How to Install Reusable Hydraulic Fittings?

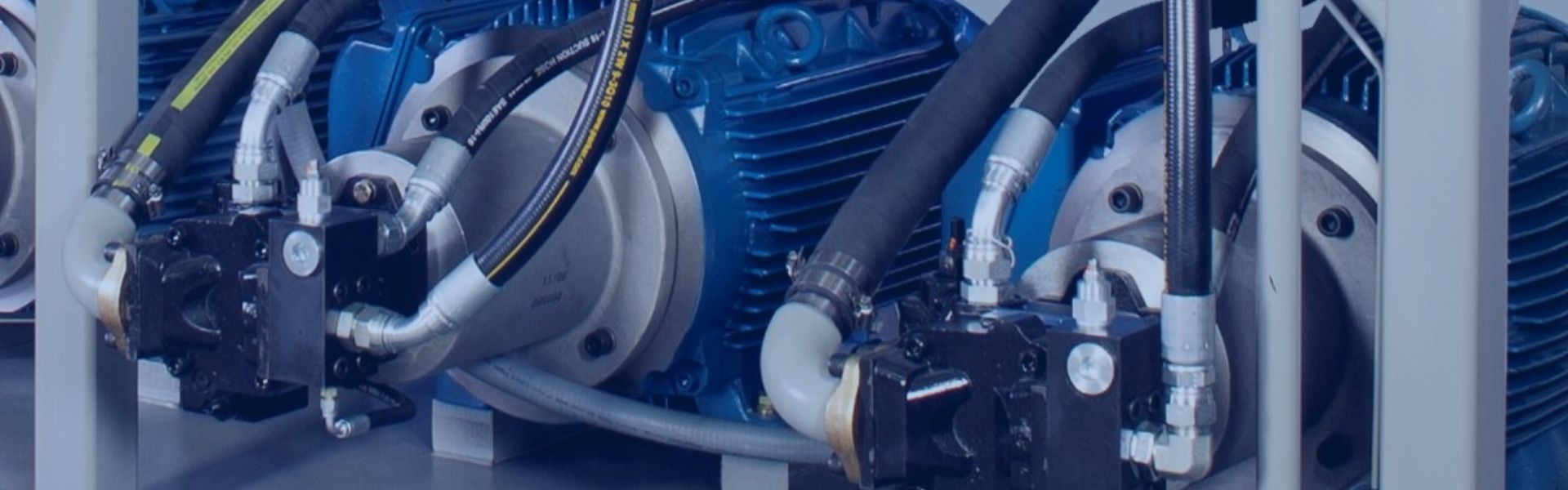

When it comes to hydraulic systems, the fittings you choose can make or break your operation. Reusable hydraulic hose fittings offer a host of benefits that can improve efficiency, reduce downtime, and save you money in the long run. Let’s delve into the essential tools, safety precautions, and best practices for installing and maintaining these fittings.

Table of Contents

Tools and Materials

Installing reusable hydraulic hose fittings requires not only skill but also the right tools and materials. Preparing the tools and materials in advance ensures a smooth and efficient installation.

Adjustable wrenches

First, there are adjustable wrenches. These versatile tools are essential for securely tightening fittings. It is recommended to have a set of different sized wrenches to accommodate different fitting sizes.

Hose Cutters

The next must-have tool is a hose cutter. These tools are specifically designed to make clean cuts on hydraulic hoses, which is essential for a solid installation.

Measuring Tape

You’ll want to have an accurate tape measure on hand. Accurate measurements are key to ensuring that the hose is cut to the desired length, thus ensuring the performance of your hydraulic system.

Lubricants

Finally, a quality lubricant is often overlooked but is critical to a smooth installation. Lubricating the inside of hoses and fittings makes assembly easier and also helps prevent future leaks. Make sure to use a lubricant that is compatible with your hydraulic system to avoid any adverse reactions.

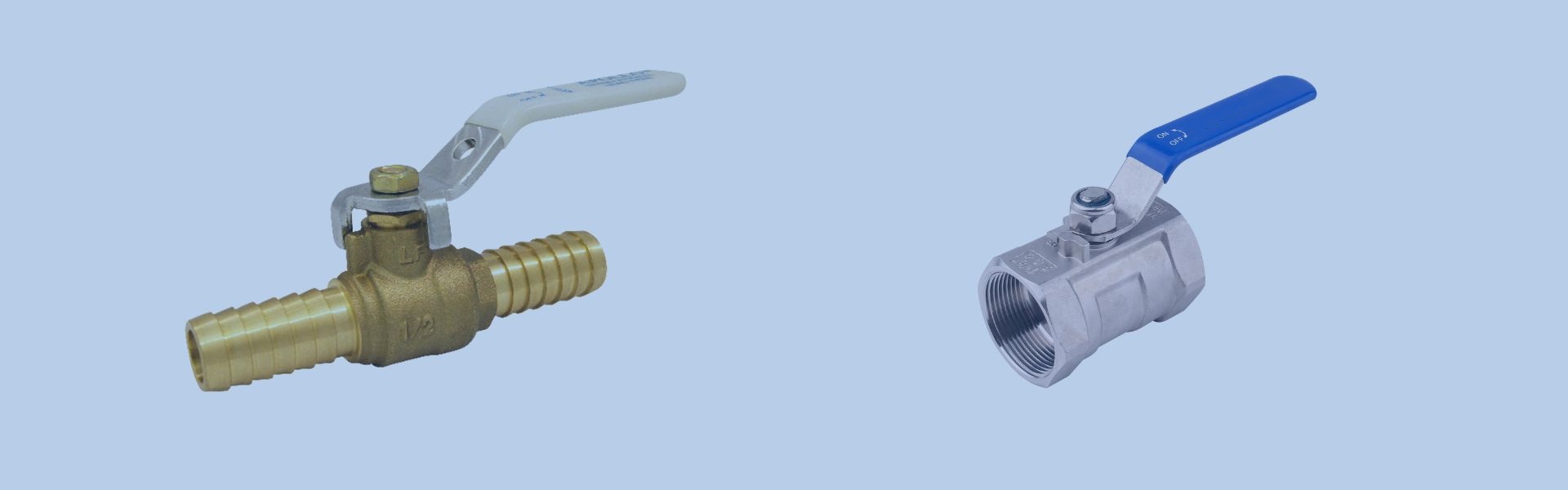

Types of Reusable Hydraulic Hose Fittings

Straight Fittings: Straight fittings connect hoses in a straight line and are commonly used in most hydraulic systems.

Elbow Fittings: If your hydraulic system is subject to environmental constraints that require it to make turns, get elbow fittings. They allow hoses to be connected at an angle, usually 45 or 90 degrees.

Tee Fittings: When you need to divert or merge flow, you’ll want to have tee fittings. Tee fittings connect three hoses and are often used in more complex hydraulic systems.

Safety Equipment

Safety Goggles: Protecting your eyes should be your top priority. Safety goggles will protect your eyes from splashing hydraulic fluid.

Gloves: A good pair of gloves will protect your hands from cuts and hydraulic fluid contact. Choose gloves that are both protective and dexterous.

Ear protection: Hydraulic systems can be noisy. Ear protection helps minimize noise and protects your hearing.

Safety Precautions

Safety is not a necessity in the field of hydraulic installation. Prioritizing safety not only prevents accidents but also ensures that the installation process runs smoothly. So what are the key safety measures you should take? Let’s find out.

The Importance of Hydraulic Installation Safety

Accident Prevention: The high-pressure nature of hydraulic systems can lead to a variety of hazards, including burns and injuries. Proper safety measures can reduce these risks.

Ensure a smooth installation: A safe work environment allows you to focus on the task at hand and ensures a smooth installation process.

Safety Measures to Take Before Beginning Installation

Shut down the hydraulics: Before you start, make sure the hydraulics are shut down. This eliminates the risk of accidental start-up, which could result in serious injury.

Clear the Work Area: Remove any obstructions from the work area. A clutter-free space is not only easier to work in, it is also safer.

Pro Tips for Increased Safety

Pressure Relief: Before starting any work, relieve the hydraulic pressure in the system. This is critical to prevent accidental leakage of hot, pressurized fluids.

Check for leaks: Use a piece of board or cardboard to check hoses for pinhole leaks. Do not use your hands, as hydraulic fluid can be injected into the skin and cause serious complications.

Correct Connections: Ensure that compatible high and low-pressure components are used. Mismatched components can cause ruptures and leaks.

Preparing the Hose

Before considering fittings and connections, start with the hoses themselves. Proper preparation is the cornerstone of a successful hydraulic installation. So how do you do it? Let’s take an in-depth look.

Properly measure and cut hydraulic hoses

Use a tape measure: The first step is to measure the hose. Grab a tape measure, determine the desired length, and mark it. Remember, it’s best to measure twice and then cut.

Use a hose cutter: After measuring, it’s time to cut. Use a specialized hydraulic hose cutter to make a clean cut. This will ensure a better seal and a stronger fit.

Tips to ensure a clean cut for an optimal fit

Clean the hose: Before you start cutting, wipe down the hose to make sure it is free of dirt and debris. An unclean hose can affect the integrity of the joint.

Double-check measurements: It may sound obvious, but always double-check measurements before cutting. A small mistake here could lead to a bigger problem.

Hose preparation considerations

Consider hose expansion: Hydraulic hoses can expand or contract due to pressure and temperature. Be sure to take these changes into account when taking measurements.

Check manufacturer’s requirements: Different manufacturers have different measurement standards. Always check with the manufacturer to avoid wasting scrap.

Step-by-step Guide

Assembling reusable fittings onto hydraulic hoses is a task that requires precision and attention to detail. While the steps may seem simple, each one plays a vital role in ensuring a safe and efficient hydraulic system. Let’s take a closer look at the importance of each step and some best practices.

Insertion of fittings

Slip fitting: Secure the reusable fitting and insert it into the hose. If there is resistance to insertion, use a little pre-prepared lubricant.

Check the fit: Make sure the fitting slides in smoothly while maintaining a tight fit. Looseness can lead to leaks, while tightness can make it difficult to secure properly.

Tighten by hand

Start by hand: Initially tighten the fitting by hand. You want to align the threads and make sure they do not deflect. (The threads are left-handed, so remember to rotate them to the left.)

Feel the resistance: When tightening by hand, you will feel some resistance. This is a good indication that the threads are engaging properly.

Double-check: Before moving on to the next step, double-check to make sure the fitting is securely hand-tightened.

Wrench Tightening

Grab your wrench: Select an adjustable wrench that fits the size of the fitting.

Turn carefully: Start turning the wrench slowly, making sure not to over-tighten. Over-tightening can cause the hose to distort or even strip the threads, compromising the integrity of the connection.

Final Check: After tightening the fitting, do a quick check to make sure it’s secure. Look for any signs of misalignment or gaps that could indicate a problem.

How to tighten the fitting correctly

Use an adjustable wrench: Take the adjustable wrench and place it on the reusable fitting. Turn the wrench until the fitting feels tight. At this point it is tight enough to form a seal, but not so tight as to damage the hose or fitting.

Common mistakes to avoid

Overtightening: This is the most common mistake and can lead to a host of problems, including leaks and even cracked joints. Always follow the manufacturer’s torque specifications, if available.

Misalignment: Make sure hoses and fittings are perfectly aligned before tightening. Misalignment can lead to improper sealing and potential leaks.

Pro Tips for Safe Installation

Marking Technique: Use a marker to draw a line on the nut and extend it across the adapter. This helps you measure how tight the fitting is.

Check and recheck: After fixing, it’s a good idea to double-check. Make sure there are no gaps or misalignments.

Test Installation

After assembling the hydraulic coupler, you are not done yet. The next critical step is to test the installation. This will ensure that the fitting is secure, leak-free, and ready to go.

Leak and Flow Test Procedure

Turn on the hydraulic system: The first step is to start the hydraulic system. This allows you to monitor pressure levels and ensure that the system is operating properly.

Check for leaks: Once the system is turned on, carefully inspect the fittings and surrounding area. If leaks are found, they will need to be rechecked or reinstalled.

Solutions to Problems

Retighten fittings: If the problem is not serious, then you can fix minor leaks with a simple adjustment.

Replace the hose: If the leak persists, then you’ll need to find out where the leak is occurring in your hydraulic system, and then you’ll need to replace the hose or fitting with a new one.

Simple Tips

Use a calibrated gauge: Always use a gauge that has been calibrated within the last 12 months. This ensures accurate readings.

Follow an approved test program: Always perform tests under controlled conditions and record the results. This not only ensures safety but also helps with future troubleshooting.

Hydrostatic vs. barometric testing: Hydrostatic testing uses water as the test medium, while barometric testing uses air or a non-flammable gas. The choice between the two depends on your specific needs and system design.

Maintenance and Troubleshooting

With hydraulic systems, proper maintenance ensures that reusable hydraulic hose fittings last longer and perform better. Let’s take an in-depth look at some maintenance tips that can save you time and money in the long run.

Maintenance Tips

Check for wear and tear on a regular basis: Make it a habit to check your fittings for any signs of deterioration. Look for cracks, rust, or any other anomalies that could jeopardize the integrity of your system.

Clean regularly: Dirt and debris can affect the performance of your fittings. Use a mild detergent and a soft-bristled brush to clean the outside of the fittings.

Troubleshooting Common Problems

Leaks: If a leak is detected, first check the tightness of the fitting. A quick turn of the wrench will seal minor leaks.

Poor Flow: If the hydraulic fluid is not flowing properly, check for clogged or damaged hoses and fittings. Clogged hoses can be cleaned, damaged ones should be replaced with new ones.

Professional Troubleshooting Tips

Use the right tool: Always use the correct size wrench when tightening or loosening fittings. The wrong size could strip threads and cause more problems.

Check system pressure: If you are experiencing problems, it is a good idea to check the system pressure with a calibrated pressure gauge. This can help you pinpoint the problem more accurately.

Check the manual: If in doubt, consult the manufacturer’s manual. Manuals often contain valuable information on troubleshooting and maintenance for your parts.

Benefits of using Topa reusable hydraulic hose fittings

In the hydraulic industry, the type of fittings used can have a significant impact on the efficiency and longevity of a system. Reusable hydraulic hose fittings offer a variety of advantages that can benefit professionals in the field.

● Cost Effectiveness

Long-Term Savings: While the initial cost of reusable fittings may be high, they save money over time. You can disassemble and reuse them in different applications, reducing the need for new purchases.

Reduced downtime: Time is money, especially when dealing with hydraulic system failures. Reusable fittings can be quickly replaced or adjusted, minimizing downtime.

● Environmental Advantages

Reduce Waste: By reusing couplings, you can reduce waste, which is good for the environment.

Sustainable Practices: Companies that prioritize sustainability will find reusable fittings to be a great fit for environmental practices.

● Easy to use

Simple to install: Reusable fittings are often easier to install than crimp options. This is especially beneficial for field repairs.

No Special Tools Required: Unlike some other types of fittings, reusable fittings typically do not require specialized crimping tools, making them easier to repair quickly.

● Reliability

High-quality materials: Reusable fittings are often made from high-grade steel or other durable materials, ensuring long life and reliable performance.

Secure connection: When properly installed, reusable fittings provide a secure, leak-free connection that can withstand high pressures and harsh conditions.

Conclusion

Reusable hydraulic hose fittings provide an economical, reliable and environmentally friendly solution for your hydraulic system. They are easy to install and maintain, making them an excellent choice for professionals in the hydraulic industry. But if, after reading this article, you still have questions about installing reusable fittings, contact us!

FAQ

Reusable hydraulic fittings are fittings designed to be used multiple times, allowing the hose to be replaced without discarding the fitting.

You will need a wrench, a hose cutter, and the correct reusable fitting and hose for the application.

Cut the hose to the desired length, clean the cut end, and ensure it is free of debris and damage before fitting.

Slide the reusable fitting onto the hose, ensuring it is positioned correctly, and then tighten the fitting using the proper tool to secure it.

Yes, reusable hydraulic fittings can be used several times as long as they are not damaged or worn out.

Check the fitting for damage, ensure it is correctly tightened, and replace any worn or damaged seals if necessary.

Topa Blog

Find out more about Topa Blog and learn more about specialized hydraulic fittings.