Leaks in hydraulic systems can lead to significant operational inefficiencies and safety hazards. When fluid escapes from a system, it not only reduces the overall pressure and performance but can also cause system components to work harder to compensate for the lost fluid, leading to increased wear and tear.

Understanding Tubing and Swivel Nut Fittings

A. Types of Tubing and Fittings

Hydraulic systems utilize various types of tubing and fittings, each designed for specific applications and pressure requirements. Common types of tubing include:

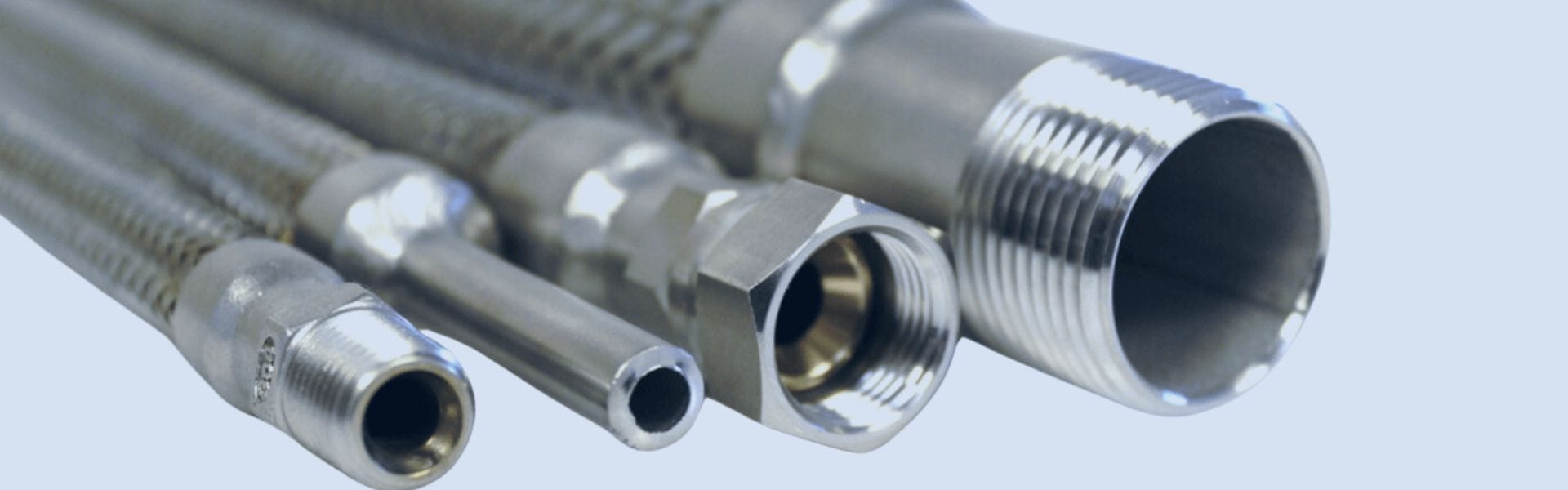

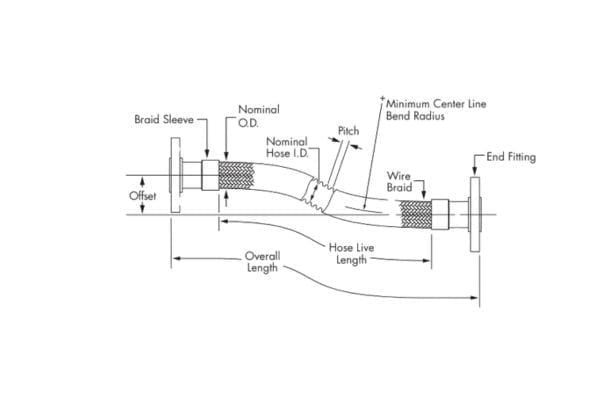

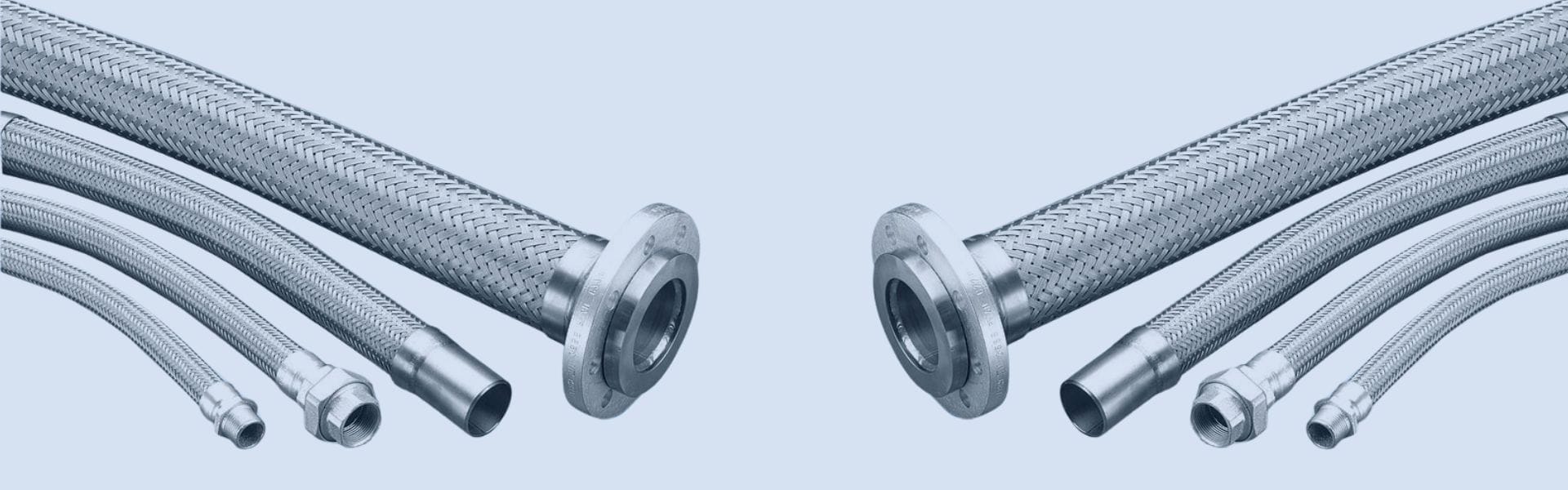

Seamless Tubing: Manufactured from solid round billets, seamless tubing is strong and resistant to high pressures. It’s often used in high-stress applications where integrity is crucial.

Welded Tubing: This type involves joining metal pieces together using welding techniques. While generally more cost-effective than seamless tubing, welded tubing may have lower pressure ratings due to potential weak spots at the welds.

Flexible Hoses: These are often used in applications requiring movement or vibration. Made from rubber or synthetic materials, flexible hoses can accommodate bends without compromising the flow of hydraulic fluid.

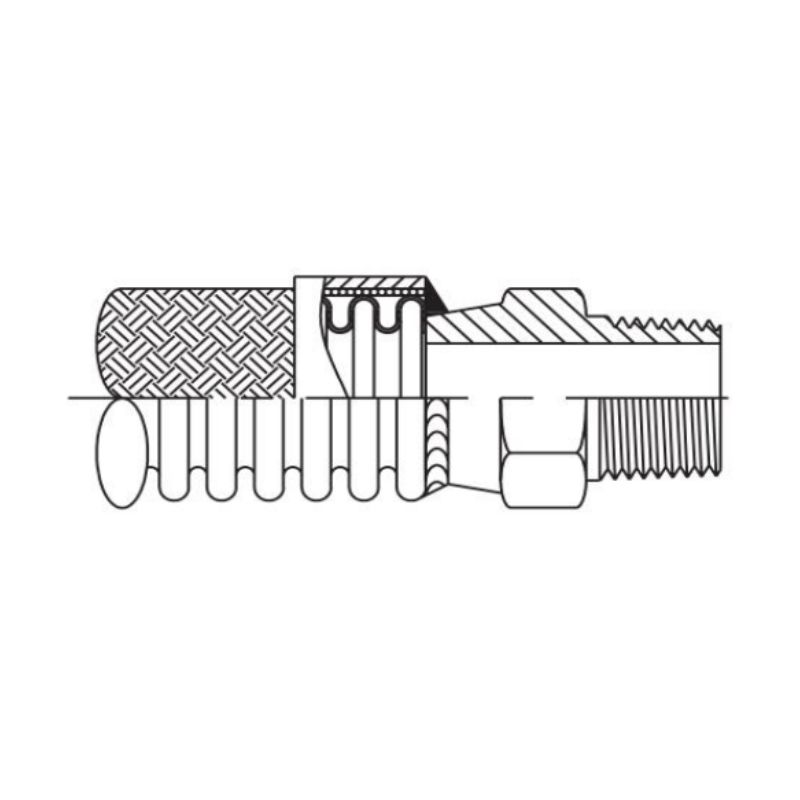

Swivel nuts come in various designs, such as an o-ring face seal (ORFS) and 37-degree flare fittings. ORFS fittings create a reliable seal using an o-ring and are less prone to leakage compared to traditional flared fittings. Flare fittings provide a metal-to-metal seal and are commonly used in high-pressure applications.

B. How Connections Work

Swivel nuts and tubing fittings function by creating a secure and leak-proof connection. The mechanics of these connections can be broken down as follows:

Alignment: Proper alignment of the tubing with the fitting is crucial. The tubing must fit snugly against the sealing surface of the fitting to avoid creating a gap where leaks can occur.

Compression: When the swivel nut is tightened, it compresses the tubing against the fitting, forcing the sealing surfaces together. This compression generates the necessary clamping force to maintain a tight seal.

Sealing Mechanism: In ORFS fittings, the o-ring is held in place by the fitting’s design, allowing for metal-to-metal contact outside the o-ring groove. This design helps maintain the o-ring’s integrity, reducing the risk of extrusion or damage during operation.

Understanding these mechanics is essential for ensuring that connections are assembled correctly, which directly impacts the reliability of the hydraulic system.

C. Common Applications

Tubing and swivel nut fittings are prevalent in numerous industries and applications, including:

Manufacturing: Hydraulic systems are integral to machinery such as presses, injection molding machines, and conveyors. Reliable tubing and fittings are crucial for maintaining consistent operation.

Construction: Hydraulic equipment like excavators, bulldozers, and cranes rely on these connections to ensure fluid transfer and functionality under demanding conditions.

Automotive: In automotive applications, hydraulic systems are used for power steering, brake systems, and lift mechanisms, all of which depend on high-quality tubing and fittings for performance and safety.

Oil and Gas: Hydraulic systems used in drilling, extraction, and processing rely on secure connections to prevent leaks in critical operations.

Identifying Leak Symptoms

A. Visual Indicators of Leaks

Identifying leaks in hydraulic systems often begins with observing visual indicators. Here are some common signs to look for:

Fluid Pooling: The accumulation of hydraulic fluid beneath connections or hoses is one of the most straightforward signs of a leak. The presence of fluid can indicate a slow but persistent leak that may worsen over time.

Discoloration: Fluid leaks can lead to discoloration on surfaces surrounding the tubing or fittings. This may manifest as dark spots or streaks on the tubing, fittings, or the surface beneath. Discoloration can also occur due to the degradation of materials, indicating potential leaks or failures.

Corrosion: Prolonged exposure to hydraulic fluids can cause corrosion on metal fittings and tubing. Signs of corrosion, such as rust or flaking, not only suggest a leak but can also indicate the need for immediate replacement to prevent further damage.

Staining on Surrounding Surfaces: Leaked fluids may stain surrounding materials, such as hoses, mounting brackets, or the ground. These stains can serve as visual cues for leak detection and may vary in color depending on the type of hydraulic fluid used.

B. Auditory Signs

In addition to visual cues, auditory signs can help diagnose leaks in hydraulic systems. Some common sounds to listen for include:

Hissing: A hissing sound often indicates pressurized fluid escaping from a small opening. This sound can be more pronounced during system operation and may help pinpoint the leak’s location.

Bubbling: If air is being drawn into the hydraulic system due to a leak, it may create a bubbling sound as the fluid circulates. This can signal that the integrity of the seal is compromised, leading to potential air contamination in the system.

Whistling or Squealing: These sounds can occur if hydraulic fluid is forced through a restricted area due to a leak. The turbulence created by the leak can lead to unusual noises, signaling that the system may be under stress.

Change in Normal Operational Sounds: Any deviation from the typical operational sounds of the hydraulic system can indicate a problem. If the system is noisier than usual or sounds erratic, it could be a symptom of a leak affecting performance.

C. Performance Issues

Leaks can significantly impact the performance of hydraulic systems, leading to various operational challenges:

Pressure Instability: Leaks can cause fluctuations in hydraulic pressure, resulting in inconsistent performance. Pressure drops can affect the system’s ability to maintain adequate force or speed, which may compromise the efficiency of hydraulic machinery.

Decreased Efficiency: When leaks occur, the hydraulic system may need to work harder to maintain performance levels. This can lead to increased energy consumption and wear on system components, ultimately shortening their lifespan.

Increased Maintenance Needs: Leaks often lead to more frequent maintenance and inspections, which can be costly and time-consuming. If left unaddressed, they can escalate into more severe issues that require extensive repairs.

Potential for Catastrophic Failure: In severe cases, leaks can lead to complete system failure, resulting in costly downtime and potential safety hazards. This emphasizes the importance of early detection and prompt repairs to prevent minor leaks from escalating into major issues.

Tubing and Swivel Nut Leak Reasons

A. Inadequate Torque and Improper Assembly

One of the primary causes of leaks in tubing and swivel nut connections is inadequate torque during assembly. Torque is the measure of rotational force applied to a fastener, and it plays a critical role in achieving a secure connection that can withstand internal pressure and vibrations.

Understanding Torque Requirements: Each type of fitting and tube requires a specific amount of torque to ensure that the joint is properly sealed. Insufficient torque can lead to gaps between the sealing surfaces, allowing hydraulic fluid to escape. Over time, even slight pressure fluctuations can exacerbate this issue, resulting in leaks.

Effects of Improper Assembly: Improper assembly practices, such as failing to follow manufacturer guidelines or using incorrect tools, can also contribute to inadequate torque. If the assembly process is rushed or lacks attention to detail, it can result in loose fittings that fail under pressure.

Monitoring and Maintenance: Regular inspection and monitoring of torque levels can help prevent leaks. Utilizing torque wrenches and adhering to the recommended torque specifications during installation can significantly reduce the risk of inadequate sealing.

B. Misalignment or Improper Fit

Alignment plays a crucial role in the integrity of tubing and swivel nut connections. Misalignment or improper fit can create leak paths, leading to significant performance issues.

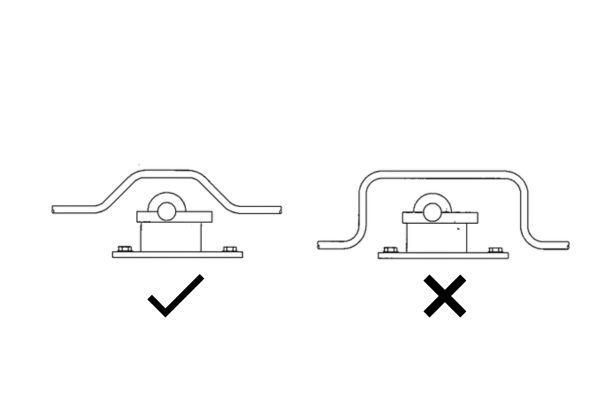

Importance of Proper Alignment: For a seal to function correctly, the tube must be aligned with the fitting’s sealing surface before tightening the nut. If the tube is misaligned, it can create stress points that compromise the seal. This misalignment can be due to improper bending of the tube or incorrect assembly practices.

Consequences of Improper Fit: An improper fit can occur if the tube is cut incorrectly, resulting in gaps that the fitting nut cannot close adequately. When these gaps exist, they form weak points where hydraulic fluid can escape, leading to leaks.

Preventive Measures: To ensure proper alignment, technicians should visually inspect the connections before tightening. Making necessary adjustments to the tube’s position can prevent future leaks and maintain the integrity of the system.

C. O-ring Damage

O-rings are essential components in tubing and swivel nut connections, acting as seals that prevent fluid leakage. Damage to O-rings can significantly impact system performance.

Types of O-ring Damage:

Extrusion: Occurs when internal pressure forces the O-ring out of its groove, often due to improper assembly or excessive pressure.

Pinching or Deformation: Can happen during installation if the O-ring is not properly seated, leading to visible deformations that compromise sealing ability.

Wear and Tear: Over time, O-rings can wear out due to exposure to hydraulic fluids, temperature fluctuations, and environmental factors, resulting in cracks or brittleness.

Implications of O-ring Damage: A damaged O-ring can create a leak path, allowing fluid to escape and potentially leading to system inefficiencies. Regular inspection and replacement of O-rings can help maintain system integrity.

Best Practices for O-ring Management: To minimize the risk of O-ring damage, operators should ensure proper material selection, adhere to correct installation procedures, and regularly inspect O-rings for signs of wear.

D. Braze Overflow and Fitting Damage

Issues related to brazing and damaged fittings can also lead to leaks in hydraulic systems.

Braising Issues: Brazing is a process used to join metal components through the use of a filler metal. However, improper brazing techniques can result in braze overflow, where excess filler material obstructs the sealing surfaces. This overflow can prevent proper sealing and lead to leaks.

Identifying Fitting Damage: Damage to fittings can range from minor scratches to significant cracks. Even small imperfections on sealing surfaces can prevent a proper seal, allowing hydraulic fluid to escape. Regular inspection of fittings for damage during installation and maintenance can help identify potential issues before they lead to leaks.

Repair and Replacement Considerations: If braze overflow or fitting damage is identified, it may be necessary to re-braze or replace the affected components. Using high-quality fittings and adhering to recommended brazing practices can help minimize these issues.

Troubleshooting Leak Sources

A. Systematic Diagnosis Steps

Diagnosing leaks in tubing and swivel nut connections requires a structured approach to ensure all potential issues are identified and resolved effectively.

Initial Inspection: Start with a visual inspection of the tubing and fittings. Look for obvious signs of leakage, such as fluid pooling around connections, discoloration, or corrosion. Take note of any unusual sounds that may indicate a leak.

Isolate the System: Shut down the hydraulic system and relieve any pressure to ensure safety during the diagnosis process. Lockout/tagout procedures should be followed to prevent accidental activation.

Check Connections: Inspect all connections, focusing on the swivel nuts and tubing joints. Verify that the fittings are properly tightened and that there are no signs of misalignment or improper fit.

Evaluate Torque Settings: Use a torque wrench to confirm that all fittings are tightened to the manufacturer’s specified torque. If the torque is inadequate, retighten as necessary.

Inspect O-rings: Remove the fittings and examine the O-rings for signs of damage, wear, or improper seating. Replace any O-rings that appear compromised.

Test for Leaks: Reassemble the connections and conduct a leak test. This can be done by re-pressurizing the system and observing the connections for leaks.

Identify the Root Cause: If a leak is detected, use the information gathered during the inspection to identify the root cause. Consider factors such as assembly practices, alignment, and potential fitting damage.

Document Findings: Keep a detailed record of the diagnosis process, including any observations and actions taken. This documentation can help in future troubleshooting efforts.

B. Tools and Techniques for Leak Detection

Utilizing the right tools and techniques is essential for effective leak detection. Here are some commonly used methods:

Pressure Gauges: These instruments measure the pressure in the hydraulic system. A sudden pressure drop can indicate a leak. Installing pressure gauges at strategic points can help pinpoint areas where leaks are occurring.

Leak Detection Fluids: These fluids are applied to suspected leak areas. They create bubbles when in contact with escaping fluid, providing a clear visual indication of a leak. This method is simple and effective for small leaks.

Ultrasonic Detectors: These devices detect high-frequency sounds generated by leaks. They are especially useful for identifying leaks that are not visible to the naked eye. Ultrasonic detectors can pinpoint the exact location of a leak, even in noisy environments.

Thermal Imaging Cameras: These cameras can identify temperature differences in components, which may indicate fluid leakage. They are particularly useful for larger systems where traditional methods may be less effective.

Smoke Testers: In some cases, introducing smoke into the system can help visualize leak paths. The smoke will escape from any leaks, providing a clear indication of where attention is needed.

Fluorescent Dye Testing: Adding fluorescent dye to the hydraulic fluid can make leaks more visible. When exposed to UV light, the dye will glow, highlighting the source of the leak.

C. Importance of Safety Measures

Safety should always be a priority when diagnosing leaks in hydraulic systems. Here are key precautions to consider:

Lockout/Tagout Procedures: Before starting any diagnosis, ensure the system is properly shut down and locked out to prevent accidental operation. Tagging the equipment helps communicate that maintenance is in progress.

Personal Protective Equipment (PPE): Technicians should wear appropriate PPE, including gloves, safety glasses, and protective clothing. This helps protect against exposure to hydraulic fluids, which can be hazardous.

Pressure Relief: Always relieve pressure from the hydraulic system before beginning any inspection or repair work. This minimizes the risk of fluid spray, which can cause injury.

Proper Ventilation: Ensure that the work area is well-ventilated, especially when using leak detection fluids or performing tasks that may release fumes.

Tool Safety: Use tools correctly and ensure they are in good working condition. Improper use of tools can lead to accidents and injuries.

Emergency Preparedness: Have a plan in place for responding to leaks or accidents. This includes having spill kits and first aid supplies readily accessible.

Repairing Leaks: Options and Best Practices

A. Repair vs Replacement Decisions

When addressing leaks in tubing and swivel nut connections, a critical decision must be made: whether to repair or replace the affected components. Here are key considerations for making this choice:

Extent of Damage: Evaluate the severity of the damage. Minor leaks, such as those caused by improper torque or misalignment, may be effectively repaired. However, if fittings or tubing exhibit significant damage, such as cracks, severe corrosion, or extensive wear, replacement is often the safer and more reliable option.

Cost Analysis: Consider the cost implications of repair versus replacement. Repairs might initially seem more economical, but if they require frequent attention or result in ongoing leaks, the cumulative costs may exceed those of replacing the component outright.

Downtime Considerations: Assess the impact of repair versus replacement on system downtime. Repairs can often be completed more quickly, reducing operational interruptions. However, if a component’s reliability is in question, a replacement might provide long-term peace of mind and avoid future downtime.

B. Best Practices for Making Repairs

If a decision to repair is made, following best practices will help ensure the repair is effective and long-lasting. Here are key techniques for repairing leaks in tubing and swivel nut connections:

Proper Cleaning: Before making any repairs, clean the affected area thoroughly. Remove any debris, oil, or residue that may interfere with the repair process. This will ensure that any sealing materials adhere properly.

Re-Torqueing Connections: If the leak is suspected to be due to inadequate torque, re-torque the connections according to the manufacturer’s specifications. Use a calibrated torque wrench to ensure that the correct pressure is applied without overtightening.

Replacing O-rings: If O-ring damage is identified, replace the O-rings with ones that meet the correct specifications (size, material, and durometer). Ensure that the new O-rings are seated correctly in their grooves before reassembling the fittings.

Sealing Compounds: For certain applications, using a thread sealing compound may help improve the seal between threaded fittings. However, it’s essential to use the appropriate type of sealant, as some compounds may not be compatible with hydraulic fluids.

Braze or Weld Repair: In some cases, braze or weld repairs may be viable for damaged tubing or fittings. This requires specialized skills and equipment, so it’s advisable to engage a qualified technician for this type of repair.

Conducting Pressure Tests: After making repairs, perform pressure tests to verify that the leak has been successfully resolved. This will help ensure that the system is safe for operation before returning it to service.

C. Importance of Following Manufacturer Guidelines

Adhering to manufacturer guidelines is crucial when repairing leaks in hydraulic systems. Here’s why:

Safety Assurance: Manufacturers design their components based on rigorous testing and safety standards. Following their guidelines ensures that repairs are performed in a manner that maintains the integrity and safety of the system.

Warranty Considerations: Many manufacturers have specific stipulations regarding warranty coverage. Not following their guidelines during repairs could void warranties, leaving you responsible for future failures.

Performance Reliability: Manufacturer guidelines provide insights into the best practices for installation, repair, and maintenance. Following these recommendations helps ensure that the system operates reliably and efficiently over time.

Compatibility and Materials: Manufacturers specify materials and components that are compatible with their systems. Using non-approved replacements can lead to incompatibility issues, resulting in further leaks or damage.

Conclusion

Leak diagnosis is not merely a reactive measure; it is a proactive strategy that is essential for the longevity and efficiency of hydraulic systems. Identifying and addressing leaks promptly can prevent costly downtime and safety hazards, protecting both the equipment and personnel involved. By prioritizing leak management, organizations can significantly enhance their operational reliability, ensuring that hydraulic systems function at optimal levels.

FAQ

What are common signs of a leak in tubing and swivel nut connections?

Common signs include visible fluid pooling, discoloration, corrosion on fittings, and unusual sounds like hissing or bubbling. Performance issues, such as fluctuating pressure, may also indicate a leak.

What causes leaks in hydraulic systems?

Leaks can be caused by inadequate torque, misalignment of fittings, damaged O-rings, braze overflow, and physical damage to the fittings themselves.

How can I diagnose a leak in my hydraulic system?

Start by visually inspecting for signs of leaks, listening for unusual sounds, and checking system performance. Use tools like pressure gauges and leak detection fluid for a thorough diagnosis.

Should I repair or replace a leaking fitting?

The decision depends on the extent of the damage. If the fitting or tubing can be repaired effectively and safely, it may be a suitable option. However, if damage is extensive, replacement is often more reliable.

What safety precautions should I take when diagnosing leaks?

Always power down the equipment, wear appropriate personal protective equipment (PPE), and ensure the area is secure. Be aware of potential hazards, such as pressurized fluids.

How can I prevent leaks in my hydraulic system?

Implement best practices like regular maintenance, proper assembly techniques, using high-quality components, and following manufacturer guidelines to ensure the integrity of your connections.