How to Measure Hydraulic Hose Fittings

Table of Contents

Introduction

Accurate measurement of hydraulic hose fittings is critical to maintaining system integrity and preventing costly failures. Ensuring the correct size and type of fittings prevents leaks, enhances compatibility, and maintains system efficiency. Hydraulic fittings come in various types, including NPTF, SAE, and DIN, each serving specific applications like fluid power, automotive, and industrial machinery. Proper measurement involves using tools like calipers and thread pitch gauges to accurately determine dimensions, which helps in selecting the right fittings, thus avoiding mismatches that could lead to operational inefficiencies and safety hazards.

Step-by-Step Guide to Measuring Hydraulic Hose Fittings

Preparation

Clean the Fitting and Hose: Before starting, ensure that both the fitting and the hose are clean. Dirt and debris can interfere with accurate measurements and may damage the measuring tools.

Gather Necessary Tools: Assemble all required tools, including measuring tape, calipers (both ID and OD), a thread pitch gauge, and a protractor. Having these tools readily available will streamline the measurement process.

Safety Precautions: Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses. Ensure that the hydraulic system is depressurized and disconnected to avoid accidental injury.

Measuring the Thread Size

Accurately measuring the thread size of hydraulic hose fittings is essential for ensuring proper fit and function within hydraulic systems. This process involves several key steps and considerations:

Using the Thread Pitch Gauge

Placement of the Gauge: Begin by placing the teeth of the thread pitch gauge onto the threads of the fitting. It’s crucial to achieve a tight fit, meaning there should be no gaps between the gauge and the threads. This ensures that the pitch is measured correctly.

Determining Thread Pitch: The thread pitch gauge helps to measure the distance between threads, known as the thread pitch. This measurement is vital for identifying the correct fitting size and type. The pitch is usually measured in threads per inch (TPI) for imperial threads or in millimeters for metric threads.

Ensuring Accuracy: Ensure the gauge is clean and free from debris before use, as dirt can cause inaccurate readings. Additionally, if the fitting is worn or damaged, it might be harder to get an accurate pitch measurement. In such cases, verify with multiple gauge sizes to find the best match.

Handling Worn or Old Fittings

Challenges with Worn Fittings: Over time, fittings can become worn or damaged, which may affect the accuracy of your measurements. Wear and tear can alter the thread pitch slightly, leading to potential mismatches.

Use New Fittings for Best Results: For the most accurate measurements, it’s advisable to use new fittings whenever possible. New fittings will provide the most precise measurements, free from any distortions caused by wear.

Consult a Professional: If you encounter discrepancies or have doubts about the measurements, consulting with a professional can be very helpful. Experienced technicians can provide insights and confirm the correct size and type of fitting needed.

Tools and Techniques: In some cases, specialized tools and techniques, such as thread identification kits, can be employed to handle worn or old fittings. These kits often come with various gauges and charts that can help in accurately identifying the thread pitch despite wear.

Determining the Outside Diameter (OD)

Accurately determining the outside diameter (OD) of hydraulic hose fittings is crucial for ensuring a proper fit and function within hydraulic systems. This process involves using calipers and following precise measurement techniques to avoid errors and ensure reliability.

Calipers Usage Technique

Zero Out the Calipers: Before beginning the measurement process, it is essential to zero out the calipers. This ensures that the measurements start from a true zero point, avoiding any initial discrepancies. Digital calipers usually have a reset button for this purpose, while manual calipers can be adjusted manually.

Positioning the Fitting: Place the fitting between the jaws of the calipers. Ensure that the fitting is positioned correctly, with the calipers perpendicular to the axis of the fitting. This positioning is crucial to obtaining an accurate measurement, as any tilt or misalignment can result in incorrect readings.

Closing the Jaws: Gently close the jaws of the calipers around the fitting until they hold it tightly. Avoid applying excessive force, as this can deform the fitting or the calipers, leading to inaccurate measurements. The goal is to achieve a snug fit without any gaps.

Reading the Measurement: Once the calipers are correctly positioned and closed, read the measurement from the caliper scale. Digital calipers will display the measurement on a screen, while manual calipers require you to read from a vernier scale.

Multiple Measurement Approach for Accuracy

Measure at Multiple Points: To ensure accuracy and consistency, it is advisable to measure the outside diameter at several points around the fitting. This helps to identify any irregularities or variations in the fitting’s diameter. Typically, at least three measurements at different points around the circumference should be taken.

Ensuring Consistency: When taking multiple measurements, ensure that each measurement is performed in the same manner, with the calipers perpendicular to the fitting and zeroed out before each measurement. Consistency in the measurement technique helps to minimize errors.

Averaging the Measurements: Once multiple measurements have been taken, calculate the average of these measurements. Averaging helps to account for any slight variances and provides a more accurate representation of the fitting’s true outside diameter. For example, if the measurements taken are 20.2 mm, 20.3 mm, and 20.1 mm, the average would be (20.2 + 20.3 + 20.1) / 3 = 20.2 mm.

Recording the Results: Document the measurements and the calculated average for reference. Keeping a record of these measurements can be useful for future reference and for verifying the fitting’s specifications.

Calculating the Inside Diameter (ID)

Accurately calculating the inside diameter (ID) of hydraulic hose fittings is crucial for ensuring proper fit and functionality within hydraulic systems. This process involves using calipers to measure female threads and taking multiple measurements to ensure precision.

Using Calipers for Female Threads

Inserting the Calipers: To measure the internal diameter of female threads, insert the jaws of the calipers inside the fitting. Ensure that the jaws are fully inserted and positioned correctly to capture the internal dimensions accurately.

Positioning for Precision: Make sure the calipers are positioned perpendicularly to the fitting walls to get precise readings. The jaws should be evenly aligned within the fitting without any tilt or misalignment, which could lead to inaccurate measurements.

Reading the Measurement: Once the calipers are properly positioned, gently close the jaws until they touch the internal walls of the fitting. Read the measurement displayed on the calipers. For digital calipers, the reading will be shown on the screen, while for manual calipers, you will need to read the measurement from the vernier scale.

Ensuring Precise Readings

Taking Multiple Measurements: To ensure accuracy, take multiple measurements at different points within the fitting. This step is particularly crucial for fittings that have experienced wear and tear, as the internal diameter may not be uniform. Measure at least three different points along the circumference of the fitting.

Consistency in Technique: Maintain consistency in your measurement technique. Each time you measure, ensure the calipers are zeroed out and positioned perpendicularly within the fitting. Consistency helps minimize measurement errors.

Calculating the Average: After taking multiple measurements, calculate the average of these readings to obtain the most accurate internal diameter. For instance, if the measurements are 15.1 mm, 15.2 mm, and 15.0 mm, the average would be (15.1 + 15.2 + 15.0) / 3 = 15.1 mm.

Evaluating the Thread Pitch

Accurately evaluating the thread pitch of hydraulic hose fittings is essential for ensuring compatibility and proper function within hydraulic systems. This process involves using a thread pitch gauge or alternative methods to measure the distance between threads.

Thread Pitch Gauge Application

Placement of the Gauge: To determine the thread pitch, start by placing the teeth of the thread pitch gauge onto the fitting threads. Ensure the gauge fits snugly without gaps between the gauge teeth and the threads. This snug fit is crucial for obtaining an accurate measurement.

Measuring the Pitch: The thread pitch gauge helps measure the distance between the threads, known as the pitch. The pitch is typically measured in threads per inch (TPI) for imperial measurements or in millimeters for metric measurements. It indicates how many threads are in a given unit length.

Matching with Standardized Charts: Once the pitch is measured, compare it with standard thread identification charts from fitting manufacturers. These charts will help you identify the specific type and size of the thread, such as NPT, BSP, or JIC threads. Accurate identification is vital for selecting compatible fittings.

Alternative Methods Without a Pitch Gauge

Using Calipers for Manual Measurement: If a thread pitch gauge is unavailable, you can manually measure the thread pitch using calipers. This method involves counting the number of threads within a specific length.

Counting Threads per Inch: For imperial measurements, count the number of threads within a one-inch span using calipers. Align the calipers with the start of the thread and count the number of full threads within one inch. This count gives you the threads per inch (TPI).

Converting to Metric: If you need to convert the measurement to metric, use the conversion factor where 1 inch equals 25.4 millimeters. Measure the distance for a known number of threads and then divide by the number of threads to find the pitch in millimeters.

Estimating the Fitting Angle

Accurately estimating the fitting angle is crucial for selecting the appropriate hydraulic fittings, ensuring system compatibility and optimal performance. This process involves using a protractor and understanding the significance of common fitting angles.

Protractor Usage

Using a Protractor: To measure the angle of the fitting, place the protractor along the axis of the fitting. Align one side of the fitting with the zero line of the protractor. Make sure the fitting is stable and correctly positioned for an accurate reading.

Measuring the Angle: Read the angle from the protractor where the other side of the fitting aligns with the degree markings on the protractor. The most common fitting angles are 45°, 90°, and occasionally 22.5°. Ensure that you take the measurement carefully to avoid any parallax errors, which can occur if the protractor is not viewed straight on.

Common Angles and Their Significance

90° Fittings:

Significance: A 90° fitting, also known as an elbow fitting, is used primarily in tight spaces where a straight fitting would not fit. This type of fitting allows the hose to change direction at a right angle, making it ideal for applications where it needs to navigate obstacles.

Applications: Commonly used in compact hydraulic systems, automotive applications, and machinery with confined spaces.

45° Fittings:

Significance: A 45° fitting provides a gentler angle compared to a 90° fitting, which can reduce the stress on the hose and the fluid flow turbulence. It’s often used where a slight directional change is needed without the sharp turn of a 90° fitting.

Applications: Suitable for systems requiring moderate direction changes, such as in agricultural machinery and certain industrial equipment.

22.5° Fittings:

Significance: Less common than 45° and 90°, a 22.5° fitting offers a minimal directional change. This angle can be crucial in systems where space constraints are less stringent but where precise routing is necessary to avoid obstacles or other components.

Applications: Typically used in specialized applications or custom hydraulic systems that require specific routing configurations.

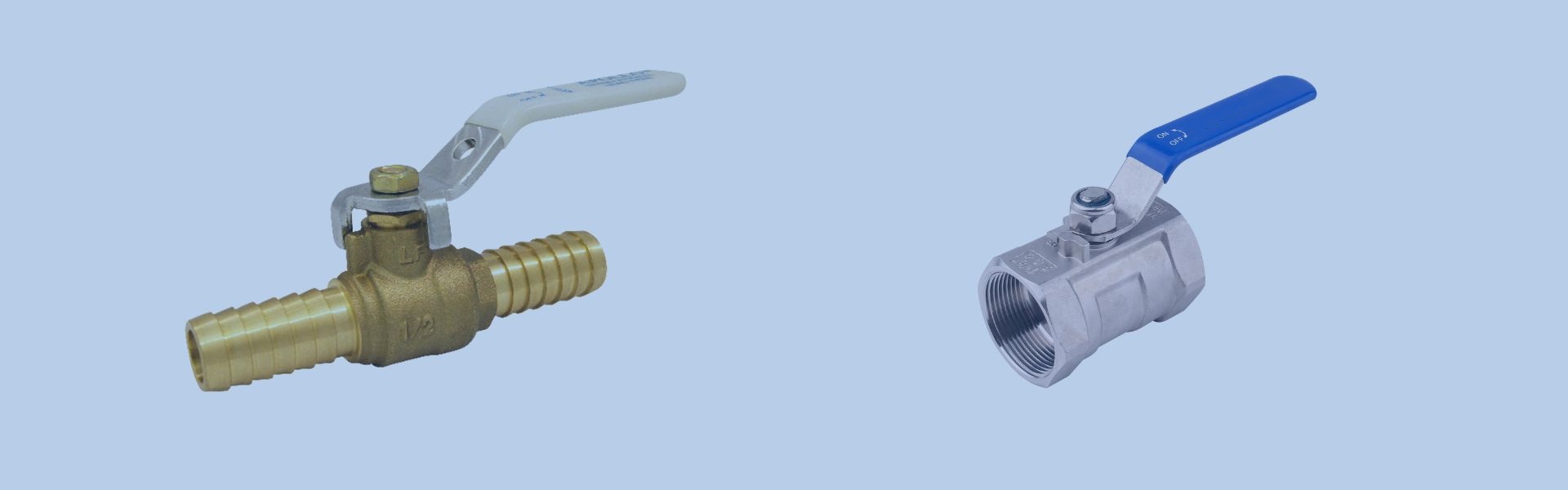

Common Connector Types and Their Measurements

Understanding the various types of hydraulic connectors and how to measure them is crucial for ensuring the compatibility and efficiency of hydraulic systems. Here’s an overview of some of the most common connector types and their measurement guidelines.

NPTF Connectors

Characteristics: NPTF connectors have a tapered thread that seals by forming a mechanical seal between the male and female threads. This taper creates a wedging effect, providing a leak-proof seal without the need for additional sealing compounds.

Measurement Tips: To measure NPTF threads, use a thread pitch gauge to determine the threads per inch (TPI). Measure the outside diameter (OD) at the largest point of the male thread or the smallest point of the female thread. The taper angle is typically 1° 47′, so ensure the calipers are positioned correctly to account for this taper.

SAE J514 JIC/37°

Features: JIC fittings have a 37° flare seating surface that creates a seal when the male and female fittings are tightened together. This flare provides a reliable seal under high pressure.

Identification: Use a thread pitch gauge to measure the TPI, and a caliper to measure the male thread’s OD or the female thread’s ID. The flare angle can be checked with a protractor.

SAE J1926 Straight Thread O-ring Boss

Features: These fittings use straight threads and an O-ring to create a seal. The O-ring compresses against a machined seat, providing a leak-proof connection.

Identification: Measure the thread pitch and OD with a thread pitch gauge and calipers, respectively. Check for the presence of an O-ring groove.

ISO Connectors

Features: ISO fittings are standardized internationally and are known for their reliability and uniformity. They come in various types, including ISO 6149, which uses straight threads and an O-ring seal.

Measurement Guidelines: Measure the thread pitch and OD using a thread pitch gauge and calipers. Identify the specific ISO standard by consulting manufacturer charts.

DIN Connectors

Features: DIN (Deutsches Institut für Normung) connectors are widely used in Europe. They include various types like DIN 2353, which has 24° cone fittings.

Measurement Guidelines: Similar to ISO, use a thread pitch gauge and calipers to measure the threads and diameter. Match these measurements with DIN standards for identification.

Conclusion

Accurate measurement of hydraulic hose fittings is essential to ensure system compatibility and prevent failures. Key points include the importance of precise measurement and the use of tools like calipers, thread pitch gauges, and protractors. Regular maintenance and staying updated with industry standards are vital for optimal performance. Properly measuring thread size, outside diameter, inside diameter, thread pitch, and fitting angle, combined with understanding common connector types, ensures reliable and efficient hydraulic systems. Regular checks and adherence to standards will help maintain system integrity and performance.

FAQ

What tools do I need to measure hydraulic hose fittings?

It would help if you had a measuring tape, calipers (for both inside and outside diameters), a thread pitch gauge, and a protractor to measure hydraulic hose fittings accurately.

How do I measure the thread size of a hydraulic fitting?

Use a thread pitch gauge to measure the distance between the threads. Place the gauge on the threads and ensure a snug fit. Then, the measurement will be matched with manufacturer charts to determine the specific thread type and size.

How do I determine the outside diameter (OD) of a fitting?

Use calipers to measure the OD by placing the fitting between the jaws of the calipers and closing them tightly. Ensure the calipers are perpendicular to the fitting for accurate measurements. Take multiple measurements around the fitting and average them for precision.

How do I measure the inside diameter (ID) of a female fitting?

Insert the jaws of the calipers inside the fitting to measure the ID. Ensure the calipers are positioned correctly to get precise readings. Like OD measurements, take multiple measurements at different points for accuracy.

How do I evaluate the thread pitch without a thread pitch gauge?

If a thread pitch gauge is unavailable, use calipers to measure the number of threads per inch manually. Count the threads within a one-inch span for imperial measurements, or convert to metric as needed.

How do I measure the angle of a fitting?

Use a protractor to measure the angle of the fitting. Align one side of the fitting with the zero line of the protractor and read the angle where the other side aligns with the degree markings.