JIC vs NPT Fittings: The Ultimate Guide

Hydraulic systems are the lifeblood of many industrial applications, from manufacturing to construction and beyond. At the heart of these systems are hydraulic fittings, which serve as the critical links ensuring the safe and efficient flow of hydraulic fluid. This comprehensive guide aims to provide an in-depth understanding of JIC and NPT hydraulic fittings—two of the most commonly used types of hydraulic fittings. From their origins and design features to installation procedures and maintenance tips, this guide covers everything you need to know to make informed decisions for your hydraulic needs.

What is a Hydraulic Fitting?

Hydraulic fittings are critical components in a hydraulic system, serving as connections between hoses, pipes, and other components. These fittings ensure the safe flow of hydraulic fluid, which is critical to the overall function of the system.

Understanding JIC Fittings

Origins and Standards

JIC (Joint Industry Council) fittings have their roots in AN (Army-Navy) fittings developed during World War II for aviation applications. The JIC standard was later established to simplify manufacturing processes and reduce costs. These fittings conform to SAE J514 and ISO 8434-2 standards, making them a reliable choice for various industries.

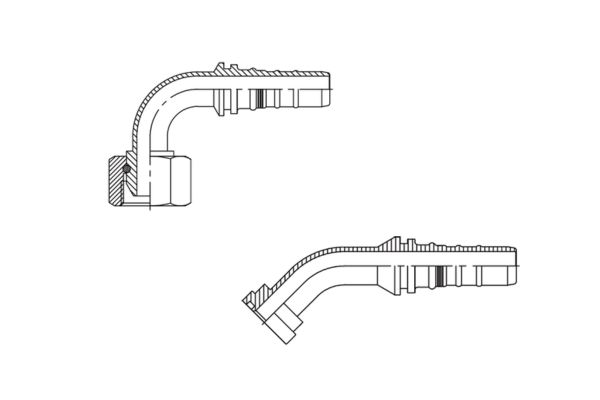

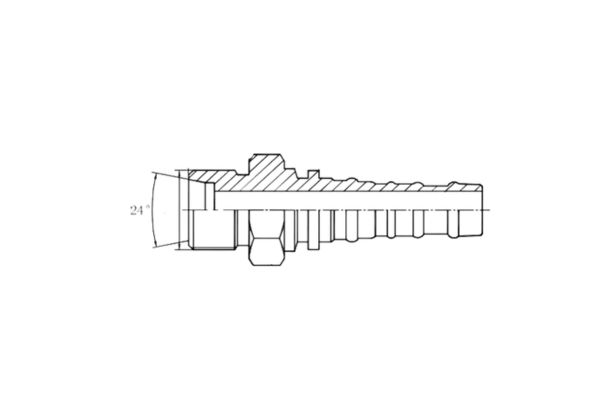

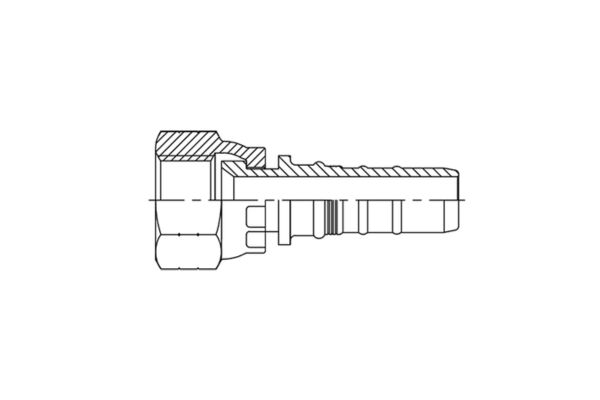

Design Features

● 37-degree flare: The hallmark of JIC fittings is the 37-degree flare, which provides a strong mechanical connection.

● Thread Size: JIC fittings come in various sizes, adhering to the 2A/2B thread fit standard.

● Sealing Method: These fittings employ a metal-to-metal sealing mechanism, eliminating the need for additional sealants.

Advantages

● High-Pressure Resistance: JIC fittings are designed to withstand high pressures, making them ideal for demanding hydraulic applications.

● Reusability: One of the standout features is their reusability, offering long-term value.

● Leak Resistance: The 37-degree flare design minimizes the risk of leaks, ensuring a secure connection.

Disadvantages

● Cost Considerations: While JIC fittings offer numerous advantages, they can be more expensive than other types of fittings.

● Limited Compatibility: These fittings are not universally compatible with other thread types, which may limit their application in some systems.

Dash | Thread | Threads Pre | Female Thread | Male Thread |

-2 | 5/16 | 24 | 6.7 | 7.9 |

-3 | 3/8 | 24 | 8.3 | 9.5 |

-4 | 7/16 | 20 | 9.9 | 11.1 |

-5 | 12 | 20 | 11.5 | 12.7 |

-6 | 9/16 | 18 | 12.7 | 14.3 |

8 | 3/4 | 16 | 17.5 | 19.1 |

-10 | 7/8 | 14 | 20.6 | 22.2 |

-12 | 1-1/16 | 12 | 24.6 | 27.0 |

-14 | 1-3/16 | 12 | 28.2 | 30.2 |

-16 | 1-5/16 | 12 | 31.4 | 33.3 |

-20 | 1-5/8 | 12 | 39.3 | 41.3 |

-24 | 1-7/8 | 12 | 45.6 | 47.6 |

-32 | 2-1/2 | 12 | 61.5 | 63.5 |

JIC hydraulic fittings size chart

Understanding NPT Fittings

● Origins and Standards

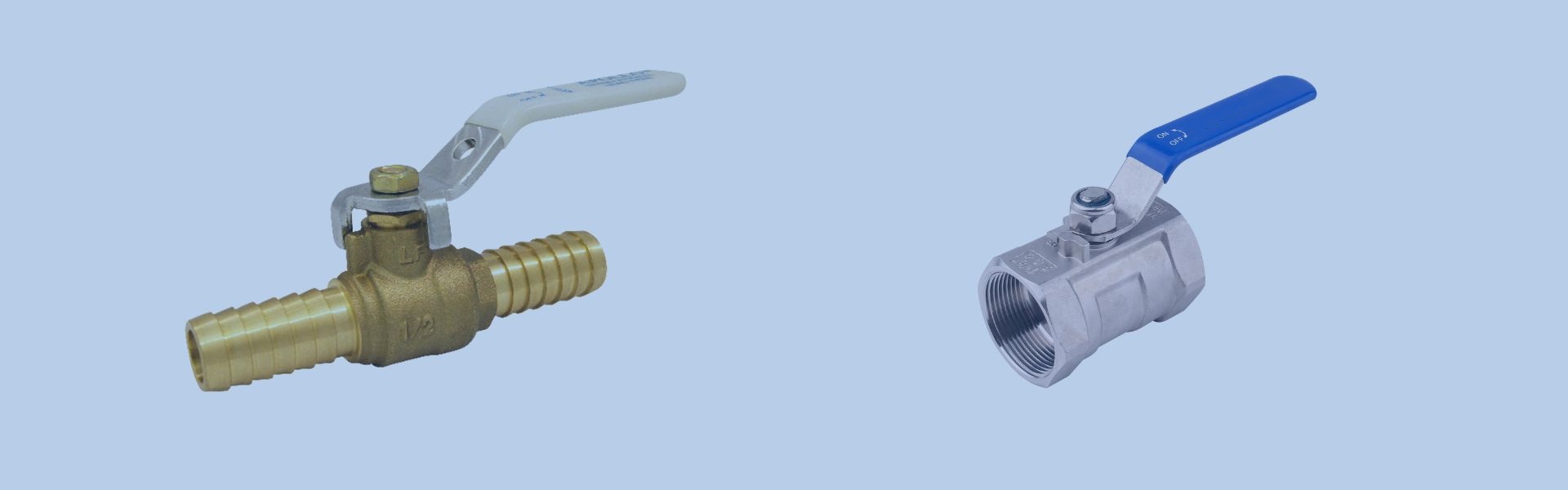

NPT, or National Pipe Thread Taper, is a standard that originated in North America and is widely used in various industries. Governed by the American National Standard for Tapered Pipe Threads (ANSI/ASME B1.20.1), NPT hydraulic fittings are designed for consistency, ensuring reliable and leak-free connections.

● Typical Applications

NPT hose fittings are commonly used in industries such as plumbing, HVAC, and pharmaceutical manufacturing. Their versatility extends to oil and gas, chemical processing, and water treatment systems.

● Design Features

Tapered Threads: The unique tapered design creates a tighter seal as the fitting is threaded deeper into the pipe.

Sealing Method: NPT pipe fittings usually require a thread sealant to ensure a leak-free connection.

Thread Size: NPT threads are standardized and measured according to ANSI/ASME B1.20.1, which specifies pitch diameter, major diameter, and minor diameter.

● Advantages

Versatility: NPT hydraulic fittings are suitable for a wide range of applications and industries.

Cost-effectiveness: These fittings are generally less expensive than other types, offering a cost-efficient solution.

Wide Availability: NPT adapter fittings are readily available in various sizes and materials, making them a convenient choice.

● Disadvantages

Risk of Over-tightening: The tapered design can lead to over-tightening, which may damage the threads.

Thread Sealant Required: Unlike some other types of fittings, NPT usually requires a thread sealant, adding an extra step to the installation process.

DASH | SIZE | THREAD | Male Thread | Female Thread |

02 | 1/8″ | 1/8-27 | 10.32 | 9.12 |

04 | 1/4″ | 1/4-18 | 13.89 | 11.90 |

06 | 3/8″ | 3/8- 18 | 17.06 | 15.08 |

08 | 1/2″ | 1/2-14 | 21.43 | 19.05 |

12 | 3/4″ | 3/4-14 | 26.98 | 24.20 |

16 | 1″ | 1-11.1/2 | 33.33 | 30.56 |

20 | 1-1/4″ | 1-1/4-11.1/2 | 42.46 | 38.89 |

24 | 1-1/2″ | 1-1/2-11.1/2 | 48.41 | 45.24 |

32 | 2″ | 2-11.1/2 | 60.32 | 57.15 |

NPT hydraulic fittings size chart

Comparison of JIC and NPT

Thread Type

JIC hydraulic fittings feature a 37-degree flare, while NPT pipe fittings have tapered threads. The former offers a metal-to-metal seal, whereas the latter relies on the taper to create a tight fit.

Sealing Mechanism

JIC’s 37-degree flare provides a robust mechanical seal, eliminating the need for additional sealants. On the other hand, NPT hose fittings usually require a thread sealant to ensure a leak-free connection.

Degree of Pressure Resistance

JIC fittings are designed to withstand high pressures, making them ideal for demanding hydraulic applications. hydraulic NPT fittings are versatile but may not offer the same level of pressure resistance as JIC fittings.

Cost Effectiveness

NPT fittings are generally more cost-effective and widely available. However, JIC fittings, while more expensive, offer long-term value due to their reusability and high-pressure resistance.

Which is Best?

The choice between JIC and NPT depends on various factors like application requirements, budget, and availability. JIC is often the go-to for high-pressure systems, while NPT is a versatile choice for less demanding applications.

Are JIC and NPT Fittings Interchangeable?

Discussion of Compatibility and Adapters

They are not interchangeable. JIC and NPT hydraulic fittings are very different in appearance and are fundamentally different in design and function; JIC fittings rely on a 37-degree flare for sealing, while NPT uses tapered threads. While there are adapters available to connect JIC fittings to NPT hydraulic fittings, these adapters are specialized parts and are not a standard feature of either fitting type.

Risks and Precautions

Thread Mismatch: Attempting to interchange JIC and NPT hydraulic fittings without an adapter can result in thread wear and leakage. The threads are not designed to match, and forcing them to do so can compromise the integrity of the hydraulic system.

Pressure resistance: JIC fittings are generally better suited for high-pressure applications, while NPT hydraulic fittings may not have the same pressure resistance. Using NPT pipe fittings in a high-pressure system designed for JICs can lead to failure.

Sealant requirements: NPT hydraulic fittings typically require the use of thread sealant. If you are converting from a JIC that does not require sealant, you will need to add this extra step to your process.

Cost: Adapters can be expensive and may make NPT hose fittings less cost-effective. In addition, using an adapter creates another potential point of failure in the system.

JIC and NPT Fitting Selection

Application Requirements

The first factor to consider is the specific needs of your hydraulic system. JIC fittings are generally better suited for high-pressure applications, while NPT hydraulic fittings are more versatile and can be used in a variety of settings. Understanding the pressure requirements, fluid type, and operating conditions is crucial for making an informed decision.

Budgetary Constraints

Cost is always a significant factor in any decision-making process. NPT adapters are generally more budget-friendly but may require additional components like thread sealants. JIC fittings, although more expensive upfront, offer long-term value due to their reusability and high-pressure resistance.

Component Availability

Lastly, consider the availability of the components you need. NPT pipe fittings are widely available and come in various materials and sizes. JIC fittings, while also available in different sizes, may not be as readily accessible, depending on your location and the specific requirements of your hydraulic system.

How to Install JIC and NPT Fittings

Tools Required

Adjustable wrench

Thread sealant (optional, but recommended for added safety)

Safety Precautions:

Always wear safety goggles to protect your eyes from any debris.

Use gloves to protect your hands.

Ensure the hydraulic system is depressurized to avoid sudden bursts of fluid.

JIC Fitting Step-by-Step Guide

Preparation: Before you begin, clean the work area to avoid contamination. Make sure you have all the necessary tools and parts on hand.

Thread inspection: Inspect the threads on the fitting and hose or pipe. Look for any signs of wear, corrosion, or damage that could affect the connection.

Insertion: Align the JIC fitting with the hose or pipe and insert carefully. Make sure it is properly aligned with the flare or base.

Tighten: Use an adjustable wrench to tighten the fitting until snug. Then tighten another quarter turn to ensure a secure connection.

NPT Fitting Step-by-Step Guide

Preparation: As with the JIC fittings, begin by cleaning the work area. Prepare all tools required for installation.

Thread Sealant: Apply thread sealant to the male threads of the NPT fitting. This is critical for a leak-tight seal.

Insertion: Carefully align the NPT fitting with the appropriate female threads. Insert the fitting, making sure it is inserted straight in to avoid cross-threading.

Tighten: Use an adjustable wrench to tighten the fitting. Because the NPT threads are tapered, be careful not to over-tighten or the threads may strip.

Maintenance Tips for JIC and NPT Hydraulic Fittings

Maintaining hydraulic fittings is just as important as selecting the correct fitting. Proper maintenance ensures longevity, efficiency, and safety. Below are some tips for keeping JIC and NPT adapters in top condition.

Leak Detection and Prevention

Periodic Inspection: Periodically check for signs of leakage around the fitting. Look for wet spots, drips, or puddles.

Pressure Test: Perform a pressure test to identify any weaknesses in the hydraulic system.

Sealant: For NPT fitting, consider reapplying thread sealant during maintenance checks to ensure a leak-free connection.

When to Replace Fittings

Visual Inspection: Look for signs of wear, corrosion, or damage. If there are any visible signs, the fitting should be replaced.

Performance Problems: Consider replacing fittings if you notice a drop in system performance, such as reduced pressure or fluid leaks.

Regular Maintenance: Replace fittings at specific intervals according to the manufacturer’s guidelines to ensure optimum performance.

Whether you’re dealing with high-pressure requirements or looking for a cost-effective, versatile solution, this guide provides all the information you need to navigate the complex landscape of hydraulic fittings. Armed with this knowledge, you can make choices that are not just good but optimal for your specific hydraulic needs.

FAQ

What are JIC fittings used for?

JIC fittings are commonly used in high-pressure hydraulic applications due to their 37-degree flare design, which offers a robust mechanical seal.

How do NPT differ from JIC?

NPT hydraulic fittings have tapered threads and usually require a thread sealant, whereas JIC fittings have a 37-degree flare and generally do not require additional sealants.

Can JIC and NPT be interchanged?

While there are adaptors that can connect JIC to NPT, it’s generally not advisable due to the risks involved, such as thread mismatch and varying pressure resistance.

How do I prevent leaks in NPT hydraulic fittings?

Applying a thread sealant to the male threads before insertion can help prevent leaks.

What tools are required for installing JIC and NPT fitting?

An adjustable wrench is essential for both, and thread sealant is usually required for NPT fitting.

How often should I inspect my hydraulic fittings?

Regular inspection intervals depend on the system’s usage and the manufacturer’s guidelines, but a monthly check is generally a good practice.

When should I replace my hydraulic fittings?

Replace fittings if you notice signs of wear, or corrosion, or if there are performance issues like reduced pressure or fluid leaks.

Are JIC fittings reusable?

Yes, one of the advantages of JIC fittings is their reusability, offering long-term value.

What safety precautions should I take when installing fittings?

Always wear safety goggles and gloves, and ensure the hydraulic system is depressurized before starting any installation or maintenance work.

Which is more cost-effective: JIC or NPT?

NPT pipe fittings are generally more budget-friendly, but JIC fittings offer long-term value due to their high-pressure resistance and reusability.

Why Choose Topa Fittings?

When it comes to hydraulic fittings, quality and reliability are paramount. That’s where Topa hydraulic fittings comes into play. Here’s why you should choose Topa JIC and NPT tube fittings for your hydraulic systems:

Unmatched Quality

Our fittings are manufactured to meet the highest industry standards. Whether it’s JIC’s 37-degree flare or NPT’s tapered threads, you can count on Topa for a leak-free, secure connection.

High-Pressure Resistance

Especially with our JIC fittings, you’ll find exceptional resistance to high pressures, making them ideal for demanding hydraulic applications.

Cost-Effectiveness

Our NPT hydraulic fittings offer a budget-friendly yet highly reliable option. Plus, our JIC fittings, while more expensive upfront, provide long-term value due to their durability and reusability.

Versatility

Whether you need fittings for high-pressure applications or something more versatile for various uses, Topa has you covered with both JIC and NPT options.

Easy Installation

Our fittings are designed for easy installation, reducing downtime and increasing efficiency. Plus, we offer all the necessary accessories like thread sealants for NPT pipe fittings.

Safety First

We prioritize your safety. Our fittings are rigorously tested to ensure they meet all safety standards, giving you peace of mind during installation and operation.

Expert Support

Our team of skilled professionals is always ready to assist you, whether you need help selecting the right fitting or troubleshooting an issue.

One-Stop Solution

From JIC to NPT, we offer a comprehensive range of hydraulic fittings, making Topa your one-stop solution for all your hydraulic needs.