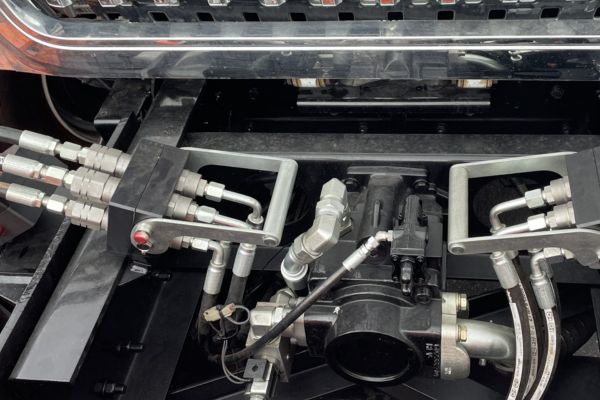

Compatibility in hydraulic systems is crucial because any mismatch between fittings can lead to significant issues, including fluid leaks, pressure drops, and even system failures. Common scenarios where fitting conversion becomes necessary include retrofitting older systems with new components, integrating equipment from different manufacturers, and addressing regional differences in fitting standards. These situations demand a thorough understanding of the conversion process to maintain system integrity.

Common Compatibility Issues

Ensuring compatibility in hydraulic fittings is critical for the safe and efficient operation of hydraulic systems. However, several common issues can arise when fittings are not properly matched. These issues often involve thread compatibility, pressure ratings, material compatibility, and discrepancies in seals and angles. Understanding these challenges is essential for preventing system failures and maintaining the integrity of hydraulic equipment.

Thread Compatibility

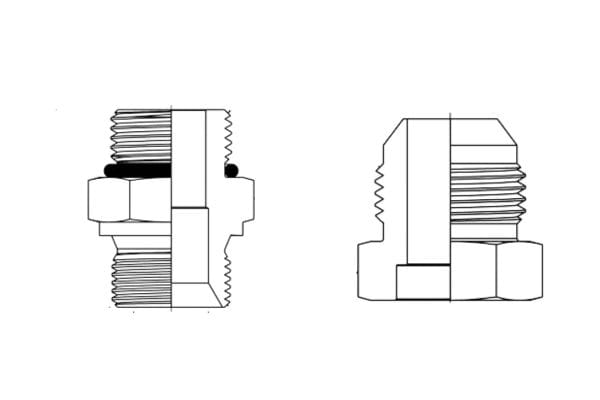

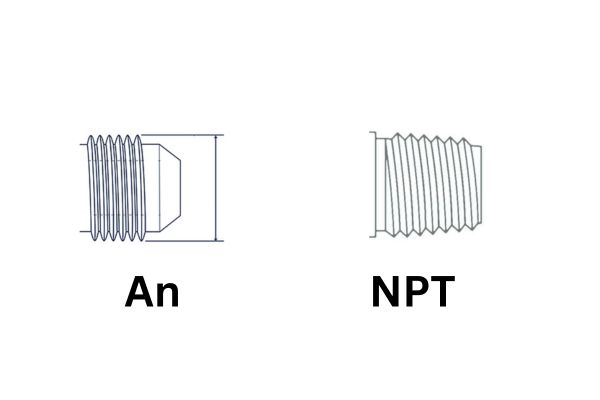

One of the most frequent compatibility issues in hydraulic systems involves thread types. Hydraulic fittings come with various thread standards, and mixing incompatible threads can lead to significant problems.

Issues Arising from Incompatible Thread Types: When different thread types are used together, they may not seal properly, leading to leaks and pressure drops. For example, a tapered thread fitting like NPT (National Pipe Tapered) may not seal correctly with a parallel thread fitting like BSPP (British Standard Pipe Parallel). The mismatch can result in threads not engaging fully, causing a loose connection that compromises the system’s integrity.

Examples of Thread Types That Are Often Mismatched:

NPT vs. BSPT: Both are tapered threads, but they have different thread angles and pitches, making them incompatible.

JIC vs. BSPP: JIC fittings have a 37-degree flare, while BSPP fittings typically have a flat face or a 30-degree seat, leading to a poor seal if mixed.

Metric vs. Imperial Threads: Using metric threads (e.g., DIN) with imperial threads (e.g., SAE) can result in a mismatch, as the thread profiles are different.

Pressure Rating Mismatches

Pressure rating is another critical factor in hydraulic fitting compatibility. Each fitting is designed to withstand specific pressure levels, and using fittings with incompatible pressure ratings can be dangerous.

The Importance of Matching Pressure Ratings: Hydraulic systems operate under high pressure, and fittings must be able to withstand these conditions. A fitting with a lower pressure rating than the system requires can fail under pressure, leading to leaks, burst fittings, or even catastrophic system failures.

Potential Dangers of Mismatched Pressure Ratings:

System Leaks: A fitting that cannot handle the system’s pressure may develop leaks, compromising the system’s efficiency and safety.

Component Failure: In extreme cases, the fitting may rupture, causing a sudden loss of pressure and potential damage to surrounding components.

Safety Hazards: High-pressure hydraulic systems pose significant safety risks, and failure caused by pressure mismatches can result in serious injury to personnel.

Material Incompatibility

Material compatibility is another crucial aspect of hydraulic fitting conversion. Using fittings made from incompatible materials can lead to problems such as galvanic corrosion, which occurs when dissimilar metals are used together in the presence of an electrolyte (e.g., hydraulic fluid).

Issues with Using Different Materials Together: When different metals, such as steel and aluminum, are used together in hydraulic fittings, galvanic corrosion can occur. This type of corrosion weakens the fittings, leading to leaks and potential system failures.

Case Studies/Examples of Material Incompatibility Problems:

Steel and Aluminum: A common example of galvanic corrosion occurs when steel fittings are used with aluminum components. Over time, the aluminum corrodes at an accelerated rate, leading to fitting failure.

Brass and Stainless Steel: While less common, issues can arise when brass fittings are used with stainless steel components, especially in corrosive environments.

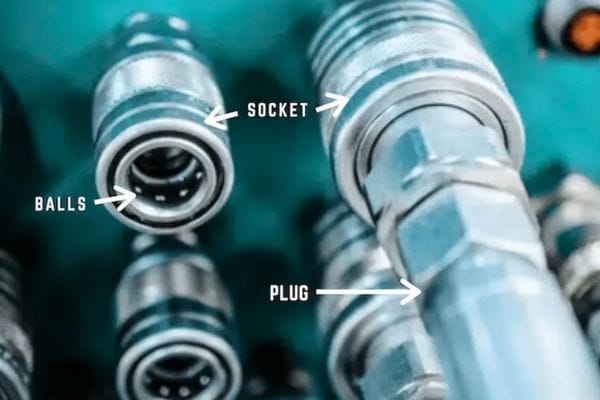

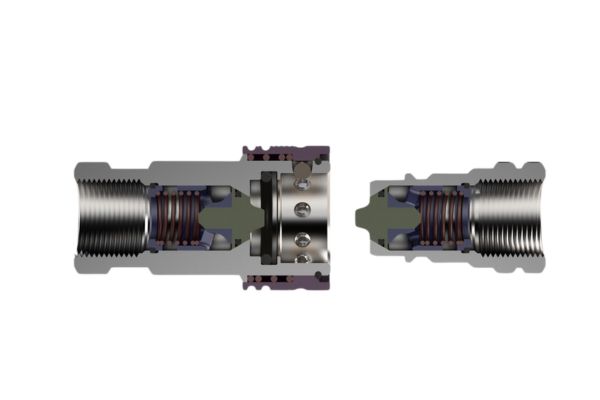

Seal and Angle Discrepancies

Seals play a vital role in ensuring that hydraulic fittings are leak-proof. However, discrepancies in sealing methods and seat angles can cause compatibility issues.

The Role of Sealing Methods in Fitting Compatibility: Different fittings use various sealing methods, such as O-rings, metal-to-metal contact, or threaded seals. Mixing fittings with different sealing methods can result in poor seals and leaks.

Problems That Arise from Incompatible Seat Angles and Seals:

JIC vs. BSPP Seals: JIC fittings have a 37-degree seat angle, while BSPP fittings typically have a 30-degree seat angle. Using these fittings together can result in a poor seal, leading to leaks.

ORFS vs. Flare Fittings: ORFS fittings use an O-ring face seal, while flare fittings rely on metal-to-metal contact. Attempting to seal these two types together can cause inadequate sealing and system leaks.

When and Why Conversion is Necessary

Hydraulic fitting conversion becomes essential in various situations to maintain the efficiency, safety, and reliability of hydraulic systems. Understanding when and why conversion is necessary can help prevent costly failures and ensure that your hydraulic systems operate at their best.

Scenarios Requiring Conversion

Retrofitting or Upgrading Existing Systems

Description: Over time, hydraulic systems may require upgrades or retrofitting to accommodate new technologies, enhance performance, or replace outdated components. These changes often necessitate the conversion of fittings to ensure compatibility with new parts.

Example: Upgrading a hydraulic system from low-pressure to high-pressure components may require replacing old fittings with new ones that can withstand higher pressures. Conversion is necessary to match the new fittings with the existing system’s components, ensuring a seamless transition.

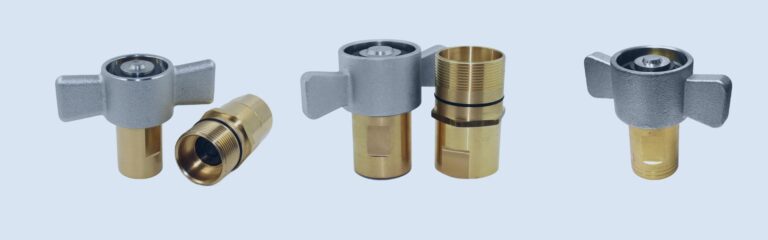

Integrating Components from Different Manufacturers

Description: In many industrial settings, hydraulic systems comprise components from various manufacturers. Each manufacturer may use different fitting standards, leading to compatibility challenges when these components are integrated into a single system.

Example: A hydraulic system that combines components from European and American manufacturers may require conversion to align the differing thread standards (e.g., BSP from Europe and NPT from the U.S.). Fitting conversion ensures that these components work together without leaks or pressure loss.

Cross-Region Compatibility Issues

Description: Hydraulic systems often need to operate across different regions with varying standards, such as metric in Europe and imperial in the U.S. Converting fittings is essential to bridge these differences and maintain system integrity.

Benefits of Hydraulic Fitting Conversion

Improved System Performance

Proper fitting conversion ensures that all components in a hydraulic system work together harmoniously, leading to optimal performance. By addressing compatibility issues, conversion helps maintain the system’s pressure levels, flow rates, and overall efficiency.

Extended Equipment Life

When fittings are properly converted, they help reduce wear and tear on hydraulic components. This leads to a longer lifespan for the equipment, as the system experiences fewer leaks, pressure drops, and mechanical failures.

Enhanced Safety and Reliability

Safety is a paramount concern in hydraulic systems, where high pressures and forces are at play. Converting fittings to ensure compatibility reduces the risk of leaks, bursts, and other failures that could lead to accidents or injuries.

Risks of Ignoring Conversion Needs

Potential for Leaks and System Failures

Failing to convert incompatible fittings can lead to poor seals, resulting in leaks that compromise the hydraulic system’s efficiency. Over time, these leaks can escalate into more severe system failures, causing unplanned downtime and costly repairs.

Long-Term Damage to Hydraulic Components

Incompatible fittings can cause excessive wear on hydraulic components, leading to accelerated degradation. Over time, this can result in the need for frequent repairs or replacements, increasing the overall cost of maintaining the system.

Increased Maintenance Costs

Ignoring the need for fitting conversion can lead to ongoing maintenance issues, as the system becomes more prone to leaks, failures, and inefficiencies. The cumulative effect of these issues is higher maintenance costs over the system’s lifetime.

Steps to Ensure a Successful Hydraulic Fitting Conversion

Successfully converting hydraulic fittings requires a comprehensive approach that addresses both the current state of the system and the steps necessary to ensure compatibility and performance.

Assessing the Current System

Before embarking on any conversion process, it’s crucial to conduct a thorough assessment of the existing hydraulic system. This step ensures that you understand the current setup and can identify any potential compatibility issues that need to be addressed.

Detailed Inspection of Existing Fittings and Components

Begin by visually inspecting all existing fittings, hoses, and components within the hydraulic system. Look for signs of wear, corrosion, or damage that might indicate underlying issues.

Document the types of fittings currently in use, noting their thread types, seat angles, pressure ratings, and material composition. This information will be essential when selecting compatible conversion fittings.

Pay close attention to areas where leaks have occurred or where fittings have been replaced frequently. These spots often highlight areas of incompatibility or improper installation.

Identifying Specific Compatibility Issues

Cross-check the existing fittings against the components they connect to, ensuring that threads, seat angles, and materials are compatible. Mismatches in these areas can lead to leaks, pressure drops, or component failure.

Consider the operating conditions of the system, such as pressure, temperature, and fluid type. These factors can affect the performance of certain fittings, especially if they are not designed for the specific environment in which they are used.

Identify any regions within the system where different standards (e.g., metric vs. imperial) are used, as these will require special attention during the conversion process.

Choosing the Right Conversion Fittings

Once you’ve assessed the current system and identified compatibility issues, the next step is to select the appropriate conversion fittings.

How to Select Fittings That Match System Requirements

Choose fittings that match the system’s operating pressure and temperature ratings. Ensure that the selected fittings can handle the highest pressure and temperature that the system will experience during operation.

Consider the material of the conversion fittings. For example, if the system operates in a corrosive environment, stainless steel fittings may be necessary to prevent corrosion and ensure long-term durability.

Ensure that the thread types of the conversion fittings are compatible with the existing components. For instance, if the system uses BSP threads, you should select conversion fittings with matching BSP threads or appropriate adapters.

Importance of Consulting Technical Documentation and Experts

Always consult the technical documentation provided by the manufacturers of the fittings and components. This documentation typically includes detailed information about thread types, pressure ratings, and material compatibility.

If you are unsure about the compatibility of certain fittings, seek advice from industry experts or the manufacturers’ technical support teams. Expert consultation can prevent costly mistakes and ensure that the conversion process is done correctly.

Use online tools and calculators provided by manufacturers to help determine the correct fittings for your system. These tools can simplify the selection process by matching system requirements with available fittings.

Ensuring Proper Installation

Proper installation of conversion fittings is critical to ensuring that the converted system operates without leaks or other issues. Following best practices during installation can help avoid common pitfalls.

Best Practices for Installing Conversion Fittings

Before installation, clean all fittings and components thoroughly to remove any debris or contaminants that could interfere with the seal. Ensure that the threads are clean and free from damage.

Apply the appropriate thread sealant or lubricant to the threads, as recommended by the manufacturer. This step helps to prevent leaks and ensures a secure connection between fittings.

Use the correct tools and torque specifications during installation. Over-tightening or under-tightening fittings can lead to leaks or damage to the components. Refer to the manufacturer’s guidelines for the proper torque settings.

Common Installation Mistakes to Avoid

Avoid cross-threading during installation, as this can damage the threads and lead to a poor seal. Start threading the fittings by hand to ensure proper alignment before using tools.

Do not mix thread types (e.g., NPT with BSP) unless a specific adapter is used. Mismatched threads will not seal properly and can result in leaks or component failure.

Ensure that all seals, such as O-rings, are correctly positioned and not damaged during installation. A damaged seal can cause leaks and reduce the efficiency of the system.

Testing and Verification

After installing the conversion fittings, it’s essential to test the system to ensure that the conversion has been successful. Testing and verification help to identify any issues before the system is put into full operation.

Steps to Test the System After Conversion

Perform a pressure test on the system at the maximum operating pressure to check for leaks or weaknesses in the fittings. Monitor the system for any signs of pressure loss or fluid leaks during the test.

Run the system under normal operating conditions and observe the performance of the converted fittings. Ensure that there are no abnormal noises, vibrations, or fluctuations in pressure that could indicate a problem.

Check all fittings and connections for leaks immediately after the system is turned off. Tighten any connections as necessary and re-test if any leaks are found.

How to Verify That the Conversion Has Resolved Compatibility Issues

Compare the system’s performance before and after the conversion. Improved performance, reduced maintenance needs, and the absence of leaks are indicators that the conversion was successful.

Inspect the converted fittings after a period of operation to ensure that they are still secure and functioning as expected. If any issues are identified, they should be addressed immediately to prevent further problems.

Document the results of the testing and verification process, including any adjustments made during testing. This documentation can be useful for future maintenance and troubleshooting.

Ongoing Monitoring and Maintenance

Even after a successful conversion, ongoing monitoring, and maintenance are essential to ensure the long-term reliability and efficiency of the hydraulic system. Regular checks can help detect and address issues before they lead to significant problems.

Importance of Regular Checks and Maintenance Post-Conversion

Schedule regular inspections of the hydraulic system, focusing on the converted fittings and connections. Look for signs of wear, corrosion, or leaks that may develop over time.

Perform routine maintenance on the system, including replacing worn seals, tightening loose fittings, and cleaning components. Regular maintenance helps to prevent minor issues from escalating into major failures.

Keep detailed records of all maintenance activities, including any issues detected and the actions taken to resolve them. This information can be invaluable for diagnosing problems and planning future maintenance.

Signs That Further Adjustments May Be Needed

If you notice a decline in system performance, such as reduced pressure or flow rate, it may indicate that further adjustments are needed. Check the converted fittings and connections for potential issues.

Unusual noises, vibrations, or fluid discoloration can also signal that something is wrong with the system. Investigate these signs promptly to identify and address the underlying cause.

If the system requires frequent maintenance or experiences recurring issues, it may be necessary to re-evaluate the conversion fittings and consider alternative solutions.

Conclusion

In conclusion, addressing hydraulic fitting compatibility issues through proper conversion is not just a short-term fix—it is a long-term investment in the safety, efficiency, and reliability of your hydraulic systems. Prioritizing these factors will help you maintain system integrity, reduce downtime, and ultimately save on costs related to repairs and maintenance. By being proactive and thorough in your approach to hydraulic fitting conversion, you can ensure that your systems continue to perform optimally for years to come.

FAQ

What is hydraulic fitting conversion?

Hydraulic fitting conversion involves adapting or replacing fittings in a hydraulic system to ensure compatibility between different components, often due to varying thread types, pressure ratings, or material standards.

When is hydraulic fitting conversion necessary?

Conversion is necessary when retrofitting or upgrading systems, integrating components from different manufacturers, or addressing cross-region compatibility issues.

How do I know if my hydraulic fittings need to be converted?

You may need to convert fittings if you encounter leaks or pressure drops, or if your system uses components with mismatched thread types, materials, or pressure ratings.

What are the risks of not converting incompatible hydraulic fittings?

Ignoring the need for conversion can lead to leaks, system failures, long-term damage to components, and increased maintenance costs.

How do I choose the right conversion fittings?

Select fittings that match your system’s thread types, pressure ratings, and material requirements. Consulting technical documentation or experts can help ensure compatibility.

What should I do after converting hydraulic fittings?

After conversion, thoroughly test the system for leaks and performance issues, and regularly monitor and maintain the fittings to ensure long-term reliability.