Maintaining hydraulic hoses comes with several challenges. Some of the most common issues include hose wear due to abrasion, improper installation, incorrect hose routing, and contamination from foreign particles. These challenges, if not addressed in a timely manner, can lead to hose failure, system downtime, and even safety hazards. Inconsistent or neglected maintenance practices often exacerbate these problems, resulting in costly repairs and operational inefficiencies.

Understanding Hydraulic Hose Maintenance Challenges

Hydraulic hoses are essential components in fluid power systems, but they often face several challenges that can lead to reduced efficiency, system failure, and increased maintenance costs. Understanding these issues is the first step toward effective hydraulic hose maintenance.

Frequent Maintenance Issues

Hose Wear and Tear Due to Usage and External Factors

Hydraulic hoses are subjected to a variety of conditions that can cause deterioration over time. Abrasion, exposure to harsh chemicals, high pressure, extreme temperatures, and UV light are all external factors that contribute to hose wear and tear. Constant bending and flexing during operation also create stress points, which can weaken the hose structure. Over time, this results in cracks, splits, or even hose ruptures, ultimately leading to system failure if not addressed through regular maintenance.

Fluid Contamination Leads to Damage and Reduced Efficiency

Fluid contamination is a major issue that compromises hydraulic hose performance. Dirt, debris, metal particles, and moisture can enter the hydraulic system and cause internal damage to hoses. Contaminated hydraulic fluid leads to abrasive wear inside the hose, clogging the system, reducing efficiency, and degrading hose materials. Over time, this can result in costly breakdowns and repairs, as the system struggles to maintain the necessary pressure and flow.

Improper Installation or Hose Routing

Incorrect hose installation or poor routing is another frequent issue in hydraulic hose maintenance. If hoses are installed with improper bends or are too tightly coiled, they can experience excessive stress and premature failure. Misalignment between hoses and fittings or incorrect hose length can create unnecessary tension, leading to leaks, reduced system efficiency, and ultimately, hose failure. Additionally, hoses installed in areas with sharp edges or subjected to excessive vibration are more likely to suffer damage.

Consequences of Poor Maintenance

Increased Downtime and Repair Costs

When hydraulic hoses are not properly maintained, they are more likely to fail unexpectedly. Unplanned downtime due to hose failure can significantly disrupt operations, delaying production and increasing operational costs. Emergency repairs are not only time-consuming but often more expensive than preventive maintenance. Moreover, frequent breakdowns may require the replacement of other parts within the system, further driving up costs.

Safety Hazards and Potential Environmental Damage Due to Leaks

Hydraulic hose failures can pose serious safety risks. A hose rupture can release high-pressure fluid, which can cause severe injuries to nearby workers. Additionally, leaks from damaged hoses can lead to environmental contamination, especially if the hydraulic fluid spills into water sources or sensitive ecosystems. The financial penalties for environmental cleanup and regulatory violations can be substantial, not to mention the potential damage to a company’s reputation.

Premature Hose Failure Affecting Overall System Performance

Hose failure doesn’t just affect the hose itself—it impacts the overall hydraulic system. Leaks or loss of pressure can reduce the efficiency of machinery, leading to poor performance and reduced productivity. In some cases, a single hose failure can cause other system components to overcompensate, increasing wear and tear on the entire system. As a result, the overall lifespan of the hydraulic equipment may be shortened.

Why Regular Maintenance is Often Neglected

Lack of Awareness or Trained Staff

One of the key reasons regular hydraulic hose maintenance is often neglected is a lack of awareness or training. Many operators and maintenance personnel may not fully understand the importance of inspecting hoses regularly or might not know the signs of impending hose failure. Additionally, some businesses may not have personnel specifically trained in hydraulic system maintenance, leading to oversight or improper maintenance practices.

Over-Reliance on Reactive Maintenance Instead of Preventive Measures

Many companies adopt a reactive approach to maintenance, only addressing hydraulic hose issues after a failure occurs. This reactive mindset often stems from a desire to reduce upfront costs. However, waiting until a hose fails to take action is short-sighted, as it often results in more expensive emergency repairs, unplanned downtime, and the need for replacement components. Preventive maintenance, although requiring an initial investment of time and resources, is far more cost-effective in the long run.

Key Strategies for Effective Hydraulic Hose Maintenance

Implementing key strategies for hydraulic hose maintenance is essential to reduce downtime, extend hose lifespan, and avoid costly repairs. The following strategies focus on preventive maintenance, proper hose selection, correct installation techniques, regular inspections, and proper storage to ensure the long-term efficiency of hydraulic systems.

Preventive Maintenance Programs

Importance of Setting Up a Preventive Maintenance Schedule

Preventive maintenance is the cornerstone of an effective hydraulic system management plan. Regular maintenance not only extends the lifespan of hoses but also reduces the likelihood of unexpected failures, which can lead to costly downtime. A well-designed preventive maintenance schedule allows businesses to detect potential issues early, preventing minor problems from escalating into major failures. By establishing routine checks, hoses can be replaced before they reach a critical wear stage, ensuring continued system performance.

Steps to Establish a Routine Maintenance Plan

To establish an effective routine maintenance plan, businesses need to:

Inventory and Track Hose Lifespan: Maintain records of all hoses, including their installation date, usage conditions, and expected lifespan. This allows for the timely replacement of aging hoses.

Set Inspection Intervals: Regularly inspect hoses based on their usage intensity, typically ranging from every few months to annually.

Assign Trained Personnel: Ensure that only trained staff are responsible for carrying out hose inspections and maintenance to detect early signs of failure.

Develop a Checklist: Create a standardized checklist for maintenance tasks, including inspecting for leaks, checking for wear, and monitoring pressure ratings.

Using Technology Such as IoT Sensors for Predictive Maintenance

Advances in technology now enable the use of IoT sensors for predictive maintenance. These sensors can monitor hose pressure, temperature, and overall performance in real time, providing early warnings when parameters deviate from safe limits. Predictive maintenance, as opposed to traditional time-based approaches, allows businesses to address maintenance needs before a failure occurs, maximizing equipment uptime and reducing unexpected breakdowns.

Proper Hose Selection

How Selecting the Right Hose Type for the Application Can Prevent Maintenance Issues

Choosing the right hydraulic hose for a specific application is critical for avoiding maintenance issues. Selecting an inadequate hose can lead to early wear, overheating, or even catastrophic failure. When selecting a hose, factors such as pressure rating, temperature, compatibility with hydraulic fluids, and environmental exposure need to be carefully considered.

Overview of Industry Standards (SAE, ISO) and How to Choose the Correct Hose

Hydraulic hoses are manufactured according to various industry standards, including SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization). These standards help ensure consistency in hose performance and safety. For example:

SAE 100R standards define different types of hoses based on pressure and material.

ISO 18752 classifies hoses based on their pressure rating, from low to high-pressure hoses. Understanding these standards helps businesses select hoses that meet the specific requirements of their hydraulic system, ensuring long-term reliability.

Importance of Understanding Hose Pressure Ratings, Temperature Limits, and Fluid Compatibility

When selecting a hydraulic hose, it’s essential to consider three key factors:

Pressure Ratings: Ensure that the hose can handle the system’s operating pressure with a suitable safety margin. Operating a hose beyond its pressure rating can lead to sudden failure.

Temperature Limits: Hoses have temperature limits, both for the fluid they carry and their external environment. Exceeding these limits can degrade the hose material, leading to cracks or blistering.

Fluid Compatibility: The hydraulic fluid used in the system must be compatible with the hose material. Using incompatible fluids can lead to internal corrosion, swelling, or degradation of the hose lining.

Ensuring Correct Hose Installation

Proper Techniques for Hydraulic Hose Installation

Correct installation is crucial for hydraulic hose longevity. Improper installation can cause undue stress on the hose, leading to premature failure. Proper installation involves using the correct length of the hose, ensuring proper alignment between the hose and fittings, and allowing for adequate hose movement during operation to avoid over-stressing the hose.

Avoiding Common Mistakes Like Twisting or Over-Tightening Fittings

Two common mistakes in hose installation are twisting the hose and over-tightening fittings. Twisting can cause internal strain, reducing the hose’s capacity to handle pressure and increasing wear. Over-tightening fittings, on the other hand, can damage the hose end, causing leaks and reducing the overall effectiveness of the hose. Proper training and adherence to manufacturer guidelines are necessary to avoid these pitfalls.

Importance of Correct Hose Routing and Bend Radius

Hose routing is an essential aspect of installation. Improper routing can lead to abrasion, excessive bending, or kinking, which can significantly reduce the hose’s service life. When routing hoses, always follow the manufacturer’s recommended bend radius, ensuring the hose isn’t bent too tightly. A tighter bend than specified can weaken the hose’s structure, leading to cracks or rupture under pressure.

Regular Hose Inspections

How to Conduct Visual and Physical Inspections

Regular inspections are the backbone of preventive maintenance. Visual and physical inspections should be conducted to check for signs of wear, damage, or leaks. Key inspection points include:

Surface Condition: Check for abrasions, cuts, or cracking on the hose exterior.

Fittings: Ensure that fittings are securely attached and free from leaks.

Hose Flexibility: Assess the flexibility of the hose—any stiffness or hardening can be a sign of wear.

Signs of Wear and Damage to Watch For (Abrasions, Leaks, Blisters, etc.)

Certain signs are early indicators of hydraulic hose failure, including:

Abrasions: Worn areas on the hose surface, especially if they penetrate the reinforcement layer.

Leaks: Even small leaks can indicate a significant issue with the hose or its fittings.

Blisters or Bulges: These are signs that the internal hose layers may be failing, typically due to pressure or chemical exposure.

Cracking: Surface cracks are an indicator that the hose material has deteriorated, usually due to heat, UV exposure, or over-flexing.

Tools and Technologies for Efficient Hose Diagnostics

Using advanced diagnostic tools such as pressure gauges, ultrasonic leak detectors, and thermography cameras can enhance the accuracy and effectiveness of hose inspections. These tools allow maintenance teams to identify hidden weaknesses, monitor temperature changes, and detect internal issues that may not be visible during a standard inspection.

Proper Hose Storage Practices

Best Practices for Storing Hoses to Prevent Damage

Improper storage can significantly affect the performance and lifespan of hydraulic hoses. When storing hoses, they should be kept away from direct sunlight, sources of heat, and chemicals. It is also important to avoid stacking hoses too tightly, as this can cause flattening or deformation of the hose structure.

How Improper Storage Can Affect the Hose’s Lifespan and Performance

If hydraulic hoses are stored in conditions that expose them to moisture, UV rays, or excessive heat, their material may degrade over time, even before they are put into service. Improper storage can also lead to kinks, crushing, or internal wear, making the hose less reliable when it is eventually installed.

Recommended Conditions for Storing Hydraulic Hoses

For optimal storage, hoses should be kept in a cool, dry environment with consistent temperatures. Avoid exposure to:

UV Light: Store hoses in opaque containers or areas that block sunlight to prevent material degradation.

Moisture: Excess humidity can lead to internal corrosion or contamination in the hose.

Extreme Temperatures: Both high and low temperatures can cause hoses to harden or crack over time. Aim to store hoses within the manufacturer’s recommended temperature range.

Best Practices to Extend Hydraulic Hose Lifespan

Hydraulic hoses are a vital component of many industrial systems, and extending their lifespan is essential to reducing downtime, avoiding costly repairs, and maintaining system efficiency. Implementing best practices such as protecting hoses from external damage, reducing stress on hoses, using high-quality fittings, and ensuring that personnel are properly trained can significantly increase the longevity of hydraulic hoses.

Protecting Hoses from External Damage

Using Protective Sleeves or Covers to Reduce Abrasions

Abrasions are one of the most common causes of hydraulic hose failure, especially in environments where hoses are exposed to rough surfaces or constant friction. Using protective sleeves or spiral wraps around hoses can help shield them from external damage. These sleeves are made from durable materials designed to resist abrasion, thereby protecting the outer layers of the hose. By adding this extra layer of protection, the hose is less likely to experience wear and tear that can lead to leaks or rupture over time.

Shielding Hoses from Heat and Corrosive Chemicals

Heat and exposure to corrosive chemicals can cause significant damage to hydraulic hoses, leading to material degradation, cracks, or blistering. In environments where hoses are exposed to high temperatures, it is important to use heat-resistant hoses or add heat shields to protect them. Similarly, in chemical processing plants, hoses should be shielded from corrosive chemicals by using hoses made from compatible materials and adding barriers between the hose and chemical sources. Proper protection from external environmental factors is critical to preserving the integrity of hydraulic hoses.

Reducing Hose Stress

Avoiding Tight Bends or Over-Extension of Hoses During Use

One of the most effective ways to extend the life of hydraulic hoses is to avoid placing unnecessary stress on them. Tight bends or sharp turns can cause kinks or restrict the flow of hydraulic fluid, leading to pressure buildup and eventual hose failure. Ensuring that hoses are installed with the proper bend radius, as recommended by the manufacturer, is crucial. Hoses should never be bent more tightly than specified, as this places excessive stress on the hose structure.

Importance of Selecting the Right Hose Length and Fitting Configurations

Using hoses that are too short or too long can also lead to issues. Hoses that are too short may become over-extended during operation, leading to strain at the connection points, while excessively long hoses may become entangled or more prone to kinks. Selecting the correct hose length ensures that hoses can flex and move within their intended range without experiencing stress. Additionally, choosing the appropriate fitting configurations reduces strain on the hose, allowing for smoother operation and reducing the risk of leaks or failures.

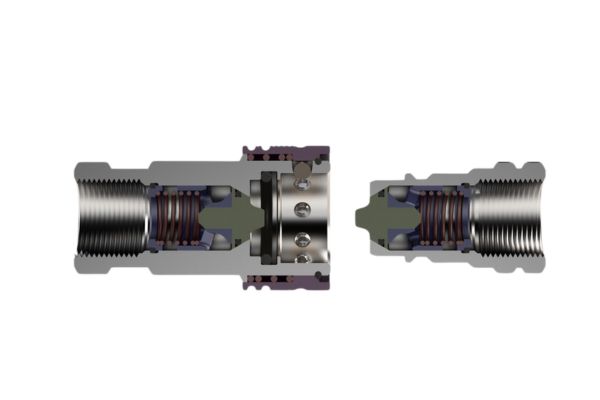

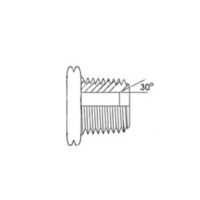

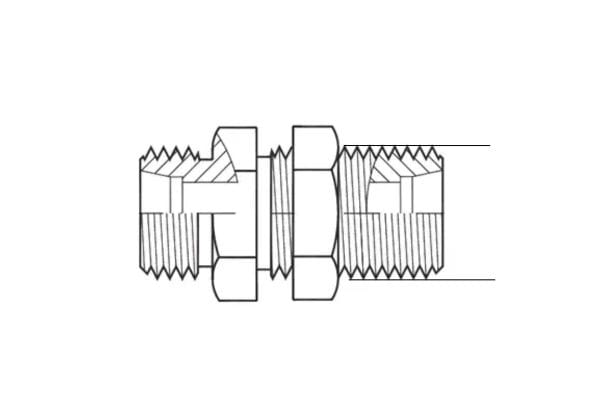

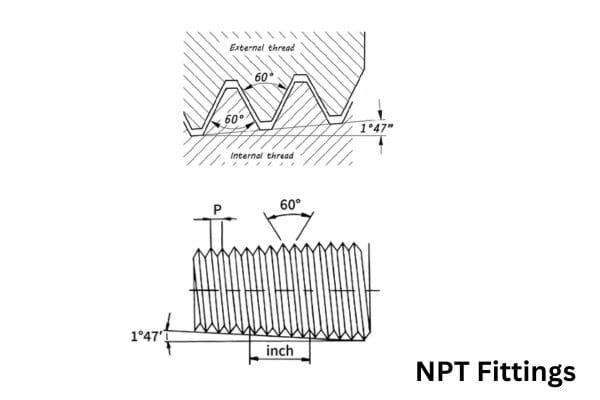

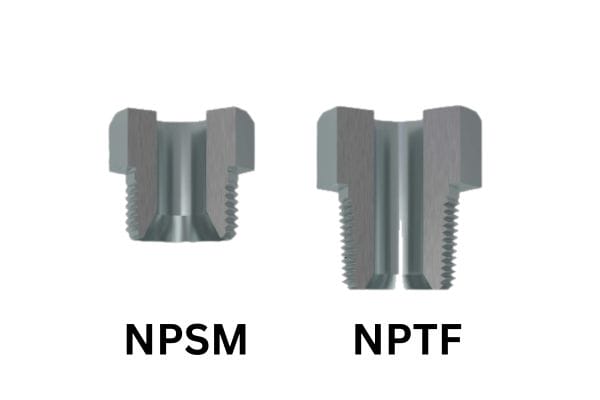

Using Quality Fittings and Adapters

The Role of Fittings in Hydraulic Hose Maintenance

Fittings play a crucial role in hydraulic hose performance and longevity. Poor-quality or incompatible fittings can lead to leaks, pressure drops, or even catastrophic hose failure. Using high-quality, certified fittings ensures that the hose connections remain secure, reducing the risk of leaks and extending the lifespan of the hose assembly. Moreover, proper fitting selection reduces the chance of issues such as cross-threading, which can damage both the hose and the fitting.

Ensuring Compatibility Between Hoses and Fittings to Avoid Leaks

One of the most important considerations in hydraulic hose maintenance is ensuring that hoses and fittings are compatible. Different types of hoses and fittings are designed for specific pressure ratings, fluid types, and temperature ranges. Using incompatible components can lead to improper sealing, resulting in leaks, pressure loss, and damage to the hose system. Always ensure that the fittings and adapters used are designed to work with the specific hose type and application to prevent maintenance issues down the line.

Conclusion

Proactive maintenance is critical for achieving long-term system efficiency and reliability. By addressing issues before they escalate, businesses can reduce downtime, minimize repair costs, and extend the life of their hydraulic systems. A commitment to regular inspections, proper installation, and the use of high-quality components will not only improve system performance but also contribute to overall safety and environmental responsibility.

FAQ

How often should I inspect my hydraulic hoses?

It’s recommended to inspect hydraulic hoses every few months, depending on usage intensity, or as part of a regular preventive maintenance schedule.

What are the common signs of hydraulic hose wear?

Common signs include abrasions, cracks, leaks, blisters, bulges, and reduced flexibility.

How can I prevent hydraulic hose leaks?

Ensure proper installation, use high-quality fittings, and regularly inspect hoses for wear and damage to prevent leaks.

What should I do if my hydraulic hose shows signs of damage?

If a hose shows signs of damage, replace it immediately to prevent failure and ensure system safety.

How do I choose the right hydraulic hose for my application?

Consider factors such as pressure rating, temperature limits, fluid compatibility, and the specific requirements of your system.

Why is proper hose storage important?

Proper storage prevents damage from environmental factors such as UV exposure, moisture, and temperature fluctuations, extending hose lifespan.