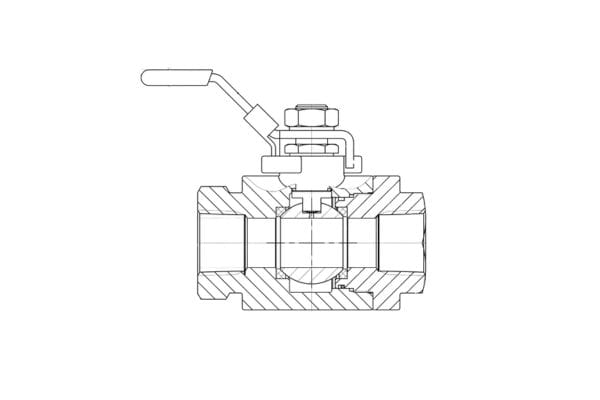

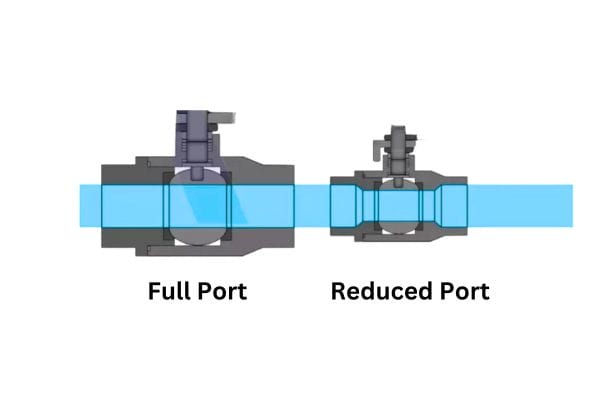

Full port ball valves have a bore that matches the pipe diameter, allowing for maximum flow and minimal pressure drop, making them ideal for high-flow, high-pressure, or viscous fluid applications. In contrast, reduced port ball valves have a smaller bore, which can cause flow restrictions and pressure drops. Selecting the right valve ensures optimal performance and cost-efficiency for your specific needs.

What is a Reduced Port Ball Valve?

Definition and Key Features of Reduced Port Ball Valves

A reduced port ball valve is a type of ball valve designed with a smaller bore compared to the diameter of the pipe it connects to. In other words, the internal opening of the valve is reduced, creating a narrower flow path for the fluid. This design is often used in applications where the flow rate requirements are lower or where the pipe size is relatively large compared to the valve.

Key features of a reduced port ball valve include:

Smaller Bore Size: The bore of the ball is smaller than the pipe diameter, which results in a restricted flow through the valve.

Flow Restriction: Due to the smaller opening, these valves cause a higher pressure drop across the valve, which may be suitable for systems with less stringent flow needs.

Compact and Cost-Effective Design: Reduced port valves are typically smaller and less expensive than full port ball valves, making them an attractive option for systems that do not require high flow or pressure management.

Despite the flow restriction, reduced port ball valves still offer the same simple quarter-turn operation, providing reliable shutoff and easy maintenance.

How Reduced Port Design Affects Flow Efficiency

The reduced port design directly impacts the flow efficiency of the system. Here’s how:

Flow Resistance and Pressure Drop: Since the bore of the valve is smaller than the pipe, the flow is partially restricted as it passes through the valve. This restriction leads to an increase in pressure drop, meaning the system will require more energy to maintain the same flow rate, potentially reducing the overall efficiency of the system.

Lower Flow Rate: The restricted bore size means that less fluid can pass through the valve at once compared to a full port valve. This makes reduced port ball valves ideal for systems with low-flow demands, where excessive flow is not necessary.

Turbulence and Friction: The narrower flow path can lead to increased turbulence within the valve, resulting in more friction as the fluid moves through. This can slightly reduce the overall energy efficiency in certain applications, especially if the system is designed to move large volumes of fluid.

Despite these drawbacks, reduced port valves are a good option for low-flow or low-pressure applications where the energy cost of maintaining a high flow rate isn’t a concern. Their ability to control the flow while maintaining a smaller, more compact design makes them suitable for less demanding systems.

Full Port vs Reduced Port Ball Valve: Key Differences Explained

Flow Capacity: How Full Port and Reduced Port Compare

Full Port Ball Valve Flow Capacity

A full port ball valve is designed with a bore that matches the diameter of the pipe, allowing fluid to flow through the valve without any internal restrictions. This unrestricted flow means the valve can handle higher flow rates without significantly reducing pressure or creating turbulence. Full port valves are ideal for applications where maximum flow is required, such as in high-flow systems, industrial processes, or pipelines.

Reduced Port Ball Valve Flow Capacity

In contrast, a reduced port ball valve has a smaller internal bore, resulting in a reduced flow path. This design creates flow restrictions, limiting the volume of fluid that can pass through the valve. While this design is cost-effective and suitable for low-flow systems, it can’t handle the same high flow volumes as a full port valve. In applications where flow rate is not critical, such as residential plumbing or irrigation systems, reduced port valves can provide sufficient capacity while keeping costs lower.

Comparison:

Full Port Valve: Ideal for high-flow applications due to the large bore and minimal flow restriction.

Reduced Port Valve: Best suited for low-flow applications, where the reduced bore and higher flow resistance do not present a problem.

Pressure Drop: Impact of Flow Path Restriction

Pressure Drop in Full Port Valves

Because a full port ball valve has a bore that is the same size as the pipe, it causes minimal pressure drop. The flow path is smooth and unobstructed, which means that the fluid can pass through the valve with very little resistance. This makes full port valves highly efficient in maintaining system pressure, especially in high-pressure applications. In systems where pressure consistency is important, such as in chemical processing or oil pipelines, full port valves are crucial for maintaining flow without sacrificing pressure.

Pressure Drop in Reduced Port Valves

In a reduced port ball valve, the smaller internal bore increases the resistance to flow, resulting in a higher pressure drop across the valve. As fluid flows through the valve, it encounters a bottleneck at the narrower opening, which creates additional friction and reduces the pressure downstream. This is a tradeoff of the reduced port design and is generally acceptable in low-flow, low-pressure applications. However, for systems that require pressure control, such as in high-pressure industrial systems, the pressure drop caused by the reduced port valve can lead to inefficiency.

The Role of Bore Size in System Efficiency

Bore Size in Full Port Valves

The bore size in a full port ball valve is designed to match the pipe diameter, allowing fluid to flow with minimal resistance. A larger bore means that there is less friction as the fluid moves through, maintaining the efficiency of the entire system. The large, unobstructed bore also reduces the chances of turbulence or clogging, making full port valves ideal for high-demand systems that require both high flow and low pressure loss.

Bore Size in Reduced Port Valves

In reduced port ball valves, the bore size is smaller than the pipe diameter, which creates flow restrictions and increases the friction the fluid encounters. The smaller bore leads to a higher pressure drop, which can reduce the overall system efficiency. For low-flow applications where the pressure drop is less of a concern, the smaller bore is not an issue. However, in systems that require high efficiency and smooth fluid dynamics, full port valves are often preferred due to their ability to minimize resistance and friction.

Pressure Rating: Full Port vs Reduced Port in High-Pressure Systems

Pressure Rating of Full Port Ball Valves

Full port ball valves are typically designed to handle higher pressures due to their unobstructed flow path and larger internal bore. The design allows for better pressure handling without compromising the flow or causing significant pressure loss. This makes full port valves ideal for high-pressure systems, such as oil and gas pipelines, power plants, and chemical reactors, where pressure must be maintained consistently throughout the system.

Pressure Rating of Reduced Port Ball Valves

Reduced port ball valves, due to their smaller bore and increased flow resistance, are less capable of handling high-pressure applications. The smaller bore means more stress is placed on the valve, and the pressure drop becomes more significant, especially in systems where high-pressure control is crucial. Reduced port valves are better suited for low-pressure systems, where the reduced bore does not significantly impact the overall performance of the system.

Flow Optimization: Which Valve Provides Better Efficiency?

Flow Optimization in Full Port Valves

Full port ball valves are designed to optimize flow efficiency by minimizing resistance. The large bore ensures that fluid flows freely through the valve, reducing turbulence and pressure loss. For applications that require continuous, uninterrupted flow, such as HVAC systems, water treatment plants, and industrial manufacturing, full port valves are the best option to ensure that flow optimization is achieved. They provide maximum flow without the penalties of additional resistance, leading to energy savings and improved overall system performance.

Flow Optimization in Reduced Port Valves

While reduced port valves offer cost savings, they are not optimized for high flow efficiency. The smaller bore causes increased flow resistance, leading to pressure drops and inefficient fluid movement. However, in low-flow applications where the efficiency of flow is less of a concern, reduced port valves are still effective. They offer a cost-effective solution for systems where high-flow optimization is not a priority but must be balanced against the higher pressure losses they create.

Valve Sealing and Durability: Which Valve Lasts Longer?

The Role of Valve Sealing in Flow Control

Valve Sealing and Its Importance in Performance

The sealing mechanism in a ball valve is crucial for ensuring a tight shutoff and preventing leaks when the valve is closed. Proper sealing also helps in flow control, allowing the valve to regulate the flow of liquids, gases, or slurries with precision. The seal is usually made of materials such as rubber, Teflon, or metallic gaskets that create a barrier between the internal ball and the valve body.

In full port valves, the sealing mechanism is typically larger and can accommodate more aggressive fluid flow due to the wider internal bore. The absence of flow restrictions means the valve is under less strain during operation, potentially resulting in less wear on the sealing components.

In contrast, reduced port valves have a smaller bore, which can create higher fluid velocity and more pressure fluctuations, leading to greater wear on the seals over time. The increased flow resistance can put additional stress on the valve’s sealing components, particularly in systems with high pressure or abrasive fluids.

Sealing Quality and Valve Longevity

The quality of the valve sealing plays a significant role in determining its longevity and performance. A poor seal can lead to leakage, causing fluid loss and reducing the effectiveness of the system. Regular maintenance and the selection of appropriate materials for sealing can extend the life of both full port and reduced port valves.

Durability of Full Port vs Reduced Port Ball Valves

Full Port Ball Valve Durability

Full port ball valves are designed to handle high-flow conditions with minimal flow resistance, which generally leads to less strain on the valve body and internal components. Because of the larger bore, full port valves are better suited to withstand high-pressure systems and can handle larger volumes of fluid without experiencing significant wear. Additionally, their ability to maintain consistent flow without creating excessive friction reduces the wear and tear on internal components, leading to longer valve life.

Full port ball valves are also ideal for environments where fluid cleanliness is a concern, as their design reduces the potential for debris buildup or clogging. With proper maintenance and periodic inspection, full port ball valves are often more durable and reliable in demanding applications.

Reduced Port Ball Valve Durability

In reduced port ball valves, the smaller bore causes more flow resistance and pressure drop, which can result in higher stress on internal components such as the valve body, seals, and stem. The increased fluid velocity through the smaller opening can lead to erosion or abrasion of the sealing materials, especially in systems with abrasive fluids or high-flow rates. While reduced port valves are often designed for lower-pressure and low-flow applications, continuous operation in these conditions can reduce their overall lifespan compared to full port valves.

Additionally, the reduced port design may lead to higher levels of turbulence, which could cause more stress on the valve components and increase the likelihood of damage over time. Reduced port valves are often more cost-effective, but their durability can be compromised when exposed to higher pressures or abrasive conditions.

How Valve Materials Affect Longevity and Performance

Materials in Full Port Ball Valves

The materials used in full port ball valves play a critical role in their performance and durability. Full port valves are often made from materials such as stainless steel, brass, or carbon steel, depending on the application’s requirements. These materials are corrosion-resistant, strong, and durable, making them ideal for harsh environments. Stainless steel valves, for example, are commonly used in systems that deal with aggressive chemicals, high temperatures, or corrosive fluids, providing longer-lasting performance and reducing the frequency of replacements.

The sealing material in full port valves is also essential for longevity. Valves with Teflon seals or metallic gaskets are designed for superior sealing and can handle extreme pressure and temperature conditions without degradation, increasing their service life.

Materials in Reduced Port Ball Valves

Reduced port ball valves are typically made from similar materials like brass, bronze, or carbon steel for cost-effectiveness and ease of manufacture. While these materials still offer good durability, the overall valve life can be affected by the flow restrictions that cause additional wear and tear on the internal components, especially if the valve is exposed to abrasive fluids or high-pressure conditions.

In low-flow systems, the choice of material may not be as critical because the internal components are under less stress. However, when dealing with abrasive particles or high-temperature fluids, choosing corrosion-resistant materials such as stainless steel or alloy steels can help extend the life of the valve.

When to Choose Full Port vs Reduced Port Ball Valves

Choosing Based on System Requirements: Flow, Pressure, and Fluid Type

The decision between full port and reduced port ball valves largely depends on your system’s specific needs, such as flow rate, pressure conditions, and the type of fluid being handled. Each valve type has distinct advantages, and choosing the right one involves evaluating how these factors align with the requirements of your system.

Flow Requirements: If your system requires a high-flow capacity, a full port valve is the best choice. Full port valves offer unrestricted flow, ensuring that your system operates at maximum efficiency. Reduced port valves, on the other hand, are better suited for systems with lower flow requirements where minor flow restriction doesn’t pose a problem.

Pressure Considerations: For high-pressure systems, where maintaining consistent pressure is crucial, a full port valve ensures minimal pressure drop. The larger bore size allows fluid to pass through without significant resistance, making it ideal for high-pressure applications. In contrast, reduced port valves introduce more resistance, causing higher pressure drops, which can be problematic in systems that require tight pressure control.

Fluid Type: The viscosity and nature of the fluid are also important factors. If your system handles viscous or abrasive fluids, a full port valve is generally the better option. The larger bore ensures that the valve can handle thicker fluids without clogging or excessive wear. For cleaner, low-viscosity fluids, a reduced port valve may be sufficient.

By understanding how your system’s flow, pressure, and fluid type affect the performance of the valve, you can make an informed decision about which type best meets your operational needs.

Full Port Valves in High-Flow, High-Pressure Applications

Full port ball valves excel in high-flow and high-pressure applications. These applications often require valves that can manage large volumes of fluid without compromising pressure or causing significant pressure loss. Full port valves are designed to accommodate high flow rates and ensure that the system remains efficient even under demanding conditions.

Oil and Gas Pipelines: These systems require high-flow capacity to transport large volumes of oil and gas over long distances. The minimal pressure drop of full port valves ensures that the system maintains efficient flow without requiring extra energy.

Chemical Processing: In industries where chemical reactions take place and fluids need to flow freely without obstruction, full port ball valves prevent clogging and provide reliable performance.

Water Treatment Systems: Full port valves are often used in municipal water treatment plants and industrial water systems, where large quantities of water must be moved through pipes without compromising flow or pressure.

Power Plants: Full port valves are crucial in steam, water, and gas control systems in power plants, as they allow for high flow rates while maintaining the necessary pressure levels.

Reduced Port Valves in Low-Flow, Cost-Effective Systems

While full port valves are ideal for high-flow systems, reduced port valves shine in applications where flow rates and pressure are less critical. These valves offer an economical solution for systems where a slight flow restriction does not negatively impact performance.

Residential Plumbing Systems: In homes and small buildings, reduced port valves are commonly used for regulating the flow of water, as they can easily manage the lower flow rates typically seen in these systems.

Irrigation Systems: In smaller agricultural or residential irrigation systems, reduced port valves provide a cost-effective way to control water flow with minimal need for high-pressure handling.

Small-Scale Industrial Processes: For processes that require low-flow or low-pressure fluid transport, reduced port valves are often sufficient to manage fluid flow without adding unnecessary complexity or cost.

Conclusion

The choice between a full or reduced orifice ball valve depends on the specific needs of your system while balancing performance and cost. The right valve choice depends on factors such as flow rate, pressure, fluid type, and budget, ensuring that the valve you select provides the best balance of efficiency and cost-effectiveness for your system.

FAQ

What is the main difference between a full port and a reduced port ball valve?

A full port valve has a bore that matches the pipe diameter, offering unrestricted flow, while a reduced port valve has a smaller bore, which creates flow restrictions and higher pressure drops.

When should I use a full port ball valve?

Use a full port valve in high-flow or high-pressure systems where maintaining maximum flow efficiency and minimal pressure loss is essential.

Are reduced port valves less expensive than full port valves?

Yes, reduced port valves are generally more affordable because of their smaller bore size and simpler design, making them a cost-effective choice for low-flow applications.

Do reduced port valves cause more pressure loss than full port valves?

Yes, reduced port valves cause greater pressure loss due to their smaller bore size, which restricts the flow more than a full port valve.

Which valve lasts longer, full port or reduced port?

Full port valves tend to last longer due to their lower flow resistance, resulting in less wear and tear on internal components. Reduced port valves may experience more wear due to higher flow friction.

Can I replace a reduced port valve with a full port valve?

Yes, you can replace a reduced port valve with a full port valve to improve flow efficiency, but make sure your system is designed to handle the increased flow and pressure capacity of a full port valve.