Pressure loss is wasted fuel and slow performance. This guide reveals how hose diameter, fittings, routing, and fluid choice impact efficiency, providing actionable strategies to reclaim power and reduce your excavator’s operating costs.

Understanding Pressure Loss: The Invisible Tax on Power

Pressure loss is the drop in hydraulic pressure as fluid moves from the pump toward an actuator such as a cylinder or motor.

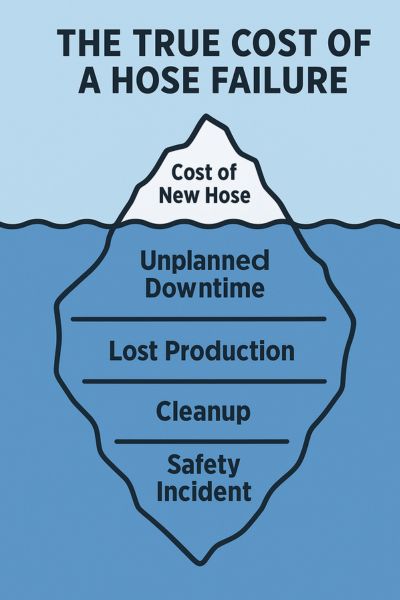

Every PSI or Bar lost represents energy produced by the engine but never converted into useful work. Instead, that energy escapes as heat — raising operating costs while lowering machine performance.

Why Pressure Loss Hurts Productivity

Pressure loss affects both efficiency and machine health.

- The engine must burn more fuel to generate the extra pressure needed to compensate.

- Higher fluid temperature accelerates oil oxidation and reduces oil life.

- Components like pumps, hoses, and seals experience greater stress.

- Machine response slows, especially under heavy load or in long hose circuits.

In short,pressure loss silently drains power and money.

Two Sources of Pressure Loss

Friction Loss

Friction occurs as the fluid rubs against the inner surface of the hose.

- Smaller hose ID = higher friction

- Longer hose = higher friction

- Rough inner wall = higher friction

- Higher viscosity = higher friction

Turbulence Loss

Turbulence appears when the flow pattern is disrupted.

- Sharp bends

- Tight routing

- Adapters and elbows

- Sudden changes in hose size

- Misaligned fittings

These disturbances cause chaotic flow and pressure drop.

Quick Comparison: Friction Loss vs. Turbulence Loss

| Item | Friction Loss | Turbulence Loss |

| Main Cause | Fluid sliding along hose walls | Flow disturbance from components |

| Trigger Factors | Small ID, long hoses, viscous oil | Elbows, tees, size changes, sharp bends |

| Flow Pattern | Smooth but resisted | Irregular, chaotic |

| Typical Location | Entire hose length | Fittings, adapters, bent sections |

| Heat Generation | Medium | High |

| Impact on Machine | Gradual loss of power | Sudden drop in responsiveness |

Energy You Can See and Feel

Pressure loss always becomes heat.

If one hose consistently shows a higher surface temperature than the others — especially under load — that hose is likely causing excessive pressure drop.

Signs include:

- Hot spots visible on a thermal camera

- Hose too warm to touch compared to others

- Slower cylinder movement on that circuit

- Oil temperature rising faster during long work cycles

A cooler hydraulic circuit is a more efficient, more powerful, and more reliable system.

The Main Artery: Optimizing Hose Diameter and Length

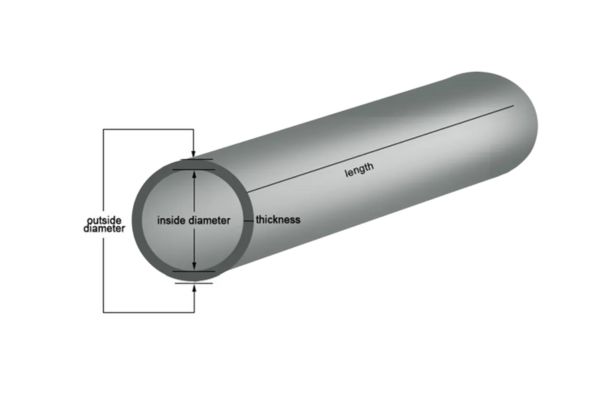

The physical dimensions of a hose are the dominant factor behind friction loss.

Inner diameter (ID) and length decide how hard the pump has to work to push fluid through the circuit.

Get those two wrong and the system runs hot, noisy, and weak, even if every other component is perfect.

The Power of Proper Diameter

Think of hose ID as the size of a highway for oil.

- A larger ID gives more “lanes” for fluid to pass through.

- Flow speed drops, so friction against the hose wall falls sharply.

- Pressure loss reduces, which means less wasted energy and less heat.

Even a small step up in ID can make a noticeable difference.

For example, moving from a ½” to a ⅝” pressure line at the same flow rate:

- Fluid velocity drops

- Friction loss per meter/foot drops

- Oil temperature rise over the working day is lower

Undersized hoses are one of the most common reasons for:

- Hot running systems

- Slow actuators at the end of long circuits

- Premature hose and seal wear

A hose that is too small behaves like a partially closed valve. It throttles the system all day long.

Shorter Is Always Better (Within Reason)

Friction loss is cumulative.

Every extra meter or foot of hose adds more resistance.

- Double the hose length → roughly double the friction loss in that line.

- Long, loose “spaghetti” routing wastes energy and money.

- Extra length also means more oil volume, higher cost, and more potential leak points.

Some slack is necessary:

- To allow boom, arm, or attachment movement

- To keep hose away from pinch points and sharp edges

- To allow proper clamping and support

But beyond those needs, spare length is pure penalty.

A compact, well-routed circuit with the same ID will always have less pressure loss than a long, looping one.

The Goldilocks Principle: “Right-Sizing” the Hose

The target is not “as big as possible”, it is “big enough for the flow at the correct velocity”.

If velocity is too high:

- Friction loss rises sharply

- System noise increases

- Oil heats faster

- Hose and fittings see more stress

If velocity is too low:

- The system becomes heavy and costly

- Hose bundles take up more space

- Response can feel “lazy” in some circuits

Most designers use recommended velocity ranges based on line type.

Typical Velocity Targets (Rule of Thumb)

| Line Type | Typical Velocity Range |

| Pump suction line | 0.7–1.5 m/s (2–5 ft/s) |

| Return line | 1–3 m/s (3–10 ft/s) |

| Pressure line | 3–6 m/s (10–20 ft/s) |

Simple logic for right-sizing:

- Start from the required flow (GPM or LPM).

- Select a hose ID that keeps velocity inside the target range.

- Keep routing as short and direct as possible.

- Avoid sudden jumps in size (e.g., ⅜” → 1″) that create turbulence at transitions.

A “right-sized” hose:

- Carries the design flow without choking it

- Holds pressure with minimal loss along its length

- Stays cooler under heavy, continuous work

This is why hose diameter and length are treated as the main artery of hydraulic design. Get them right, and the rest of the system runs smoother, cooler, and closer to rated power.

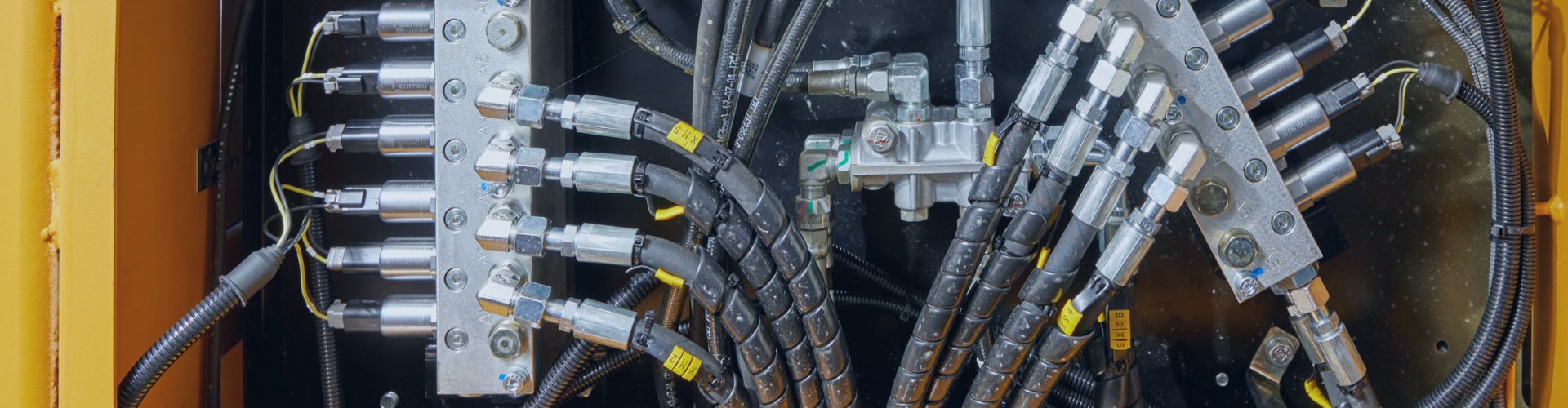

The Turbulence Factor: Bends, Couplings, and Fittings

Every time hydraulic fluid changes direction or passes through a connection, its smooth “laminar” flow is disrupted, creating turbulence. This chaotic, swirling flow is a major source of pressure loss, and the type of fitting used has a huge impact.

Minimizing Bends and Sharp Angles

A smooth, gentle bend in a hose is far more efficient than a sharp 90° fitting. A poor routing choice that forces a hose into a tight kink or requires multiple angled fittings will significantly increase pressure drop compared to a clean, sweeping path.

Not All Fittings Are Created Equal

Fittings with smooth, gradual internal passages create less turbulence than those with abrupt changes in direction or diameter. For example, a forged, swept 90° elbow fitting is vastly superior to a block-style or braised-joint elbow.

The Impact of Quick Couplers

Quick-disconnect couplers, while essential for attachments, are a major source of restriction. Their internal poppet valves and complex flow paths create significant turbulence. Understanding this loss is key when sizing systems with multiple attachments.

| Fitting/Bend Type | Internal Flow Path | Notes |

| Straight Hose Length | Smooth, unobstructed bore. | The ideal path; used as the benchmark for comparison. |

| Gentle Hose Bend | Smooth, continuous curve. | The most efficient way to change direction. Always stay within the hose’s minimum bend radius. |

| Forged “Swept” Elbow | Smooth, curved internal passage. | The best choice for a 90° fitting. Designed to minimize turbulence. |

| Standard Block Elbow | Sharp, drilled 90° internal angle. | Creates a significant vortex and pressure drop. Avoid in high-flow or pressure-sensitive lines. |

| Quick Disconnect Coupler | Complex path with poppet valves. | A necessary evil for attachments. Its high loss must be factored into system design. |

The Lifeblood: Fluid Viscosity and Flow Rate

The hydraulic fluid is more than just a medium that transfers pressure.

Its viscosity and the way it moves through the circuit directly decide how much power reaches the actuators — and how much is lost as heat inside the hoses.

Viscosity: The Thickness Tax

Viscosity describes how “thick” or “thin” a fluid is.

- High viscosity = thick, sticky oil

- Low viscosity = thin, free-flowing oil

Thicker oil creates more internal friction.

Molecules slide past each other with more resistance, so the pump must work harder to push the fluid through hoses, valves, and fittings. This extra effort shows up as:

- Higher pressure loss in lines

- Higher oil temperature

- Higher fuel consumption

Cold starts are the worst case.

At low temperature, even the correct oil grade becomes much thicker:

- Pump sees higher inlet resistance and may start to cavitate

- Pressure lines show a larger pressure drop than during normal operation

- Actuators move slowly and feel “heavy”

As the system warms up, viscosity drops into its designed range and pressure loss falls.

The goal is to keep viscosity within a window where the oil is not too thick (high pressure loss) and not too thin (weak lubrication and internal leakage).

The Exponential Effect of Flow Rate

Flow rate defines how much oil the pump is moving, usually expressed in LPM or GPM.

Inside a fixed hose ID, higher flow rate means higher velocity.

Pressure loss from friction does not increase in a straight line with velocity.

It rises roughly with the square of flow speed. That means:

- Double flow velocity → about four times the pressure loss

- Triple flow velocity → about nine times the pressure loss

This is why undersized hoses cause so much trouble:

- To push the same flow through a smaller ID, velocity jumps

- Friction increases sharply

- Pressure drop across that hose section becomes large

- The line runs much hotter than the rest of the system

At high flow velocities, the operator may notice:

- Faster oil heating under continuous duty

- Noisy operation in certain lines

- Sluggish cylinders at the end of long hose runs

Viscosity and Flow Rate: How They Interact

Viscosity and flow rate always act together. For the same hose and system:

| Condition | Effect on Pressure Loss | Typical Symptoms |

| High viscosity, low flow | Medium pressure loss | Slow response, heavy feel |

| High viscosity, high flow | Very high pressure loss | Strong heating, possible pump noise |

| Correct viscosity, high flow | Elevated pressure loss | Local hot spots, higher fuel use |

| Correct viscosity, moderate flow | Controlled pressure loss | Stable temperature, consistent response |

| Very low viscosity, high flow | Lower line loss, higher leakage | Weak force, poor lubrication |

The best hydraulic circuits keep both viscosity and velocity in a controlled range so that pressure loss and temperature stay under control.

Choosing the Right Fluid

Selecting the excavator manufacturer’s recommended multi-grade hydraulic oil is a simple way to keep viscosity in the target band across different temperatures.

Multi-grade hydraulic fluids are blended to:

- Stay thin enough during cold starts so the pump can build pressure

- Stay thick enough at high operating temperature to maintain lubrication and reduce internal leakage

- Limit changes in viscosity across the working temperature range

This leads to:

- Lower pressure loss during warm-up

- More stable actuator speed from morning to midday

- Less stress on pumps, valves, hoses, and seals

Combined with properly sized hoses and realistic flow velocities, the right fluid choice turns the hydraulic oil into a stable, predictable “lifeblood” that delivers pressure where it is needed instead of wasting it as heat.

A System-Wide Audit for Peak Efficiency

Armed with this knowledge, you can perform a practical audit of your machine to identify and correct areas of high pressure loss. This proactive approach improves performance, reduces fuel costs, and extends the life of hydraulic components.

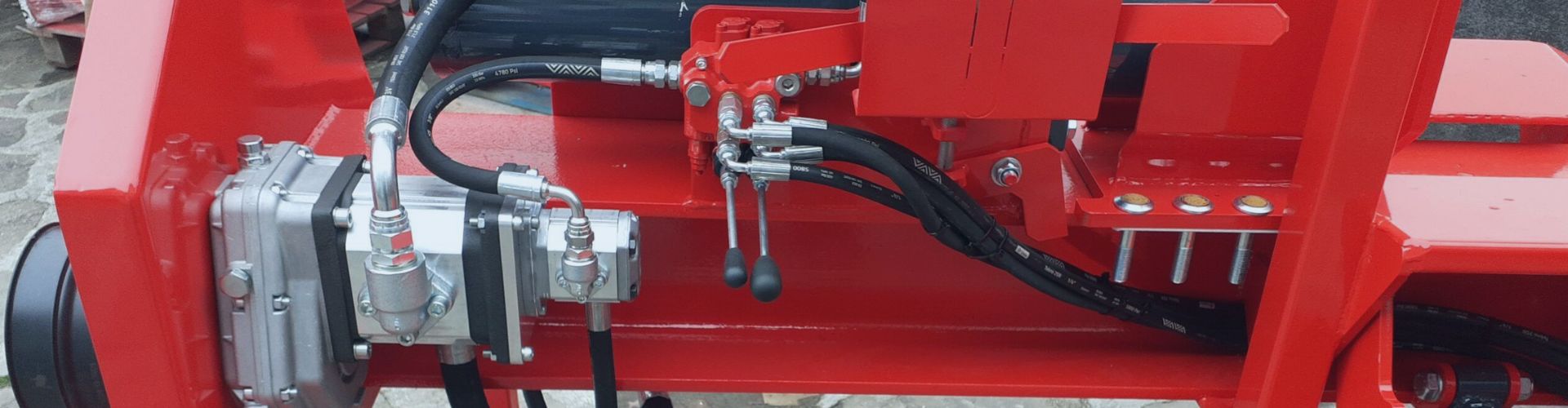

Trace the Flow Path

Start at the pump and mentally follow the path of a high-flow circuit, like the boom lift or travel motor. Look at every hose, every fitting, and every bend. Question why each component is there and if a more efficient alternative exists.

Hunt for Inefficient Routing

Look for hoses that are excessively long or that use sharp, blocky fittings where a gentle hose bend could have been used. Check for tight kinks or areas where hoses are flattened, as these are extreme points of restriction that generate immense heat.

Standardize for Efficiency

When replacing hoses and fittings, make efficiency a priority. Consolidate your inventory to favor swept elbows over block elbows. Train technicians on the importance of proper hose length and routing to avoid creating new problems during repairs.

| Audit Area | Key Question to Ask | Potential Optimization Action |

| Hose Diameter (ID) | Is the hose ID correctly matched to the flow rate for this line per manufacturer specs? | Upsize any hose found to be significantly undersized for its application. |

| Hose Length | Is this hose longer than it needs to be? Are there any unnecessarily large service loops? | Shorten the hose during the next replacement to the optimal length. |

| Bends & Routing | Is the hose kinked or bent tighter than its minimum bend radius? | Re-route or re-clamp the hose to achieve a smoother, wider bend. |

| Fittings & Adapters | Is a sharp block fitting being used where a swept elbow would fit? Are there extra, unnecessary adapters? | Replace inefficient fittings with high-flow swept alternatives. Eliminate redundant adapters. |

| Fluid Condition | Is the fluid the correct type and viscosity? Is it clean and within its service life? | Follow OEM recommendations for fluid type and change intervals. |

Pressure loss is not a mystery fault in the system – it is the direct result of choices in hose size, fittings, routing, and fluid. By right-sizing hose ID and length, using high-flow swept fittings, keeping routing clean, and running the correct multi-grade oil, you turn wasted heat back into useful power, faster cycles, and lower fuel bills.

If you’re ready to upgrade your excavator circuits, Topa can supply matched hydraulic hoses, assemblies, and protective sleeves built for high flow and stable pressure.

FAQ

What is the easiest way to identify a line with high pressure loss?

Use an infrared thermometer or thermal camera. The energy lost from pressure drop is converted directly to heat. A hose or fitting that is significantly hotter than the surrounding components is a clear indicator of a problem.

Will replacing a hose with a slightly larger one improve my machine’s speed?

Yes, it is very likely. By reducing the pressure loss between the pump and the motor or cylinder, more of the pump’s energy is available to do work, which often translates to faster cycle times and better performance.

Are quick couplers always bad for pressure loss?

They are not “bad,” but they are a significant point of restriction. They are a necessary component for tool versatility. The key is to be aware of their impact and ensure the rest of the system (hoses, fittings) is as efficient as possible to compensate.

How much does a sharp 90-degree fitting really affect performance?

It can be substantial, especially in high-flow lines like those for a hammer or travel motor. A single sharp elbow can have the same pressure drop as several feet of straight hose. Using a swept elbow instead is a simple and effective upgrade.

Does a dirty filter cause pressure loss in the hose lines?

A clogged suction filter can starve the pump, and a clogged return line filter can create high back pressure. While these don’t directly cause pressure loss *within the hose line itself*, they are critical parts of the overall system efficiency and can cause similar symptoms like heat and slow performance.

My machine seems slow when it’s cold. Is this related to pressure loss?

Yes, directly. Cold hydraulic fluid has a much higher viscosity (it’s thicker). The pump must work much harder to push this thick fluid through the hoses and fittings, resulting in significant pressure loss and sluggish performance until the system warms up.