremely durable, often outlasting other materials in demanding applications.

Cons:

Higher Cost: Stainless steel is typically the most expensive material option, which can be a limiting factor for some projects.

Weight: Stainless steel is heavier than aluminum and plastics, which may be a drawback in applications where weight is a concern.

Best Use Cases:

Stainless steel Camlock fittings are ideal for chemical processing, oil and gas, food and beverage, and any application where strength, corrosion resistance, and durability are critical.

Polypropylene and Nylon (Plastic Couplings)

When to Use:

Chemical Compatibility: Polypropylene and nylon are highly resistant to a wide range of chemicals, making them suitable for transferring corrosive substances.

Cost-Effective: These plastic materials are generally less expensive than metals, offering a budget-friendly option for less demanding applications.

Lightweight: Plastic couplings are extremely lightweight, making them easy to handle and install, particularly in portable or temporary systems.

Best Use Cases:

Plastic Camlock fittings are ideal for low-pressure applications, chemical transfer, and situations where weight and cost are primary concerns, such as in laboratory settings or temporary fluid systems.

Choosing the Right Material for Your Application

When selecting the material for Camlock fittings, making an informed decision is crucial to ensure that the couplings perform optimally and have a long service life. The right material choice can prevent costly failures, minimize maintenance needs, and ensure the safety and efficiency of the system. Below are key factors to consider when determining the best material for your Camlock fittings:

Chemical Compatibility

One of the most critical factors in material selection is chemical compatibility. The material of the Camlock coupling must be capable of withstanding the chemical properties of the fluid or gas being transferred.

Material Compatibility: The wrong material can lead to chemical reactions that degrade the coupling, potentially causing leaks, contamination, or even catastrophic failure. For instance, stainless steel is highly resistant to a wide range of aggressive chemicals, making it ideal for industries such as chemical processing, oil and gas, and pharmaceuticals, where harsh chemicals are often used. It can handle both acidic and alkaline substances without corroding, ensuring the integrity of the connection over time.

On the other hand, polypropylene and nylon are excellent choices for less aggressive but still corrosive substances. These materials are often used in the transfer of certain acids and bases, where metal couplings might corrode. Polypropylene, in particular, is resistant to a variety of chemicals, including most organic acids, alkalis, and alcohols, making it suitable for chemical transfer applications in laboratories or industrial settings where non-metallic couplings are preferred.

Brass and Aluminum: While brass and aluminum have good general resistance to corrosion, they are less suited to highly corrosive environments. Brass is typically used in water systems and certain non-corrosive chemical applications, while aluminum is often chosen for its lightweight and cost-effectiveness in non-corrosive environments.

Temperature Resistance

Temperature plays a significant role in the performance of Camlock fittings. The material must withstand the operating temperature range of the system without losing structural integrity or compromising the connection.

Operating Temperature: Different materials respond differently to temperature variations. Stainless steel is known for its high-temperature resistance, making it suitable for applications where the system may be exposed to extreme heat. It can maintain its strength and durability even at temperatures exceeding 500°C, making it a top choice for high-temperature environments such as steam applications or in industries where processes involve heating and cooling cycles.

Brass also offers good resistance to heat, though not as high as stainless steel. It is commonly used in applications with moderate temperatures, such as in heating systems or where the temperature does not exceed its limits.

Plastic materials like polypropylene and nylon, while excellent in chemical resistance, have lower temperature tolerance. Polypropylene, for instance, is suitable for applications where the operating temperature does not exceed 80-100°C. Exposing plastic couplings to higher temperatures can lead to warping, softening, or even failure, making them unsuitable for high-temperature applications. However, they remain a practical choice for low-temperature environments or when the fluid being transferred is at ambient temperature.

Corrosion Resistance

The environment in which the Camlock coupling is used greatly influences material selection, particularly concerning corrosion resistance. Corrosion can weaken the coupling, leading to leaks, system failures, and safety hazards.

Environmental Factors: Stainless steel is renowned for its excellent corrosion resistance, even in highly corrosive environments such as those found in chemical processing plants, offshore oil rigs, and marine applications. It resists corrosion from saltwater, chemicals, and other harsh substances, making it a reliable choice for long-term use in challenging environments.

Brass also offers good corrosion resistance, particularly against water and many other non-aggressive fluids, making it a popular choice in plumbing, HVAC systems, and marine applications where exposure to water and moisture is a concern. However, brass can be prone to dezincification, a form of corrosion where zinc is leached from the alloy, which may limit its use in certain environments.

Aluminum provides a balance between corrosion resistance and cost. It is commonly used in less corrosive environments where its natural oxide layer provides sufficient protection. However, in highly acidic or alkaline environments, aluminum may corrode more quickly than other materials.

Polypropylene and Nylon couplings are resistant to a variety of chemicals, making them suitable for environments where metal couplings would corrode. They are ideal for applications where exposure to corrosive chemicals is a concern, provided the temperature conditions are within their operating range.

Industry-Specific Recommendations

Selecting the right material for your Camlock fittings often depends on the specific industry and application:

Agriculture: In agricultural applications, where irrigation systems and equipment need to be both lightweight and cost-effective, aluminum couplings are often the material of choice. They offer the necessary durability for outdoor use while being easy to handle and install.

Chemical Processing: For handling corrosive chemicals safely, stainless steel or polypropylene couplings are recommended. Stainless steel is the preferred material for its unmatched strength and corrosion resistance, while polypropylene is suitable for less aggressive chemicals, offering a more economical solution.

Food and Beverage: Stainless steel is ideal for food and beverage applications due to its hygienic properties, resistance to corrosion, and non-reactivity with food products. It ensures that the couplings do not contaminate the product, maintaining the integrity and safety of the food or beverage being processed.

Marine Applications: In marine environments, where exposure to saltwater is a constant concern, brass and stainless steel are the materials of choice. Brass is commonly used in fittings exposed to water due to its good corrosion resistance, while stainless steel is preferred for critical applications requiring the highest level of corrosion resistance.

Size and Compatibility

Selecting the correct size of Camlock fittings is essential to ensuring the efficiency, safety, and longevity of your fluid transfer systems. The size of the coupling must match the dimensions of the hoses or pipes it will connect to, ensuring a secure and leak-free connection. Additionally, compatibility with existing systems is crucial to avoid operational disruptions and potential hazards.

Determining the Right Size:

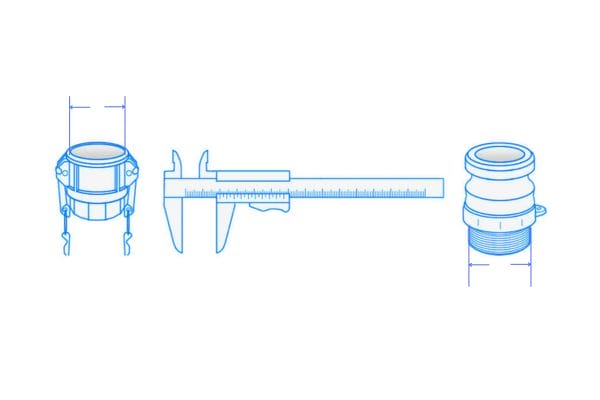

One of the first steps in selecting a Camlock coupling is determining the correct size. This involves understanding both the internal diameter (ID) and external diameter (OD) of the hoses or pipes in your system and ensuring the coupling size matches these dimensions.

Importance of Matching Coupling Size to Hose or Pipe Size

The size of the Camlock coupling must correspond to the size of the hose or pipe it will be attached to. If the coupling is too small or too large, it can lead to a weak connection, resulting in leaks, pressure loss, or even disconnection during operation. For instance, a 2-inch Camlock coupling is designed to connect to a 2-inch hose or pipe, ensuring a tight and secure fit. Using a mismatched size can compromise the integrity of the entire system.

Correct sizing is particularly important in high-pressure applications where even a slight mismatch can lead to catastrophic failures. The right size ensures that the coupling can handle the system’s operating pressure without risk of failure.

Understanding Camlock Coupling Size Designations

Camlock fittings are available in a range of sizes, typically measured in inches. Common sizes include 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 3″, and 4″. These sizes refer to the internal diameter of the hose or pipe the coupling is designed to connect with.

In addition to the diameter, it’s also important to consider the coupling’s body size and thread size if applicable. For example, a Type B Camlock coupling with a 2-inch body size may have a 2-inch female thread on one side to connect to a pipe, while the other side connects to a 2-inch hose. Understanding these designations helps ensure that you choose the correct coupling for your specific application.

Compatibility with Existing Systems

Ensuring that the selected Camlock coupling is compatible with your existing system is crucial for maintaining operational efficiency and preventing issues down the line.

Ensuring a Proper Fit with Existing Hoses, Pipes, or Fittings:

Compatibility goes beyond just matching sizes. The coupling must also fit seamlessly with the existing hoses, pipes, or fittings in your system. This includes considering factors like the type of thread (e.g., NPT, BSP) and whether the materials are compatible. For example, if your system uses hoses with NPT threads, you’ll need a Camlock coupling with matching NPT threads to ensure a secure connection.

It’s also important to consider the coupling’s configuration. For instance, if your system uses a hose with a male end, you’ll need a Camlock coupling with a female end to ensure compatibility. Similarly, if the system requires quick disconnection capabilities, selecting the appropriate Camlock type, such as Type C or Type E, is essential for maintaining system integrity and ease of use.

Avoiding Leaks and Ensuring a Secure Connection

One of the most common issues with incompatible Camlock fittings is leaks. Leaks can occur if the coupling is not properly sized or if the materials of the coupling and the connected hose or pipe are incompatible. For example, using a stainless steel coupling with a polypropylene hose might result in a poor seal, leading to potential leaks.

To avoid leaks, it’s important to ensure that the coupling’s gasket material is compatible with the fluids being transferred. Gaskets are typically made of materials like Buna-N, Viton, or EPDM, each offering different levels of resistance to chemicals and temperatures. Choosing the correct gasket material is critical to achieving a tight seal and preventing leaks.

Additionally, ensuring a secure connection involves regularly inspecting the couplings for wear and tear. Over time, the cam arms, gasket, or body of the coupling may wear down, leading to a loose connection. Routine maintenance and timely replacement of worn parts are key to preventing leaks and ensuring the coupling remains secure during operation.

Interchangeability with Different Brands

Camlock fittings are generally designed to be interchangeable between different brands, as long as the sizes and types match. However, there can be slight variations in design and manufacturing tolerances, so it’s always advisable to test compatibility, especially in critical applications. Ensuring that your Camlock coupling is interchangeable with existing equipment from different manufacturers can provide flexibility and reduce downtime if a replacement is needed.

Pressure and Temperature Ratings

When selecting Camlock fittings, understanding the pressure and temperature ratings is essential to ensuring the safety, efficiency, and reliability of your fluid transfer system. These ratings determine the conditions under which the couplings can perform without risk of failure.

Understanding Pressure Ratings

Pressure ratings refer to the maximum pressure that a Camlock coupling can safely handle without compromising its integrity. This rating is usually measured in pounds per square inch (PSI) or bars and is a crucial factor to consider, especially in high-pressure applications.

Explanation of Pressure Ratings in Relation to Camlock Fittings

Camlock fittings are designed to withstand specific pressure levels, which vary depending on the material and size of the coupling. For instance, stainless steel couplings typically have higher pressure ratings compared to aluminum or polypropylene couplings due to their superior strength and durability.

The pressure rating also varies with the size of the coupling; larger couplings generally have lower pressure ratings due to the increased surface area subjected to force. For example, a 1-inch stainless steel coupling might have a pressure rating of 250 PSI, while a 4-inch coupling of the same material might be rated at 150 PSI.

How to Choose Couplings That Can Handle Specific Pressure Requirements:

To choose the right Camlock coupling for your application, start by determining the maximum operating pressure of your system. This includes considering both the working pressure and any potential pressure spikes that might occur during operation.

Ensure that the selected coupling’s pressure rating exceeds the maximum operating pressure of your system to provide a margin of safety. For example, if your system operates at 200 PSI, it’s advisable to choose a coupling rated for at least 250 PSI to account for any unforeseen pressure fluctuations.

Conclusion

In making your final decision, it is essential to weigh the pros and cons of each material based on your operational environment, consider the compatibility with your existing system components, and ensure that the coupling can withstand the expected pressure and temperature conditions. As a final recommendation, I encourage you to take the time to assess your specific needs thoroughly. Don’t hesitate to consult with industry experts or suppliers who can offer valuable insights tailored to your particular application.

FAQ

Camlock fittings are used to quickly and securely connect hoses and pipes in various industries, such as agriculture, chemical processing, and manufacturing.

Select the size that matches the internal diameter of your hose or pipe, ensuring compatibility with your existing system.

Common materials include aluminum, brass, stainless steel, and polypropylene, each suited for different applications and environments.

Yes, but you must choose a coupling with a pressure rating that exceeds your system’s maximum operating pressure.

Stainless steel and brass couplings are ideal for high-temperature applications, while plastic couplings are better for lower temperatures.

Generally, yes. Camlock fittings from different manufacturers are designed to be compatible, but it’s always best to verify compatibility before use.